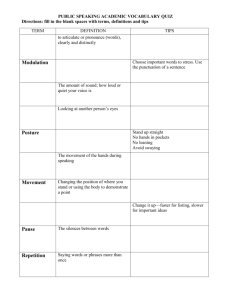

II. SYATEM REQUIREMENTS

advertisement

Research of On-line Quality Management System for Filter Tips based on MES Yue Zhang, Kai-chaoYu, Wei-ping Zhang Department of Electrical Engineering, Kunming University of Science and Technology, Kunming, China (zhangyue22589@126.com) Abstract – Combined with the quality management requirements, the article took the quality management in the productive process of filter tips in tobacco enterprises as a research object. And it analyzes the filter tips process and common quality problems, and then proposes a quality management system for filter tips based on MES. Afterwards it discusses the system requirements, the quality control model, functional model and key technologies. Finally, the visual, real-time and dynamic quality management in the productive process of filter tips are realized. Key words – Filter tips, MES, Quality management, System, I. INTRODUCTION Quality is the eternal theme of enterprises, and is also to achieve sustainable development, to win the victory in the next competition, more importantly, and it is the key to improving efficiency way [1]. IT can promote the modernization of cigarette production and quality management, and it is an effective way to improve overall competitiveness of the cigarette industry. At present, in the tobacco enterprises, the management information system and automation technology have large-scale application[2]. But ignoring the effective co-ordination between them, it leads to enterprises upper plans lack the effective real-time information support and the lower levels are lack of optimized scheduling and coordination. So companies would be difficult to real-time reaction. Manufacturing Execution Systems(MES), which is for shop floor production management techniques and real-time information system, is the information link between the ERP and production of automatic control system [3] [4]. Quality control is an important component part of MES. In the field of quality management, MES can effectively integrate the process level, site quality data acquisition, quality management of production processes and statistical analysis of these features which belong to the underlying control layer in tobacco enterprises [5-8]. Filter tips production as an important part of cigarette production process, its production efficiency and finished product quality directly affect the quality of the cigarette[9]. So Research of On-line Quality Management System for Filter Tips based on MES is particularly important[10-15]. II. SYATEM REQUIREMENTS As an important component part of the cigarette, the quality of filter tips relates to the taste of smokers in smoking, also whether they could play a filtering tar droplet and reduce the role of nicotine intake. So quality control of the filter tips is particularly important because it is directly related to the quality of cigarettes good or bad. During the whole process, the quality control of filter tips working procedure is key point. It is a decisive role of cigarettes’ qualified products. The filter tips process in Fig. 1. Currently, quality problems of filter tips are mainly concentrated in draw resistance of filter rods, hardness, circumference and length. In six production processes of filter tips, they are quantitative indicators of Tow opening, Plasticized, Rolling forming and Filter tips cutting. So the four processes are critical detection points during the On-line Quality Management System for filter tips. Principal detection parameters is the "roll pressure, roll ratio; plasticizer supply and the quantity supplied; various parts of the filter tips temperature, diameter and glue temperature; the length of filter tips and feed frequency." MES technology platform analyzes the real-time effective data from the filter tips manufacturing site, then it control the processing quality of each working procedure timely. To eliminate quality defects in the bud, and lower cost of quality, the platform will do real-time monitoring, prediction, diagnosis and on line debugging. Accordingly, the following requirements, which can achieve its quality control, are: A. Real-time, dynamic At present, in most tobacco companies, quality management mostly use Static quality management and control by quality plan issued, production testing after sequence and quality of statistical reports forms. So the control effectiveness and efficiency are very restricted. On line quality management system needs to be able to collect real-time data from the manufacturing process. The system grasps the quality of the state and reflects the problem of manufacturing process. The aim is to control the production quality dynamically. B. Visualization Vast amounts of quality data miscellaneous and difficult to understand, and the data behind the information is also difficult to express. The system can put quality information to the tables, graphs, images and other visualization methods people are accustomed to Preparation Tow Upgrade Tow Opening accept Plasticized by Tow Collected Glue Supply Filter Tips Filling Filter Tips Collected Filter Tips Cutting Rolling Forming Paper