IPS-E-PR-880(1)

FOREWORD

The Iranian Petroleum Standards (IPS) reflect

the views of the Iranian Ministry of Petroleum

and are intended for use in the oil and gas

production facilities, oil refineries, chemical and

petrochemical plants, gas handling and

processing installations and other such facilities.

0

IPS is based on internationally acceptable

standards and includes selections from the items

stipulated in the referenced standards. They are

also supplemented by additional requirements

and/or modifications based on the experience

acquired by the Iranian Petroleum Industry and

the local market availability. The options which

are not specified in the text of the standards are

itemized in data sheet/s, so that, the user can

select his appropriate preferences therein.

The IPS standards are therefore expected to be

sufficiently flexible so that the users can adapt

these standards to their requirements. However,

they may not cover every requirement of each

project. For such cases, an addendum to IPS

Standard shall be prepared by the user which

elaborates the particular requirements of the

user. This addendum together with the relevant

IPS shall form the job specification for the

specific project or work.

The IPS is reviewed and up-dated approximately

every five years. Each standards are subject to

amendment or withdrawal, if required, thus the

latest edition of IPS shall be applicable

The users of IPS are therefore requested to send

their views and comments, including any

addendum prepared for particular cases to the

following address. These comments and

recommendations will be reviewed by the

relevant technical committee and in case of

approval will be incorporated in the next revision

of the standard.

Standards and Research department

No.19, Street14, North kheradmand

Karimkhan Avenue, Tehran, Iran .

Postal Code- 1585886851

Tel: 88810459-60 & 66153055

Fax: 88810462

Email: Standards@nioc.org

ﭘﻴﺶ ﮔﻔﺘﺎر

( ﻣﻨﻌﻜﺲ ﻛﻨﻨﺪه دﻳﺪﮔﺎﻫﻬﺎيIPS ) اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮان

وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ و ﺑﺮاي اﺳﺘﻔﺎده در ﺗﺄﺳﻴﺴﺎت ﺗﻮﻟﻴﺪ

واﺣﺪﻫﺎي ﺷﻴﻤﻴﺎﻳﻲ و، ﭘﺎﻻﻳﺸﮕﺎﻫﻬﺎي ﻧﻔﺖ،ﻧﻔﺖ و ﮔﺎز

ﺗﺄﺳﻴﺴﺎت اﻧﺘﻘﺎل و ﻓﺮاورش ﮔﺎز و ﺳﺎﻳﺮ ﺗﺄﺳﻴﺴﺎت،ﭘﺘﺮوﺷﻴﻤﻲ

.ﻣﺸﺎﺑﻪ ﺗﻬﻴﻪ ﺷﺪه اﺳﺖ

ﺑﺮاﺳﺎس اﺳﺘﺎﻧﺪاردﻫﺎي ﻗﺎﺑﻞ ﻗﺒﻮل،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

ﺑﻴﻦاﻟﻤﻠﻠﻲ ﺗﻬﻴﻪ ﺷﺪه و ﺷﺎﻣﻞ ﮔﺰﻳﺪهﻫﺎﻳﻲ از اﺳﺘﺎﻧﺪاردﻫﺎي

ﻫﻤﭽﻨﻴﻦ ﺑﺮاﺳﺎس ﺗﺠﺮﺑﻴﺎت.ﻣﺮﺟﻊ در ﻫﺮ ﻣﻮرد ﻣﻲﺑﺎﺷﺪ

ﺻﻨﻌﺖ ﻧﻔﺖ ﻛﺸﻮر و ﻗﺎﺑﻠﻴﺖ ﺗﺄﻣﻴﻦ ﻛﺎﻻ از ﺑﺎزار داﺧﻠﻲ و ﻧﻴﺰ

ﻣﻮاردي ﺑﻄﻮر ﺗﻜﻤﻴﻠﻲ و ﻳﺎ اﺻﻼﺣﻲ در اﻳﻦ،ﺑﺮﺣﺴﺐ ﻧﻴﺎز

ﻣﻮاردي از ﮔﺰﻳﻨﻪﻫﺎي ﻓﻨﻲ ﻛﻪ در.اﺳﺘﺎﻧﺪارد ﻟﺤﺎظ ﺷﺪه اﺳﺖ

ﻣﺘﻦ اﺳﺘﺎﻧﺪاردﻫﺎ آورده ﻧﺸﺪه اﺳﺖ در داده ﺑﺮگﻫﺎ ﺑﺼﻮرت

ﺷﻤﺎره ﮔﺬاري ﺷﺪه ﺑﺮاي اﺳﺘﻔﺎده ﻣﻨﺎﺳﺐ ﻛﺎرﺑﺮان آورده ﺷﺪه

.اﺳﺖ

ﺑﺸﻜﻠﻲ ﻛﺎﻣﻼً اﻧﻌﻄﺎف ﭘﺬﻳﺮ ﺗﺪوﻳﻦ ﺷﺪه،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

