University of Houston Master Construction Specifications Insert Project Name 1.1

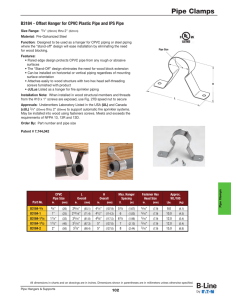

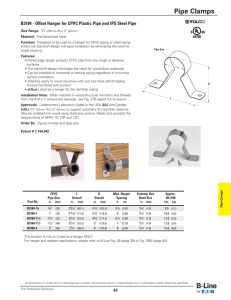

advertisement