Project Proposal and Feasibility Study Team 12: Iron Man

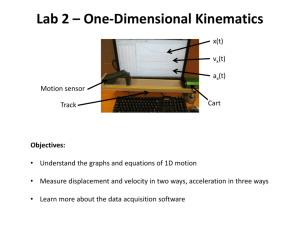

advertisement

Project Proposal and Feasibility Study Team 12: Iron Man Allen Bosscher Andrew Vriesema Lukas Woltjer Calvin College ENGR 339/340 Senior Design Project Winter 2013 COPYRIGHT © 2013 Team 12. All Rights Reserved Executive Summary This report outlines and describes the preliminary design and research for the running cart prototype. Team 12, Iron Man, has decided to design and build an off-road capable running cart that can be easily collapsible and transported. For this design, the team will make the vehicle as light as possible while maintaining the necessary strength to carry a teenage passenger. The team has specifically designed the running cart with a disabled passenger in mind. The important aspects for this design that needed significant engineering focus were the collapsibility, quick-wheel change, overall passenger comfort, and maneuverability of the running cart. The team will also attempt to make the design as inexpensive as possible for future manufacturing and business possibilities. Through the research and analysis presented in this report, Team 12 has concluded that creating an off-road running cart is feasible. Table of Contents 1. Introduction ............................................................................................................1 1.1 Team Members ...................................................................................................................... 1 1.2 Project Definition .................................................................................................................. 2 2. Project Management ..............................................................................................3 2.1 Team Organization ................................................................................................................ 3 2.1.1 Team Member Roles ...................................................................................................... 3 2.1.2 Team Documents ............................................................................................................ 3 2.2 Schedule Management .......................................................................................................... 3 2.3 Budget ................................................................................................................................... 4 2.4 Method of Approach ............................................................................................................. 4 3. Requirements .........................................................................................................5 3.1 Physical Requirements .......................................................................................................... 5 3.1.1. Strength .......................................................................................................................... 5 3.1.2. Portability ...................................................................................................................... 5 3.1.2.1. Size.......................................................................................................................... 5 3.1.2.2. Weight ..................................................................................................................... 5 3.1.3. Capabilities .................................................................................................................... 5 3.2 Cost Requirements ................................................................................................................ 6 3.2.1 Material Costs ................................................................................................................. 6 3.2.2. Manufacturing Costs...................................................................................................... 6 4. Research .................................................................................................................7 4.1 Material Options .................................................................................................................... 7 4.2 Similar Projects ..................................................................................................................... 7 4.3 Resources .............................................................................................................................. 8 4.4 Safety Requirements ............................................................................................................. 8 5. Task Specifications and Scheduling ......................................................................9 5.1 Project Categories ................................................................................................................. 9 5.2 Task Completion Level ......................................................................................................... 9 6. Design ..................................................................................................................11 6.1. Design Criteria ................................................................................................................... 11 6.2 Frame Material .................................................................................................................... 11 6.2.1 Frame Material Design Criteria .................................................................................... 11 Page i 6.2.2 Frame Material Alternatives ......................................................................................... 12 6.2.3 Frame Material Design Decisions ................................................................................ 13 6.3 Quick Change Wheel Design .............................................................................................. 14 6.3.1 Quick Change Wheel Design Criteria .......................................................................... 14 6.3.2 Quick Change Wheel Design Alternatives ................................................................... 15 6.3.3 Quick Change Wheel Design Decisions ....................................................................... 16 6.4 Collapsible Design .............................................................................................................. 17 6.4.1 Collapsible Design Criteria .......................................................................................... 17 6.4.2 Collapsible Design Alternatives ................................................................................... 18 6.4.3 Collapsible Design Decisions ....................................................................................... 18 6.5 Block Diagram .................................................................................................................... 19 6.6 Preliminary Design .............................................................................................................. 20 7. Testing Plans ........................................................................................................24 8. Business Analysis ................................................................................................25 8.1 Marketing Study .................................................................................................................. 25 8.1.1 Competitive Analysis ................................................................................................... 25 8.1.1.1 Existing Competitors ............................................................................................. 25 8.1.1.2 Potential Competitors............................................................................................. 25 8.1.2 Target Markets .............................................................................................................. 25 8.1.2.1 Handicapped Clients .............................................................................................. 26 8.1.2.2 Caretakers .............................................................................................................. 26 8.1.2.3 Health Organizations ............................................................................................. 26 8.2 Cost Estimate....................................................................................................................... 26 8.2.1 Development ................................................................................................................. 26 8.2.2 Production ..................................................................................................................... 27 8.2.2.1 Fixed Costs............................................................................................................. 27 8.2.2.2 Variable Costs ........................................................................................................ 28 8.2.2.3 Financial Summary ................................................................................................ 