vii i ii

advertisement

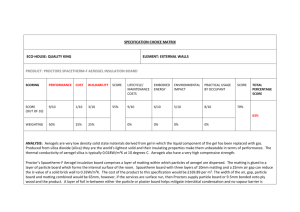

vii TABLE OF CONTENTS CHAPTER I TITLE PAGE TITLE i DECLARATION ii DEDICATION iii ACKNOWLEDGEMENT iv ABSTRACT v ABSTRAK vi TABLE OF CONTENTS vii LIST OF TABLES xi LIST OF FIGURES xii LIST OF SYMBOLS xv LIST OF ABBREVIATIONS xvi LIST OF APPENDICES xvii INTRODUCTION 1 1.1 Background of Research 1 1.2 Problem Statement 4 1.3 Hypothesis 5 1.4 Objectives of Research 7 1.5 Scope of Research 7 1.6 Outline of Research 9 viii II LITERATURE REVIEW 10 2.1 Rice Husk Ash as a Silica Source 10 2.2 Silica Aerogel 12 2.3 The Sol-Gel Process 14 2.3.1 Hydrolysis and Condensation 15 2.3.2 Gelation and Aging 19 2.3.3 Drying 19 2.4 Immobilization of Enzyme 22 2.4.1 Enzyme as Catalyst 23 2.4.2 Immobilization Techniques 24 2.4.3 Immobilization of Enzymes by 25 Encapsulation via Sol-Gel Method 2.5 Tyrosinase 2.5.1 27 Immobilized Tyrosinase in the 30 Removal of Phenol III RESEARCH METHODOLOGY 33 3.1 Raw Materials and Chemical Reagents 33 3.2 Synthesis of Tyrosinase Encapsulated Silica 34 Aerogel (TESA) 3.3 3.2.1 Preparation of Sodium Silicate 34 3.2.2 Synthesis of Wet Gel 35 3.2.3 Drying of Wet Gel 35 Characterization of Tyrosinase Encapsulated 36 Silica Aerogel (TESA) 3.3.1 X-Ray Diffraction (XRD) Technique 37 3.3.2 Fourier Transformed-Infrared (FTIR) 40 Spectroscopy 3.3.3 Field Emission-Scanning Electron 43 Microscopy (FESEM) 3.3.4 Energy Dispersive X-ray Analysis (EDX) 44 ix 3.3.5 Transmission Electron Microscopy 45 (TEM) 3.3.6 3.4 3.5 Thermogravimetry Analysis 46 Optimization of Synthesis Condition 47 3.4.1 Effect of Solvent Extraction 47 3.4.2 Effect of Aging Period 48 3.4.3 Effect of Enzyme Loading 48 Assays of Enzymatic Activity 49 3.5.1 Assay of Free Tyrosinase Activity 50 3.5.2 Assay of Encapsulated Tyrosinase 51 Activity 3.6 3.5.3 Leaching Study 53 3.5.4 Influence of Temperatures 53 3.5.5 Influence of pH 54 Application of Tyrosinase Encapsulated Silica 54 Aerogel (TESA) IV 3.6.1 The Removal of Phenol 54 3.6.2 Reusability 55 RESULTS AND DISCUSSION 56 4.1 56 Synthesis of Tyrosinase Encapsulated Silica Aerogel (TESA) 4.2 Characterization of Tyrosinase Encapsulated 58 Silica Aerogel (TESA) 4.2.1 Physical Appearance 59 4.2.2 X-ray Diffraction (XRD) Analysis 59 4.2.3 FTIR Spectroscopy 60 4.2.4 Field Emission Scanning Electron 64 Microscopy (FESEM) 4.2.5 Energy Dispersive X-ray Analysis 68 (EDX) 4.2.6 Transmission Electron Microscopy (TEM) 69 x 4.2.7 4.3 4.4 Thermal Analysis 73 Optimization of Synthesis Conditions 75 4.3.1 Effect of Solvent Extraction 75 4.3.2 Effect of Aging Period 78 4.3.3 Effect of Enzyme Loading 79 Enzymatic Activity 81 4.4.1 81 Assay of Free Tyrosinase and Tyrosinase Encapsulated Silica Aerogel (TESA) Activity 4.5 4.4.2 Leaching Study 83 4.4.3 Influence of Temperatures 83 4.4.4 Influence of pH 85 Application of Tyrosinase Encapsulated Silica 87 Aerogel (TESA) V 4.5.1 The Removal of Phenol 87 4.5.2 Reusability 88 CONCLUSIONS AND RECOMMENDATIONS 91 5.1 Conclusions 91 5.2 Recommendations 94 REFERENCES 96 APPENDICES 111 xi LIST OF TABLES TABLE NO. TITLE PAGE 3.1 The assignments of the main FTIR bands for silica 42 4.1 FTIR wavenumbers and assignment for the functional group present in the tyrosinase 62 4.2 FTIR assignments of silica aerogel 62 4.3 Major elemental analysis (mass% ± SD) of free tyrosinase, silica aerogel (with and without solvent extraction) and TESA (with and without solvent extraction) 68 xii LIST OF FIGURES FIGURE NO. TITLE PAGE 1.1 The encapsulation of tyrosinase into silica aerogel network 6 1.2 Flow diagram of research activities 9 2.1 (a) Hydrolysis, (b) condensation and (c) polycondensation reactions, during the sol-gel process in the synthesis of silica aerogel 17 2.2 Polymeric structure of silica framework in acidic and basic conditions 18 2.3 Monooxygenation reaction catalyzed by tyrosinase 28 2.4 Oxidation of o-diphenol to o-quinone 29 2.5 Oxidation of phenol catalyzed by tyrosinase 31 3.1 Derivation of Bragg’s law for X-ray diffraction 38 3.2 The illustration