x ii iii

advertisement

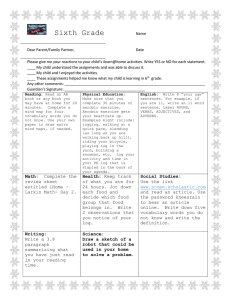

x TABLE OF CONTENTS CHAPTER 1 2 TITLE PAGE DECLARATION ii DEDICATION iii ACKNOWLEDGEMENTS iv ABSTRACT vi ABSTRAK vii TABLE OF CONTENTS viii LIST OF TABLES xiii LIST OF FIGURES xvi LIST OF ABBREVIATIONS xxvi LIST OF SYMBOLS xxix LIST OF APPENDICES xxxi INTRODUCTION 1 1.1 Background of Research 1 1.2 Objectives of the Study 4 1.3 Scope of the Study 5 1.4 Significance of the Study 6 1.5 Thesis Organization 8 LITERATURE REVIEW 9 2.1 Introduction 9 2.2 Palm Oil 10 xi 2.3 POME (Palm Oil Mill Effluent) 19 2.4 POME Management 22 2.4.1 Pond System 23 2.4.2 Anaerobic Digestion of POME 24 2.4.3 Aerobic Treatment of POME 29 2.5 Granulation Technology 32 2.5.1 Sequencing Batch Reactor 34 2.5.2 Definition of Aerobic Granulation 39 2.5.3 Factors Affecting the Formation of Aerobic Granular sludge 2.5.3.1 Influence of Feast and Famine Regimes 2.5.3.2 2.5.4 42 Aggregate Selection by Settling Times 43 2.5.3.3 Hydrodynamic Shear Force 45 2.5.3.4 Substrate Composition 46 2.5.3.5 Organic Loading Rate 48 2.5.3.6 Aerobic Starvation 49 2.5.3.7 Dissolved Oxygen (DO) 50 2.5.3.8 Reactor Configurations 51 Characteristics of Aerobic Granular Sludge 2.5.5 41 52 2.5.4.1 Morphology 52 2.5.4.2 Settleability 54 2.5.4.3 Density and Strength 55 2.5.4.4 Fractal Dimension 57 2.5.4.5 Microbial Structure 58 2.5.4.6 Microbial Diversity 59 Applications of Aerobic Granulation Technology 2.5.5.1 62 Biological Treatment of Wastewater 62 xii 2.5.5.2 Nitrogen and Phosphorus Removal 3 65 METHODOLOGY 68 3.1 Introduction 68 3.1.1 Research Design and Procedure 69 3.1.2 The Framework and Outline of Study 70 3.2 Experimental Setup 74 3.3 Raw POME and Seed Sludge Sampling 77 3.4 Reactor Maintenance 80 3.5 General Analytical Procedures 81 3.6 Molecular Analyses 83 3.6.1 DNA Extraction 83 3.6.2 Polymerase Chain Reaction (PCR) 84 3.6.3 Gel Electrophoresis 85 3.6.4 Denaturing Gradient Gel Electrophoresis (DGGE) 3.6.5 87 Basic Local Alignment Search Tool – nucleotide (BLASTn) and Sequencing 3.6.6 Multivariate Statistical Analysis of DGGE Gel 3.7 88 89 Fluorescence in situ Hybridisation Technique (FISH) 91 3.7.1 Sampling and Fixation 91 3.7.2 Microscopes Slide 92 3.7.3 FISH on Slides Method 93 3.7.4 Microscopy and AOB Detection 94 3.8 Fractal Dimension Analysis 95 3.9 Morphology Characterisation of Aerobic Granular Sludge Cultivated Using POME 3.9.1 Microscopic Examination using PAX-IT® 3.9.2 98 Field Emission 99 Scanning Microscopy Analysis (FESEM) Electron 99 xiii 3.10 4 5 Summary FORMATION OF AEROBIC GRANULAR SLUDGE WITH POME 100 4.1 Introduction 100 4.2 Preliminary Experimental Results 101 4.3 Dynamics of SBR 111 4.4 Development of Aerobic Granular Sludge 114 4.5 Biomass Profile and Settling Properties 126 4.6 Reactor Performance and Removal Efficiencies 129 4.7 Summary 133 EFFECT OF VOLUMETRIC ORGANIC LOADING ON AEROBIC GRANULATION 134 5.1 Introduction 134 5.2 Formation of Aerobic Granular Sludge using POME at Different OLR 5.3 6 99 136 Size and Fractal Dimension of Aerobic Granular Sludge 144 5.4 Organic Shock Loading Condition 150 5.5 Aerobic Granular Sludge for POME Treatment 152 5.6 Summary 159 MICROBIAL CHARACTERIZATION OF AEROBIC GRANULAR SLUDGE 160 6.1 Introduction 160 6.2 Identification 162 6.2.1 PCR Amplification of 16S rRNA Gene 162 6.2.2 PCR Products Analyzed by Denaturing Gradient Gel Electrophoresis (DGGE) 6.2.3 166 AOB Community