SYNTHESIS AND CHARACTERIZATION OF ALCOHOL-FREE TYROSINASE ENCAPSULATED SILICA AEROGEL

SYNTHESIS AND CHARACTERIZATION OF ALCOHOL-FREE TYROSINASE

ENCAPSULATED SILICA AEROGEL

NOR SURIANI BINTI HJ. SANI

UNIVERSITI TEKNOLOGI MALAYSIA

SYNTHESIS AND CHARACTERIZATION OF ALCOHOL-FREE TYROSINASE

ENCAPSULATED SILICA AEROGEL

NOR SURIANI BINTI HJ. SANI

A thesis submitted in fulfilment of the requirements for the award of the degree of

Master of Science (Chemistry)

Faculty of Science

Universiti Teknologi Malaysia

AUGUST 2009

iii

YÉÜ Åç uxÄÉäxw ytÅ|Äç? a|~ T{Åtw a|étÅ u|Ça|~ `tÄx~ tÇw a|~ T{Åtw mtÜxxy u|Ça|~ T{Åtw a|étÅ

iv

ACKNOWLEDGEMENT

In the name of Allah the Almighty Lord of the world. Thanks to Him for giving me the opportunity and will to finish this thesis. Heartfelt thanks to my project supervisor, Prof. Dr. Halimaton Hamdan, who introduced me to the field of catalysis. Her patience, criticism and thoughtful guidance throughout this study are greatly appreciated. Without her continued support and interest, this thesis would not be the same as presented here. I would like to express my sincere appreciation and gratitude to Dr. Lee Siew Ling for her knowledge, guidance, evaluation and supporting me throughout the undertaking of this research. I am also very thankful to my research team, especially to Mrs. Fitri Hayati, Mrs. Rozana Abu Bakar and Ms.

Nurul Hidayah Yunus for giving me the motivation, knowledge, assistance and valuable advice in completing this project.

My appreciation also goes to all the staff at Faculty of Science, UTM and

Department of Chemistry, who in many ways contributes to the success of my study.

Not forgetting my beloved husband, Nik Ahmad Nizam Nik Malek for his endless support, encouragement, friendship, advice and understanding. I greatly appreciate it.

I want to extend my utmost gratitude and appreciation to my parents, family, fellow friends and those who provide assistance in this research either intentionally or unintentionally throughout the progress of this research. Finally, I would like to acknowledge MOSTI, IRPA and NSF for financial support and scholarship.

v

ABSTRACT

Encapsulation of tyrosinase enzyme into nanoporous silica aerogel via an alcohol-free colloidal sol-gel route using rice husk ash (RHA) as silica source was studied. Tyrosinase encapsulated silica aerogel (TESA) was synthesized with and without solvent extraction process at room temperature and neutral pH in order to study their effect on the enzyme activity and to minimize enzyme denaturation. The physicochemical properties of TESA was characterized by X-ray diffraction (XRD) technique, fourier transformed-infrared (FTIR) spectroscopy, field emissionscanning electron microscopy (FESEM), energy dispersive X-ray (EDX) analysis, transmission electron microscopy (TEM) and thermogravimetric analysis (TGA).

These characterizations confirmed tyrosinase in TESA was located inside the network of silica aerogel. Enzymatic activity of tyrosinase was assayed through the reduction of ascorbic acid using UV Visible spectrophotometer. Almost 98% of tyrosinase was successfully loaded into silica aerogel as determined by the leaching test of TESA. TESA without solvent extraction showed higher tyrosinase activity than TESA extracted by amyl acetate/acetone (v/v:1/1). The highest activities for both TESA were obtained with 10.00 mg/mL of enzyme loading that was aged for 2 days. The stability of tyrosinase in TESA was enhanced towards extreme temperature as well as acidic and basic conditions. Free tyrosinase was totally inactivated at pH < 4 and pH > 9 and at temperature exceeding 55 °C, while TESA showed a significant activity at these conditions. In the application of TESA, about

80% of phenol was removed after 3 hours contact with TESA. The reusability of tyrosinase in TESA was observed to be very high since TESA can be reused to remove phenol up to 10 times without significant loss. As a conclusion, nanoporous silica aerogel from RHA prepared with and without solvent extraction techniques can be used as suitable support for the improvement of the tyrosinase stability and it can be applied to remove phenol.

vi

ABSTRAK

Kajian terhadap enzim tirosinase yang dikapsulkan ke dalam aerogel berasaskan silika melalui kaedah koloid sol-gel tanpa melibatkan alkohol telah dijalankan. Pengkapsulan tirosinase ke dalam aerogel berasaskan silika (TESA) yang mempunyai liang bersaiz nano telah disintesis menggunakan abu sekam padi (RHA) sebagai sumber silika. Di dalam kaedah ini, TESA disintesis pada suhu bilik dan pH neutral melalui proses pengekstrakan dan tanpa pengekstrakan bagi mengkaji kesannya terhadap aktiviti enzim di samping mengurangkan penyahaslian enzim.

Sifat-sifat fiziko-kimia TESA telah dicirikan dengan kaedah XRD, FTIR, FESEM,

EDX, TEM dan TGA. Pencirian mengesahkan bahawa tirosinase telah berjaya dikapsulkan ke dalam silika aerogel dan ianya terletak di dalam rangkaian jaringan silika aerogel. Aktiviti tirosinase telah ditentukan dengan kaedah spektofotometer

UV Tampak melalui proses penurunan asid askorbik. Hasil Ujian Larut Lesap terhadap TESA menunjukkan hampir 98% tirosinase berjaya dimuatkan di dalam silika aerogel. TESA yang disintesis tanpa melibatkan pengekstrakan mempunyai aktiviti yang lebih tinggi berbanding TESA yang disintesis melalui pengekstrakan menggunakan pelarut amil asetat/aseton (v/v:1/1). Aktiviti yang tinggi bagi keduadua TESA diperolehi apabila sebanyak 10.00 mg/mL enzim dikapsulkan ke dalam silika aerogel pada suhu bilik selama 2 hari. Kestabilan tirosinase di dalam TESA terhadap asid dan alkali meningkat. Tirosinase tidak menunjukkan sebarang aktiviti pada pH < 4 dan pH > 9 juga pada suhu melebihi 55 °C tetapi tirosinase di dalam

TESA menunjukkan aktiviti pada keadaan tersebut. Kajian penggunaan TESA terhadap penyingkiran fenol menunjukkan 80% fenol berjaya disingkirkan selepas bertindak balas dengan TESA selama 3 jam. Kebolehan tirosinase di dalam TESA untuk menyingkirkan fenol berulang-kali adalah tinggi kerana TESA boleh digunakan sehingga 10 kali tanpa menunjukkan sebarang penyusutan yang ketara.

Kesimpulannya, silika aerogel daripada RHA, dengan liang bersaiz nano, yang disintesis sama ada melalui proses pengekstrakan atau tanpa proses pengekstrakan, mampu menjadi tapak kepada enzim bagi meningkatkan kestabilan tirosinase dan menyingkirkan fenol.

vii

1.4

1.5

1.6

Objectives of Research

Scope of Research

Outline of Research

CHAPTER

TABLE OF CONTENTS

TITLE PAGE

TITLE

DECLARATION

DEDICATION

ACKNOWLEDGEMENT

ABSTRACT

ABSTRAK

TABLE OF CONTENTS

LIST OF TABLES

LIST OF FIGURES

LIST OF SYMBOLS

LIST OF ABBREVIATIONS

LIST OF APPENDICES xii xv xvi xvii v vi vii xi i ii iii iv

I INTRODUCTION

1.1 Background of Research

1

1

4

7

9

5

7

viii

2.1

2.3

2.4

Rice Husk Ash as a Silica Source

The Sol-Gel Process

2.3.1 Hydrolysis and Condensation

Immobilization of Enzyme

2.4.3 Immobilization of Enzymes by

Encapsulation via Sol-Gel Method

2.5.1 Immobilized Tyrosinase in the

Removal of Phenol

27

30

3.1 Raw Materials and Chemical Reagents

3.2 Synthesis of Tyrosinase Encapsulated Silica

Aerogel (TESA)

3.2.1

3.2.2

3.2.3

Preparation of Sodium Silicate

Synthesis of Wet Gel

Drying of Wet Gel

3.3 Characterization of Tyrosinase Encapsulated

Silica Aerogel (TESA)

