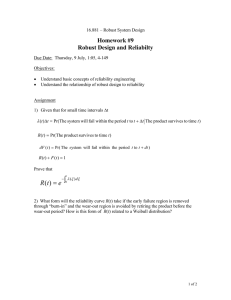

Robust Design (Taguchi Method) Presentation

advertisement

Robust Design (Taguchi Method) Background, • Robust Design method aka Taguchi Method, pioneered by Dr. Genichi Taguchi, greatly improves engineering productivity. • By consciously considering the noise factors (environmental variation during the product's usage, manufacturing variation, and component deterioration) and the cost of failure in the field the Robust Design method helps ensure customer satisfaction. • Robust Design focuses on improving the fundamental function of the product or process, thus facilitating flexible designs and concurrent engineering. Indeed, it is the most powerful method available to reduce product cost, improve quality, and simultaneously reduce development interval. Why Use Robust Design Method? • Over the last five years many leading companies have invested heavily in the Six Sigma approach, aimed at reducing waste during manufacturing and operations. great impact on the cost structure and hence on the bottom line of those companies.? • Brenda Reichelderfer of ITT Industries reported on their benchmarking survey of many leading companies – "design directly influences > 70% of the product life cycle cost; companies with high product development effectiveness have earnings three times the average earnings; and companies with high product development effectiveness have revenue growth two times the average revenue growth." – "40% of product development costs are wasted!" • The Design for Six Sigma approach is focused on: 1) increasing engineering productivity so that new products can be developed rapidly and at low cost 2) value based management. • Many companies around the world have saved hundreds of millions of dollars by using the method in diverse industries: automobiles, xerography, telecommunications, electronics, software, etc. Typical Problems Addressed By Robust Design, A team of engineers was working on the design of a radio receiver for ground to aircraft communication requiring high reliability, i.e., low bit error rate, for data transmission – On the one hand, building series of prototypes to sequentially eliminate problems would be forbiddingly expensive. – On the other hand, computer simulation effort for evaluating a single design was also time consuming and expensive. Then, how can one speed up development and yet assure reliability? In an another project, • A manufacturer had introduced a high speed copy machine to the field only to find that the paper feeder jammed almost ten times more frequently than what was planned. The traditional method for evaluating the reliability of a single new design idea used to take several weeks. How can the company conduct the needed research in a short time and come up with a design that would not embarrass the company again in the field? • The Robust Design method has helped reduce the development time and cost by a factor of two or better in many such problems. Two categories of engineering decisions, • In general, in product/system development 2 categories of engineering decisions are: – Error-free implementation of the past collective knowledge and experience – Generation of new design information, often for improving product quality/reliability, performance, and cost. • While CAD/CAE tools are effective for implementing past knowledge, Robust Design method greatly improves productivity in generation of new knowledge by acting as an amplifier of engineering skills. • With Robust Design, a company can rapidly achieve the full technological potential of their design ideas and achieve higher profits. Robustness Strategy • Variation reduction is universally recognized as a key to reliability and productivity improvement. There are many approaches to reducing the variability, each one having its place in the product development cycle. • By addressing variation reduction at a particular stage in a product's life cycle, one can prevent failures in the downstream stages. The robustness strategy is to prevent problems through optimizing product designs and manufacturing process designs. Case example • The manufacturer of a differential op-amplifier used in coin telephones faced the problem of excessive offset voltage due to manufacturing variability. High offset voltage caused poor voice quality, especially for phones further away from the central office. So, how to minimize field problems and associated cost? There are many approaches: 1. Compensate the customers for their losses. 2. Screen out circuits having large offset voltage at the end of the production line. 3. Institute tighter tolerances through process control on the manufacturing line. 4. Change the nominal values of critical circuit parameters such that the circuit's function becomes insensitive to the cause, namely, manufacturing variation. Answer: No 4 • The approach 4 is the robustness strategy. As one moves from approach 1 to 4, one progressively moves upstream in the product delivery cycle and also becomes more efficient in cost control. Hence it is preferable to address the problem as upstream as possible. The robustness strategy provides the crucial methodology for systematically arriving at solutions that make designs less sensitive to various causes of variation. It can be used for optimizing product design as well as for manufacturing process design. The Robustness Strategy uses 5 primary tools: 1. P-Diagram is used to classify the variables associated with the product into noise, control, signal (input), and response (output) factors. 2. Ideal Function is used to mathematically specify the ideal form of the signal-response relationship as embodied by the design concept for making the higher-level system work perfectly. 3. Quadratic Loss Function (also known as Quality Loss Function) is used to quantify the loss incurred by the user due to deviation from target performance. 4. Signal-to-Noise Ratio is used for predicting the field quality through laboratory experiments. 