29 9. Conclusion ...........................................................................................................30 10. Acknowledgements ............................................................................................31 11. References .........................................................................................................32 Appendix A. Work Breakdown Schedule................................................................34 Appendix B. Pro-forma Financial Statements .........................................................35 Page ii Table of Figures Figure 1: Team Picture.................................................................................................................... 1 Figure 2: Quick Release Skewer Examples .................................................................................. 15 Figure 3: Quick Release Hitch Pin................................................................................................ 16 Figure 4: Block Diagram .............................................................................................................. 19 Figure 5: Initial Sketch of Running Cart....................................................................................... 20 Figure 6: Initial Frame Design ...................................................................................................... 21 Figure 7: Forces Acting on the Frame of the Cart ........................................................................ 22 Figure 8: Simulation Results......................................................................................................... 23 Page iii Table of Tables Table 1: Task Completion Levels ................................................................................................. 10 Table 2: Frame Material Design Criteria ...................................................................................... 11 Table 3: Frame Material Alternative Properties ........................................................................... 13 Table 4: Frame Material Decision Matrix .................................................................................... 13 Table 5: Quick Wheel Change Design Criteria ............................................................................ 14 Table 6: Collapsibility Design Criteria ......................................................................................... 17 Table 7: Team Budget ................................................................................................................... 27 Table 8: Estimated Fixed Costs .................................................................................................... 27 Table 9: Estimated Variable Costs ................................................................................................ 28 Table 10: Pro-forma Statement of Income.................................................................................... 35 Table 11: Pro-forma Statement of Cash Flows ............................................................................. 36 Table 12: Break-Even Analysis .................................................................................................... 37 Table 13: Break-Even Analysis (continued) ................................................................................. 38 Table 14: Iron Man Corporation Budget ...................................................................................... 38 Page iv 1. Introduction Team 12 (Iron Man) is composed of three senior engineering students, all pursuing a degree in engineering with a mechanical concentration. Each member provides a variety of experiences, skills, and background to this project. The team consists of: Allen Bosscher, Lukas Woltjer, and Andrew Vriesema. 1.1 Team Members Figure 1: Team Picture Allen Bosscher Allen was born and raised in Grand Rapids, Michigan. He is a senior engineering student at Calvin College and expects to graduate in May 2014 with a Bachelor of Science in Engineering degree with a mechanical concentration. Allen has interned at Rapid-Line, a metal fabrication company, for the past three years. Through this internship he has learned valuable insight into production and design engineering. He plans on entering the workforce upon graduating. Lukas Woltjer Lukas was born in Nashville, Tennessee and has lived in Washington State and Portland, Oregon. He is a senior engineering student at Calvin College and expects to graduate in May 2014 with a Bachelor of Page 1 Science in Engineering degree with a mechanical concentration. Lukas has interned at Calvin College as a student researcher, Cascade Engineering as a renewable energy intern, and Oregon State University as a technical lab assistant. He plans on entering the workforce upon graduating. Andrew Vriesema Andrew was born and raised in North Haledon, New Jersey. He is a senior engineering student at Calvin College and expects to graduate in May 2014 with a Bachelor of Science in Engineering degree with a mechanical concentration. Andrew has interned at Rapid-Line for the past six months. He plans on entering the workforce upon graduating. 1.2 Project Definition The project the design team is pursuing is the research, design, construction, and testing of a running cart, usable by a person with moderate physical disabilities. Goals of this project include: a light-weight design, ease of use by the runner and the passenger, the ability to travel well on various surfaces, and ease of transportation through a collapsible design. To achieve these goals, the team will work closely with people with experience in helping disabled people. The team will use best practices in machine design and structural analysis to ensure the safety of the passenger and runner, and to ensure reliable performance of the cart. Page 2 2. Project Management 2.1 Team Organization 2.1.1 Team Member Roles Many of the tasks associated with the design project will be completed as a team, although a specific team member will be in charge of particular responsibilities. Allen Bosscher is in charge of the research and customer relation aspects of the project. He will coordinate with the rest of the team about which areas of the project will need to be researched more in depth as the project proceeds and will be in charge of compiling all collected research. Allen is also in charge of communicating with the customer and other entities that could provide assistance and direction as the project develops. He is also in charge of maintaining the team’s schedule. Lukas Woltjer is the webmaster and is responsible for updating and maintaining the team’s website. Lukas is also the primary lead on the design computer modeling aspect of the project. He is in charge of how the design options will be modeled and analyzed through a variety of methods such as finite element analysis (FEA). Andrew Vriesema is in charge of managing the design options and delegating which team member should focus on what. He is also in charge of manufacturing the prototype and troubleshooting issues that emerge with this process. 2.1.2 Team Documents All electronic documents are saved on Calvin College’s “Shared Drive” through the file path S:\Engineering\Teams\Team12. Additionally, hard copies of research documents and important correspondence are compiled by Allen Bosscher and are available upon request. The design team also has a team website located at the following URL: http://www.calvin.edu/academic/engineering/2013-14team12/index.html. This is maintained by Lukas Woltjer and will contain important documents and general team information. 2.2 Schedule Management The team has decided to dedicate one hour at the beginning of the first meeting of each week on reviewing the schedule of tasks. The team will update the schedule as needed as new issues and other project necessities arise. Allen Bosscher is the primary schedule coordinator, and will update the rest of the team on what tasks should be completed first and the deadlines associated with them. Allen is also in charge of submitting the necessary assignments as part of the senior design course in which the team is enrolled. Priority is assigned to tasks which require immediate response, which include unforeseen issues Page 3 and customer relations. The design team will strive to minimize the amount of unforeseen issues, allowing the team to focus on important yet non-urgent tasks. This was suggested by Professor David Wunder, as urgent and important tasks are large time sinks and force the team to deviate from the predicted schedule. 2.3 Budget Lukas Woltjer is the primary budget coordinator, and is in charge of maintaining the budget and adjusting it as the design progresses. Adjustments which add to the budget will be made with team consensus, and will need to reflect an important and necessary need that requires the allocation of funds. The revised budget will then be approved by the team’s faculty advisor. Increase of the budget will be avoided when possible, but the team will make sure there is a contingency which will allow for unforeseen costs to be covered. This budgeting method was suggested by Professor Matthew Heun, and has been successfully implemented in many critical projects. Because the budget is indicative of the overall cost of the running cart, great care will be taken to ensure it is accurate and that costs are kept low. The detailed budget appears in the business analysis section of the report. 