3.3.1 X-Ray Diffraction (XRD) Technique

3.3.2 Fourier Transformed-Infrared (FTIR)

3.3.3

3.3.4

Spectroscopy

Field Emission-Scanning Electron

Microscopy (FESEM)

Energy Dispersive X-ray Analysis

(EDX)

33

33

34

34

35

35

36

37

40

43

44

10

10

12

14

15

19

19

22

23

24

25

IV ix

45

(TEM)

3.4 Optimization of Synthesis Condition

3.4.1 Effect of Solvent Extraction

3.4.2

3.4.3

Effect of Aging Period

Effect of Enzyme Loading

3.5 Assays of Enzymatic Activity

3.5.1 Assay of Free Tyrosinase Activity

3.5.2 Assay of Encapsulated Tyrosinase

Activity

46

47

47

48

48

49

50

51

3.5.4

3.5.5

Influence of Temperatures

Influence of pH

53

53

54

54

Aerogel (TESA)

3.6.1 The Removal of Phenol 54

55

RESULTS AND DISCUSSION

4.1 Synthesis of Tyrosinase Encapsulated Silica

Aerogel (TESA)

4.2 Characterization of Tyrosinase Encapsulated

Silica Aerogel (TESA)

4.2.2

4.2.4

4.2.5

56

56

58

X-ray Diffraction (XRD) Analysis

Field Emission Scanning Electron

Microscopy (FESEM)

Energy Dispersive X-ray Analysis

(EDX)

64

68

Microscopy 69

(TEM)

59

59

60

REFERENCES

APPENDICES

73

75

75

78

79

81

81 x

4.3 Optimization of Synthesis Conditions

4.3.1 Effect of Solvent Extraction

4.3.2

4.3.3

Effect of Aging Period

Effect of Enzyme Loading

4.4.1 Assay of Free Tyrosinase and

Tyrosinase Encapsulated Silica

Aerogel (TESA) Activity

4.4.3

4.4.4

Influence of Temperatures

Influence of pH

Aerogel (TESA)

4.5.1 The Removal of Phenol

V CONCLUSIONS RECOMMENDATIONS

83

83

85

87

87

88

91

91

94

96

111

TABLE NO.

3.1

4.1

4.2

4.3

LIST OF TABLES

TITLE

The assignments of the main FTIR bands for silica

FTIR wavenumbers and assignment for the functional group present in the tyrosinase

FTIR assignments of silica aerogel

Major elemental analysis (mass%

±

SD) of free tyrosinase, silica aerogel (with and without solvent extraction) and TESA (with and without solvent extraction)

PAGE

42

62

62

68 xi

LIST OF FIGURES

FIGURE NO. TITLE

1.1

1.2

2.1

2.2

The encapsulation of tyrosinase into silica aerogel network

Flow diagram of research activities

(a) Hydrolysis, (b) condensation and (c) polycondensation reactions, during the sol-gel process in the synthesis of silica aerogel

Polymeric structure of silica framework in acidic and basic conditions

2.3

2.4 Oxidation o -quinone

2.5

Monooxygenation reaction catalyzed by tyrosinase

3.1

Oxidation of phenol catalyzed by tyrosinase

Derivation of Bragg’s law for X-ray diffraction

3.2

3.3

4.1

4.2

The illustration of the X-ray powder diffraction method

Types of silanols exist in silica surface

Optical absorption spectra of (a) free tyrosinase,

λ max

= 289.14 nm, (b) TESA (with solvent extraction),

λ max

= 291.28 nm and (c) TESA (without solvent extraction),

λ max

= 292.91 nm

XRD diffractogram of (a) silica aerogel and (b)

TESA

PAGE

6

9

17

18

28

29

31

38

39

41

57

60 xii

4.3

4.4

The FTIR spectra of (a) silica aerogel and (b) free tyrosinase

FTIR spectra of (a) free tyrosinase, (b) silica aerogel,

(c) TESA with SE and (d) TESA without SE

4.5 FESEM showing the surface morphology of (a) silica aerogel with SE and (b)

TESA with SE

4.6

4.7

4.8

FESEM micrographs showing the surface morphology of (a) silica aerogel without SE and (b)

TESA without SE

FESEM micrograph showing the surface morphology of free tyrosinase

TEM micrographs showing the surface morphology of (a) silica aerogel with SE and (b) TESA with SE

4.9

4.10

TEM micrographs showing the surface morphology of (a) silica aerogel without SE and (b) TESA without SE

Thermogravimetry analysis (TGA) and Derivative thermogravimetry (DTG) curves of (a) silica aerogel without SE, weight loss = 21.102%, (b) silica aerogel with SE, weight loss = 16.284%, (c) TESA without

SE, weight loss = 10.696%, (d) TESA with SE, weight loss = 6.632% and (e) free tyrosinase, weight loss = 100%

4.11

4.12

4.13

4.14

4.15

Effect of solvent extraction to the enzymatic activity of TESA with SE

Enzymatic activities of (a) TESA with SE and (b)

TESA without SE; at different aging periods

Enzymatic activities of (a) TESA with SE and (b)

TESA without SE; of different enzyme loadings

Enzymatic activity of (a) free tyrosinase, (b) TESA without SE, (c) TESA with SE; extracted by amyl acetate/acetone (v/v:1/1) and (d) without tyrosinase; at pH 7

Enzymatic activities of (a) free tyrosinase, (b) TESA with SE; extracted by amyl acetate/acetone (v/v:1/1) and (c) TESA without SE; at different temperatures

61

64

65

66

67

70

71

74

76

78

80

82

84 xiii

4.16

4.17

4.18

Enzymatic activities of (a) free tyrosinase, (b) TESA with SE; extracted by amyl acetate/acetone (v/v:1/1) and (c) TESA without SE; at different pH

The effect of contact time on the percent removal of phenol by (a) free tyrosinase, (b) TESA without SE and (c) TESA with SE; extracted by amyl acetate/acetone (v/v:1/1)

Reusability studies of (a) TESA without SE and (b)

TESA with SE; extracted by amyl acetate/acetone

(v/v:1/1), in the removal of phenol

86

88

90 xiv

LIST OF SYMBOLS xv ppm - Part per million

μ g - gram

μ L - Liter

λ - Lambda

θ - Theta

APD

DDW

DTG

EDTA

EDX

FESEM

FTIR

HPLC

NADH

PFC

RHA

-

-

-

-

-

-

-

-

LIST OF ABBREVIATIONS

Ambient Pressure Drying

Double Distilled Deionized Water

Derivative Thermogravimetric Analysis

Ethylene Diamine Tetracetic Acid

Energy Dispersive X-ray Technique

Field Emission Scanning Electron Microscopy

Fourier Transform Infrared

High Performance Liquid Chromatography xvi

-

-

-

Nicotinamide Adenine Dinucleotide

Plug Flow Combustor

Rice Husk Ash

TESA - Tyrosinase Encapsulated Silica Aerogel

xvii

LIST OF APPENDICES

APPENDIX

A

B

C

D

E

Determination of Ascorbic Acid using UV-Vis

Spectrophotometer

EDX Elemental Analysis of Tyrosinase, Silica

Aerogel and TESA

Determination of Phenol using UV-Vis

Spectrophotometer

Paper for R&D Nanotechnology Symposium

2007, Malaysia

Paper for 26th International Symposium on

Space Technology and Science (ISTS), Japan

111

114

119

121

128

CHAPTER 1

INTRODUCTION

1.1

Research Background

Nanotechnology, the process to generate, manipulate and employ nanomaterials, represents an area holding significant promise for health care and biotechnology in many years to come [1-4]. Nanotechnology is now poised to revolutionize the biomedical field ranging from basic studies to disease diagnosis and treatment. Understanding the principle of nanotechnology may provide insight into critical biological system related to disease control, correction of genetic disorder and longevity [3].

Biosensing is one of the most emerging sectors of nanotechnology. Such growth is mainly derived from the expansion of R&D where nano dimension research is introduced to analyze living cell constituents and for efficient drug screening [5]. Biosensors are devices that incorporate biologically active element in intimate contact with a physico-chemical signal; utilize the high sensitivity and selectivity of biological sensing for analytical purposes in various fields of research and technology [6]. Many proteins are expected to play the role as biocomponents used in biosensors. Enzymes are large protein molecules that significantly increase

2 rates of reaction by lowering the activation energy. Enzymes specifically accelerate a huge number of chemical reactions at room temperature and normal pressure [7].