in Aerobic Granular Sludge Cultivated using POME 172 xiv 6.2.4 The Distribution of AOB in Granule by FISH 6.3 6.4 7 178 Microbial Population Dynamics of Aerobic Granular Sludge 180 6.3.1 188 Similarity Index Summary 190 CONCLUSIONS AND RECOMMENDATIONS 191 7.1 Conclusions 191 7.2 Recommendations 193 REFERENCES 195 xv LIST OF TABLES TABLE NO. TITLE 2.1 Six different types of palm oil biomass (Source: Agensi Inovasi Malaysia, 2011) 2.2 28 Examples of POME effluent qualities from anaerobic treatment studies 2.5 20 The performance of various experimental studies for POME treatment 2.4 18 Characteristics of POME and ASM estimated model parameters 2.3 PAGE 29 Description of the operational steps for the sequencing batch reactor (Adapted from Metcalf and Eddy, 2003) 2.6 36 The governing factors and characteristics of aerobic granular sludge for various studies on aerobic granulation for wastewater treatments 2.7 61 Aerobic granular sludge studies in industrial wastewater 64 xvi 3.1 Characteristics of POME 78 3.2 Organic loading rates for feed preparation 79 3.3 Laboratory experiment conditions for SBR reactors 79 3.4 Measurements for reactor monitoring, determination of aerobic granular sludge morphologies and reactor performance 3.5 81 List of all the primers used for the PCR reaction, classified according to the oligonucleotide probe database (Alm et al., 1996) 85 3.6 Hybridization buffer (Manz et al., 1992) 94 3.7 Washing buffer (Amann et al., 1990) 94 4.1 Physical characteristics of POME seeding sludge at day-0 4.2 Colony characterization of pure isolates from POME seed sludge 4.3 109 Characteristics of aerobic granular sludge /bioflocs at different organic loading rates 5.2 102 Properties of selected identified bacteria in POME seed sludge 5.1 102 146 Aerobic granulation process for the treatment of industrial wastewater 158 xvii 6.1 Species identification of selected DGGE bands from the seed sludge and aerobic granular sludge cultivated at different OLR 6.2 168 Species identification of selected DGGE bands from the seed sludge and aerobic granular sludge cultivated using POME 6.3 Properties of identified bacteria in aerobic granular sludge cultivated using POME 6.4 174 176 Dice coefficients (Cs) comparing the similarities of PCR–DGGE fingerprints from three reactors operated at different OLR (S: seed sludge, R1, R2 and R3: reactors operated at OLRs 1.5, 2.5 and 3.5 kgCOD m-3d-1, respectively, numbers in bracket indicates sampling time in days) 6.5 185 Dominancy of bacterial V3 region analyses based on Figures 6.3 and 6.5, respectively 187 xviii LIST OF FIGURES FIGURE NO. 2.1 TITLE PAGE Origin of palm oil. (a) Oil palm trees; (b) Oil palm fruit (Source: http://palmoil.hubpages.com/hub/palmoil; Retrieved on 3rd January 2012) 2.2 11 Examples of palm oil‟s various usage (Source: http://www.forbes.com/2009/09/18/palm-oilmarketing-cmo-network-palmoil.html; Retrieved on 3rd January 2012) 2.3 Process involved in milling of oil palm (Source: Rupani et al., 2010) 2.4 14 Average composition of FFB (% in dry weight ) (Adapted from: Dany and Eliyan, 2010) 2.5 13 15 Illustration of crude palm oil milling process at common palm oil mills in Malaysia (Source: http://plotspalmoil.com/plantations.htm; retrieved on 13th March 2012) 2.6 16 The SBR used in the present study for cultivation of aerobic granular sludge using POME 37 xix 2.7 Typical operating sequence for a