2.4 Method of Approach The team's approach is to break the project down into four stages, which may involve iteration and overlap at some stages. The first stage is to research currently available and similar projects, to see how the team can differentiate the final design product and provide a unique service or experience to the end user. Page 4 3. Requirements 3.1 Physical Requirements Our goal for the running cart is to allow a teenage handicapped child to be able to get outdoors and experience nature in a way that they would not normally be able to. This means that the running cart will need to have several physical requirements. The first of which is strength. The cart needs to be strong enough to carry a teenage child, as well as be able to handle potentially tough terrain. Another requirement for the cart is to have it be comfortable to ride in. This will allow the customer to enjoy using the cart, and let them focus on what is going on around them and not on how the ride feels. 3.1.1. Strength The strength of the cart is an important aspect of the design. The biggest challenge when it comes to strength will be supporting the weight of the person that the cart is transporting. The cart will also have to be strong enough to withstand the force of the person pushing the cart. Other forces that the cart will have to overcome include dynamic forces from the cart going over obstacles on rough terrain such as gravel or small tree roots. 3.1.2. Portability Another requirement for the cart is that it needs to be transportable. This means that the cart will be able to fold up or easily come apart in some way that a person could lift it up and place it in the back of a van. 3.1.2.1. Size The size of the cart should be big enough so that it is strong enough to comfortably support its passenger, yet small enough to be easily maneuverable in use. One factor that will affect the size of the cart will be whether or not the cart is collapsible, or if it breaks apart into sections. If the cart is able to break apart it can be larger than if it was just collapsible because the sections could be made light enough to be transported. 3.1.2.2. Weight The goal for the weight of the cart has not been determined yet. The cart should be light enough for someone to be able to push it and transport it without taking away from the strength of the cart. The design weight that will be used in the analysis of the cart is approximately 200lbs. 3.1.3. Capabilities The capabilities of the cart include being able to be easily transported from one place to another, and being able to travel off-road over terrain that a normal wheelchair would not be able to traverse. As previously stated the cart should be able to be placed and transported from one place to another. The cart Page 5 should also be able to handle different kinds of terrains. To do this the design team has considered making the cart capable of easily changing the tires to allow the cart to go from one terrain to the next. For example, the customer should be able to easily change the wheels to go from asphalt to sand. 3.2 Cost Requirements Due to medical costs related to disabilities, many families with physically disabled members don’t have the opportunity to purchase expensive equipment. This is the primary reason for why a crucial aspect of this project is to aim to keep the total product cost low. 3.2.1 Material Costs The design team will design the product in a method that will minimize materials costs in order to keep the selling price as low as possible. To do this, material options are limited to commonly available metals and polymers, despite having to make weight sacrifices to maintain necessary strength. The design team will also carefully select components such as bearings, fittings, and shafts in commonly available sizes and tolerances to reduce costs. 3.2.2. Manufacturing Costs Manufacturing costs for the budget given to Calvin College are preliminarily $0, because the team plans to do all welding, machining, and assembly in-house. For the business plan, the manufacturing costs will be approximated as assembly hours times a machinist's hourly rate. Looking beyond prototype manufacturing, the design team will need to keep manufacturing costs low without requiring large volumes. The market for a running cart exists, but more information will need to be obtained on how large and accessible said market is. Of particular interest is what portion of families with disabled persons would be interested in purchasing a cart. These ideas are discussed in greater detail in the business analysis section of the report. Page 6 4. Research 4.1 Material Options Following the constraints imposed in section 3.2.1, the design team found four material options for the frame. These options are detailed in the frame material design section of the report. Seat and cushion material options are being researched. Similar applications or appropriate materials could be bicycle seats, outdoor furniture, and automotive applications. The design team is interested in materials that will withstand mold and mildew due to sweat and water and will maintain integrity when exposed to sunlight repeatedly. Other desirable characteristics include comfort and durability (tear resistance). 4.2 Similar Projects While the team has a goal of designing and delivering a novel idea, the team does not want to ignore similar projects. Researching these projects will enable the team to observe areas of improvement and issues that should be avoided through the entire design process. With this in mind, the design team was able to find several similar projects that provided a baseline for which to build the project upon. The first similar idea researched was the project known as “Team Hoyt.” This is a father and son duo who participate in various marathons and triathlons. The son, Rick Hoyt, has cerebral palsy and is limited to riding in a special boat during the swimming portion, the front of a special bicycle during the bike portion, and a special wheelchair during the running portion of the triathlons. This idea is quite similar to the team’s design, as the primary goal of both designs are to enable a parent or family member to more easily involve a disabled or motion-limited child in outdoor endeavors. The physical differences the team plans on incorporating are the collapsible design and the quick-change wheels. The design team also desires to make the running cart more affordable than the “running chair” that Team Hoyt uses. The second similar idea is known as His Wheels. This is a non-profit Christian organization which focuses on providing people with lower-body disabilities hand-pedaled “trikes” for transportation. Their focus is mainly overseas, where the effects of polio are still common, and where many have no means of transportation or assistance, and must pull themselves around with their hands. His Wheels, although producing a somewhat similar product, are focusing on a much different need. The third similar idea is known as myTEAM TRIUMPH (mTT). This is an organization that provides resources and equipment for disabled “Captains” to participate in long-distance events with the assistance Page 7 of their “Angels”. However, mTT does not manufacture equipment and is therefore not a competitor to the Iron Man Corp. The team has yet to determine the source of running chairs that mTT offers at events. 4.3 Resources The team has established several contacts as resources for the project. The primary knowledge the team hopes to learn from resources are the specific needs and requirements of a disabled person that pertain to the running cart design. The following paragraphs describe the contacts made and the information gained. The first contact identified was His Wheels International. The team is in contact with His Wheels mostly pertaining to the ergonomics of the design. His Wheels will also assist the team due to their extensive experience with people with physical disabilities, and will be a vital resource for any specific needs corresponding to that. The primary contact with His Wheels is Alice Teisan, the founder and executive director. The second contact identified was Becky Van Zanen. She is a part-time caretaker for a disabled client, and has extensive experience using a running cart. She provided the team with extremely valuable information regarding the importance of various features of a running cart, and represented her client’s needs thoroughly. We will maintain contact with her during the design and testing of the cart, and use her input to tailor the design to meet the needs of many disabled people. The third contact identified was myTEAM TRIUMPH (mTT). This is a contact highly recommended by Becky Van Zanen, and it provides equipment and resources for disabled participants of long-distance events. The team has initiated contact with the CEO of mTT, and will hope to meet and gain information from him regarding ergonomics, competitors, and other design considerations. 