Enzymes offer three major advantages [8]:

•

Higher reaction rates: Up to a factor of 10

12

times greater than the uncatalyzed reactions

•

Reaction conditions: Enzymes operate at room temperatures less than

100 o

C, atmospheric pressures and near neutral pH

•

Reaction specificity: Enzyme specificity for both substrate and product produces fewer side reactions

Immobilizations of biological compounds into inorganic support are usually applied in various fields such as biosensing [9-11], affinity chromatography [12-14] and enzyme reactors [15-17]. One of the most challenging aspects in the development of these matrices is the integration of biological molecules in the host matrix and retaining the functionality of the biomolecules [10]. In biosensing, it is advantageous to use immobilized enzymes rather than free enzymes [18-19].

Following are the reasons for immobilization of enzyme:

•

To improve the stability of enzyme in adverse reaction conditions

•

To improve the stability of enzyme in the presence of organic solvents

•

To separate the enzyme from product stream

•

To allow a continuous flow operations and repetitive usage

The application of immobilized enzymes in analytical chemistry is not a new concept. The importance of immobilized enzymes as analytical reagents in clinical chemistry [20-21], food analysis [22-23] and the pharmaceutical industry [24-25] has

3 been steadily increasing. To simplify the enzymatic measurement of glucose, the principle of the litmus paper used for pH measurement has been implemented [6].

The first ‘enzyme test strip’ has been obtained by the impregnation of filter paper with the glucose-converting enzymes. It can be regarded as the predecessor of optoelectronic biosensors which initiated the development and application of ‘dry chemistry’ [26]. Apart from the application of complex biocatalytic system, intense effort are being made to broaden the spectrum of measurable substances and to improve the analytical parameters of biosensors by the immobilization of several enzymes in a silica host matrixes.

Silica host matrixes, made by the sol-gel process have emerged as a promising platform for immobilization of enzymes [19, 26]. The advantages of their usage in enzyme immobilization include:

•

The high surface area of silica matrix provide the possibility of high enzyme loadings in the matrix

•

The silica matrix consists of surface hydroxyl groups that can be readily attached by enzyme

•

The open pore morphology of silica matrix allows substrates to quickly move into the interior regions of the particle

•

Solvents used in the processing of the silica materials are environmentally benign thus avoid the denaturation of enzyme

Numerous techniques such as physical adsorption, covalent attachment, entrapment and encapsulation in polymer and inorganic matrixes have been explored over the years to achieve a high-yield, reproducible and robust immobilization technique that preserves the activity of the biological molecules [10, 27-29].

Enzymes find a more stable environment upon encapsulation in a silica host, because the polymeric framework grows around the biomolecules, creating a cage, thus

4 protecting the enzyme either from aggregation and unfolding or from microbial attack. Encapsulations also offer a protection for the enzyme against deterioration by the hydrophilic solvent, if the proper gel is selected [28]. Therefore, the encapsulated biomolecules often retain a sufficient level of activity and functionality presumably because of sufficient retention of their native state conformations. Moreover, the matrix pores allow the diffusion of reactant molecules and their reaction with the encapsulated biomolecules. Eventually, encapsulated enzyme can even improve the activity and storage stability of the enzymes and will be easier to be used because they can easily be recovered and washed [30].

In this research, tyrosinase was used as model enzyme because of its wide application in medicine, environmental and industrial systems [8, 24]. Tyrosinase is also suitable for the treatment of phenolic wastes [9, 11, 17]. Tyrosinase like most other enzymes, is expensive and thus the use of the soluble enzyme is not practical

[2]. Therefore, the encapsulation of tyrosinase is very attractive in order to exploit its catalytic properties and improve the cost effectiveness [5]. The improved stability of the encapsulated enzyme allows it to be highly reusable. Moreover, since enzyme does not dissolve in the solution, further purified process is not required and hence the encapsulated tyrosinase is economical to be used repetitively [8].

1.2

Problem Statement

In most of the reported applications, an orthosilicate such as tetramethyl orthosilicate (TMOS) or tetraethyl orthosilicate (TEOS) has been used as silica source in the synthesis of proteins encapsulated silica monoliths [30-33]. These silica sources present the advantages of relatively high purity sources of silica but lowering the enzymatic activity. 70% reduction of enzymatic activity was reported when lipase was encapsulated into TMOS-based silica matrix due to the presence of 5% volume of methanol in the reaction [27]. The usage of TMOS or TEOS as starting

5 materials lead to the generation of alcohol as a by-product and the presence of alcohol has been known to be detrimental to the activity of proteins by causing chain unfolding, aggregation, destruction of secondary and tertiary protein structures to a significant extent [28]. Moreover, such organic silicon precursors are usually too expensive. So the production of silica aerogel in an industrial scale is not economically practical.

Owing to their mesoporous structure, high specific surface area and extremely low thermal conductivity, aerogels are considered as an efficient candidate as a support for protein immobilization. However, the high level of sophistication and the risks involved in the supercritical drying of the gels prohibit the commercial production of the aerogels and their wide exploitation in various potential applications [34-36]. Supercritical drying process is too energy intensive and dangerous that real practice and commercialization are difficult. Therefore, it is necessary to synthesize silica aerogels by an ambient pressure drying (APD) technique at a reasonable cost [37].

1.3 Hypothesis

An alcohol-free aqueous colloidal sol-gel for the synthesis of silica monoliths with encapsulated biological entities that uses rice husk ash as the cheap silicon source for production of pure silicate solution has been developed [28, 38]. This approach completely avoids the generation of alcohol and it allows encapsulation to be carried out at neutral pH and ambient pressure in order to preserve biological activity of proteins. Thus, denaturation of the biomolecule caused by the undesirable interaction with alcohol molecules can be avoided and the degree of conformational change can be reduced.

6

In this research, after the synthesis is complete, tyrosinase molecule is expected to be encapsulated in the silica aerogel network since the tyrosinase was added into the silica sol before the gelation stage. As shown in Figure 1.1, after the addition of tyrosinase, the silica sol begins to link together in three-dimensional (3D) network and subsequently, creates a cage around the tyrosinase molecule. It is also known that when enzyme molecules are mixed with colloidal particles, the interaction between them may result in enzyme adsorption on the particle surface.

Furthermore, the preparation of silica aerogel using water glass precursor followed by an ambient pressure drying is the cheapest and safest method.

Enzyme

Support network

6

Figure 1.1

The encapsulation of tyrosinase into silica aerogel network

This research is proposed to develop an effective method for the immobilization of biomolecule into silica aerogel matrix. Unrevealing the interactions which take place in encapsulation of enzyme in the silica aerogel matrix will contribute to better understanding of various chemical and biochemical processes that occur when different synthesis conditions are applied. The fundamental understanding of the enzyme-silica support interactions can help in improving the fabrication of enzyme encapsulated silica aerogel as a potential

7 biosensor with enhanced thermal stability and enzymatic performance. Hence, this research enables new materials for biosensors to be developed.

The objectives of this research are to: i) Synthesize and characterize tyrosinase encapsulated silica aerogel ii) Investigate the influence of synthesis conditions on biocatalytic activities of tyrosinase encapsulated silica aerogel iii) Investigate the enzymatic activity of tyrosinase encapsulated silica aerogel iv) Study the application of tyrosinase encapsulated silica aerogel in the removal of phenol

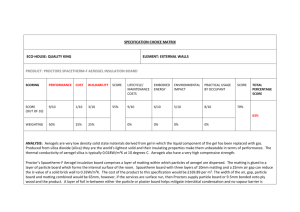

1.5 Scope of Research

The project is conducted following various phases as outlined in the flow diagram in Figure 1.2. The tyrosinase encapsulated silica aerogel (TESA) was synthesized via alcohol-free aqueous colloidal sol-gel process according to the established method [28] but with some modification. TESA, which is synthesized from rice husk ash as a silica source, was synthesized with and without solvent extraction (SE) process in order to study their relationship with the enzyme activity.

The products were characterized for their textural properties by using X-ray diffraction technique (XRD) and Fourier transformed-infrared spectroscopy (FTIR).

The interactions of tyrosinase-silica aerogel and its surface morphology were studied

8 by using Field emission-scanning electron microscopy (FESEM), Energy dispersive

X-ray spectroscopy (EDX), Transmission electron microscopy (TEM) and

Thermogravimetric analysis (TGA).

