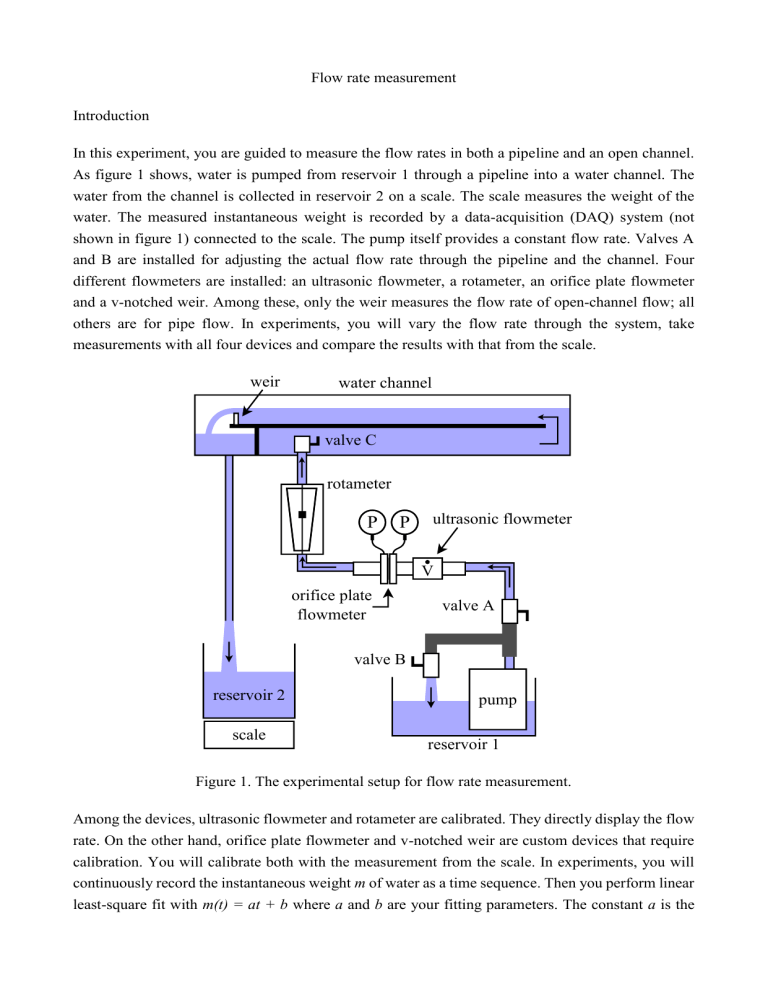

Flow rate measurement Introduction In this experiment, you are guided to measure the flow rates in both a pipeline and an open channel. As figure 1 shows, water is pumped from reservoir 1 through a pipeline into a water channel. The water from the channel is collected in reservoir 2 on a scale. The scale measures the weight of the water. The measured instantaneous weight is recorded by a data-acquisition (DAQ) system (not shown in figure 1) connected to the scale. The pump itself provides a constant flow rate. Valves A and B are installed for adjusting the actual flow rate through the pipeline and the channel. Four different flowmeters are installed: an ultrasonic flowmeter, a rotameter, an orifice plate flowmeter and a v-notched weir. Among these, only the weir measures the flow rate of open-channel flow; all others are for pipe flow. In experiments, you will vary the flow rate through the system, take measurements with all four devices and compare the results with that from the scale. weir water channel valve C rotameter P P ultrasonic flowmeter V orifice plate flowmeter valve A valve B reservoir 2 scale pump reservoir 1 Figure 1. The experimental setup for flow rate measurement. Among the devices, ultrasonic flowmeter and rotameter are calibrated. They directly display the flow rate. On the other hand, orifice plate flowmeter and v-notched weir are custom devices that require calibration. You will calibrate both with the measurement from the scale. In experiments, you will continuously record the instantaneous weight m of water as a time sequence. Then you perform linear least-square fit with m(t) = at + b where a and b are your fitting parameters. The constant a is the flow rate. Finally, you should use a to calibrate the flow rate from orifice plate flowmeter and vnotched weir. The flow rate ro through an orifice plate flowmeter has to be calculated from the pressure difference Δp across the orifice plate. The two parameters are related as 𝑟𝑜 = C × 𝜋𝑑2 4 2𝜌×∆𝑝 ×√ 𝑑 𝐷 1−( )4 , where d is the (inner) diameter of the orifice plate, ρ the density of the fluid, D the pipe’s inner diameter, and C the discharge coefficient. In this experiment, D = 1 inch (25.4mm) and ρ = 1000 kg/m3. You will run the same experiment with two different orifice plates, one with d = 0.3” and the other d = 0.6”. Then you calculate the discharge coefficient C for each case. The flow rate through a weir is estimated based on the height of water above the tip of its notch. For the weir, you will relate the height to the flow rate from the scale. Then you identify the range of flow rate that the weir can measure. Preparation 1. Turn on the DAQ system. 2. 3. 4. 5. 6. 7. 8. 9. Turn on the LabView program. Check the pipeline and water channel: is everything properly connected? Turn on the ultrasonic flowmeter. Is there any water in reservoir 2? Pour it into reservoir 1. Place reservoir 2 right in the middle of the scale. Fully open valves A and C and shut valve B. Pump water into water channel. Wait for 1 minute so that the bottom part of the channel is filled. Shut valve C, then turn the pump off. Experimental Procedure 1. Install a 0.6” orifice plate in the orifice plate flowmeter. 