ABSTRACT: In the gas industry, a ...

advertisement

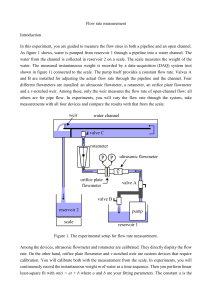

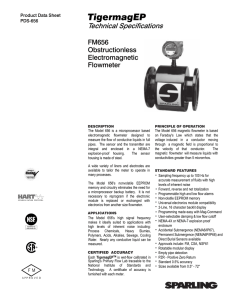

ABSTRACT: In the gas industry, a reliable, accurate and efficient measurement of gas quantities is of the utmost importance. In fact, an accurate metering of gas flow rates assures the rightness of the commercial transactions (which, of course, have economic implications) and the improvement of pipeline efficiency, by means of telecontrol systems (Cascetta and Scalabrini,1998). A flowmeter for the natural gas industry must have some specific technical characteristics. In practice, an ideal gas flowmeter should be (Cascetta and Scalabrini,1998): • Accurate and repeatable, according to the application (custody transfer metering or measurement in telecontrol); • Static (i.e. without moving parts) in order to reduce the maintenance costs and to have long-term stability and repeatability; • Safe, in order to reduce risks in hazardous area; • Obstruction less, in order to allow the transit of a robotized system (mouse, pig), normally used for the inner inspection/cleaning of the pipeline. • Non-intrusive, in order to reduce pressure drops; • Flexible, in order to satisfy a wide flow range