4.4 Safety Requirements To ensure the safety of the passenger and runner, the design team needs to consider methods to preventing any possible form of injury. The possible injury scenarios considered include: roll-over, passenger ejection, collision with stationary objects, collision with vehicles or pedestrians, abrasion from asphalt contact, injury by moving components, skin irritation/damage from unsuitable materials, cuts or skin tears from cart entry/exit, neck or head injury from excessive vibration and/or shock, and bruises and cuts to the runner due to insufficient leg clearance. The design team cannot foresee all potential hazards, but it is necessary to thoroughly test the cart and minimize the likelihood and severity of injuries sustained from use of the cart. Through communicating with the team’s resources the team learned that round tubing would be preferred on any surface that the passenger would possible come into contact with. The resources expressed this is of greater importance with handicapped passengers, as they are more likely to injure themselves. Page 8 5. Task Specifications and Scheduling 5.1 Project Categories The design team has split the design aspect of the project into five main areas: the collapsible nature of the design, strength of the design, transportability of the design, easy of assembly and quick wheel change design, and all-terrain aspect of the design. Each of these areas have specific requirements as defined earlier. 5.2 Task Completion Level The team is currently still in the research and project development stage of the design. The research at this stage in the project is centered on outlining the preliminary objectives and requirements, as well as building a foundation of similar ideas and novel concepts that could work within the scope of the project. The design team’s first semester work schedule, including accomplished and planned work, can be viewed in Appendix A. The team has reached out to several resources, which have assisted the team in defining necessary requirements and outlining features that they would like to see in the designed product. The team has constructed a SolidWorks 3D CAD file of the designed frame, and have performed finite element analysis to determine the strength of the design. The team has also researched methods by which to achieve the quick wheel change, and have selected the material that will be used for the frame and seat. The team is on schedule according to the schedule outlined in the team’s Gantt chart. The table below outlines the tasks needed to complete the project, and lists the percentage complete for each task. Page 9 Table 1: Task Completion Levels Percentage Complete Task Percentage Complete Task (%) (%) Define Project 100 Resources 75 Cutting and Approval 100 Gather Resources 75 Source out Suppliers 75 Survey to Understand Features 75 Handicapped Concerns 75 Present to Resources 25 60 Make Adjustments 25 Research Budget (continued) Secondary Design 80 25 Material Options 100 Final Design 0 Wheel Design 60 Construction of Design 0 Similar Projects 80 Gather all material 0 Jointed/collapsibility 50 Build Frame 0 80 Attach wheels and brakes 0 Preliminary Design Initial Sketch 100 Detailed First Design 100 Strength Testing 0 SolidWorks 3D Model 80 Collapsibility Testing 0 Finite Element Analysis 80 Quick-wheel Change Testing 0 80 Ease of Assembly 0 Budget Initial Sourcing 100 Testing and Modification Present Final Product 0 0 Tasks that have provided the most difficulty and required more work than expected were the resources and research tasks. Issues emerged in communicating between the several resources that have been gained, as schedules would typically not overlap. Issues that emerged throughout the research phase were finding similar projects and potential collapsible or jointed designs. However, the team was able to overcome these issues and remain on schedule. Looking forward, the team plans on beginning construction of the design on February 10. The team plans on finishing construction and beginning testing and modification on March 10. Page 10 6. Design 6.1. Design Criteria The team is following several criteria when it comes to the design of the running cart. The first of which is that the team is making the design as simple as possible. This will allow for easy assembly of any prototypes, and make any future repair work easy and inexpensive. Another design criteria for the running cart will be making the cart as light as possible, while still maintaining the necessary strength needed to carry a teenage passenger. The cart needs to be light so that a person can pick it up and transported to wherever the need to go. Also, the team will design the cart in such a way that the cart can be folded up, or taken apart to make transporting the cart easy. The cart needs to be strong so that the customers will feel comfortable using the cart without worrying about a failure of the cart. The cart will also be designed to have interchanging wheels that will be easy for the customer to switch between depending on the terrain they want to travel on. The following sections will describe each component in the system in detail, with sections on the component’s design criteria, alternatives, and design decision. 6.2 Frame Material 6.2.1 Frame Material Design Criteria The first system component the team analyzed was the material which would be used for the frame. The criteria the team used to decide upon the final material appears in the table below. Table 2: Frame Material Design Criteria Criteria Weight Cost 25 Strength 25 Manufacturability 20 Durability 15 Stewardship 5 Trust 5 Integrity 5 As shown in the table above, the cost and strength of the frame material were designated to be the most important design criteria. This is due to these criteria directly affecting the design requirements. One of the primary goals the team is designing towards is to maintain a low cost product, while still maintaining the necessary strength requirements. The manufacturability of the frame material was also designated to Page 11 be an important design criteria. This takes into consideration the ease of purchasing the material, the ease of machining the material using the tools provided in Calvin College’s metal shop, as well as the ease of welding. Durability takes into consideration the long term material properties, as well as relative ease of fixing issues that occur several years into the product’s lifespan. Finally, the team identified three design norms that are directly applicable to the frame material design. As Christians, the team ought to design in such a way as to carefully use the earth’s resources. In this way, the team is called to be stewards of the earth. Therefore, the team has included the design norm stewardship as a design criteria, as the frame material chosen must consider the availability of earth’s resources. Economic and environmental concerns of the material chosen are also included in this criteria. The next design norm is trust. This criteria is rather straightforward. The team needs to choose a frame material that will be credible, dependable, and reliable. Potential users of the product should not be concerned with the frame’s design at first glance. Integrity is the final design norm that applies to the frame design. The frame needs to be designed so that it is pleasing and intuitive to use. The material chosen needs to accomplish these goals, so that the passenger and runner are not uncomfortable with the product. These design criteria have the potential to be in tension. Maintaining the low cost of the frame while still reaching the necessary strength and integrity requirements could prove challenging. 6.2.2 Frame Material Alternatives The design team researched potential frame material options and narrowed the list down to four: 4130 alloy steel, 6061 aluminum alloy, 3AL-2.5V titanium alloy, and carbon fiber. The other material options that were researched were ultimately eliminated due to the availability of the material as well as the amount of information available. These material options were not commonly used on similar projects and would have added a large amount of difficulty in procuring and using said materials. The team selected 4130 alloy steel as a potential frame material as it is a very common material in frame constructions. This alloy of steel is also easy to machine and weld, which were important to the design team due to limited welding experience. Steel would also be the easiest material to purchase due to its large presence in the manufacturing realm.1 The team selected 6061 aluminum alloy as a potential frame material as it is commonly used in bicycle frames which are similar to the team’s design. Aluminum has a better strength-to-weight ratio than steel, and result in a stiffer frame than steel. Aluminum is also a very common material in the manufacturing realm, so procuring the material would not prove to be difficult.2 The team selected 3AL-2.5V titanium alloy as a potential frame material due to its high strength-toweight ratio and excellent resistance to corrosion. This titanium alloy is 3.5% aluminum and 2.5% vanadium by weight, which are added to the material in heat treatment processes to result in a higher Page 12 strength product. Titanium is more expensive than steel and aluminum and would provide manufacturing issues.3, 4 Carbon fiber is the final potential frame material considered by the team. Carbon fiber is gaining popularity in bicycle frames, mostly due it its light-weight yet corrosion-resistant and high strength properties. Carbon fiber is the most expensive material option, but has the largest strength-to-weight ratio. Beyond the monetary issue, carbon fiber also is more difficult to repair then the other options, as fatigue failure occurs more readily in carbon fiber. Repairing cracks and other fatigue in the frame would require more time and effort than the other options.5 The table below summarizes the material properties for all four material options. Table 3: Frame Material Alternative Properties6 Material Yield Strength Specific Strength Density Tensile Modulus (MPa) (kNm/kg) (g/cm3) (GPa) 4130 Steel 910 254 7.84 200 6061 Aluminum 270 214 2.71 69 3AL-2.5V Titanium 930 288 4.63 110 Carbon Fiber 4000 2457 1.75 250 The material properties displayed above clearly show the differences between each material. As mentioned, carbon fiber is clearly the strongest yet lightest, whereas aluminum yields at a much smaller force. 