Drag Reduction of a Tractor-Trailer Using Planar Boat Tail Plates

advertisement

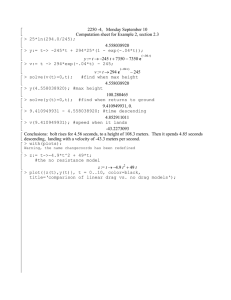

Drag Reduction of a Tractor-Trailer Using Planar Boat Tail Plates J.D. Coon and K.D. Visser Department of Mechanical and Aeronautical Engineering, P.O. Box 5725, Clarkson University, Potsdam, NY, USA 13699 Abstract The use of planar-sided boat tail plates for aft-end drag reduction on a tractor-trailer was studied numerically, experimentally and on a full scale prototype. Parametric wind tunnel tests utilized a 1:15 scale Peterbilt 379 tractor and 48 foot (14.6 m) trailer with cavity plate concepts mounted perpendicular to the trailer base. Yaw angles up to 9 degrees were examined. Qualitative numerical results confirmed a pressure increase on the aft face of the trailer. Model drag increments, obtained at zero yaw and a width-based Reynolds number of 230,000, based on trailer width, indicated reductions in the drag coefficient, based on frontal area, of up to 0.075 or about 9% of the baseline model trailer drag. Removal of the top plate degraded the performance of all devices. Performance also decreased with yaw angle for all plates mounted perpendicular to the trailer base, contrary to devices with angled plates. Devices with shorter angled plates indicated better performance with the top open rather than an open bottom. Drag reduction was more sensitive to plate inset from the trailer edge than to plate length and a zero inset of the bottom plate maximized performance. Two full scale prototypes were road tested, the first utilized rigid composite sides with a flexible top and bottom and the second was an all rigid-sided aluminum design. The former exhibited cross-country road fuel savings of about 0.5 miles per gallon (0.2 kilometers/liter), approximately 9%, over a 10,000 mile (16,093 km) trip, while the latter returned inconclusive results. Estimated fuel savings for a typical 120,000 miles (193,121 km) per year traveled were approximately 1500 gallons (5677 liters) per truck. Introduction The flow behind bluff bodies, and the desire to reduce the base pressure drag, has been the subject of numerous investigations (Hoerner 1950; Mair 1965; Kentfield 1984; Rodriguez 1991). The reduction of the drag specifically associated with tractor-trailers has also been under investigation for many years. In the early 1970’s, NASA, as well as private firms, extensively examined the concept of trailer drag by modifying the flow over the forward part of the vehicle (Montoya and 250 J.D. Coon and K.D. Visser Steers 1974) Their results indicated that commercially available devices could reduce drag by up to 24 percent. Sovram et al. (1978) reported that Mason and Beebe (1978) examined several add-on devices to increase the base pressure of a tractor-trailer in 1976. They included vertical and horizontal splitter plates, guide vanes, and non-ventilated cavities as illustrated in Figure 1a. The vertical splitter plates had little or no effect on the tractor-trailer drag, while the vanes exhibited an adverse effect. The only device that showed positive results was the non-ventilated cavity design, shown in the bottom right of Figure 1a. Mason and Beebe varied the length of the plates and found an optimum of 22 inches (0.55 m) for a conventional 48 foot (14.6 m) trailer which yielded an overall drag reduction of 5 percent. (a) (b) Fig. 1. Drag reduction concepts a) Mason and Beebe in Sovram (1978) b) Bilanin (1985) Similar research by Hucho (1987) on a small minivan style vehicle in the 1970’s substantiated the drag reduction behavior of non-ventilated cavities. Cooper (1985) conducted extensive tests on detailed scaled models of a tractor trailer and a panel truck using rounded and beveled panels on the rear end of the vehicle. His results indicated an optimum reduction in the drag of 7-10% of the baseline model drag and indicated it was not unreasonable to expect this at full scale. A patent was filed by Bilanin (1985) on a variation of the cavity design concept, illustrated in Figure 1b, that inset the endplates from the trailer perimeter. His claims indicated a drag reduction on the order of 10%. Recently patents filed by Boivin and Roberge (2001) describe an attachment of plates to the edge of the trailer and inclination toward the centerline, but with no bottom plate. NASA has extensively supported testing of devices aimed to reduce the pressure drag. A summary of the NASA work from 1973–1982 by Saltzman and Meyer (1999) indicated that a reduction in base drag, such as by using a truncated boat tail, will be necessary in light of the increase of base drag associated with forebody streamlining. In 1988, full-scale tests were performed at NASA’s Ames Research Center on a full scale, inset, non-ventilated cavity device (Lanser et al. 1991) similar to Bilanin (1985). Inset, as well as overall plate length, were optimized. The results showed that the highest drag reduction came with a plate length of 0.36w and an inset on the top and side plates of 0.06w, where w was the width of Drag Reduction of a Tractor-Trailer Using Planar Boat Tail Plates 251 the trailer. This translates to a plate length of 33 