Team 09: In The Spotlight Final Design Report Engr339/340 Senior Design Project

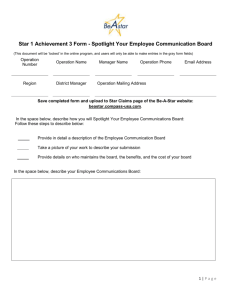

advertisement