sequencing batch reactor (Adapted from Metcalf and Eddy, 2003) 2.8 Mechanism of aerobic granular sludge formation (Adapted from Beun et al., 1999) 2.9 38 39 Photographs of bioflocs and aerobic granular sludge cultivated at different superficial velocity. (a) Bioflocs cultivated at a superficial air upflow velocity of 0.008 ms1 ; and (b) aerobic granular sludge formed at a superficial air upflow velocity of 0.025 ms-1 (Liu and Tay, 2002) 2.10 45 Micro-photographs of aerobic granular sludge developed using different types of wastewater as substrates. (a) Aerobic granules developed using POME (Abdullah et al., 2011); (b) Aerobic granules developed using brewery wastewater (Wang et al., 2007) and (c) Aerobic granules developed using dairy wastewater (Arrojo et al., 2004) 2.11 FESEM image revealed that AGSP encompasses smooth and even surface morphology (Dahalan, 2011) 2.12 53 FESEM image revealed that AGS featured an uneven surface and outer morphology (Dahalan, 2011) 2.13 47 54 Schematic presentation of simultaneous nitrificationdenitrification in aerobic granule (Adapted from: Li et al., 2008) 2.13 Conceptual aerobic granular structure indicating various functional zones variation. (Source: Gao et al., 2011) 3.1 65 66 Operational study frameworks for aerobic granular sludge formation using POME 71 xx 3.2 Overall study outline 73 3.3 Schematic diagram of operational reactor setup 75 3.4 The SBRs used for aerobic granular sludge development using POME 3.5 76 Imaginary illustration of actual POME ponding system representing raw POME and seed sludge sampling points 77 3.6 Microbial community analysis protocols 84 3.7 Photographs showing PCR products analysis by gel electrophoresis 3.8 87 Exhibit showing an electrophoresis of PCR amplified products on DGGE D-Gene System with marker dyes to indicate when to stop a DGGE run 3.9 89 Sample of a dendrogram showing Raup and Crick similarity indices using the UPGMA cluster analysis method 3.10 90 Photograph of a confocal laser scanning microscope (Axio Vision Version 4.8.1, Germany) used to analyse FISH slides and detect AOB community in aerobic granular sludge samples cultivated using POME 3.11 97 Photograph of the CLSM (Axio Vision Version 4.8.1, Germany) equipped with an Axio Imager Z-2 (Carl Zeiss, Germany) camera used to obtain image analysis of aerobic granular sludge samples 96 xxi 3.12 Comparison between; (a) The actual microscopic image of a granule and (b) The binary image of the same granule generated using ImageJ Software (Collins, 2007) 4.1 97 Micrograph of Strain 1 showing moist, slightly raised elevation of irregular colonies with a distinctively glistening surface in milky white pigmentation 4.2 103 Colony morphology of Strain 2 showing dry, flat elevation of round and irregular colonies with glistening surface in light pink. Bacterial filaments were also observed in this sample 4.3 Micrograph of Strain 3 showing dry, flat and irregular colonies with smooth surface 4.4 104 104 Micrograph of Strain 4 indicating a flat elevation and smooth surface in white colour with wrinkled edges colony morphology 4.5 105 Micrograph of Strain 5 indicating a flat elevation and smooth surface in white colour with wrinkled edges colony morphology 4.6 105 Micrograph of Strain 6 showing an irregular shaped colony morphology with glistening surface in milky white colour 4.7 106 Micrograph of gram-positive bacteria from random