inches (0.84 m) inset at approximately 7 inches (0.18 m) from each edge for a 48 foot (14.6 m) trailer. The researchers recorded an overall drag reduction of approximately 10% over a +/- 15° yaw range. Tests at NASA using innovative testing techniques to validate CFD methods on bluff body ground vehicle wakes have continued to the present (McCallen et al. 1999). Hucho and Sovran (1993) indicated that the major aerodynamic problem of a bluff type body moving at subsonic speeds through a fluid is at the rear, not the front. They state that the benefits of drag reduction are threefold: reduced fuel consumption, increased acceleration, and increased top speed. If the objective is reduced fuel consumption, the latter two benefits can be used to enhance this requirement. Re-gearing of the drive train converts increased acceleration to a fuel savings component, while a reduction in installed engine power accomplishes the same for the increased top speed capability. It is also worth mentioning, in light of the recent heightened focus on the environment, that a reduction in emissions will result from this drag reduction. The objective of the present study was to investigate and develop a working full scale prototype of a device to passively reduce the base pressure drag on a tractortrailer. Title 23 of the United States Code of Federal Regulations (Part 658.5) indicates that devices added to the rear of a semi-trailer, whose function is related to the safe and efficient operation of the vehicle, are excluded from the length determination, provided that they are not used for carrying cargo. Revision of this code is presently underway, however the current regulations stipulate a maximum length of 5 feet (1.52 m). The US Department of Transportation reported that there were 1,997,345 combination trucks, including nine-axle tractor trailers, in service in 1998. Approximately 128.4 billion miles (206.6 billion kilometers) were traveled and 21.1 billion gallons (79.5 billion liters) of fuel were consumed. A decrease in fuel consumption of only 5% would incur savings of over 1 billion gallons (3.79 billion liters) per year and, of course, billions of dollars. Wind tunnel experiments were utilized in the present study for geometry optimization and enabled comparison of model scale to full scale results. A key consideration of the full scale prototype was maintaining the functionality of tractor-trailer. Numerical Simulation Although the primary focus of this study was experimental, an effort to gain some qualitative insight into the effect of endplates, and to provide direction for experimental tests, was first undertaken using the numerical code FLUENT. The use of FLUENT is questionable when attempting to estimate drag numbers or flow structures on such an unsteady, asymmetric, separated bluff body flow, however the purpose was a quick and “dirty” look to see if there was some time averaged improvement on the aft trailer face. A simplified tractor-trailer geometry was modeled three dimensionally in a large, 50ft x 50ft x 150ft, (15.2 m x 15.2 m x 45.7 m) wind tunnel as depicted in Figure 2. A total of 2.64x105 nodes were used at a Reynolds number of 4.32x106 based on truck width. The grid was not refined in the present study as the number of nodes were as many as the available computer hardware could accommodate. The model was run under steady state conditions only and utilized a k-ε turbulence model. The purpose of the numerical model was 252 J.D. Coon and K.D. Visser simply to see if there was any pressure increase on the back of the trailer. Cases were computed with and without plates attached perpendicular to the back of the trailer. The plates were inset on each side an equal distance, d, from the trailer edge for a range 0<d<36 inches (0 < d 0.91 m) full-scale in 6 inch (0.15 m) increments. Plate length, L, was varied from 3 – 6 ft (0.91 – 1.83 m) in 1 ft (0.3 m) increments. (a) (b) Fig. 2. Simplified numerical tractor trailer representation a) Grid distribution b) Pressure distribution plane at aft face An example of the calculated pressure distribution on the baseline (no device) aft trailer face is illustrated in Figure 3a. The area of lowest pressure occurred near the bottom of the trailer and extended towards the ground plane. The addition of the plates was observed to qualitatively increase the pressure on the aft face of the truck to levels in the flow field around the truck, as illustrated in Figure 3b. Close inspection of the values in Figure 3b reveals asymmetries, probably due to a lack of grid resolution in the vicinity of the plates. As noted above, the grid was not refined due to a lack of available hardware. As the complex nature of this time dependent, separated flow field limits the accuracy of a code such as FLUENT, these numerical results were only used to obtain a general feel of what might occur in the flow with the plates attached and to assist in the wind tunnel experimental direction. Details can be found in Coon (2001) Drag Reduction of a Tractor-Trailer Using Planar Boat Tail Plates (a) 253 (b) Fig. 3. Numerical pressure distributions on aft face of trailer a) Baseline b) Boat tail plates added, d = 6 inches (0.15m), L = 48 inches (1.22 m) Experimental Study An extensive set of wind tunnel tests were conducted on a scale model of a tractortrailer in the Clarkson University Low Speed Wind Tunnel. The tunnel facility is an in-draft, open circuit type with a 4.7:1 contraction inlet. The test section is of 48 inch by 36 inch (1.22 m by 0.91 m) cross section with a length of 65 inch (1.65 m). Honeycomb and fine screens are mounted across the entrance to the contraction inlet to reduce the turbulence and flow irregularities. The maximum speed obtainable in the tunnel was approximately 58 miles/hour (26 m/s) which corresponds to a Re/m of about 1.5e06/m. Models and Apparatus A wind tunnel model was constructed at 1:15.25 scale to resemble many of the common tractor-trailers on the road today. The cab was modeled after a Peterbilt tractor model 379 and the trailer was modeled after a standard full-scale 48 foot (14.6 m) trailer. The actual total length of the model was 51.35 inches (1.3 m), with the trailer extending 37.75 inches (0.96 m) and the cab approximately 11.1 inches (0.025 m) There was a gap between the tractor and trailer of 2.5 inches (0.064 m) which is approximately 38 inches (0.97 m) full-scale. The cross-section of the tractor-trailer was approximately 6.30 in. x 7.125 in. (0.16 m x 0.18 m). Eighteen model wheels were attached, but kept immobile for the experiments. Figure 4 illustrates the model in the tunnel. The width-based Reynolds number for the experiment was approximately 2.3x105, significantly below that of full-scale width-based Reynolds numbers at common highway speeds of approximately 4.5x106. The model blockage at 0° yaw in the tunnel was 2.6%. A 0.5 inch (1.27 mm) thick splitter plate was installed to position the model in the center of the test section, out of the boundary layer, and to model the ground plane. The added blockage that the modeled ground plane contributed to the overall wind tunnel blockage was 1.4%. This brought the total test section blockage up to 4%, which is slightly below the recommended maximum of 5% (Mason et al. 1973). 254 J.D. Coon and K.D. Visser Fig. 4. Wind tunnel model of tractor trailer Four different plate cavity models were tested. The first, denoted Equal Inset (EI), is illustrated in Figure 5a and was similar to the numerical geometries. The second, Equal Inset, Zero Bottom Plate Inset (EI-0B), was identical to EI, but with the bottom plate at zero inset, as suggested by previous literature (Bilanin 1985; Lanser et al. 1991). The last two model types tested were identical to the previous two except that the top plate was removed, and were referred to as EI-NT and EI0B-NT, respectively. Figure 5b illustrates an EI-0B-NT geometry. Full-scale issues fueled the interest in top plate removal. If viable from a drag perspective, it would be more practical as a design as it incorporates less material and would be far easier to operate than a four-plate design. The geometries test matrix is listed in Table 1. (b) (a) Fig. 5. Wind tunnel plate cavity geometries a) Equal Inset (EI) b) Equal Inset, Zero Bottom No Top (EI-0B-NT) Table 1. Model test geometries: W=EI; X=EI-NT; Y= EI-0B, Z= EI-0B-NT Plate Inset (Full Scale) d, inches (m) 1.91 (0.048) 3.81 (0.096) 5.72 (0.15) 7.63 (0.19) 9.53 (0.24) 11.44 (0.29) 13.34 (0.34) 15.25 (0.39) 19.06 (0.48) L =36 inches (0.91 m) L=48 inches (1.22 m) L=60 inches(1.56 m) W,X,Y,Z W,X,Y,Z W,X,Y,Z W,X,Y,Z W,X W,X,Y,Z W,X,Y,Z W,X,Y,Z W,X,Y,Z W,X,Y,Z W,X,Y,Z W,X W,X W,X,Y,Z W,X,Y,Z W,X,Y,Z W,X,Y,Z W,X,Y,Z W,X,Y,Z W,X W,X W,X Drag Reduction of a Tractor-Trailer Using Planar Boat Tail Plates 255 A model of the Boivin and Roberge (2001) design was also constructed, containing three plates (top and sides) inclined at an angle towards the centerline with no inset from the perimeter of the trailer. An estimated plate length of 18 inches (0.46 m), full-scale, and angle of 15º , based on photographs, was modeled. A bottom plate was also added to the original design, perpendicular to the trailer face, as an additional configuration. A biaxial, drag and side force, balance was designed and built to take measurements on the tractor-trailer model. It uses two IKO International linear translators with crossed roller bearings (CRWU 80-125) mounted perpendicular to each other. They enabled motion in the direction of flow and perpendicular to the flow. Two Precision Transducers model PT1000 load cells, were used to take measurements for drag and side force on the truck model. Both have an instrument error of 0.03% of the applied load. Voltage output data from the load cells was signal conditioned with a National Instruments (NI) Strain Gauge Board Model SG-2043 and acquired with a NI data acquisition (DAQ) card model PCI-6024E. Zero Yaw Test Results The differences in drag coefficient, ∆CD, and the percentage of drag reduction, %∆CD, based on maximum frontal area for the truck model were used to compare the baseline, no device, geometry to each different device where: and CD = ∆C D = C Dbase − C Ddevice ∆CD %∆CD = *100 CDbase Drag Dynamic pressure * Frontal area (1) (2) (3) The dynamic pressure is one half of the tunnel air density multiplied