UNIVERSITI TEKNOLOGI MALAYSIA

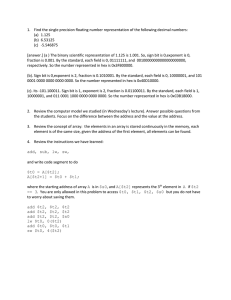

advertisement