Some of the synthesis parameters in a sol-gel process were investigated for their influences on biocatalytic activities of encapsulated enzyme namely effect of solvent extraction and enzyme loading. In order to obtain information regarding the tyrosinase-silica aerogel interaction, wet gels containing encapsulated tyrosinase was submitted to different aging periods before drying phase.

Meanwhile, biocatalytic activities of the free tyrosinase and TESA were assayed by examining the catecholase activity using UV-Vis spectrophotometer. The properties of TESA were evaluated by studying the activity of tyrosinase at different temperatures and pH ranges, as well as leaching test. TESA was used to remove phenol in aqueous solution and their efficiency in removing phenol and the stability of tyrosinase in TESA was determined through reusability study.

9

Synthesis of tyrosinase encapsulated silica aerogel (TESA)

TESA without solvent extraction (SE) TESA with solvent extraction (SE)

Characterizations of TESA

X-ray diffraction technique (XRD)

Fourier transformed-infrared spectroscopy (FTIR)

Field emission-scanning electron microscopy (FESEM)

Energy dispersive X-ray spectroscopy (EDX)

Transmission electron microscopy (TEM)

Thermogravimetry analysis (TGA)

Optimization of synthesis conditions

Effect of solvent extraction

Aging period

Enzyme loading

Enzyme assay: UV-Vis Spectrophotometer

Measurement of tyrosinase activity

Leaching test

Influence of temperatures

Influence of pH

Application of TESA

Removal of phenol

Reusability

Figure 1.2 Flow diagram of research activities

CHAPTER 1

INTRODUCTION

1.1

Research Background

Nanotechnology, the process to generate, manipulate and employ nanomaterials, represents an area holding significant promise for health care and biotechnology in many years to come [1-4]. Nanotechnology is now poised to revolutionize the biomedical field ranging from basic studies to disease diagnosis and treatment. Understanding the principle of nanotechnology may provide insight into critical biological system related to disease control, correction of genetic disorder and longevity [3].

Biosensing is one of the most emerging sectors of nanotechnology. Such growth is mainly derived from the expansion of R&D where nano dimension research is introduced to analyze living cell constituents and for efficient drug screening [5]. Biosensors are devices that incorporate biologically active element in intimate contact with a physico-chemical signal; utilize the high sensitivity and selectivity of biological sensing for analytical purposes in various fields of research and technology [6]. Many proteins are expected to play the role as biocomponents used in biosensors. Enzymes are large protein molecules that significantly increase

2 rates of reaction by lowering the activation energy. Enzymes specifically accelerate a huge number of chemical reactions at room temperature and normal pressure [7].

Enzymes offer three major advantages [8]:

•

Higher reaction rates: Up to a factor of 10

12

times greater than the uncatalyzed reactions

•

Reaction conditions: Enzymes operate at room temperatures less than

100 o

C, atmospheric pressures and near neutral pH

•

Reaction specificity: Enzyme specificity for both substrate and product produces fewer side reactions

Immobilizations of biological compounds into inorganic support are usually applied in various fields such as biosensing [9-11], affinity chromatography [12-14] and enzyme reactors [15-17]. One of the most challenging aspects in the development of these matrices is the integration of biological molecules in the host matrix and retaining the functionality of the biomolecules [10]. In biosensing, it is advantageous to use immobilized enzymes rather than free enzymes [18-19].

Following are the reasons for immobilization of enzyme:

•

To improve the stability of enzyme in adverse reaction conditions

•

To improve the stability of enzyme in the presence of organic solvents

•

To separate the enzyme from product stream

•

To allow a continuous flow operations and repetitive usage

The application of immobilized enzymes in analytical chemistry is not a new concept. The importance of immobilized enzymes as analytical reagents in clinical chemistry [20-21], food analysis [22-23] and the pharmaceutical industry [24-25] has

3 been steadily increasing. To simplify the enzymatic measurement of glucose, the principle of the litmus paper used for pH measurement has been implemented [6].

The first ‘enzyme test strip’ has been obtained by the impregnation of filter paper with the glucose-converting enzymes. It can be regarded as the predecessor of optoelectronic biosensors which initiated the development and application of ‘dry chemistry’ [26]. Apart from the application of complex biocatalytic system, intense effort are being made to broaden the spectrum of measurable substances and to improve the analytical parameters of biosensors by the immobilization of several enzymes in a silica host matrixes.

Silica host matrixes, made by the sol-gel process have emerged as a promising platform for immobilization of enzymes [19, 26]. The advantages of their usage in enzyme immobilization include:

•

The high surface area of silica matrix provide the possibility of high enzyme loadings in the matrix

•

The silica matrix consists of surface hydroxyl groups that can be readily attached by enzyme

•

The open pore morphology of silica matrix allows substrates to quickly move into the interior regions of the particle

•

Solvents used in the processing of the silica materials are environmentally benign thus avoid the denaturation of enzyme

Numerous techniques such as physical adsorption, covalent attachment, entrapment and encapsulation in polymer and inorganic matrixes have been explored over the years to achieve a high-yield, reproducible and robust immobilization technique that preserves the activity of the biological molecules [10, 27-29].

Enzymes find a more stable environment upon encapsulation in a silica host, because the polymeric framework grows around the biomolecules, creating a cage, thus

4 protecting the enzyme either from aggregation and unfolding or from microbial attack. Encapsulations also offer a protection for the enzyme against deterioration by the hydrophilic solvent, if the proper gel is selected [28]. Therefore, the encapsulated biomolecules often retain a sufficient level of activity and functionality presumably because of sufficient retention of their native state conformations. Moreover, the matrix pores allow the diffusion of reactant molecules and their reaction with the encapsulated biomolecules. Eventually, encapsulated enzyme can even improve the activity and storage stability of the enzymes and will be easier to be used because they can easily be recovered and washed [30].

In this research, tyrosinase was used as model enzyme because of its wide application in medicine, environmental and industrial systems [8, 24]. Tyrosinase is also suitable for the treatment of phenolic wastes [9, 11, 17]. Tyrosinase like most other enzymes, is expensive and thus the use of the soluble enzyme is not practical

[2]. Therefore, the encapsulation of tyrosinase is very attractive in order to exploit its catalytic properties and improve the cost effectiveness [5]. The improved stability of the encapsulated enzyme allows it to be highly reusable. Moreover, since enzyme does not dissolve in the solution, further purified process is not required and hence the encapsulated tyrosinase is economical to be used repetitively [8].

1.2

Problem Statement

In most of the reported applications, an orthosilicate such as tetramethyl orthosilicate (TMOS) or tetraethyl orthosilicate (TEOS) has been used as silica source in the synthesis of proteins encapsulated silica monoliths [30-33]. These silica sources present the advantages of relatively high purity sources of silica but lowering the enzymatic activity. 70% reduction of enzymatic activity was reported when lipase was encapsulated into TMOS-based silica matrix due to the presence of 5% volume of methanol in the reaction [27]. The usage of TMOS or TEOS as starting

5 materials lead to the generation of alcohol as a by-product and the presence of alcohol has been known to be detrimental to the activity of proteins by causing chain unfolding, aggregation, destruction of secondary and tertiary protein structures to a significant extent [28]. Moreover, such organic silicon precursors are usually too expensive. So the production of silica aerogel in an industrial scale is not economically practical.

Owing to their mesoporous structure, high specific surface area and extremely low thermal conductivity, aerogels are considered as an efficient candidate as a support for protein immobilization. However, the high level of sophistication and the risks involved in the supercritical drying of the gels prohibit the commercial production of the aerogels and their wide exploitation in various potential applications [34-36]. Supercritical drying process is too energy intensive and dangerous that real practice and commercialization are difficult. Therefore, it is necessary to synthesize silica aerogels by an ambient pressure drying (APD) technique at a reasonable cost [37].

1.3 Hypothesis

An alcohol-free aqueous colloidal sol-gel for the synthesis of silica monoliths with encapsulated biological entities that uses rice husk ash as the cheap silicon source for production of pure silicate solution has been developed [28, 38]. This approach completely avoids the generation of alcohol and it allows encapsulation to be carried out at neutral pH and ambient pressure in order to preserve biological activity of proteins. Thus, denaturation of the biomolecule caused by the undesirable interaction with alcohol molecules can be avoided and the degree of conformational change can be reduced.

6

In this research, after the synthesis is complete, tyrosinase molecule is expected to be encapsulated in the silica aerogel network since the tyrosinase was added into the silica sol before the gelation stage. As shown in Figure 1.1, after the addition of tyrosinase, the silica sol begins to link together in three-dimensional (3D) network and subsequently, creates a cage around the tyrosinase molecule. It is also known that when enzyme molecules are mixed with colloidal particles, the interaction between them may result in enzyme adsorption on the particle surface.