Feed Storage Curing Fig.1. The filter tips process making use of information technology, they can Provide the basis for quality managers. Based on production technology and processes for filter tips and combined MES, discussion on-line quality management model. It is shown in Fig.2. C. Interaction Managers in the traditional quality management system is a passive acceptance of unilateral information, it is difficult for users to interact with the management of quality data. As a result, enterprises must meet the demand of quality management for filter tips, real-time dynamic visualization and interactivity by means of On-line Quality Management System for Filter Tips based on MES. Production Start Production Orders Quality Standards Requirement Request Filter Tips Quality Completion Analysis Evaluation Results Dispatch III. VISUAl MODEL OF QUALITY MANAGEMENT AND CONTROL PROCESSES A. Information Visualization Model The online application control, namely information visualization (IV) is applied for the filter tips quality management system based on MES. IV refers to the use of computer-supported, interactive visualization of abstract data to enhance people's awareness of the abstract information. IV model is from the original data, data table, visual structure and view four modules. Original data maps for the data table through data transformation; and through visualization, data tables map transformation for visualization of structure, this process is the core of information visualization; finally, set up the graphics parameters through the view transformation and translate the structure to the visualization view, so the users can view the visualization of data in the database to serve a specific task from a particular point of view. Visualization of quality management to solve the main problem is the quality of the data mapping, conversion and interactive control. B. Quality Control Processes for Filter Tips Inspection Evaluation Data Result Data Gather Fig.2.Quality management model IV. FUNCTIONAL MODEL OF ON-LINE QUALITY MANAGEMENT SYSTEM FOR FILTER TIPS Based on the above analysis of the visualization of information model, and combined quality management process for filter tips, the functional model of the system is presented. It is shown in Fig.3. PDCA continuous quality improvement model used in the process of quality management, and it is a basic way to operate quality assurance system. Quality standards is the object of quality improvement, and it provides the standard to the entire quality management process; quality control is part implementation quality management, quality inspection is to check the quality control results; quality analysis is based on processing test, Quality Standards Q Con Quality Control Contro Cont Quality Management R Quality Inspection Manuf Supp Q Quality Analysis Q Qual Fig.3. Functional Model of On-line Quality Ma quality standards improvements. Four parts cycle, the product quality improve constantly. are not processed, the system will promptly notify the relevant modules to deal effectively with, it aims to assure the quality of production furthest. A. The applications of quality control function module B. Quality inspection function module Quality control includes two aspects. They are manufacturing process control and auxiliary process control. Physical indicators in manufacturing process quality control is to collect data automatically, then draw the control chart as well as appearance of the index through manual inspection, and inspection data entries system automatically which is collected from the bottom of shop floor. When the exception occurs, the system automatically will alarm. In auxiliary process quality control, its job is mainly to assess the implementation of process, to monitoring equipment industry parameters, production and operating environment, to confirm the raw materials. And checking the measuring devices. When the device process parameters overrun, it will be proposed to modify the corresponding process parameters. If an exception occurs , the alarm activated alarm immediately. The same is also true for the monitoring of production operations environment. When needed for the production of raw materials and components to confirm, once an exception occurs, you will be prompted to make a re-examination request, in order to avoid quality problems in raw materials for production. Quality control function module is not a single module, when these quality control links In the MES environment, the inspection process is the focus of the quality inspection, and it does inspection of the manufacturing process, quality management point of inspection, sampling the production process, and non conforming product processing inspection. As a data collection point, inspection of the quality management point is to select the key points in the production process, to compare the collected information and operating specifications, and to make the appropriate judgment. At the same time, in the production process of each stage of sampling, and sampling results into the system, at any time call access, quality inspection situation aggregates into quality