2. 3. 4. 5. 6. 7. Fully open valves A and C and shut valve B. This allows maximum flow rate into the pipeline and water channel. Turn on the pump. Wait until the flow stabilizes. Start recording the weight measurement from the scale with the LabView program. Record the flow rates from the ultrasonic flowmeter and rotameter. Record the pressure readings from the orifice plate flowmeter. Record the height of water level above the tip of the weir’s V notch. 8. 9. Stop recording the weight measurement from the scale. Pour or pump the water in reservoir 2 back into reservoir 1. 10. Adjust valves A and B to vary the flow rate into the pipeline and open channel. Repeat steps 3 9 with five different flow rates. 11. Install 0.3” orifice plate in the orifice plate flowmeter. Repeat steps 2 - 10. Operational Instructions 1. Do not touch the scale once you start recording the weight measurement. 2. 3. Start the pump before opening valve C. This keeps the bottom portion of the water channel filled. Once the flow stabilizes, record any flow rate, pressure and height measurement as soon as possible. You may have to repeat the same experiment if you drain reservoir 1. Data Processing & Discussion 1. For each sequence of weight measurement m(t), perform a least-square fit and calculate the flow rate r1. 2. Based on r1, calculate the error eu = |ru - r1| / r1 of the flow rate ru from ultrasonic flowmeter. Plot eu against r1. Question: For what flow rates does the ultrasonic flowmeter give you a reasonable measurement (i.e. eu < 10%)? 3. Based on r1, calculate the error er = |rr - r1| / r1 of the flow rate rr from rotameter. Plot eu against r1. Question: For what flow rates does the rotameter give you a reasonable measurement (i.e. er < 4. 5. 6. 7. 10%)? Use r1 to calculate the discharge coefficient C of the orifice plate flowmeter. Question: for what range of the flow rates is your calculated C between 0.54 and 0.66? Plot r1 against the height h of water above the tip of the weir’s V notch. What are the maximum and minimum flow rates that the weir can measure? Describe what happened when the weir stopped working. Among all measurement devices, which gives you the widest range of flow rate measurement? During the experiment, did the signal (e.g. position of the float, digital display, pressure, etc.) of any flowmeter fluctuate or otherwise become so unstable that you couldn’t take measurement with it? Describe how and when this happened. Pre-Lab Problems: 1. Describe how a rotameter measures flow rate. 2. Describe how an orifice plate flowmeter measures flow rate. 3. Describe how a vortex flowmeter measures flow rate. 4. Describe how a Venturi tube measures flow rate. 5. Describe how a Coriolis flowmeter measures flow rate. 6. Describe how an ultrasonic flowmeter measures flow rate.