6.2.3 Frame Material Design Decisions In order for the team to decide which material would be the best option for this design project, a decision matrix was created. This decision matrix listed the design criteria mentioned earlier and assigned a 1-10 value for each material, with 1 being the lowest and therefore least preferred. This decision matrix appears below. Options Table 4: Frame Material Decision Matrix Design Criteria Weight 4130 Steel 6061 Aluminum 3AL-2.5V Titanium Carbon Fiber Cost 25 10 8 5 1 Strength 25 8 6 6 10 Manufacturability 20 10 8 5 3 Durability 15 10 7 5 3 Stewardship 5 8 8 5 3 Trust 5 8 7 6 8 Integrity 5 10 10 7 4 The above decision matrix clearly shows that 4130 steel is the best frame material option for this project. Therefore, the team has chosen 4130 steel as the frame material. Page 13 Total 930 740 540 455 6.3 Quick Change Wheel Design 6.3.1 Quick Change Wheel Design Criteria The second system component the team analyzed was the quick wheel change method. The team is designing the product in a manner in which the wheels could be quickly and easily removed, so that different wheel options could be used. This would allow the product to easily traverse the applicable terrain options. The team hopes to achieve this result on the following terrains: road asphalt, sidewalk concrete, compacted dirt bicycle path, sand, and grass. The criteria the team used to decide upon the final quick wheel change method appears in the table below. Table 5: Quick Wheel Change Design Criteria Criteria Weight Cost 25 Ease of change 25 Change-over time 20 Durability 15 Trust 5 Transparency 5 Integrity 5 As shown in the table above, the cost and relative ease of changing the wheels were designated to be the most important design criteria. This is due to these criteria directly affecting the design requirements. One of the primary goals the team is designing towards is to maintain a low cost product, while still enabling the end users to quickly and easily change tire options. Durability takes into consideration the long term potential for the designs, as well as relative ease of fixing issues that occur several years into the product’s lifespan. The team has also identified three design norms that are directly applicable to this component. Similar to the frame material, trust is a design norm for the quick wheel change method. The team needs to design this feature in such a way that it is readily apparent to the end users how to operate and change. The end design for the quick wheel change will need to be reliable and easily repeatable. This also factors in to the next design norm, transparency. The quick wheel change design must be understandable to someone without extensive technical knowledge, as well as being consistent. The design team does not want to create confusion in the end users concerning this feature, as that will effectively eliminate the use of the feature. Integrity is the final design norm that the design team has determined applies to this component. The design team recognizes that this feature in particular will need to be pleasing and intuitive to use. If the end users do not feel comfortable with the quick wheel change Page 14 design, they will most likely not use it. This results in a product that will not perform to adequate levels on the various terrains, leading to a larger potential for damage and even personal injury to occur. These design criteria have the potential to be in tension. Maintaining the low cost of the quick wheel change method while still reaching the necessary time and ease of assembly requirement could prove challenging. 6.3.2 Quick Change Wheel Design Alternatives The team researched potential quick wheel change designs, and were able to determine two main options for the product. The first quick wheel change option has commonly been used on bicycles ever since its creation in 1927 by Tullio Campagnolo, and is commonly referred to as a quick release skewer.7 This design is shown in the figure below. Figure 2: Quick Release Skewer Examples 8 The quick release lever is tightened while in use, which secures the wheel and axle to the bicycle’s fork. To remove a wheel equipped with a quick release skewer, the user must simply loosen the quick release lever. This quick wheel change method has both positives and negatives. It is very common in the bicycle realm, so procuring the components would be relatively simple. Additionally, the installation and use of said design is straightforward, minimizing the potential for the end user to become frustrated with the design. However, this method leaves the wheels to be susceptible to theft, as the release mechanism is quite quick and easy. The potential for the wheel to become disengaged while the product is in use is also larger than other designs, so care would need to be taken to ensure that it is properly tightened. The second quick wheel change option that the team researched was quite similar to the quick release skewer idea, but is less complex. This design option is simply referred to as a quick release hitch pin system. The design option is displayed in the figure below. Page 15 Figure 3: Quick Release Hitch Pin9 This design option is very inexpensive and quite common, so purchasing this would be straightforward. However, the potential for the end user to incorrectly use this design alternative is larger than with the quick release skewer. This design would also take longer to remove than the skewer and would not be as reliable or understandable to the end user. 6.3.3 Quick Change Wheel Design Decisions In order for the team to determine which quick wheel change method would be the best option for this design project, a decision matrix was created. This decision matrix listed the design criteria mentioned earlier and assigned a 1-10 value for each option, with 1 being the lowest and therefore least preferred. The decision matrix for this component appears below. Ease of Change-over Change Time 25 25 Skewer 8 Hitch Pin 10 Options Design Criteria Weight Cost Durability Trust Transparency Integrity 20 15 5 5 5 Total 8 10 5 8 7 7 785 6 7 6 4 5 4 695 The above decision matrix clearly shows that the quick release skewer design alternative is the best quick wheel change option for this project. Therefore, the team has chosen to use this option in the preliminary design. However, this decision is not to be considered final, as the team is still researching other methods by which to achieve a quick wheel change. In addition to this research, the team will also discuss with the team’s resources what they would prefer to have as the quick wheel change method, and will update the final design and prototype as needed. Page 16 6.4 Collapsible Design 6.4.1 Collapsible Design Criteria The final system component the team analyzed was the collapsible aspect of the design. The team is designing the product in a manner in which it could be easily collapsed and moved, so that the user could easily transport the product in the back of a small car. This would allow the product to be used more often and for more varied purposes. The criteria the team used to decide upon the collapsible nature of the product appears in the table below. Table 6: Collapsibility Design Criteria Criteria Weight Ease of use 30 Cost 20 Risk to user 20 Durability 15 Trust 5 Transparency 5 Integrity 5 As shown in the table above, the ease of use for the collapsible design was designated as the most important design criteria. This design feature was the only one in which cost was not the most important design criteria, as the design team concluded that designing a low cost collapsible design was not as important as creating a design which would be easy to use and understandable to the end user. The potential risk to the end user was also one of the most important design criteria, as the collapsible feature of the design must attempt to eliminate or minimize all potential possibility of personal