by the tunnel velocity squared. The experimental results for 0° yawed geometries will be presented first followed by the yawed conditions. The method of Kline (1985) was used to estimate the uncertainty in CD , ∆CD and %∆CD. Although the typical uncertainty error in CD was ± 0.015 or approximately 2% of the measured value, the percentage of error associated with ∆CD and %∆CD can be significantly higher depending on the actual drag savings of the device as the uncertainty in ∆CD can represent a significant portion of the drag savings increment. Consider the uncertainty in ∆CD, U∆C D , which is determined as: U∆C D 2 2 ∂∆CD ∂∆CD + UC DDevice = UC DBase ∂CDBase ∂CDDevice (4) 256 J.D. Coon and K.D. Visser Since UC DBase is equal to UC DDevice this becomes: U∆C D = 2 UC DBase (5) Here the uncertainty in ∆CD is roughly 40% greater than that of CD. The percentage of error, however, is much higher, especially as the difference in drag, ∆CD, decreases. % error in ∆C D = 100 U∆C D ∆CD (6) The same is true for %∆CD. As a result, the % error in ∆CD, typically on the order of ± 0.02, becomes about 28% for an incremental drag savings of 10% over a baseline CD of, say, 0.8. A drag savings of only 5% would incur % error in ∆CD of over 55%. Percent error magnitude in %∆CD is similar. It is important that this error associated with these data be kept in mind when observing the trends in the following plots. Although many repeat cases were taken and data was acquired over significant time periods to ensure time averaged results, consideration of the error bars obscures many of the smaller trends observed between individual geometric details. Thus, despite the fact that the overall drag savings of these devices, relative to the baseline geometry, were statistically significant, the specifics of the data presented below associated with individual geometric differences should be taken only as indicative of potential trends and not definitive conclusions. Note that the error bars have been left off the figures for clarity. Equal Inset The behavior of the EI case is plotted in Figure 6a. The data indicated an optimum geometric range of plate length, L, of 45in. to 55in. (1.14m to 1.40 m) and inset, d, of 3in. to 7in. (0.076m to 0.18m) full-scale. For comparison, the values of %∆CD are presented in Figure 6b to illustrate the danger of only presenting percentages of drag reduction instead of ∆CD. Since the values of %∆CD are scaled by the baseline, an unrealistic value of the magnitude of drag of the baseline geometry can lead to erroneous conclusions. This is especially critical at model scales and Reynolds numbers. As an example, note the difference in perceived %∆CD performance of the 3 foot (0.91 m) case at an inset of 4 inches (0.10 m) compared to the values of ∆CD. Also, the incremental values of ∆CD can more readily be applied to a full scale geometry, as percentages require the baseline model CD. The maximum %∆CD was achieved with a geometric configuration of L=48in. (1.22 m) and d=5.72in. (0.14 m), yielding an 8.84% reduction in drag, however in terms of ∆ CD, the L = 36 inch (0.91 m), d = 3.8 inch (0.097 m) geometry performed as well as the 48 inch (1.22 m) case. Drag Reduction of a Tractor-Trailer Using Planar Boat Tail Plates 257 10 0.08 9 0.07 8 0.06 ∆ CD % ∆CD 7 0.05 Full Scale Plate Length 0.04 6 5 Full Scale Plate Length 5 feet 4 4 feet 3 feet 0.03 5 feet 4 feet 3 feet 3 0.02 2 0 2 4 6 8 10 12 14 16 18 20 0 2 4 6 Full Scale Inset (inches) 8 10 12 14 16 18 20 Full Scale Inset (inches) (a) (b) Fig. 6. Effect of plate length and inset on drag reduction, equal inset geometry a) ∆CD b) %∆CD Effect of Zero Bottom Plate Inset The EI-0B configuration performed best in similar geometric ranges to that of the EI cases, however, as seen in Figure 7, a local maximum in length is not as obvious. For optimum performance, the plate length should be L>45in. (1.14 m), but no strong upper limit for L is indicated. The optimum range for plate inset was within 3in.<d<8in. (0.076m<d<0.20m), with a %∆CD range from 8.5-9.0%. The maximum ∆CD for the EI-0B case was achieved with L=48in. (1.22 m) and d=5.72in. (0.14 m), yielding a ∆CD = 0.0754. Similar results were achieved for the case with L=60in. (1.52 m) and d=5.72in. (0.14 m) where ∆CD = 0.0747. The EI-0B configuration forces a streamline to extend from the bottom-most part of the trailer, unlike the plate inset which allows separation at the trailing edges of the trailer and vortex formation in the step region. This vortex strategy for drag reduction appears to work best for the top and sides of the trailer, but the bottom plate seems most effective without this formation. 