.اﺳﺖ ﺗﺎ ﻛﺎرﺑﺮان ﺑﺘﻮاﻧﻨﺪ ﻧﻴﺎزﻫﺎي ﺧﻮد را ﺑﺎ آﻧﻬﺎ ﻣﻨﻄﺒﻖ ﻧﻤﺎﻳﻨﺪ

ﺑﺎ اﻳﻦ ﺣﺎل ﻣﻤﻜﻦ اﺳﺖ ﺗﻤﺎم ﻧﻴﺎزﻣﻨﺪيﻫﺎي ﭘﺮوژه ﻫﺎ را

در اﻳﻦ ﮔﻮﻧﻪ ﻣﻮارد ﺑﺎﻳﺪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﻧﻴﺎزﻫﺎي.ﭘﻮﺷﺶ ﻧﺪﻫﻨﺪ

اﻳﻦ.ﺧﺎص آﻧﻬﺎ را ﺗﺄﻣﻴﻦ ﻣﻲﻧﻤﺎﻳﺪ ﺗﻬﻴﻪ و ﭘﻴﻮﺳﺖ ﻧﻤﺎﻳﻨﺪ

ﻣﺸﺨﺼﺎت ﻓﻨﻲ آن ﭘﺮوژه،اﻟﺤﺎﻗﻴﻪ ﻫﻤﺮاه ﺑﺎ اﺳﺘﺎﻧﺪارد ﻣﺮﺑﻮﻃﻪ

.و ﻳﺎ ﻛﺎر ﺧﺎص را ﺗﺸﻜﻴﻞ ﺧﻮاﻫﻨﺪ داد

اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ ﺗﻘﺮﻳﺒﺎً ﻫﺮ ﭘﻨﺞ ﺳﺎل ﻳﻜﺒﺎر ﻣﻮرد ﺑﺮرﺳﻲ

در اﻳﻦ ﺑﺮرﺳﻲﻫﺎ ﻣﻤﻜﻦ اﺳﺖ.ﻗﺮار ﮔﺮﻓﺘﻪ و روزآﻣﺪ ﻣﻲﮔﺮدﻧﺪ

اﺳﺘﺎﻧﺪاردي ﺣﺬف و ﻳﺎ اﻟﺤﺎﻗﻴﻪاي ﺑﻪ آن اﺿﺎﻓﻪ ﺷﻮد و ﺑﻨﺎﺑﺮاﻳﻦ

.ﻫﻤﻮاره آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻧﻬﺎ ﻣﻼك ﻋﻤﻞ ﻣﻲ ﺑﺎﺷﺪ

درﺧﻮاﺳﺖ ﻣﻲﺷﻮد ﻧﻘﻄﻪ ﻧﻈﺮﻫﺎ و،از ﻛﺎرﺑﺮان اﺳﺘﺎﻧﺪارد

ﭘﻴﺸﻨﻬﺎدات اﺻﻼﺣﻲ و ﻳﺎ ﻫﺮﮔﻮﻧﻪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﺑﺮاي ﻣﻮارد

ﻧﻈﺮات و. ﺑﻪ ﻧﺸﺎﻧﻲ زﻳﺮ ارﺳﺎل ﻧﻤﺎﻳﻨﺪ،ﺧﺎص ﺗﻬﻴﻪ ﻧﻤﻮدهاﻧﺪ

ﭘﻴﺸﻨﻬﺎدات درﻳﺎﻓﺘﻲ در ﻛﻤﻴﺘﻪﻫﺎي ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ ﺑﺮرﺳﻲ و در