injury to the end user. The design team does not want the collapsible aspect of this product to present additional risk to the end user, as this could greatly increase the possibility of lawsuits and negative public image. Additionally, if the end user believes this feature to be potentially dangerous, then they would most likely not end up using it, effectively nullifying all of the design team’s work on this design feature. Once again, durability also is a criteria that the design team took into consideration in its design. This criteria considers the life span of the design, as well as the cost to repair. Finally, the team has also identified three design norms that are directly applicable to this component. Trust is once again a design norm for this component. The team needs to design the collapsible nature of the product in such a way that it is readily apparent to the end users how to use. The end design will need to be reliable and safe. The collapsible feature of this product will also need to be transparent to the end users. It must minimize the potential to injure the end Page 17 users, as well as be readily understood. The design team does not want the collapsibility of the product to confuse the end users, as that will effectively eliminate the use of the feature, as well as increase the injury potential. Integrity is the final design norm that the design team has determined applies to this component. Similar to the quick wheel change, if the end users do not feel comfortable collapsing the product, they will most likely not use it. This would result in a product that would not be as easily transported. Additionally, the potential for the end user to be injured would increase if the collapsible feature was not used, as handling the final design would be too burdensome otherwise. These design criteria do have the potential to be in tension. While most of the design criteria focus on making the product easier to use and understand, the cost criteria will force the design team to consider the cost of such safety concerns. The design team will not sacrifice the safety of the design in order to minimize the cost, which is reflected in the relative weight of the design criteria. 6.4.2 Collapsible Design Alternatives The design team is still in the research phase for collapsible design options. However, the design team has found two broad collapsible method types that will be pursued in greater detail over the following semester. These options are to collapse the product by: detaching the product into distinct parts, or a jointed assembly, which would allow the product to be folded up to occupy a smaller area. The detaching collapsible option would consist of designing the prototype in such a way as to allow it to be taken apart into three separate parts. This would be achieved through a design which would use clips and fasteners to attach the three parts together. This option would allow the highest maneuverability and transportability of the design, as the three separate parts would be able to be positioned separately. The second collapsible option would involve jointed features, allowing the design to fold up. This would minimize the space required to transport the design, and minimize the size of the product, enabling it to be more easily maneuvered and picked up. This design is commonly used strollers, a smaller scale similar product. 6.4.3 Collapsible Design Decisions The design team is still researching collapsible design options and has not reached a definitive conclusion as to which would be preferred. This conclusion will be reached by creating a decision matrix for this feature, which would use the aforementioned design criteria. The design team will also remain in close communication with the resources that have been gained so far, as they will greatly assist the team in realizing what option would be preferred. Page 18 6.5 Block Diagram The block diagram below will be used to ensure all necessary considerations will be taken into account in the design process. It will serve as a “map” for the design team as they work on designing and assembling individual components of the cart together, so that all needs are addressed and all requirements are met. Figure 4: Block Diagram Page 19 6.6 Preliminary Design The team began the design phase with a rough sketch of what the running cart would look like, which can be seen below. Figure 5: Block diagram showing design interactions and components. Figure 5: Initial Sketch of Design This sketch, while very basic in nature, does display several of the features that the team decided were integral to the project’s success. The general appearance of the design shown above is the approximate idea of what the team views to be the final design. The green lines in the figure above correspond to the collapsible nature of the design, which was initially thought to involve a system of cranks. The red lines in the figure correspond to the very basic seat design. It should be noted again that this was the initial design that the team created, so this sketch only reflects the very basic ideas about the project. Once the team had come up with the initial sketch, it looked for ways to improve the design of the cart. To do this the team conducted research and talked to the contacts that it had made. The next step in the design of the cart was to determine what the frame of the cart would look like. The initial frame that the team has come up with was drawn using the 3D modeling program SolidWorks, and can be seen below. Page 20 Figure 6: Initial Frame Design This frame design was modeled using 4130 steel as the material, which was the material that the design team concluded was the best option for this project. This frame is still basic in nature, but does display the overall idea of the frame that the design team is considering. Once the cart had been drawn in SolidWorks, the team modeled the effects of the forces that would occur from a person sitting on it using the program Autodesk Simulation Multiphysics 2012. The figure below shows the distribution of the forces on the frame of the cart. Page 21 Figure 7: Forces Acting on the Frame of the Cart The team modeled the cart assuming a downward force of 200 lbs. This downward force of the passenger is represented by the arrows pointing down in the figure above, and is distributed over the area in which the seat is planned to be and ultimately where the passenger will be sitting. The arrows pointing up in the figure represent the reactionary force on the frame of the cart and are located where the wheels would be attached to the cart. The reactionary force that was used was also 200 lbs. After placing these forces onto the frame design the team then ran the simulation program, which displayed the stress values on the frame. The results of this simulation are shown in the figure below. Page 22 Figure 8: Simulation Results The simulation determined that the highest stress applied to the cart is 1202 Pa. The team compared this to the yield strength of 4130 Steel, which was found to be 910 MPa. The yield strength of the cart is much greater than the applied stress on the cart due to a 200 lb. force. This result showed the team that the designed frame is strong enough to support a person of 200lbs or less. The simulation also shows the team where the stress would be concentrated in the cart. This is shown by the yellow and red areas on the figure above, with the stress increasing as the color goes from yellow to red. The team plans to continue modifying and improving on the above cart design to achieve its objectives. Page 23 7. Testing Plans The design team plans on beginning construction of the prototype in early February, 2014. The design team has a month budgeted for the initial construction. Once this construction is complete, the team will begin testing and prototype optimization as needed. The design team will test the prototype in five primary aspects: the rigidity, transportability, ease of assembly, maneuverability, and ability to travel on a variety of terrains. Each testing area has been budgeted to last a week in duration. These tests will be performed in coordination with the design team’s resources, allowing these resources to have direct input into which areas of the prototype need further work. The rigidity of the prototype will be tested through stress and strain calculations through the use of strain gauges when loading the prototype with varying loads. This will enable the design team to determine the upper limit of the transportable weight. The transportability of the prototype will be tested using a team member’s car, in order to determine whether or not the design can fit within the designed size constraints. The ease of assembly of the prototype will also be tested during this time, as the difficulty of disassembling and assembling the prototype under real life conditions with test subjects will be determined. The weight of the design will also be tested and optimized at this point, which will assist the design team in determining whether the design is simple and light-weight for the end user to understand and easily handle. Finally, the maneuverability and all-terrain versatility of the