Furthermore, the preparation of silica aerogel using water glass precursor followed by an ambient pressure drying is the cheapest and safest method.

Enzyme

Support network

6

Figure 1.1

The encapsulation of tyrosinase into silica aerogel network

This research is proposed to develop an effective method for the immobilization of biomolecule into silica aerogel matrix. Unrevealing the interactions which take place in encapsulation of enzyme in the silica aerogel matrix will contribute to better understanding of various chemical and biochemical processes that occur when different synthesis conditions are applied. The fundamental understanding of the enzyme-silica support interactions can help in improving the fabrication of enzyme encapsulated silica aerogel as a potential

7 biosensor with enhanced thermal stability and enzymatic performance. Hence, this research enables new materials for biosensors to be developed.

The objectives of this research are to: i) Synthesize and characterize tyrosinase encapsulated silica aerogel ii) Investigate the influence of synthesis conditions on biocatalytic activities of tyrosinase encapsulated silica aerogel iii) Investigate the enzymatic activity of tyrosinase encapsulated silica aerogel iv) Study the application of tyrosinase encapsulated silica aerogel in the removal of phenol

1.5 Scope of Research

The project is conducted following various phases as outlined in the flow diagram in Figure 1.2. The tyrosinase encapsulated silica aerogel (TESA) was synthesized via alcohol-free aqueous colloidal sol-gel process according to the established method [28] but with some modification. TESA, which is synthesized from rice husk ash as a silica source, was synthesized with and without solvent extraction (SE) process in order to study their relationship with the enzyme activity.

The products were characterized for their textural properties by using X-ray diffraction technique (XRD) and Fourier transformed-infrared spectroscopy (FTIR).

The interactions of tyrosinase-silica aerogel and its surface morphology were studied

8 by using Field emission-scanning electron microscopy (FESEM), Energy dispersive

X-ray spectroscopy (EDX), Transmission electron microscopy (TEM) and

Thermogravimetric analysis (TGA).

Some of the synthesis parameters in a sol-gel process were investigated for their influences on biocatalytic activities of encapsulated enzyme namely effect of solvent extraction and enzyme loading. In order to obtain information regarding the tyrosinase-silica aerogel interaction, wet gels containing encapsulated tyrosinase was submitted to different aging periods before drying phase.

Meanwhile, biocatalytic activities of the free tyrosinase and TESA were assayed by examining the catecholase activity using UV-Vis spectrophotometer. The properties of TESA were evaluated by studying the activity of tyrosinase at different temperatures and pH ranges, as well as leaching test. TESA was used to remove phenol in aqueous solution and their efficiency in removing phenol and the stability of tyrosinase in TESA was determined through reusability study.

9

Synthesis of tyrosinase encapsulated silica aerogel (TESA)

TESA without solvent extraction (SE) TESA with solvent extraction (SE)

Characterizations of TESA

X-ray diffraction technique (XRD)

Fourier transformed-infrared spectroscopy (FTIR)

Field emission-scanning electron microscopy (FESEM)

Energy dispersive X-ray spectroscopy (EDX)

Transmission electron microscopy (TEM)

Thermogravimetry analysis (TGA)

Optimization of synthesis conditions

Effect of solvent extraction

Aging period

Enzyme loading

Enzyme assay: UV-Vis Spectrophotometer

Measurement of tyrosinase activity

Leaching test

Influence of temperatures

Influence of pH

Application of TESA

Removal of phenol

Reusability

Figure 1.2 Flow diagram of research activities

CHAPTER 2

LITERATURE REVIEW

2.1 Rice Husk Ash as a Silica Source

Rice husk is a major waste product of the rice-processing industries. Like most of the other biomass materials such as sugar, cane leaf, corn leaf, rice husk is also recognized as a potential source for energy generation from gasification or incineration processes. Acid leaching [39] and gasification [40] methods have been investigated for recovering silica from rice husk. Of all the plant residues, the ash of rice husk contains the highest amount of silica (SiO

2

). The burning of rice husk in air results in the formation of rice husk ash (RHA) with SiO

2 content of 85% to 98% depending on the burning condition, furnace type, rice variety, moisture content, weather and geographic area [41].

RHA is available in abundance at no cost. The presence of silica in RHA is known since 1938 and extensive literatures have reported the uses of RHA as silica replacement for the production of silicon based materials in industrial and technological applications [42-47]. Some small amounts of inorganic impurities are usually present in the ash together with unburned carbon. The unburned carbon can be removed from the ash by further heating at high temperature; however high

11 temperature usually leads to crystallization of the amorphous silica to cristobalite and/or tridymite [48]. The crystallization of silica in RHA occurs when the burning conditions of husk are uncontrolled [42]. The crystallization form of silica has drawbacks towards the preparation of silicon based materials since silica ash is inactive in its crystalline form [42, 49]. Highly reactive silica in RHA can be produced by maintaining the combustion temperature below 500 °C under oxidising conditions for relatively long period or high temperature up to 680 °C for less than one minute [43]. In addition, the combustion environment affects the specific surface area of silica, hence temperature and environment must be considered in the pyroprocessing of rice husk to produce ash with a maximum reactivity of silica [48].

However, silica in RHA can remain in amorphous form if the combustion temperatures up to 900 °C for less than an hour, whereas crystalline silica can be produced at 1000 °C when heated for more than 5 minutes [44].

However, silica can be easily extracted at low temperature of 40 °C because of the amorphous nature of silica in RHA. Amorphous silica in RHA can be extracted using low temperature alkali extraction since the solubility of amorphous silica is very low at pH below than pH 10 and it increases sharply above pH 10. The unique solubility behaviour of amorphous silica enables it to be extracted in pure form from RHA by dissolution under alkaline conditions [50]. This low energy method based on alkaline solubilization of amorphous silica can be cost effective compared to the current smelting method. Hence, it provides a lower alternative energy compared to the current high energy method. The development of a simple low energy chemical method for producing pure silica from rice husk has lead to a variety of industrial applications for RHA.

Silica is an excellent insulator, having low thermal conductivity, high melting point, low bulk density and high porosity. The use of silica as a support for catalysts is well known. Silica is widely used in glass, ceramics and cement as a major component and in pharmaceuticals, cosmetics, and detergents industries as a bonding and adhesive agents [51]. It has also been used as a major precursor for a variety of inorganic and organometallic materials which have the applications in synthetic

12 chemistry as catalysts and in thin films or coatings for electronic and optical materials [52-54]. Other solid forms of silica include the crystalline quartz, tridymite and cristabolite. These forms of silica are generally inappropriate as catalyst supports because they are non-porous. Pelleted diatomaceous earth is a naturally occurring form of siliceous material which is sometimes used as a catalyst support because it has a porous structure and relatively crush-resistant. However, it also contains alumina and iron impurities which may be harmful to many catalytic reactions [55].

Silica offers a number of advantages; the thermal stability of porous silica is excellent; having a glass transition temperature of 900 °C and no weight loss at

450 °C and the pore size can be controlled and easily limited to 10 nm [31].

Silica matrix with a mesoporous structure and high surface area was first reported in the preparation of aerogel by Steven Kistler in 1931. With the use of supercritical drying, he produced aerogel and shows that the gel morphology could be tuned by variation of drying conditions [56]. However, this method is not commercially viable because it is time consuming and requires a great deal of capital investment. In addition, high temperature and pressure that are required to obtain the supercritical condition can create a potentially explosive situation. Therefore, as alternative, ambient temperature and pressure are vital in the synthesis of aerogel.

What is an aerogel? According to Husing [57], there are two useful definitions of aerogel. The first one is defined according to the preparation method in which “all materials prepared from wet gels by a special drying process, the supercritical drying technique, were called aerogels irrespective of their structural properties”. The second definition addresses whether a product obtains an intact microstructure in its gel: “materials in which the typical of the pores and the network is largely maintained while the pore liquid of a gel is replaced by air are called

13 aerogels”. As overall, an aerogel is a porous solid material in which a very high percentage (95%) of its volume is filled with air [58].

Silica aerogel was first discovered in 1931 by Kistler [59-60]. In order to form the aerogel network, polymerization of silicic acid (Si(OH)

4

) was generated by acidic neutralization of sodium silicate in water. This process can be represented in

Equation 1.