ﺻﻮرت ﺗﺼﻮﻳﺐ در ﺗﺠﺪﻳﺪ ﻧﻈﺮﻫﺎي ﺑﻌﺪي اﺳﺘﺎﻧﺪارد ﻣﻨﻌﻜﺲ

.ﺧﻮاﻫﺪ ﺷﺪ

ﻛﻮﭼﻪ، ﺧﺮدﻣﻨﺪ ﺷﻤﺎﻟﻲ، ﺧﻴﺎﺑﺎن ﻛﺮﻳﻤﺨﺎن زﻧﺪ، ﺗﻬﺮان،اﻳﺮان

19 ﺷﻤﺎره،ﭼﻬﺎردﻫﻢ

اداره ﺗﺤﻘﻴﻘﺎت و اﺳﺘﺎﻧﺪاردﻫﺎ

1585886851 : ﻛﺪﭘﺴﺘﻲ

66153055 و88810459 - 60 : ﺗﻠﻔﻦ

88810462 : دور ﻧﮕﺎر

Standards@nioc.org

:ﭘﺴﺖ اﻟﻜﺘﺮوﻧﻴﻜﻲ

General Definitions:

Throughout this Standard

definitions shall apply.

the

following

Company :

Refers to one of the related and/or affiliated

companies of the Iranian Ministry of Petroleum

such as National Iranian Oil Company, National

Iranian

Gas

Company,

and

National

Petrochemical Company etc.

Purchaser:

Means the “Company" Where this standard is

part of direct purchaser order by the “Company”,

and the “Contractor” where this Standard is a

part of contract documents.

Vendor And Supplier:

Refers to firm or person who will supply and/or

fabricate the equipment or material.

Contractor:

Refers to the persons, firm or company whose

tender has been accepted by the company.

Executor :

Executor is the party which carries out all or part

of construction and/or commissioning for the

project.

Inspector :

The Inspector referred to in this Standard is a

person/persons or a body appointed in writing by

the company for the inspection of fabrication and

installation work

Shall:

Is used where a provision is mandatory.

Should:

Is used where a provision is advisory only.

Will:

Is normally used in connection with the action

by the “Company” rather than by a contractor,

supplier or vendor.

May:

Is used where a provision is completely

discretionary.

: ﺗﻌﺎرﻳﻒ ﻋﻤﻮﻣﻲ

.در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺗﻌﺎرﻳﻒ زﻳﺮ ﺑﻪ ﻛﺎر ﻣﻲ رود

: ﺷﺮﻛﺖ

ﺑﻪ ﺷﺮﻛﺖ ﻫﺎي اﺻﻠﻲ و واﺑﺴﺘﻪ وزارت ﻧﻔﺖ ﻣﺜﻞ ﺷﺮﻛﺖ ﻣﻠﻲ

ﺷﺮﻛﺖ ﻣﻠﻲ ﺻﻨﺎﻳﻊ، ﺷﺮﻛﺖ ﻣﻠﻲ ﮔﺎز اﻳﺮان، ﻧﻔﺖ اﻳﺮان

.ﭘﺘﺮوﺷﻴﻤﻲ و ﻏﻴﺮه اﻃﻼق ﻣﻴﺸﻮد

:ﺧﺮﻳﺪار

ﻳﻌﻨﻲ "ﺷﺮﻛﺘﻲ" ﻛﻪ اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﺳﻔﺎرش

ﺧﺮﻳﺪ ﻣﺴﺘﻘﻴﻢ آن "ﺷﺮﻛﺖ" ﻣﻴﺒﺎﺷﺪ و ﻳﺎ "ﭘﻴﻤﺎﻧﻜﺎري" ﻛﻪ اﻳﻦ

. اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﻗﺮارداد آن اﺳﺖ

:ﻓﺮوﺷﻨﺪه و ﺗﺎﻣﻴﻦ ﻛﻨﻨﺪه

ﺑﻪ ﻣﻮﺳﺴﻪ و ﻳﺎ ﺷﺨﺼﻲ ﮔﻔﺘﻪ ﻣﻴﺸﻮد ﻛﻪ ﺗﺠﻬﻴﺰات و ﻛﺎﻻﻫﺎي

. ﻣﻮرد ﻟﺰوم ﺻﻨﻌﺖ را ﺗﺎﻣﻴﻦ ﻣﻴﻨﻤﺎﻳﺪ

:ﭘﻴﻤﺎﻧﻜﺎر

ﻣﻮﺳﺴﻪ وﻳﺎ ﺷﺮﻛﺘﻲ ﮔﻔﺘﻪ ﻣﻴﺸﻮد ﻛﻪ ﭘﻴﺸﻨﻬﺎدش، ﺑﻪ ﺷﺨﺺ

ﺑﺮاي ﻣﻨﺎﻗﺼﻪ وﻳﺎ ﻣﺰاﻳﺪه ﭘﺬﻳﺮﻓﺘﻪ ﺷﺪه اﺳﺖ

: ﻣﺠﺮي

ﻣﺠﺮي ﺑﻪ ﮔﺮوﻫﻲ اﺗﻼق ﻣﻲ ﺷﻮد ﻛﻪ ﺗﻤﺎم ﻳﺎ ﻗﺴﻤﺘﻲ از

.ﻛﺎرﻫﺎي اﺟﺮاﻳﻲ و ﻳﺎ راه اﻧﺪازي ﭘﺮوژه را اﻧﺠﺎم دﻫﺪ

:ﺑﺎزرس

در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺎزرس ﺑﻪ ﻓﺮد ﻳﺎ ﮔﺮوﻫﻲ اﺗﻼق ﻣﻲ ﺷﻮد ﻛﻪ