prototype will be tested in the field through several methods. The prototype will be tested at the minimum on the following surfaces: road asphalt, sidewalk concrete, compacted dirt bicycle path, sand, and grass. The force needed to start, stop, and maintain a set speed will be recorded on each terrain, enabling the team to determine which tires are best for which surface and which terrains the design team should be focused on. Page 24 8. Business Analysis 8.1 Marketing Study 8.1.1 Competitive Analysis 8.1.1.1 Existing Competitors Companies that could be considered competitors to Iron Man include wheelchair manufacturers, custom running cart makers, high-end running cart makers, and other athletic wheelchair manufacturers. Very few companies with an online presence make a product similar to what the Iron Man team will be producing. These competitors are generally well focused in their respective market, and make a decent product; their products are both comfortable and reliable. Their biggest strength over Iron Man is their name recognition. However, these competitors also have weaknesses. Iron Man has found very few competitors that are effectively targeting the normal family with a disabled child/adult. Such existing products have some design flaws that make it difficult for the caretaker, and hard on the passenger. Products that do not include these design flaws are prohibitively expensive to the normal family, or perform well in some areas while being impractical for storage or poor in comfort. 8.1.1.2 Potential Competitors Companies that could be considered competitors to Iron Man are mostly start-up companies that see the team’s product and want to make it cheaper, or believe they can provide a superior product or the same design at a better profit margin. Large companies that produce wheelchairs or similar products may desire to enter the market, and would present significant competition with their extensive capital for marketing and production. As long as Iron Man’s business continues to build name recognition and maintains a good brand name, competition will likely not be able to take the team’s market share. There appears to be a significantly larger market than the team’s planned capacity, so some competition would most likely not directly affect the customer base Iron Man has built up. Iron Man has to stay competitive in design, cost, and customer support to avoid being put out of business if a large company were to enter the market. 8.1.2 Target Markets An estimated 3.3 million American citizens are bound to a wheelchair. 10 Not all of them are limited to the extent that they would benefit from our running chair, but if even 1% was, that gives us a market of 33,000. In addition, it is reported that about 11,000 new spinal cord injuries occur each year, resulting in paraplegia (loss of lower body function), and quadriplegia (loss of function in arms and legs) 11, 12. Based upon this research, the design team has identified physically handicapped clients, caretakers, and health organizations as the primary potential target markets. Page 25 8.1.2.1 Handicapped Clients The product designed and produced by Iron Man would allow handicapped clients to experience nature in a way that they would not otherwise be able to. Making this product affordable is extremely important to handicapped clients, because they generally have more expenses to cover with a comparably smaller income than others in their age demographic. These clients will be looking for comfort as a primary product feature, as well as features that are targeted towards caretakers. 8.1.2.2 Caretakers Caretakers will be able to better care for their clients by being able to take them out more often and with greater ease. Dependability, light weight, ease of maneuverability, ease of client transfer, and transportability are features that were identified which would be important to caretakers. These features would also benefit the handicapped clients, because it would make it easier for their caretakers to take them outside for a run. 8.1.2.3 Health Organizations Health organizations would be looking for a product with low cost and high dependability. Using this product, they could offer a wider variety of activities to their clients, increasing their reputation and client base. The design team surveyed each of these three demographics in order to gauge what features were most desirable and what price they would be expecting to pay for the product. Through these conversations it was clear to the design team that the overall cost of the product was the primary concern in all three target markets. Following this, the dependability and passenger comfort were emphasized. The need for this product was shown in each of the three target markets, as all of the potential clients that were surveyed expressed the desire to purchase the product. The price of the product varied between the clients, according to what features they mentioned were necessary. The average price from all three surveyed markets came out to roughly be $1,500. This correlates nicely with the design team’s estimated production cost. 8.2 Cost Estimate 8.2.1 Development The development budget for Iron Man is limited to the funds provided through the senior design course at Calvin College as well as any external grants that the team was able to secure. The design team is not currently seeking out donors for the project, as the budget submitted by the team to Calvin College was approved. This budget is listed in the table below, which details the estimated cost of all necessary items to produce the design. Page 26 Table 7: Team Budget Item Estimated Cost [$] Metal for frame 150 Bolts and joint fasteners 25 Wheels (all) 100 Brake component 50 Seat materials and padding 40 Sheet metal for passenger deck 20 Bearings 20 Forks/wheel mounts 50 Handles 15 Brake hardware (lever, cable, etc.) 10 Paint 30 Suspension 75 Total 585 The budget approved by Calvin College was $665, which enables the group a fifteen percent leeway in the overall cost of the design. This will hopefully solve any as of now unforeseen budgetary issues that will emerge as the design progresses. 8.2.2 Production 8.2.2.1 Fixed Costs The estimated complete development costs appear in the table below. Overhead costs are also included. Table 8: Estimated Fixed Costs Item Cost ($) Total Development Budget Design Time ($100/hr) Prototype Tooling and Manufacturing 30,585 30,000 585 36,400 CNC Band Saw 25,000(13) MIG Welder 2,400(14) Knee Mill 9,000(15) Other Capital Expenditures 480,000(16) Manufacturing Plant 400,000 Offices 80,000 20,600 Overhead Page 27 Advertising 5,000 Legal Fees 5,000(17) Interest Fees Electricity 10,000 4,600(18) 567,585 Total 8.2.2.2 Variable Costs The variable costs for the product sold by Iron Man are based upon the estimated market and annual sales. These estimations are described in the financial summary section of the report, and are detailed in the proforma financial statements in Appendix C. The estimated complete variable costs, on a per-unit basis, appear in the table below. Table 9: Estimated Variable Costs Item Cost ($/unit) 245 Machined Components Frame 150(19) Passenger Deck 20(20) Suspension System 75(20) 340 Purchased Components Brake System 60 (21, 22, 23) Bolts and joint fasteners 25(24) Wheels (three per unit) 100(25) Bearings 20(26) Seat Cushion 40(27) Paint 30(28) Forks/wheel mounts 50(29) Handles 15(30) 17 Packaging Cardboard 10(31) Poly-foam 4(32) Instruction Manual 3 200 Labor Saw operator 40 Mill operator 40 Welder 80 Assembly 40 0 Distribution 802 Total Page 28 8.2.2.3 Financial Summary The estimated retail price of the running cart produced by Iron Man is roughly $1,000. This retail price is based off of market data collected by the team, which surveyed the three main target markets, handicapped clients, caretakers, and health organizations. These markets are described in the target markets section of the report. The price anticipated by these clients for such a product averaged around $1,500. The full product cost that the design team expects is roughly $800. The difference between the full product cost and the estimated retail price is the expected profitability per unit for Iron Man. This profitability is therefore $200 per unit. Based upon the pro-forma financial statements prepared by the team this product is therefore expected to be profitable. These statements appear in Appendix C. The break-even point computed by the team will occur in the first year with the 644th unit sold. The expected annual units sold is estimated to be 1,000 units. The design team based these break-even results according to the expectation that Iron Man will have a first year sales revenue of roughly $1,000,000. This is reasonable, as at the expected retail price of $1,000 only 1000 units would have to be sold. As mentioned earlier, roughly 3.3 million American citizens are bound to a wheelchair. Selling 1000 units to this market would correspond to only a 0.03% target market acceptance. Targeting individual American citizens would most likely be the most time consuming and challenging, especially with a start-up company. The design team would therefore achieve these desired annual sales