Na

2

SiO

3

+ H

2

SO

4

+ H

2

O Si(OH)

4

+ Na

2

SO

4

(1)

According to Kistler’s method, the aqueous silica hydrogels were repeatedly rinsed with anhydrous methanol to remove all amounts of water. However, this method has numerous disadvantages particularly the toxicity of methanol and the flammable solvent which is needed to be handled at very high temperature and pressure [34]. Subsequently, ethanol based processing using silicon alkoxides derivatives (e.g. tetraethylorthosilicate or TEOS) are the preferred soluble silica source for the formation of silica aerogels over last few decades since water/alcohol solvent exchange could be avoided [61-63]. Via this method, alcohol is used as a homogenizing agent since water and alkoxysilanes are immiscible. Nevertheless, gels can be prepared from silicon-alkoxide-water mixtures without the addition of solvent because alcohol that is produced as a by-product of the hydrolysis reaction is sufficient to homogenize the initially phase separated system. Silicic acid that was produced from the reaction of silicon-alkoxide-water mixtures is very sensitively condensed with itself and rapidly generates sol particles. As condensation continues, a three dimensional gel network is formed which subsequently fill the mould dimension and entrain all of the liquid solvent.

14

An aerogel is one of the most fascinating solid materials because it is very light and highly transparent polymer material which is often called “frozen smoke” because of its hazy blue appearance [58]. Silica aerogel is a highly porous, open cell and low-density foam. Since its microstructure consists of nano-sized pore which is created from linked particles, it exhibits many desirable properties [64]. The applications of the silica aerogel have expanded into many fields [54] such as fillers for paints and varnishes, thermal and acoustic insulation materials, adsorbents and catalyst supports, as electronic materials such as Cherenkov detectors and sensor materials [65-66]. In addition, the highly hydrophobic of aerogel can be used to remove oil from water stream [54].

2.3 Sol-Gel Process in Aerogel Synthesis

A sol is defined as a colloidal dispersion of particles in a liquid while a gel is a substance that contains a continuous solid skeleton enclosing a continuous liquid phase. Thus, the formal definition of sol-gel processing is the growth of colloidal particles and their linking together to form a gel [59]. The sol-gel process is a wetchemical technique for the fabrication of materials (typically a metal oxide) starting either from a chemical solution (sol short for solution) or colloidal particles (sol for nanoscale particle) to produce an integrated network (gel) of silicon precursor through a change of interaction between the colloidal particles which is changing the systems characteristics from a liquid to a gel [60].

The most documented method for the preparation of silica aerogel is the solgel route [53, 67]. In sol-gel chemistry, the addition of water allows hydrolysis of the precursor to occur which is then followed by a condensation reaction. The completion of hydrolysis reaction depends on the water/precursor ratio and the catalyst added. Condensation can be occurred by the reaction of two silanol group reacted with an alkoxy group. The properties and structure of gels are highly

15 dependent upon the chemical environment during the reaction [60]. Conventional silica sol-gel process consists of hydrolysis of an alkoxide precursor such as tetramethoxysilane (TMOS) or tetraethoxysilane (TEOS) with the aid of a base or acid catalyst to form a homogenous colloidal suspension of silica which is known as a sol. The sol is then aged extensively for further polycondensation reaction and subsequent dried to remove the solvents and by-products. Gelation period varied depend on the precursors and catalysts. A gel network can be formed by polymeric formation of covalent bonds that are presented by the formation of particulate sols network which are held together by Van der Waals interaction [53].

Sol-gel processing is not only used for the preparation of silica gel but also for the synthesis of ceramic products, thin film and coatings over porous membranes

[59]. Sol-gel based materials have diverse applications in optics, electronics, energy, space, biosensors, medicine and separation technology [27-28, 56]. The wide application of sol-gel is due to its ability to form pure and homogenous products at very low temperature [60]. Thus, sol-gel technology can replace the old ceramic fabrication processes in which powders are shaped into objects and subsequently densified at temperature close to their liquids. The most fascination of sol-gel technology derives from the ability to control its composition and microstructure at the molecular level combined with the ability to shape the materials at room temperature for example by casting bulk gels in precision moulds, spinning fibres or dip coating thin film [67].

The chemistry involves in the sol-gel process consists of an initial hydrolysis of the silane precursors followed by the condensation of the hydrolyzed silicate monomers. The hydrolysis reaction comprises a series of three steps primarily by nucleophilic substitutions. In the first stage, nucleophilic attacks the positive charged

16 metal atom brought about by its interaction with negative charge of oxygen atom that is associated with water molecules. This reaction generates the increase of the coordination number of the metal ion. The next step involves the movement of a positively charge proton to a negatively charge –OR group of the metallo-organic precursor [68]. Finally, R-OH molecule is released as a product. The formation of gel in first stage undergoes polycondensation in the next stage. The nucleophilic substitutions step that was involves in the hydrolysis reaction and the chemical reactions for the polycondensation reaction are expressed by the sol-gel chemistry equations in Figure 2.1.

OR

OH

RO Si OR + 4 H

2

O

H / OH

HO Si OH

+ 4 ROH

OR

OH

R'

OR

Si OR + 3 H

2

O

H / OH

OR

R'

OH

Si OH

OH

+ 3 ROH

HO

OH

Si

OH

OH + R'

(a) Hydrolysis of silane precursors

OR

OH

H / OH

Si OR

HO Si

OH

O Si

OR

OH

(b) Condensation of the pre-hydrolyzed silane precursors

OH

R' + H

2

O

17 n HO

OH

Si O

OH

OH

Si R'

H / OH

OH

Si

R'

O

O

O Si

O

O

Si

O

O

Si

O

O

Si

O

R'

Si

O

OH

Si

O

R'

(c) Polycondensation reaction

Figure 2.1 (a) Hydrolysis, (b) condensation and (c) polycondensation reactions, during the sol-gel process in the synthesis of silica aerogel

Hydrolysis and condensation reactions occur simultaneously in the sol-gel process. The overview of sol-gel processing by Brinker [59] and Coltrain and Kelts,

[69] explained that the processing factors influencing the hydrolysis and condensation of silicates are catalyst, steric and inductive effects provided by alkyl groups, the ratio of water to precursor and the solvent. During the hydrolysis and condensation stages of sol-gel processing, each of these elements are shown to play an important role in determining the trends of gel structure. This trend was observed from the evolution of silicates derived from alkoxide precursors. Since silicon alkoxide precursor is insensitive to hydrolyse, its reactivity is commonly enhanced by catalyst which improves the strength of the nucleophile. Catalysts derived from acidic or basic conditions affected the sol-gel structure by influencing the hydrolysis and condensation kinetics [56].

18

After the initial and condensation reactions, the silicate monomers condense into dimeric and oligomeric species that form polymeric silica chains or clusters.

Due to the dissimilarity of catalysis mechanisms which form different particles, the growth of silicate species is also different. Thus, the shape and texture of these silicate dimers or oligomers are determined by the type of catalyst as shown in

Figure 2.2.

SOL-GEL BASED ON ACID-CATALYZED

•

Produced weak branched polymeric networks

•

Yield a highly dense polymer and microporous gel

SOL-GEL BASED ON BASE-CATALYZED

•

Produced high branched polymeric networks

•

Yield a loosely packing polymer and mesoporous gel

Figure 2.2

Polymeric structure of silica framework in acidic and basic conditions

In acidic condition, the hydrolysis reaction occurs at a faster rate than condensation reaction. The rate of condensation reaction decreases with the increasing number of siloxane linkages around the centre of silicon atom leads to

19 weak branched polymeric networks. The weakly branched polymers yield a highly dense and microporous gels with uniform distribution of small slit shaped pores and a narrow pore size distribution [68]. In a basic condition, on contrary, condensation reaction is accelerated compared to hydrolysis. The rate of condensation reaction increases with the increasing number of siloxane linkages. Thus, highly branched networks with ring structures are formed [70]. Highly branched system produces the mesoporous gels due to loose packing and more linear polymer [68].

2.3.2 Gelation and Aging

As the polymeric network extends all over the total volume, the sol thickens to a gel. The gelation point is defined as the time when an infinite, spanning polymers or aggregate first appears [59]. It is influenced by the size of container, solution pH, nature of the salt concentration, anion and solvent, type of initial alkoxy group and the amount of water [71-72]. After gelation, the next phase in sol-gel fabrication is the aging process. When the gel is kept in contact with the pore-filling liquid, its structure and properties keep changing as a function of time. This process is called aging. During this phase, some shrinkage and stiffness of the gel network is occurred along with a corresponding expulsion of solvent. Gels of desired densities and pore structures as well as surface areas can be obtained by simply varying the aging time, temperature, pH and added electrolyte [52, 73].