isolate in POME seeding sludge indicating gram-positive rods (Light microscopy magnification: 1000x) 107 xxii 4.8 Micrograph of gram-negative bacteria from Strain 6 in POME seeding sludge indicating gram-negative rods (Light microscopy magnification: 1000x) 4.9 SBR bubble column used for the development of aerobic granular sludge using POME 4.10 112 Dynamic process conditions of the SBR used in the present study 4.11 108 113 Microscopic observation of aerobic granular sludge morphology. Photos were taken using light microscope (Magnification: <200 µm). (a) Seed sludge exhibited nonclear boundary at day-0 (b) Small brown granules with an average diameter of 1.0 mm sampled at day-20 (c) Aerobic granular sludge with diameters of between 2.0 to 4.0 mm sampled at day-60. (d) Mature aerobic granular sludge at day-60 exhibited a spherical shape with a clear outline boundary 4.12 115 (a) SEM analyses of the sludge used as an inoculum indicated a typical flocculent activated sludge with a comparatively feathery structure surrounded by fluffy edges in which the boundaries of individual particles were generally uneven and unclear, and (b) The surface of a mature aerobic granular sludge with dense microbial composition 4.13 116 The morphology of fresh POME seeding sludge using PAX-IT® 117 xxiii 4.14 SEM examinations of mature aerobic granular sludge. (a) The morphology of a mature granule at day-60 of operation; (b) Surface of mature granule 4.15 118 Different layers accommodating the surface of an aerobic granular sludge for simultaneous nitrification- denitrification process 4.16 120 Scanning electron micrograph of aerobic granular sludge developed using POME indicating clusters of cocci on granule surface (Magnification: 25,000x) 4.17 121 Aerobic granular sludge developed using POME also showing domination of rod-shaped bacteria (size ~ 300 – 500 nm) that are tightly linked and embedded via EPS (Magnification: 5,000x) 4.18 122 The surface of the granule is layered with some glue-like substances (Magnification: 500x) 4.19 124 Cavities found on aerobic granular sludge developed using POME resembling a channel-like structure (Magnification: 10,000x) 4.20 125 Cavities are likely filled with EPS substances which acts as cohesive material maintaining the bounds between bacterial cells and colonies (Magnification: 5,000k) 4.21 126 The steady increase in biomass concentrations in SBR used in the present study (○) MLSS concentration; (●) MLVSS concentration. 127 xxiv 4.22 The trends of the concentration of reactor MLSS in the reactor and the SVI values of the aerobic granules (○) MLSS concentration; (▲) SVI 4.23 129 Profile of COD removal performances of the SBR system. (∆) Percentage removal; (○) Effluent; (●) Influent 4.24 130 Profile of ammonia removal performances of the SBR system. (∆) Percentage removal; (○) Effluent; (●) Influent 131 Profile of colour removal performances of the SBR 4.25 system. (∆) Percentage removal; (○) Effluent; (●) Influent 5.1 The change of biomass concentration in SBR at different 132 OLRs, respectively. (●) 2.5 kgCOD m-3d-1; (○) 3.5 kgCOD m-3d-1; (▲) 1.5 kgCOD m-3d-1 5.2 137 Evolution of aerobic granular sludge morphology in R2; (a) seed sludge obtained from POME facultative pond; (b) after day-10; (c) after day-17 and (d) mature granules after day-60 of SBR operation. (Scale bar represents 1 mm) 5.3 138 The MLVSS concentrations in SBRs