0.08 10 0.07 9 8 0.05 %∆CD ∆ CD 0.06 Full Scale Plate Length 5 feet 0bottom 0.04 4 feet 0bottom 7 6 Full Scale Plate Length 5 feet 0bottom 5 4 feet 0bottom 3 feet 0bottom 0.03 3 feet 0bottom 4 0.02 3 0 2 4 6 8 10 Full Scale Inset (inches) (a) 12 14 0 2 4 6 8 10 12 14 Full Scale Inset (inches) (b) Fig. 7. Effect of plate length and inset on drag reduction, zero bottom geometry a) ∆CD b) %∆CD 258 J.D. Coon and K.D. Visser Removal of Top Plate The effect of removing the top plate decreased the performance for both the EI-NT and EI-0B-NT four-plate configurations. For the EI-NT case, no indication of an optimum length was observed between the configurations. Best results were obtained with the lowest plate inset, d. Although it was not tested, the optimum configuration may even be a zero plate inset (d=0). The maximum ∆CD of the EINT configurations tested occurred at L=48in. (1.22 m) and d=1.91in. (0.049 m), yielding a drag reduction of ∆CD = 0.0517 or about 6.2%. In contrast, the model type EI-0B-NT operated most effectively when plate inset was in the range 2in.<d<5in, (0.051m<d<0.13m) yielding a maximum ∆CD = 0.0532 at L=60in. (1.52 m) and d=3.81in. (0.097 m) or a %∆CD=6.3%. This was closely followed by the configuration having L=48in. (1.22 m) and d=3.81in. (0.097 m) for a ∆CD = 0.0521 or %∆CD=6.3%. The impact of no top plate is summarized in Figure 8 for the 48 inch (1.22 m) length plate geometry. The EI-NT geometry performed at 57% below that of the EI, while the EI-0B-NT dropped to 59% of the corresponding EI-0B maximum value. Both configurations also exhibited a shift in the optimum inset value. The EI results indicated an optimum range for plate inset of 3in.<d<7in (0.076m<d<0.18m) while the optimum range for the EI-NT case occurs at a lower range of 0in.<d<4in. (0.0m<d<0.10m) Similarly, the EI-0B case had a local maximum in the range 3in.<d<8in. (0.076m<d<0.20m), but the EI-0B-NT case indicated maximum performance within the range 2in.<d<5in. (0.051m<d<0.13m). 0.08 0.07 0.06 ∆ CD 0.05 0.04 0.03 Four Foot Plate Cases 0.02 EI EI-0B EI-NT EI-0B-NT 0.01 0 0 2 4 6 8 10 12 14 16 18 Full Scale Inset (inches) Fig. 8. Effect of no top plate, plate length and inset on drag reduction of 4 foot (1.22 m) plate length Yaw Test Results As Cooper (1982) has indicated, yawed conditions can play a major role on the drag reduction, however yaw angles greater than 9 degrees are relatively insignificant for trucks at 56 mi/hr (90 km/hr) based on statistical wind estimates. Since these yaw angles are exceeded < 10% of the time, the present study restricted testing to < 10 degrees. Limited yaw measurements were performed on select Drag Reduction of a Tractor-Trailer Using Planar Boat Tail Plates 259 model configurations from the zero degree tests from –3° to +9°, with an increment of 3°. For all perpendicular plate configurations tested, and at low angles, the behavior of the drag with yaw angle was concave down. In other words, the ∆CD improvement decreased with increasing yaw angle. The device with maximum ∆CD from the zero degree tests, the EI-0B, L=4ft. (1.22 m) , d=5.72in. (0.15 m) is illustrated in Figure 9. For all configurations tested with 4 foot (1.22 m) plate length, drag benefits decreased with yaw angle. Erratic behavior was observed at higher yaw angles for the model with L=3 foot (0.91 m). This may be attributed to the effect of less area exposed to the flow with a shorter plate length L. Removal of the top plate had a consistent, negative offset on drag reduction over the yaw angle range, similar to that of the 0° yaw data of Figure 8. Yaw tests were also conducted on variations of the Boivin and Roberge (2001) design. As previously mentioned, this design does not include a plate inset for any of the three plates which were placed at a 15° angle with respect to the trailer top and sides. Contrary to the perpendicular plate behavior, at low yaw angles the trend is somewhat concave up. That is, ∆CD increases with increasing yaw angle over the range ±3°. The behavior is similar for the inverted case which even indicated better performance. The addition of an orthogonal bottom plate to the design improved the drag yet further, but the performance remained below the 4 foot (1.22 m) optimum at 0° yaw. It should be noted that the curves are not ideally symmetric about a yaw angle of zero degrees. Two possible explanations can be given for this behavior. First, although the centerline of the model was aligned with the tunnel free-stream, the addition of the aft devices could be cause for a non-symmetric geometry. Each aft device was carefully hand-built and attached with magnetized strips to the trailer, however the impact of small scale construction and alignment errors at this scale could be more serious than it was thought to be, certainly more so with a tunnel model than the full scale device. Secondly, the asymmetries present at +/- 3 degrees can be seen to fall with in the estimated error bands of a ∆CD of about +/0.02, indicating that there may be no asymmetry present at all. 0.1 0.08 0.06 ∆ CD 0.04 0.02 0 4 foot, zero bottom, 6 inch inset -0.02 Makka original Makka, inverted -0.04 Makka fourth plate added -0.06 -3 0 3 Yaw Angle (Degrees) 6 9 Fig. 9. Effect of yaw angle on drag of selected designs At higher yaw degrees, the results became more erratic and somewhat unexplainable, possibly due to measurement uncertainty, as seen in Figure 9. At +6°, the inverted case continues its convex behavior (as experienced over ±3°). 