2.3.3 Drying

The drying step is extremely important in sol-gel processing. When solvent is removed from the gel, the presence of liquid in microporous regions can cause

20 capillary tension on the solid gel structure. If the stress is too severe, extensive cracking in monolithic gels will occur. To prevent this to happen, the capillary stress must be minimized by a number of techniques; reducing the solvent evaporation rate, adding a solvent of surfactant of lower surface area energy, hypercritically drying which removes the solid-liquid interface or forming a monodispersion of pore size

[63, 71, 73].

The gel can be dried at very high pressure and temperature corresponding to the supercritical conditions of the dispersed liquid in the gel to yield aerogels. The surface area of the gel may be retained to a great extent even after drying through the supercritical drying process. Supercritical drying was firstly used by Kistler in 1931 to make aerogel [59, 60]. The idea in using the supercritical drying was to eliminate liquid-vapour interface inside pores during drying and thus achieving zero capillary forces. In practice, the liquid solvent of the wet gel was first transformed into its supercritical conditions by increasing the temperature and pressure above the critical point of the solvent. At this stage, the solvent could be considered as supercritical fluid since both liquid and gas are presents. Subsequently, the solvent was released at constant temperature and passes from supercritical condition to gas phase without crossing any liquid-vapour interphase. Historically in this process, alcohol played a role as an extraction solvent. The extraction with alcohol has been termed as the high temperature supercritical drying since many alcohols reach their critical condition at very high temperature and high pressure. However, the high level of sophistication instruments, high risks and high cost involves in the supercritical drying of the gel prohibited the commercial production of the aerogel [34, 36, 74-75].

Therefore, the synthesis of aerogel via an ambient pressure drying (APD) is one way to reduce the production cost. APD has been considered as a promising technique to be applied on a large scale for industrial purposes. It does not require high pressure and high temperature conditions unlike the supercritical drying technique. Recently, many researchers focus their work on this route in an attempt to develop cost-effective and simple process for the production of silica aerogels [35-37,

75-76]. However, significant collapse of pores may occurred due to the differential

21 stresses induced in the gel matrix as a result of the capillary forces happens in the pores of varying radii by the liquid-vapour interface during the APD process of the pore liquid [77].

Nevertheless, the differential stresses of gel which induces the collapse of pores can be minimized by either synthesizing gel with wider pores or by exchanging the pore liquid of gel with a low surface tension solvent before the drying step. Since water has high surface tension, the water in the pores of gel can be exchanged with the solvent from aging media and hence minimizing the pore water content [73, 77]. The success in preventing the loss of surface area in aerogel which has been produced via APD, by using novel sol-gel routes is reported. Brinker and his co-workers [52] reported the synthesis of aerogel via APD using two step routes from tetraethoxysilane (TEOS) at pH 8 produced aerogel with surface area up to

1000 m

2

/g. Meanwhile, Komarneni and his team [78] reported a two step synthesis of aerogel with surface area up to 1447 m

2

/g from TEOS by a series of subsequent post-synthesis treatments involving solvent aging, silane coating and vacuum drying of the wet gel.

However, the techniques available to date suffer from the disadvantages such as huge requirement of the expensive chemicals for the solvent exchange and surface modification of the hydrogels. Thus, Schwertfeger and his team [36] reported the synthesis of silica aerogels using low-cost water-glass precursor without solvent exchange and supercritical drying of the wet-gels. However, the process involves huge consumption of expensive silylating agents such as trimethylchlorosilane

(TMCS) and hexamethyldisiloxane (HMDSO) for the surface modification of the wet-gels. This again makes the production process expensive and the use of the lowcost precursor such as waterglass becomes meaningless.

22

2.4 Immobilization of Enzyme

In the process of enhancing the stability and reusabilityof enzyme, enzymes are often immobilized by physical or chemical means to the surface of insoluble supports. An immobilized enzyme can be defined as any enzyme which is not freely soluble and whose movement in space is completely or partially restricted to a small region [26]. It is also known as the process of imprisoning an enzyme molecule in a distinct phase that allows for exchange but is separated from the bulk phase in which substrate effectors or inhibitor molecules is dispersed [25]. The immobilized enzyme is usually insoluble in water and the support that is usually used to immobilize enzyme is composed of a high molecular weight, hydrophilic polymer. Although its movement is partially or completely restricted within the microenvironment, the term “immobilization” does not imply that the enzyme can never move within its distinct phase [79].

Immobilization of enzymes on solid surface places them in a more natural environment and in many cases; allow them to function more efficiently [25]. When soluble enzyme is used for catalyzing a reaction, the reaction can only be terminated by deactivating the enzyme or by changing the environment. In the case of immobilized enzyme, the extent of reaction can be adjusted either by changing the residence time of the reactants or by removing the immobilized enzyme support from the reaction solution [26]. Immobilized enzymes also retain their catalytic properties for a longer period of time, thus making their use even more economical.

Other benefit of immobilized enzymes is the inhibition of enzyme activity whereby the excess of product can be minimized [8]. Immobilized enzymes can also be used for multi enzyme systems where several enzymes are placed in the same support thus; enabling it to catalyze a sequence reaction [5].

The appropriate matrix or support for the immobilization of enzyme is chosen based on several different properties which affect the production process [80].

One of the properties is that the materials need to have high surface area particularly

23 up to 100 m

2

/g for high enzyme loadings and high porosity to provide access for the substrate. The immobilization matrix must also be resistant to chemical degradations and mechanical stability. Microbial resistance of matrix is also an important property that needs to be considered since a major concern to any immobilized enzyme process is the presence of microbes. Furthermore, the durability of the carrier is often determined by its resistance to microbial degradation [79].

Enzyme technology is truly an ancient art which has been used in our lives since antiquity [7]. Enzyme has been used for thousands of years without a clear understanding of their nature. The first recorded use of enzyme involves the production of cheese from the stomach lining of calves, which contain chymosin.

Primitive herdsmen discovered that storing milk in the stomach of animals resulted in a tasty solid food called cheese. The action of chymosin which is a coagulating enzymes present in the stomach, induces gelation of the protein casein and changes the milk to curd and whey. The casein gel is cut and drained to remove the whey and the remaining solid, curd is pressed to produce cheese. This is one of the earliest recorded applications of enzymes to the processing of foods [79].

The properties and reactions of enzyme catalysis were first recognized by

Kirchhoff where he discovered that a component of wheat was capable of producing sugar from starch. Then, in 1833, Payen and Persoz obtained a malt extracted, amylase, which hydrolyzed starch into sugar [5]. In 1846, Dubonfout discovered the activity of invertase and Berthelot observed the same activity in an alcohol precipitate from yeast [7]. However, the term “enzyme” was coined by Kühne in

1878 and in 1893. Ostwald first classified enzymes as a catalyst. The next leap in the understanding of enzymes came in 1894 when Emil Fisher first proposed the “lock and key” theory to explain the specificity of enzymes [8]. By the beginning of the

24

20 th

century, the protein nature of enzymes was recognized [7]. Knowledge of the chemistry of protein drew heavily on the improving techniques and concept of organic chemistry in the second half of the 19 th

century. Modern enzyme chemistry was heralded by the proposed hypothesis for enzyme reactions reported by Michaelis and Menten and the isolation of an enzyme, urease by Sumner [5].

The immobilization process is well known having the potential to increase the enzyme stability. Tyrosinase has been immobilized on a variety of supports using different procedures by various researches. A variety of techniques have been developed to immobilize enzymes on the solid supports. The common immobilization technique can be classified into two general methods; chemical and physical methods. The former is based on the covalent bond formation and the latter depends on non-covalent bond formation where weaker interactions or containment of the enzymes are involved [26, 79]. The chemical methods involve covalent attachment and cross linking using multi reagents while the physical methods include adsorption, entrapment and micro-encapsulation of enzyme on solid support.

Enzymes can be adsorbed physically on a surface-active adsorbent by contact of an aqueous solution with an adsorbent. The advantages of the adsorption technique are the procedure being simple, inexpensive and possible in separating and purifying enzyme while being immobilized. However, the bonding strength of adsorbed enzyme is weak thus the immobilization yield is very low. It was demonstrated by Pialis and his co-workers [9] that only 70% of enzyme uptake was observed when tyrosinase was immobilized on nylon 6,6 membranes for the phenol production. Besides, the state of immobilization is very sensitive to solution pH, ionic strength and temperature.