5. Orthogonal Arrays are used for gathering dependable information about control factors (design parameters) with a small number of experiments. Design of Experiments • • • A robust product is one that works as intended regardless of variation in a product's manufacturing process, variation resulting from deterioration, and variation in use. Robust design can be achieved when the designer understands these potential sources of variation and takes steps to desensitize the product to these potential sources of variation. Robust design can be achieved through "brute force" techniques of added design margin or tighter tolerances or through "intelligent design" by understanding which product and process design parameters are critical to the achievement of a performance characteristic and what are the optimum values to both achieve the performance characteristic and minimize variation. When the operation of the product or achievement of a performance characteristic can be mathematically related to a product or process design parameter, optimum product and process design parameters can be calculated. When these relationships are unknown, design of experiments (DOE) can aid in determining these optimum parameter values and, thereby, developing a more robust design. Design of Experiments Description • • Design of Experiments is based on the objective of desensitizing a product's performance characteristic(s) to variation in critical product and process design parameters. Genichi Taguchi developed the concept of "loss to society". In this concept, variability in critical design parameters will increase the loss to society which is an expanded view of the traditional, internally-oriented cost of quality. This is a quadratic relationship of increasing costs (loss to society) as these critical design parameter values vary from the desired mean value of the parameter. To consider quality implications during design, the design process can be segmented into three stages. 1. The first stage, system design, establishes the functionality of the product, the physical product envelope, and general specifications. 2. The second stage, parameter design, establishes specific values for design parameters related to physical and functional specifications. It is during these first two stages that the designer has the greatest opportunity to reduce product costs through effective functional design and parameter specification. 3. The third stage, tolerance design, establishes the acceptable tolerances around each parameter or target. The third stage typically will add costs to the product through efforts to ensure compliance with the tolerances associated with product parameters. Design of Experiments Description...cont’d • Since an organization cannot cost-effectively inspect quality into the product, it must focus on minimizing variability in the product through product and process design and control of processes. However, some variability is uncontrollable or very difficult to control. This difficult to control variation is referred to as noise. Noise is the result of variation in materials, processes, the environment and the product's use or misuse. Products need to be designed so that they are robust their performance is insensitive to this naturally occurring, difficult to control variation. Design of Experiments techniques provide an approach to efficiently designing industrial experiments which will improve the understanding of the relationship between product and process parameters and the desired performance characteristic. This efficient design of experiments is based on a fractional factorial experiment which allows an experiment to be conducted with only a fraction of all the possible experimental combinations of parameter values. Orthogonal arrays are used to aid in the design of an experiment. The orthogonal array will specify the test cases to conduct the experiment. Frequently, two orthogonal arrays are used: a design factor matrix and a noise factor matrix, the latter used to conduct the experiment is the presence of difficult to control variation so as to develop a robust design. This approach to designing and conducting an experiment to determine the effect of design factors (parameters) and noise factors on a performance characteristic is represented below. Design of Experiments Description...cont’d • These experimental results can be summarized into a metric called the signal to noise ratio which jointly considers how effectively the mean value (signal) of the parameter has been achieved and the amount of variability that has been experienced. As a result, a designer can identify the parameters that will have the greatest effect on the achievement of a product's performance characteristic. The design parameters or factors of concern are identified in an inner array or design factor matrix which specifies the factor level or design parameter test cases. The outer array or noise factor matrix specifies the noise factor or the range of variation the product will be exposed to in the manufacturing process, the environment or how the product used (conditions it is exposed to). This experimental set-up allows the identification of the design parameter values or factor levels that will produce the best performing, most reliable, or most satisfactory product over the expected range of noise factors or environmental conditions. After the experiments are conducted and the signal to noise ratio determined for each design factor test case, a mean signal to noise ratio value is calculated for each design factor level or value. This data is statistically analyzed using analysis of variation (ANOVA) techniques. Very simply, a design factor with a large difference in the signal noise ratio from one factor setting to another indicates that the factor or design parameter is a significant contributor to the achievement of the performance characteristic. When there is little difference in the signal to noise ratio from one factor setting to another, this indicates that the factor is insignificant with respect to the performance characteristic. Design of Experiments Description...cont’d • From the result, the designer can: – Identify parameter values which maximize achievement of performance characteristic and minimize the effect of noise, thereby achieving a more robust design. – Identify parameters that have no significant effect on performance. In these cases, tolerances can be relaxed and cost reduced. – Identify parameter values which reduce cost without affecting performance or variation. • These steps take initial effort, but can reduce cost and improve the performance of the product. Variability Reduction • Variability Reduction is a multipart strategy to reduce product variation and make a product more robust or fit to use, e.g., meet its performance requirements regardless of variation. 1. Broadly speaking, there are three sources of variation: manufacturing variation 2. environmental/deterioration variation 3. usage variation. Variability reduction involves understanding customer needs and developing a product and process design that balances these needs with process capabilities and potential sources of variation. Thus variability reduction is broader than SPC and DOE individually and more proactive than SPC. The following diagram represents an overall framework for variability reduction or quality engineering. In the real field,