ﻛﺘﺒﺎً ﺗﻮﺳﻂ ﻛﺎرﻓﺮﻣﺎ ﺑﺮاي ﺑﺎزرﺳﻲ ﺳﺎﺧﺖ و ﻧﺼﺐ ﺗﺠﻬﻴﺰات

.ﻣﻌﺮﻓﻲ ﺷﺪه ﺑﺎﺷﺪ

:ﺑﺎﻳﺪ

.ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺟﺒﺎري اﺳﺖ اﺳﺘﻔﺎده ﻣﻴﺸﻮد

:ﺗﻮﺻﻴﻪ

.ﺑﺮاي ﻛﺎري ﻛﻪ ﺿﺮورت اﻧﺠﺎم آن ﺗﻮﺻﻴﻪ ﻣﻴﺸﻮد

:ﺗﺮﺟﻴﺢ

ﻣﻌﻤﻮﻻً در ﺟﺎﻳﻲ اﺳﺘﻔﺎده ﻣﻲﺷﻮد ﻛﻪ اﻧﺠﺎم آن ﻛﺎر ﺑﺮاﺳﺎس

.ﻧﻈﺎرت ﺷﺮﻛﺖ ﺑﺎﺷﺪ

: ﻣﻤﻜﻦ اﺳﺖ

. ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺧﺘﻴﺎري ﻣﻴﺒﺎﺷﺪ

IPS-E-PR-880(1)

1

ENGINEERING STANDARD

FOR

PROCESS DESIGN

OF

GAS (VAPOR)-LIQUID SEPARATORS

FIRST REVISION

JANUARY 2010

اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ

ﺑﺮاي

ﻣﺎﻳﻊ-(ﻃﺮاﺣﻲ ﻓﺮآﻳﻨﺪي ﺟﺪاﻛﻨﻨﺪه ﻫﺎي ﮔﺎز )ﺑﺨﺎر

وﻳﺮاﻳﺶ اول

1388 دي

This Standard is the property of Iranian Ministry of Petroleum.

All rights are reserved to the owner. Neither whole nor any

part of this document may be disclosed to any third party,

reproduced, stored in any retrieval system or transmitted in

any form or by any means without the prior written consent of

the Iranian Ministry of Petroleum.

2

ﺗﻤﺎم ﺣﻘﻮق آن ﻣﺘﻌﻠﻖ ﺑﻪ.اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﺘﻌﻠﻖ ﺑﻪ وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ

ﺗﻤﺎم ﻳﺎ،ﻣﺎﻟﻚ آن ﺑﻮده و ﻧﺒﺎﻳﺪ ﺑﺪون رﺿﺎﻳﺖ ﻛﺘﺒﻲ وزارت ﻧﻔﺖ اﻳﺮان

ذﺧﻴﺮه، ﺑﻪ ﻫﺮ ﺷﻜﻞ ﻳﺎ وﺳﻴﻠﻪ از ﺟﻤﻠﻪ ﺗﻜﺜﻴﺮ، ﺑﺨﺸﻲ از اﻳﻦ اﺳﺘﺎﻧﺪارد

. ﻳﺎ روش دﻳﮕﺮي در اﺧﺘﻴﺎر اﻓﺮاد ﺛﺎﻟﺚ ﻗﺮار ﮔﻴﺮد، اﻧﺘﻘﺎل،ﺳﺎزي

Jan. 2010/ 1388 دي

CONTENTS :

Page

No

IPS-E-PR-880(1)

: ﻓﻬﺮﺳﺖ ﻣﻄﺎﻟﺐ

4 .............................................................................. ﻣﻘﺪﻣﻪ-0

0. INTRODUCTION .....................................................4

5 .................................................................... داﻣﻨﻪ ﻛﺎرﺑﺮد-1

1. SCOPE ..........................................................................5

5 ............................................................................. ﻣﺮاﺟﻊ-2