25

Proteins and other bio-materials can be immobilized within the pore of support prepared from organic polymers. The entrapped molecule cannot escape from the support but materials which have low molecular weight can enter and leave the support by diffusion. The immobilized enzyme that is produced by this technique provides an extremely large surface area. Enzyme can also be entrapped within cross-linked polymers by forming a highly cross-linked network of polymer. A wide variety of cross linking agents have been proposed for immobilizing enzymes but only glutaraldehyde is extensively used. This method has a major advantage in the fact that there is no chemical modification of the enzyme; therefore the intrinsic properties of an enzyme are not distorted [26]. However, this technique has unappealing features. For instance, during the polymerization process, enzyme activity can be affected by the free radicals. The enzyme leakage and limitation of diffusion for the higher molecular weight reactants may occur.

Covalent bonding technique of enzyme immobilized on solid matrix is the most widely studied in the development of enzyme immobilization. This method has the advantages of high activity retention, hydraulic properties and temperature stability. Enzyme immobilization that is produced using covalent bonding technique results in high stability, ease in handling and simple preparation. The carrier can also be re-used after enzyme deactivation. However, immobilization technique renders the enzyme inactive if the active site is blocked. Possible leakage of the chemical used to activate the surface can also occur during the immobilization which may be harmful to enzyme [79].

2.4.3 Immobilization of Enzymes by Encapsulation Technique via Sol-Gel

Method

In the last decade, a new approach has been developed to achieve the immobilization of enzyme by using silica-based inorganic polymers. This method

26 was pioneered by Avnir and his co-workers [62] which are based on so-called sol-gel process. Mild processing conditions, excellent thermostability and chemical inertness of the support are the significant characteristics of this method. The silica alkoxide precursor has been extensively used in the conventional sol-gel method [60].

However, the use of TMOS or TEOS as starting materials lead to the generation of alcohol as a by-product, the presence of which can be detrimental to the protein activity. Therefore, it is important to develop an alcohol free sol gel process by encapsulation of the biological materials in a transparent matrix.

Sol-gel process offers an opportunity to develop one type of immobilization technique which is encapsulation in inorganic porous network. It is a useful method for biocatalyst entrapment because inorganic polymeric networks can be prepared even under mild ambient condition. Progressive improvements in the enzyme encapsulation technique indicates that enzyme remain catalytically active. Sol-gel encapsulation offers a number of desirable advantages [81]. The hydrophilicity of the matrix can be readily controlled. The inorganic matrix has high mechanical and chemical stability which allows enzyme to encapsulate in a rigid glass framework physically. The rigid glass framework of inorganic matrix provides stabilizing interaction with enzyme and keeps away from leaching problem. In addition, the high degree of biomolecules rigidity reduces the denaturizing phenomena. In other aspect, surface area of support from the sol gel method is controllable and can withstand the high range of temperature. Lastly, encapsulated biomolecules typically show improved resistance to thermal and chemical denaturation which can increase the storage and operational stability of enzyme.

Silica has been extensively used as carriers for enzyme [82]. One of the reason is that it possesses high mechanical strength at a wide range of operating pressures as proven by its use in High Performance Liquid Chromatography (HPLC)

[83]. Additionally, silica has relatively higher thermal and chemical stabilities and is resistant to microbial degradation. Since then, various biologically active species of interest such as enzymes, proteins, antibodies, virus and bacteria have been immobilized via sol gel process in different silica supports [10, 74, 84-85].

27

However, the disadvantage in sol gel process is during the drying technique, the drastic change of a gel texture can be occurred due to the capillary stresses [53,

72]. In addition, an enzyme consists of a proteidic chain which is folded onto itself, is very sensitive to drying stresses. In order to developed more effectively biocatalyst having improved activity, high storage stability and protection against deterioration by the hydrophilic solvent, the extensive encapsulation technique of enzyme on silica matrix with varieties of drying technique must be highlighted.

2.5

Tyrosinase

One of the “versatile” enzymes in nature is tyrosinase (monophenols monooxygenase, odiphenol: O

2

oxidorecductase, E. C. 1.14.18.1). Tyrosinase was discovered by Bertrand and Bourquelot almost 100 years ago [86]. Tyrosinase is a tetramer having weighs about 130 000 Daltons. Mushroom tyrosinase or fungal tyrosinase, bacterial tyrosinase and vertebrate tyrosinase consist of a binuclear copper active site which can exist in three states [87];

•

Met: the resting form of tyrosinase with an oxidized, anti ferromagnetically coupled bicupric complex in the active site

•

Oxy: an oxidized form of tyrosinase wherein the coordinated oxygen exists as peroxide and contains Cu

2+

in the active site

•

Deoxy: a reduced form of tyrosinase consisting of a univalent copper complex in the active site

28

Tyrosinase is also recognized as a key enzyme for melanin biosynthesis in plants and animals. Therefore, tyrosinase inhibitors should be clinically useful for the treatment of some dermatological disorders associated with melanin hyper pigmentation and also important in cosmetics for whitening and depigmentation after sunburn [88]. In plants, sponges and many invertebrates, they are important components of wound healing and the primary immune response [89]. In arthropods, they are also involved in sclerotization of the cuticle after molting or injury. In mammals, tyrosinases are found in melanocytes of the retina and skin [90]. In food industry, tyrosinase is responsible for the enzymatic browning reactions in damaged fruits during post-harvest handling and processing. The controlling of the enzymatic browning during processing is important in fruit pulp manufacturing [91].

Tyrosinase is usually used to catalyze two main reactions via separate active sites [92]. The first reaction catalyzed by tyrosinase is a monooxygenation where one atom of molecular oxygen is incorporated into aromatic structure and the reducing agent, AH

2

is oxidized. Although alternative reducing agents were used to increase reactions rates, the odiphenol generated from the above reaction can act as the reductant. Thus, costly external cofactors are not required by this enzyme [93]. The second reaction catalyzed by tyrosinase is the oxidation of odiphenol to oquinone.

Non-enzymatic polymerization of the oquinone by oxidative coupling then occurs by a series of oligomerization and polymerization reactions with the subsequent formation of melanin or melanin-like compounds [86, 94]. Mechanism reaction of monooxygenation and oxidation reaction catalysed by tyrosinase is illustrated in

Figures 2.3 and 2.4, respectively.

OH

OH

+ O

2

+ AH

2

+ H

2

O + A

R

R

Figure 2.3

Monooxygenation reaction catalyzed by tyrosinase

OH

29

OH

+ 1/2 O

2

O

+ H

2

O

OH

O

R

R

Figure 2.4 Oxidation of o -diphenol to o -quinone

Tyrosinase is very delicate. Vigorous shaking and temperature higher than

60 °C can cause denaturation to the protein and lead to the inactivation of tyrosinase.

Tyrosinase should be used at a pH range between 5 and 7, since it can loses its activity at pH values lower than 5. The optimum pH region for the activity of tyrosinase is between 6 and 7 [92]. The tyrosinase concentrated solution (

<

1 mg/mL at pH 7) shows little loss of activity when stored for several months while in dilute solution, tyrosinase can lose their activity within 20 minutes even when stored at low temperature (

<

5 °C) [18]. Most tyrosinase prepared from various sources share the same substrate specificity, so that this tyrosinase is similar in their reactivity and stability based on reaction inactivation [92, 95]. However, they might exhibit differences in other factors such as thermostability and deactivation by mechanical forces where there exist different molecular properties; structure and genetic expression [5].

30

2.5.1 Immobilized Tyrosinase in the Removal of Phenol

Aromatic compounds including phenols and aromatic amines constitute one of the major classes of pollutants that are of concern in many countries [96]. Some of the industrial area that discharge phenol include oil refineries, coke and coal conversion plants, plastics and petrochemical companies, dyes, textiles and paper industries. Almost all phenols are toxic. Furthermore, phenol and many of its derivatives are considered to be hazardous pollutants. Due to its toxicity and hazard, the concentration of phenol which is greater than 50 ppb is harmful to some aquatic species and the ingestion of 1 g phenol may be fatal to humans [97]. As a consequence, this may affect the ecosystem of water sources where phenols are discharged. Thus, the removal of phenol in water is important.