of the X-ray powder diffraction method 39 3.3 Types of silanols exist in silica surface 41 4.1 Optical absorption spectra of (a) free tyrosinase, λmax = 289.14 nm, (b) TESA (with solvent extraction), λmax = 291.28 nm and (c) TESA (without solvent extraction), λmax = 292.91 nm 57 4.2 XRD diffractogram of (a) silica aerogel and (b) TESA 60 xiii 4.3 The FTIR spectra of (a) silica aerogel and (b) free tyrosinase 61 4.4 FTIR spectra of (a) free tyrosinase, (b) silica aerogel, (c) TESA with SE and (d) TESA without SE 64 4.5 FESEM micrographs showing the surface morphology of (a) silica aerogel with SE and (b) TESA with SE 65 4.6 FESEM micrographs showing the surface morphology of (a) silica aerogel without SE and (b) TESA without SE 66 4.7 FESEM micrograph showing the surface morphology of free tyrosinase 67 4.8 TEM micrographs showing the surface morphology of (a) silica aerogel with SE and (b) TESA with SE 70 4.9 TEM micrographs showing the surface morphology of (a) silica aerogel without SE and (b) TESA without SE 71 4.10 Thermogravimetry analysis (TGA) and Derivative thermogravimetry (DTG) curves of (a) silica aerogel without SE, weight loss = 21.102%, (b) silica aerogel with SE, weight loss = 16.284%, (c) TESA without SE, weight loss = 10.696%, (d) TESA with SE, weight loss = 6.632% and (e) free tyrosinase, weight loss = 100% 74 4.11 Effect of solvent extraction to the enzymatic activity of TESA with SE 76 4.12 Enzymatic activities of (a) TESA with SE and (b) TESA without SE; at different aging periods 78 4.13 Enzymatic activities of (a) TESA with SE and (b) TESA without SE; of different enzyme loadings 80 4.14 Enzymatic activity of (a) free tyrosinase, (b) TESA without SE, (c) TESA with SE; extracted by amyl acetate/acetone (v/v:1/1) and (d) without tyrosinase; at pH 7 82 4.15 Enzymatic activities of (a) free tyrosinase, (b) TESA with SE; extracted by amyl acetate/acetone (v/v:1/1) and (c) TESA without SE; at different temperatures 84 xiv 4.16 Enzymatic activities of (a) free tyrosinase, (b) TESA with SE; extracted by amyl acetate/acetone (v/v:1/1) and (c) TESA without SE; at different pH 86 4.17 The effect of contact time on the percent removal of phenol by (a) free tyrosinase, (b) TESA without SE and (c) TESA with SE; extracted by amyl acetate/acetone (v/v:1/1) 88 4.18 Reusability studies of (a) TESA without SE and (b) TESA with SE; extracted by amyl acetate/acetone (v/v:1/1), in the removal of phenol 90 xv LIST OF SYMBOLS °C - Degree Celsius cm - Centi meter g - Gram K - Kelvin kV - Kilo Volt L - Liter M - Molar m - Meter mg - Mili gram min - Minute mL - Mili Liter mM - Mili Molar mm - Mili meter nm - Nano meter ppm - Part per million rpm - Rotation per minute v - Volume W - Watt Å - Angstrom μg - Micro gram μL - Micro Liter λ - Lambda θ - Theta xvi LIST OF ABBREVIATIONS APD - Ambient Pressure Drying CaA - Calsium Aluminosilicate DDW - Double Distilled Deionized Water DTG - Derivative Thermogravimetric Analysis EDTA - Ethylene Diamine Tetracetic Acid EDX - Energy Dispersive X-ray Technique FESEM - Field Emission Scanning Electron Microscopy FTIR - Fourier Transform Infrared HMDSO - Hexamethyldisiloxane HPLC - High Performance Liquid Chromatography IR - Infrared NaA - Sodium Aluminosilicate NADH - Nicotinamide Adenine Dinucleotide PFC - Plug Flow Combustor RHA - Rice Husk Ash SE - Solvent Extraction SD - Standards Deviation TEM - Transmission Electron Microscopy TESA - Tyrosinase Encapsulated Silica Aerogel TEOS - Tetraethyl Orthosilicate TMOS - Tetramethyl Orthosilicate TGA - Thermogravimetric Analysis UV-Vis - Ultra Violet-Visible XRD - X-Ray Diffraction xvii LIST OF APPENDICES APPENDIX TITLE PAGE A Determination of Ascorbic Acid using UV-Vis Spectrophotometer 111 B EDX Elemental Analysis of Tyrosinase, Silica Aerogel and TESA 114 C Determination of Phenol using UV-Vis Spectrophotometer 119 D Paper for R&D Nanotechnology Symposium 2007, Malaysia 121 E Paper for 26th International Symposium on Space Technology and Science (ISTS), Japan 128