260 J.D. Coon and K.D. Visser This differs from both the original and 4-plate cases. The common element in the original and 4-plate cases is the presence of a top plate. It is possible that a negative effect from the top plate is occurring at +6°. This is inexplicable at the present, however, since at +9° the trend is reversed. That is, at +9°, the 4-plate angled outperforms both the original and the inverted Boivin and Roberge (2001) design. It is suspected that the low Reynolds number effects are contributing to this behavior in addition to measurement uncertainty. The general conclusion in the yaw tests is that further data is necessary at more yaw angles and higher Reynolds numbers to substantiate any claims made for yaw trends of the angled plate design, or any variations. Literature Comparison The optimum geometrical results from the present experimental data were compared to that of Bilanin (1985) and Lanser, et al. (1991) using the definitions of Figure 10. Plate insets, G and D, and the plate length, L, were nondimensionalized by the trailer width, W. Fig. 10. Geometry definitions for literature comparison Table 2 presents results for the optimum geometries. In terms of plate placement, both the Bilanin (1985) and Lanser, et al. (1991) published geometries compare most closely to the present experimental case with zero bottom plate inset, since they all have the same bottom plate position. The G/W and D/W inset ratios reported by Bilanin were twice as great as the current experimental inset ratios, indicating higher optimum plate insets for the former design. Bilanin also specifies a range for optimum inset ratio of 0.1<G/W=D/W<0.2, but the current experimental values still lie outside this range at G/W=D/W=0.06. The plate length ratio reported by Bilanin (1985) of L/W=0.44 is less than that of the present optimum at L/W=0.50, however, he also specified that the full-scale range for optimum plate length should be in between 40in.<L< 56in. (1.02m <L< 1.42m) within which the present study falls. Drag Reduction of a Tractor-Trailer Using Planar Boat Tail Plates 261 Table 2. Optimum geometry for current and published results Case Equal inset Bottom plate inset = 0 Bilanin (1985) Lanser et al. (1991) Length, L/W 0.50 0.50 0.44 0.36 Inset, G/W = D/W 0.06 0.06 0.13 0.06 The results of Lanser et al. (1991) indicate similar geometries to the present study with identical insets of G/W=D/W=0.06. Plate length ratio differs, from L/W=0.50 in the present study to L/W=0.36 for Lanser, et al, but recall, as discussed earlier, that plate inset had a much stronger influence on drag reduction than does the plate length. Although it is tempting to speculate that an increase in the drag savings would occur as Reynolds numbers increased into the full scale regime, other investigations have indicated this is not always the case (Watkins et al. 1987; Cooper 1985) provided the model scale Re is great enough A full-scale tractortrailer operates at a Re of about 4x106 based on width of the trailer. Full-scale wind tunnel tests have shown that the drag coefficient for tractor-trailers lies in the range 0.6 to 0.9 at typical road speeds (McCallen et al. 1999). It has been indicated (SAE J1252) that although the Re based on width need not match full scale for acceptable results, it should be a minimum of 7x105. Others have indicated a minimum of 1x106 (Watkins et al. 1993) or 2x106 based on the square root of frontal area (Cooper 1985). Full Scale Study A prototype of the most promising configuration was constructed for the road testing to compare with tunnel results and to provide an opportunity for the students involved in the project to get “real world” data. As pointed out by Saunders et al. (1985), wind tunnel results tend to be quite optimistic, not only because of some unknown Re scale effects, but by other factors such as turbulence levels. The primary objectives of the prototype were to maintain full functionality of tractor-trailer unit with regards to loading and unloading of cargo and to find a balance between manufacturing requirements and aerodynamic ideals. The first full scale prototype was engineered to be collapsible such that it could be folded to within three inches of the doors. The collapsing sequence is illustrated in Figure 11. The nature of the design development timescale was that the prototype was fabricated as the tunnel tests continued. Hence, the length of 32 inches (0.81 m) was chosen for the prototype, based on the work of Lanser et al. (1991), before the tunnel tests indicated 48 inches (1.22 m) may be better. The main frame of the device was constructed using 2 inch by 2 inch aluminum (0.05m x 0.05 m) box beams TIG welded to 2 inch (0.05 m) by 1 inch (0.025 m) horizontal box beams on the top and bottom. Both the top and bottom panels were constructed of a flexible canvas to allow the unit to fold in. The side plates were constructed out of fiberglass panels on separate aluminum frames. To facilitate access to the trailer, the device was only hinged to the right door. Weatherstripping was placed on the frame where each beam met the doors to improve sealing. To alleviate concerns about the added weight of the main frame and flaps, 262 J.D. Coon and K.D. Visser the standard extruded aluminum hinges were replaced with steel hinges. Deployment required manual actuation of the two side flaps, both of which