at different OLR respectively. (●) 2.5 kgCOD m-3d-1; (○) 3.5 kgCOD m-3d-1; (▲) 1.5 kgCOD m-3d-1 5.4 Aerobic granular sludge developed using 140 POME dominating reactor content at the end of experiments 141 xxv 5.5 Microscopic photographs of the seed sludge and mature granules in the SBRs; (a) activated seed sludge on day-0; (b) bioparticles in R1; (c) aerobic granular sludge in R2 and (d) aerobic granular sludge in R3 after day-60 of experiment 5.6 SEM examination of a mature aerobic granular sludge featuring a porous structural morphology 5.7 142 147 Fractal dimension vs size profile for aerobic granular sludge indicating an almost linear relationship between fractal dimension and equivalent diameter of less than 700 µm 5.8 148 SVI vs size of aerobic granular sludge profile indicating good and positive association of two important parameters of granules 5.9 149 (a) Micrograph of aerobic granular sludge cultivated on day-60 at OLR 2.5 kgCOD m-3d-1 as compared to (b) disintegration of granule at OLR 19 kgCODm-3d-1 5.10 151 Profile of COD removal efficiencies in reactors (●) 2.5 kgCOD m-3d-1; (○) 3.5 kgCOD m-3d-1; (▲) 1.5 kgCOD m-3d-1 5.11 Profile of COD removal efficiencies in R2 during shock load conditions at 19 kgCOD m-3d-1 5.12 153 154 Profile of ammonia and color removal efficiencies in reactors R2 and R3, respectively. Ammonia removals at (●) 2.5 kgCOD m-3d-1; (○)3.5 kgCOD m-3d-1; Color removals at (▲) 2.5 kgCOD m-3d-1 (∆) 3.5 kgCOD m-3d-1 156 xxvi 6.1 PCR products of aerobic granular sludge cultivated using POME 6.2 PCR products of aerobic granular sludge cultivated using POME 6.3 164 165 DGGE profiles of the bacterial communities in the three SBRs namely R1 (OLR 1.5 kgCOD m-3d-1), R2 (OLR 2.5 kgCOD m-3d-1) and R3 (OLR 3.5 kgCOD m-3d-1) during the aerobic granulation process. The band references are tabulated in Table 6.1. (MG: Mature Granule; a, b, c, d, e indicates operation at day - 17, 21, 31, 35 and 41, respectively) 6.4 167 Scanning electron micrograph of cocci-colonies possibly Trichococcus sp. found on mature aerobic granular sludge surface (Magnification: 1000x) 6.5 174 DGGE profiles of the AOB communities in the three SBRs namely R1, R2 and R3 for mature aerobic granular sludge cultivated at day-60. The band references are tabulated in Table 6.2. (OLR is in kgCOD m-3d-1). Species identification of selected bands is also tabulated in Table 6.2 6.6 173 The distribution of AOB in aerobic granular sludge after in situ hybridization with a Cy3-labelled probe NSO1225. (a) AOB colonies in aerobic granule developed at OLR 2.5 kgCOD m-3d-1 and (b) AOB colonies in aerobic granule developed at OLR 3.5 kgCOD m-3d-1 178 xxvii 6.7 Dendrogram showing Raup-Crick similarity between microbial communities collected from the various state of aerobic granular sludge formation using POME (MG: Mature Granule; a, b, c, d, e indicates operation at day17, 21, 31, 35 and 41, respectively) 6.8 180 Dendrogram generated using BioNumerics® software indicating similar cluster observation based on DGGE profiles of aerobic granular sludge samples (MG: Mature Granule; a, b, c, d, e indicates operation at day- 17, 21, 31, 35 and 41, respectively) 6.9 181 Raup and Crick similarity index calculated from the DGGE profiles. The labelled data points refer to (a) Pure seed sludge originated from POME; (b) Bioflocs obtained at OLR 1.5 kgCOD m-3d-1; (c) Mature granules obtained