by aggressively targeted the wealthiest target market first, the health organizations. Advertising to this target market would allow name recognition to grow quicker than pursuing the other target markets. There are ten open hospitals in Kent County, Michigan. These would be the first health organizations targeted by the design team due to their close proximity to Calvin College. There are 5,724 hospitals in the United States. The design team estimates that an average of two running carts will be purchased by all interested hospitals, which means to achieve the anticipated annual units sold, 417 hospitals would need to purchase Iron Man’s product. The team anticipates achieving the annual sales volume by selling to each target market. Page 29 9. Conclusion Now that the preliminary design and design research has been completed, the design team has concluded that this project is feasible. There is a lot more work that needs to be accomplished on this project, but the research and preliminary designs completed so far have allowed the team to narrow its focus for the upcoming semester. More detailed designs will need to be created and in-depth finite element analyses will be used in order to refine the product. The team plans on completing this design and analyses next semester, as well as purchasing all necessary material and constructing the prototype. Extensive testing will then take place, during which the team will optimize and refine the prototype as needed, while staying within the allotted budget. Page 30 10. Acknowledgements The design team would like to thank the entire Calvin College engineering department, in particular Professor Nielsen, who served as the team’s advisor for the duration of the project. The team would also like to thank Alice Teisan, the primary contact from the organization His Wheels for her support and advice on design options. Thanks to Curtis Kortman for his initial involvement in the project and for initiating contact with the potential customer. Thanks to Ronald Robb of mTT for meeting with us. Thanks to Becky and Robert Van Zanen for providing many design considerations and initial design ideas. Finally, the team would like to thank Phil Jasperse for his support in the metal shop and throughout the construction of the design. Page 31 11. References “CDC FastStats Disabilities Page.” Centers for Disease Control and Prevention. 30 May 2013. Web. 10 Nov. 2013. Brault, Matthew W. "School-Aged Children With Disabilities in U.S. Metropolitan Statistical Areas: 2010." American Community Survey Briefs (2011). Web. 10 Nov. 2013. <http://www.census.gov/prod/2011pubs/acsbr10-12.pdf>. Global Trikes. His Wheels International, Nov. 2013. Web. 10 Nov. 2013. <http://www.hiswheels.org/global-trikes/>. Lee, Amy F. Statistics of Children with Special Needs. The Inclusive Church, 3 June 2013. Web. 10 Nov. 2013. <http://theinclusivechurch.com/2013/06/03/statistics-of-children-with-special-needs/> Riley, William F., Leroy D. Sturges, and Don H. Morris. "Material Properties and Stress-Strain Relationships." Mechanics of Materials. 6th ed. Hoboken, NJ: John Wiley, 2007. 153-73. Print. VanderLeest, Steven. Engineering 339. Calvin College, Grand Rapids. 4 Oct. 2013. Lecture. Wunder, David. Engineering 339. Calvin College, Grand Rapids. 25 Sept. 2013. Lecture. 1. Gunton, Neil. "The Art of Bicycle Touring." N.p., 1 Nov. 2003. Web. 8 Dec. 2013. 2. Brown, Sheldon. "Frame Materials for the Touring Cyclist." Frame Materials for the Touring Cyclist. N.p., Aug. 2010. Web. 08 Dec. 2013. 3. Vydehi Arun Joshi. Titanium Alloys: An Atlas of Structures and Fracture Features. CRC Press, 2006. 4. "Supra Alloys Inc. - Titanium Grades." Titanium Grades Information. N.p., n.d. Web. 08 Dec. 2013. 5. Johnson, Todd. "Carbon Fiber Basics." About.com Composites / Plastics. N.p., n.d. Web. 08 Dec. 2013. 6. Riley, William F., Leroy D. Sturges, and Don H. Morris. "Average Properties of Selected Engineering Materials." Mechanics of Materials. 6th ed. Hoboken, NJ: John Wiley, 2007. N. pag. Print. 7. Frank Berto (2009). The Dancing Chain (3rd ed.). Van der Plas Publications. pp. 140–141. 8. "Bicycle Tutor." The Bicycle Tutor RSS. N.p., n.d. Web. 08 Dec. 2013. 9. "Eberl Iron Works, Inc." Quick Release Pin for Parking Lot Sign Kit. N.p., n.d. Web. 08 Dec. 2013. 10. "Disability in America Infographic." Disabled World. N.p., n.d. Web. 08 Dec. 2013. 11. "Spinal Cord Injury Facts & Statistics." Spinal Cord Injury Facts & Statistics. N.p., n.d. Web. 08 Dec. 2013. 12. "Types of Paralysis - Quadriplegia (Tetraplegia) and Paraplegia." Quadriplegia Paraplegia Tetraplegia and Types of Paralysis. N.p., n.d. Web. 08 Dec. 2013. Page 32 13. "W.F. Wells W-9-14A CNC Automatic Bandsaw FREE Shipping." EBay. N.p., n.d. Web. 08 Dec. 2013. 14. "Lincoln Power MIG 256 (208/230) - (K3068-1)." Lincoln Power MIG 256 (208/230). N.p., n.d. Web. 08 Dec. 2013. 15. "Metalworking Tools, Lathes, Drill Presses, Saw Blades, Drill Bits, Reamers, Threading, End Mills." Global Industrial. N.p., n.d. Web. 08 Dec. 2013. 16. “RSMeans’ Dollar-per-square-foot Construction Costs for Four Industrial-type Buildings." RSMeans’ Dollar-per-square-foot Construction Costs for Four Industrial-type Buildings. N.p., n.d. Web. 08 Dec. 2013. 17. "How Much Are Legal Fees to Launch a Startup Company?" Startup Lawyer. N.p., n.d. Web. 08 Dec. 2013. 18. "Household Electricity Bills Skyrocket." USATODAY.COM. N.p., n.d. Web. 07 Dec. 2013. 19. "1015 Steel Square Structural Tubing." Zoro Tools Industrial Supplies. N.p., n.d. Web. 08 Dec. 2013. 20. "Metals Depot - America's Metal Superstore!" MetalsDepot®. N.p., n.d. Web. 08 Dec. 2013. 21. "Novara Brake Cable Kit." REI. N.p., n.d. Web. 08 Dec. 2013. 22. "Shimano R451 Long Reach Caliper Bicycle Brake- BR-R451." Www.bikesomewhere.com. N.p., n.d. Web. 08 Dec. 2013. 23. "Avid FR-5 Brake Levers." Jensonusa.com/. N.p., n.d. Web. 08 Dec. 2013. 24. “Hex Nut Assortment, Standard, Steel, Zinc, Number of Pieces 216." EBay. N.p., n.d. Web. 08 Dec. 2013. 25. "Northern Industrial Tools Tire/Wheel - 26in., Spoked." Amazon.com. N.p., n.d. Web. 08 Dec. 2013. 26. "Zipp 950 Disc Wheel Rear Wheel Bearing Set Bicycle Ball Bearings." VBX Ball Bearings. N.p., n.d. Web. 08 Dec. 2013. 27. "Carex Memory Foam Seat Cushion." Walmart.com. N.p., n.d. Web. 08 Dec. 2013. 28. “Dupli-Color BSP304 Paint Shop Finishing System Candy Apple Green Paint." Auto Body Tool Mart. N.p., n.d. Web. 08 Dec. 2013. 29. "700 Steel Fork 1 1/8" Threadless Black Thread Less BIKE ROAD CRUISER FIXIE." EBay. N.p., n.d. Web. 08 Dec. 2013. 30. “2012 RITCHEY WCS TRUE GRIPS BLACK MTB BIKE." EBay. N.p., n.d. Web. 08 Dec. 2013. 31. “Staples® Corrugated Shipping Boxes." Staples.com. N.p., n.d. Web. 08 Dec. 2013. 32. “Charcoal Pick & Pluck Foam." OnlineFabricStore.net. N.p., n.d. Web. 08 Dec. 2013. Page 33 Appendix A. Work Breakdown Schedule Page 34 Appendix B. Pro-forma Financial Statements Table 10: Pro-forma Statement of Income The Iron Man Corporation Pro-forma Statement of Income Year 1 Year 2 Year 3 Sales revenue 1,000,000 1,100,000 1,210,000 Variable Cost of Goods Sold 553,080 608,180 668,790 Fixed Cost of Goods Sold 190,000 190,000 190,000 Depreciation 7,202 12,772 9,978 Gross Margin 249,718 289,048 341,232 Variable Operating Costs 70,000 77,000 84,700 Fixed Operating Costs 37,600 37,600 37,600 Operating Income 142,118 174,448 218,932 Interest Expense 7,966 14,182 10,682 Income Before Tax 134,152 160,266 208,250 Income tax (40%) 53,661 64,107 83,300 Net Income After Tax 80,491 96,160 124,950 Page 35 Table 11: Pro-forma Statement of Cash Flows The Iron Man Corporation Pro-Forma Statement of Cash Flows Year 1 Year 2 Year 3 Beginning Cash Balance - 800,293 1,391,625 Net Income After Tax 80,491 96,160 124,950 Depreciation expense 7,202 12,772 9,978 Invested Capital (Equity) 535,400 535,400 535,400 Increase (decrease) in borrowed funds 227,600 (50,000) (50,000) Equipment Purchases (50,400) (3,000) (3,000) Ending Cash Balance 800,293 1,391,625 2,008,953 Page 36 Table 12: Break-Even Analysis Year 1 Sales revenue Less: Variable Costs: Year 2 1,000,000 Year 3 1,100,000 1,210,000 Variable Cost of Goods Sold 553,080 608,180 668,790 Variable Operating Costs 70,000 77,000 84,700 Total Variable Costs 623,080 685,180 753,490 Contribution Margin Less: Fixed Costs 376,920 414,820 456,510 Fixed Cost of Goods Sold 190,000 190,000 190,000 Fixed Operating Costs 37,600 37,600 37,600 Depreciation 7,202 12,772 9,978 Interest Expense 7,966 14,182 10,682 Total Fixed Costs 242,768 254,554 248,260 Income Before Tax 134,152 160,266 208,250 Page 37 Table 13: Break-Even Analysis (continued) Year 1 Total Fixed Costs Contribution Margin % 242,768 Break Even Sales Volume Break Even Unit Volume 644,084 Year 2 Year 3 254,554 38% 248,260 38% 38% 675,013 644 658,025 675 658 Table 14: Iron Man Corporation Budget Equipment Purchases Equipment Purchases Year 1 50,400 Equipment Purchases Year 2 3,000 Equipment Purchases Year 3 3,000 Year 1 7,202 Year 3 12,343 8,815 429 735 429 7,202 MACRS Rates (7-year recovery period) Depreciation Year 2 0.1429 12,772 0.2449 9,978 0.1749 Interest Expense: Annual interest rate on debt 7% Year 1 Year 2 Year 3 Average debt balance 113,800 202,600 152,600 Interest expense 7,966 14,182 10,682 Page 38