are within reach of the truck operator from the ground (a) (b) (c) Fig. 11. Full scale prototype storage sequence a) open b) collapsing c) closed A tensioning system was devised so that the cloth stayed taut and the side flaps remained opened during operation. High-strength climbing rope was attached to the flaps via eyelets on the top and bottom of each flap. A ratcheting tie-down tensioner (a “come-along”) pulled the flaps into the open position. In order to close the device the tensioners were relaxed and the rope unhooked. A locking mechanism latched the device to the driver side door when the doors were closed and the trailer in motion. The flaps were secured in place when non-operational by two keyed hasp locks. Issues associated with fitting the device to the truck doors were alleviated by purchasing doors from the local trucking company, LaValle Trucking Inc. (LTI), who were going to road test the device, and installing the device on the doors before the doors were put on the trailer. Originally, the prototype was to be centered on the back face of the trailer, inset from all sides by about 7 inches (0.18 m). Due to complexities within the trailer doors, such as hinges and latches, the prototype placement had to be changed. The bottom of the prototype framing was inset about 20 inches (0.51 m), because of interference with the latches used to get in and out of the trailer, and the sides were inset 10 inches (0.25 m). Figure 12 illustrates the installed prototype. (a) (b) Fig. 12. Full scale prototype configuration on test vehicle a) closed b) open The prototype was tested on a cross-country trip that covered approximately 10,000 miles (16,093 km). Several factors were compared before, during, and after the trip took place, including fuel mileage, fuel consumed, payload, idle times, and Drag Reduction of a Tractor-Trailer Using Planar Boat Tail Plates 263 average speeds. The truck was fitted with an onboard fuel consumption and condition monitoring computer. It should be noted that as this was a one-truck test and not a standard SAE Type II test (SAE J1321 1981) the data collected could have an appreciable bias due to the particular ambient atmospheric and road conditions experienced during the trip. The results from the test indicate that the addition of the device increased the fuel mileage from 5.8 to 6.3 miles per gallon (mpg), or 2.5 to 2.7 km/liter, ± 0.1%, for a savings of approximately 0.5 mpg (0.2 km/liter) This corresponds to an 8.3% average increase in fuel mileage. Based on these values, an estimated savings for a typical 120,000 miles (193,121 km) per year use would be on the order of 1500 gallons (5677 liters) per truck. Single trip and single truck bias without a control issues aside, the preliminary data did indicate encouraging results in the right direction. Observation of the device before the cross-country road test did indicate an increase in pressure in the aft region of the trailer. The upper and lower canvas surfaces bulged outwards from the stationary position, indicating a pressure difference across the material. A second generation device was constructed based on experience gained with the first test. It utilized all aluminum rigid sides with a split plate design as illustrated in Figure 13a. Unfortunately, uncertainty in results and a short 5500 mile (8851 km) trip, combined with questionable data reporting led to inconclusive results. In addition, geometry and fatigue issues, as illustrated in Figure 13b, caused complications. Excessive vibration, according to the driver, was the cause of the cracking along the hinges, breakage of a pin joint in the top flap, and resulting geometry mismatch that led to increased cavity ventilation. (a) (b) Fig. 13. Full scale aluminum prototype a) installed on trailer b) hinge fatigue Conclusions The wind tunnel and full scale data presented in this study verify results from the literature that significant drag reduction can occur through the use of a cavity device mounted on the aft face of a tractor-trailer rig. The best results were obtained with a four foot (1.22 m) plate width yielding a drag savings of about 264 J.D. Coon and K.D. Visser CD=0.075 or about 9% of the baseline drag. It should be noted that because the incremental drag is a difference of two substantially larger values, the error in ∆CD was appreciable. All the wind tunnel results indicated a higher sensitivity for plate inset on drag reduction than for plate length. Setting the bottom plate inset close to the bottom of the trailer base appears to be essential to maximizing drag reduction. The optimum experimental plate inset, d, was found to agree very closely to that of Lanser, et al. (1991). Removal of the top plate decreased performance by about 30% in all cases, but there still was an observable drag reduction and this may be a key factor in realizing the practical role of such a device on a full-scale level. Device performance decreased with yaw angle for plates mounted perpendicular to the trailer base. Each of the angled plate design variations, however, displayed a concave up behavior at low yaw angles, contrary to the concave down behavior of the perpendicular