at OLR 3.5 kgCOD m-3d-1; (d) Mature granules obtained at OLR 2.5kgCOD m-3d-1 189 xxviii LIST OF ABBREVIATIONS AGS - Aerobic granular sludge AGSP - Photosynthetic aerobic granular sludge AIM - Agensi Inovasi Malaysia AN - Ammoniacal nitrogen AOB - Ammonia oxidizing bacteria APHA - American Public Health Association BAS - Biofilm airlift suspension BLASTn - Basic Local Alignment Search Tool - nucleotide BOD - Biochemical oxygen demand CDM - Clean development mechanism CER - Certified emission reduction CLSM - Confocal laser scanning microscopy COD - Chemical oxygen demand CSTR - Continuous stirred tank reactor DGGE - Denaturing gradient gel electrophoresis DNA - Deoxyribonucleic acid DO - Dissolved oxygen DOE - Department of Environment EBPR - Enhanced biological phosphorus removal EDM - Euclidean distance map EDTA - Ethylenediaminetetraacetic acid EPS - Extracellular polymeric substances EQA - Environmental Quality Act FA - Formamide xxix FFB - Fresh fruit bunches FISH - Fluorescence in situ Hybridization HB - Hybridisation buffer HRT - Hydraulic retention time MLSS - Mixed liquor suspended solid MLVSS - Mixed liquor volatile suspended solid MPOB - Malaysian Palm Oil Board NMDS - Non metric multidimensional scaling OLR - Organic loading rate PAO - Polyphosphate-accumulating bacteria PBS - Phosphate buffered saline PCR - Polymerase chain reaction PFA - Paraformaldehyde POME - Palm oil mill effluent PORE - Palm oil refinery effluent RNA - Ribonucleic acid SBAR - Sequencing batch airlift reactor SBR - Sequencing batch reactor SDS - Sodium dodecyl sulphate SEM - Scanning electron microscopy SRT - Sludge retention time SS - Suspended solid SVI - Sludge volume index TAE - Tris-acetate-EDTA TEMED - Tetramethylethylenediamine TN - Total nitrogen TSS - Total suspended solid UASB - Up-flow anaerobic sludge blanket UASFF - Up-flow anaerobic sludge fixed-film UFF - Up-flow fixed film UPGMA - Unweighted pair group method with Arithmetic Mean UTM - Universiti Teknologi Malaysia xxx UV - Ultraviolet VER - Volumetric exchange rate WB - Washing buffer 16s rRNA - 16 Sequencing Ribosomal Ribonucleic Acid xxxi LIST OF SYMBOLS b(S) - gray-levels distribution Ca2+ - calcium CaCO3 - calcium carbonate CO2 - carbon dioxide (mgl-1 or mmolL-1) CODfeed - substrate strength in terms of COD concentration (mgL-1) CTO654r - reverse AOB specific primer CTO189f - forward AOB specific primer ddH2O - double sterile water Df - fractal dimension H/D - column height to diameter ratio (mm) K2HPO4 - dipotassium phosphate Mg2+ - magnesium MgCl2 - magnesium chloride Mw - molecular weight N - nitrogen (mgL-1) NaCl - sodium chloride (mL) NaOH - sodium hydroxide NH4Cl - ammonium chloride NH4-N - ammonia P - phosphorus (mgL-1) PO4-P - phosphate P/COD - phosphorus to chemical oxygen demand ratio P(S) - perimeter Q - substrate flow rate (Ld-1) xxxii SS0 - total amount of granular sludge SSt - amount of sludge solids in supernatant after t min T - temperature (°C) Tris-HCL - tris-sodium hydrochloride Vr - reverse PCR primer Vf - forward PCR primer Vr - working volume of reactor (L) Vpome - volume of POME (mL) Vtapwater - volume of tap water (mL) Vs - settling velocity of a particle § - integrity coefficient dp - diameter of a particle µ - viscosity of a solution ρp - density of a particle ρ - density of a solution xxxiii LIST OF APPENDICES APPENDIX A TITLE List of proceedings and publications PAGE 226