reports. When quality inspection finds substandard products, it focus on putting information into the system timely, and determine the level, then it issues a re-examination request again. C. Quality analysis module applications In this module, the focus is on the quality factor analysis, including product quality analysis and process conditions. Index related will be collected to analyze the quality of products, then by mathematical statistics, analysis, it finds problems, and according to the problems to feedback and make improvements timely. To analyze the state of the product process, we should pay attention to the process status information, a comprehensive analysis of the observed information and continuous improvement can assure the product quality in the greatest degree. V. KEY TECHNOLOGIES OF THE SYSTEM 1) Using model-driven technology to achieve the production control based on the production model can, providing a flexible modeling tool and managing the entire production process by the model driven 2) Through the model-driven technology, strengthen quality control; automatically generated quality inspection request according to the changes in work orders, schedules and grades, Testing equipment data and formation the quality of data analysis and evaluation by KPI Data feedback and automatic acquisition 3) Realize the monitoring of the production of dynamic data, and visual display the actual situation of filter rod production process by monitoring the screen. 4) Use the digital measuring devices, connected to the wireless transmitter to send the digital signal, and connected to a computer to transmit data through the intranet on a regular spread to the enterprise server to complete the data collected from the production site. 5) Use the real-time database technology, realize the mass data storage and application of real-time data; acquisition multiple quality control points in the production process to achieve the production of dynamic real time data acquisition, monitoring and statistical analysis, made the production management more scientific, organization more flexible and more timely decision-making. VI. CONCLUSION The quality management of corporation is a very complicated and important work. Quality management level has a direct impact on the survival and development. Quality management system is for continuous improvement and meeting the daily production and business needs, which can greatly enhance the competitiveness of enterprises. The key to the implementation of MES filter tips on-line quality management system is to achieve effective integration of information sharing with other MES module and the underlying control, real-time quality monitoring by the flow of information integration and control integration, the entire process of production, in order to achieve closed-loop quality control. Analysis of MES and filter tips online quality management system processes, functional model and key technologies, explore and practice on these issues, I believe that the quality management system based on MES is fine, because the homogenization and standardization of information technology is the best solution. REFERENCES [1] Gong Qingtao. Research on real-time on-line intellegence quality control technology for the tobacco MES, [MS Thesis], Qingdao: Ocean University of China., 2009,.1-2. [2] Hu Jun. MES in the production process and quality control of the cigarette industry analysis, Nanjing: Nanjing University of Technology and Engineering, 2004,.13-15 [3] Cao Jianghui, Wang Ningsheng, manufacturing execution system present situation and trend, 2002,pp.6-7 [4] Kaichao Yu, Wenli Shi, “Study of Engine Assembly line Quality Management System Based on MES” in the 3rd International Asia Conference on Industrial Engineering and Management Innovation , 2009.06 [5] Li ronghuang, Xiang Wwenyin, Hong Zhitang. Autosupplier quality management and quality improvement methods, mechanical design and manufacture,2007(3) : 171-174 [6] Wang Wanlei. MES key technical research [D].dalian: dalian university of technology, 2005. 24-28 [7] Sander Holm. A comprehensive quality management, China Economic Publishing House,2003 [8] Liu Haibo, Yang Shiyuan. Based on quality information technology total quality management information system design, Shanghai: Shanghai quality magazine,2005 [9] MESA International, MES explained: A high level vision, White paper 6(Pittsburgh: Manufacturing Execution Systems Assoc.,1997) [10] Maraghy, RJUrbanic. Modeling of manufacturing systems complexity [J].CIRE2003,52(1):363-366. [11] The Benefits of MES:A Report from the field, MESA International white Paper numberl,5/1997,www.mesa.com [12]McClellanM. Applying Manufacturing Execution Systems [M].CRC Press [13] Kelly T. Electronic date system. MES in the age of agile manufacturing[J]. A Presentation at MESA Roundtable4, Chicago, Sep.13,1995. [14] Object Management Group. Manufacturing Domain Task Force RFI-3 Manufacturing Execution Systems (MES). OMG Document mfg/97-11-01. November 6, 1997. [15] Computer System Inc.Integra table MES the challenge and the opportunity, advanced manufacturing research consulting, http://www.amrc.com,1999