plate-cavity devices. At small yaw angles, the four-plate angled plate device achieved the highest drag reduction, indicating the importance of the presence of the bottom plate to maximize performance. A full-scale, fully operational prototype was road tested and indicated that the addition of such a cavity device increased the fuel mileage by 0.5 mpg (0.2 km/liter) or about 8%. Estimated savings for a typical 120,000 miles (193,121 km) per year use would be on the order of 1500 gallons (5677 liters) per truck The positive results obtained from the scale and full size tests have prompted a continued study of the potential use of a cavity design for drag reduction, especially the possibility of a design employing only three sides. A new series of models is being constructed to optimize length, inset, and boat tail angle. Yaw behavior, optimization of three plate geometries, and downstream effects obtained with seven hole probe flow field surveys will be conducted. In addition, two more full scale prototypes are being designed with the aim of improving functionality in addition to obtaining full scale data. Acknowledgements The authors would like to thank the National Collegiate Inventors and Innovators Alliance (NCIIA) for their support of this project through an E-Team grant and the New York State Energy Research & Development Authority (NYSERDA) Grant Agreement #6436 for their support. The contributions by the local trucking firm, LaValle Trucking Inc of Potsdam, NY, of time and labor on the road are also much appreciated. Finally, a big thank you to the enthusiastic undergraduate Clarkson students who participated in this project: Anna Sawabini, Matthew Pausley, Matthew Menotti, Jamison Coon, and Matthew Allen. References Bilanin AJ (1985) Vehicle Drag Reducer. US Patent 4682808 Boivin and Roberge (2001) Vehicle Drag Reducer. US Patent Number 6257654 Bureau of Transportation (2000) National Transportation Statistics Coon JD (2002) The Effects of Non-Ventilated Plate-Cavity Devices on Drag Reduction of Tractor Trailers. Masters Thesis, Clarkson University, Potsdam NY. Drag Reduction of a Tractor-Trailer Using Planar Boat Tail Plates 265 Cooper K (1982) The Wind Tunnel Testing of Heavy Trucks to Reduce Fuel Consumption. SAE 821285 Cooper K (1985) The Effect of Front Edge Rounding and Rear-Edge Shaping on the Aerodynamic Drag of Bluff Vehicles in Ground Proximity, SAE 850288 Cooper KR, Mason WT, Bettes WH (1982) Correlation Experience with the SAE Wind Tunnel Test Procedures for Trucks and Buses. SAE 820375 Davidson L, Krajnovic S (2001) Large Eddy Simulation of Flow around a Ground Vehicle Body AIAA 2001-01-0702 Hoerner SF (1950) Base Drag and Thick Trailing Edges. J Aeronautical Sciences:622-628 Hucho W (1987) Aerodynamics of Road Vehicles Hucho W, Sovran G (1993) Aerodynamics of Road Vehicles. Annual Review of Fluid Mechanics Kentfield, JAC (1984) Short, Multi-Step, Afterbody Fairings. J Aircraft: Vol.21 No. 5 pp.351-2 Kline SJ (1985) The Purposes of Uncertainty Analysis. J. of Fluids Eng: 153 - 160 Lanser WR, Ross JC, Kaufman AE (1991) Aerodynamic Performance of a Drag Reduction Device on a Full-Scale Tractor/Trailer. SAE 912195. Mair WA (1965) The Effect of a Rear-Mounted Disc on the Drag of a Blunt-Based Body of Revolution. The Aeronautical Quarterly Royal Aeronautical Society:350-360 Mason Jr WT, Beebe PS, Schenkel FK (1973) An Aerodynamic Test Facility for ScaleModel Automobiles International Automotive Engineering Congress Mason Jr WT, Beebe PS (1978) The Drag Related Flow Field Characteristics of Trucks and Buses, Aerodynamic Drag Mechanisms of Bluff Bodies and Road Vehicles, General Motors Research Laboratories, pp. 45-93 McCallen R, Couch R, Hsu J, Browand F, Hammache M, Leonard A, Brady M, Salari K, Rutledge W, Ross J, Storms B, Heineck JT, Driver D, Bell J, Zilliac G (1999) Progress in Reducing Aerodynamic Drag for a Higher Efficiency of Heavy Duty Trucks (Class 7-8). SAE 1999-01-2238. Montoya LC, Steers LL (1974) Aerodynamic drag reduction tests on a full-scale tractor trailer combination with several add-on devices. NASA TM X-56028 Rae WH, Pope A (1984) Low Speed Wind Tunnel Testing Rodriguez O. (1991) Base Drag Reduction by Control of the Three-dimensional Unsteady Vortical Structures;. Experiments in Fluids Vol. 11 p218-226 SAE J1252 (1981) SAE Wind Tunnel Test Procedures for Trucks and Buses SAE J1321 (1981) Joint ATA/SAE Fuel Consumption Test Procedure, Type-II Saltzman EJ, Meyer RR (1999) A Reassessment of Heavy Duty Truck Aerodynamic Design Features and Priorities. NASA/TP-1999-206574 Saunders JW, Watkins S, Hoffmann PH, Buckley FT (1985) Comparison of On-Road and Wind Tunnel Tests for Tractor Trailer Aerodynamic Devices, and Fuel Saving Predictions. SAE 850286 Sovran G, Morel T, Mason W (1978) Aerodynamic Drag Mechanisms of Bluff Bodies and Road Vehicles, General Motors Research Laboratories Watkins S, Saunders JW, Hoffmann PH (1993) Comparison of Road and Wind Tunnel Drag Reductions for Commercial Vehicles. J. of Wind and Industrial Aerodynamics: 411420 Watkins S, Saunders, JW, Hoffmann PH (1987) Wind Tunnel Modeling of Commercial Vehicle Drag Reducing Devices: Three Case Studies. SAE 870717