2. REFERENCES...........................................................5

6 ............................................................ ﺗﻌﺎرﻳﻒ و واژﮔﺎن-3

3. DEFINITIONS AND TERMINOLOGY ...........6

6 ........................................................... ﻣﻨﻌﻘﺪ ﻛﻨﻨﺪ ه1-3

3.1 Coalescer ...............................................................6

6 ........................................................... ﺣﺠﻢ ﻛﻨﺘﺮﻟﻲ2-3

3.2 Control Volume ...................................................6

6 ........................ ﻣﺎﻳﻊ- ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻣﺘﺪاول ﮔﺎز3-3

3.3 Conventional Gas-Liquid Separator ............6

7 ........................................................ ارﺗﻔﺎع ﺟﺪاﻳﺶ4-3

3.4 Disengaging Height ............................................7

7 ...................................................... ﺻﺎﻓﻲ ﭘﺎرﭼﻪ اي5-3

3.5 Fabric Filter .........................................................7

7 .................................................... ﻣﺨﺰن ﺗﺒﺨﻴﺮ آﻧﻲ6-3

3.6 Flash Tank ............................................................7

7 ................................................................ زﻣﺎن ﻣﺎﻧﺪ7-3

3.7 Hold-Up Time ......................................................7

7 ................................................................. ﻗﻄﺮه ﮔﻴﺮ8-3

3.8 Knock-Out ............................................................7

7 ............................................................ آﺑﭽﻜﺎن ﺧﻂ9-3

3.9 Line Drip ...............................................................7

7 ........................ ( ﻗﻄﺮه ﮔﻴﺮ )اﺳﺘﺨﺮاج ﻛﻨﻨﺪه ﻗﻄﺮه10-3

3.10 Demister( Mist Extractor).............................7

8 ............................................................... ﻋﺎري ﺳﺎز11-3

3.11 Scrubber ..............................................................8

8 ................................................................ ﻟﺨﺘﻪ ﮔﻴﺮ12-3

3.12 Slug Catcher.......................................................8

8 ............................................................ ﺑﺎزده ﻫﺪف13-3

3.13 Target Efficiency ..............................................8

8 ............................. ﺳﺮﻋﺖ ﻧﻬﺎﻳﻲ ﻳﺎ ﺳﺮﻋﺖ ﺳﻘﻮط14-3

3.14 Terminal Velocity or Drop-Out Velocity..8

8 ............................................................ ﻓﻀﺎي ﺑﺨﺎر15-3

3.15 Vapor Space .......................................................8

8 ...................................... ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻛﺎري ﻣﺠﺎز16-3

3.16 Maximum Allowable Working Pressure ..8

8 ....................................................... ﻓﺸﺎر ﻋﻤﻠﻴﺎﺗﻲ17-3

3.17 Operating Pressure ..........................................8

1

Jan. 2010/ 1388 دي

IPS-E-PR-880(1)

8 ................................................................ ﺧﻮردﮔﻲ18-3

3.18 Corrosion ............................................................8

8 ..................................................... ﻧﺸﺎﻧﻪ ﻫﺎ و اﺧﺘﺼﺎرات-4

4. SYMBOLS AND ABBREVIATIONS ................8

10 ............................................................................ واﺣﺪﻫﺎ-5

5. UNITS ...........................................................................10

10 ............................................................................ ﻋﻤﻮﻣﻲ-6

6. GENERAL ...................................................................10

11 ....................................... ﻣﺎﻳﻊ- ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﮔﺎز1-6

6.1 Gas-Liquid Separators......................................11

11 .......................................... ﻣﻜﺎﻧﻴﺰم ﻫﺎي ﺟﺪاﺳﺎزي2-6

6.2 Separation Mechanisms ...................................11

12 ................. ﻧﻜﺎت ﻋﻤﻮﻣﻲ در ﻟﻮﻟﻪ ﻛﺸﻲ ﺟﺪا ﻛﻨﻨﺪه3-6

6.3 General Notes on Separator Piping ..............12

13 .................................................... ﺟﻨﺲ ﺟﺪا ﻛﻨﻨﺪه4-6

6.4 Separator Material .............................................13

14 ................................ ﻣﺎﻳﻊ/ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻣﺘﺪاول ﮔﺎز-7

7.CONVENTIONAL GAS/LIQUID

SEPARATORS ............................................................14

14 ..................................................................... ﻋﻤﻮﻣﻲ1-7

7.1 General ...................................................................14

14 ................................................... ﻣﻌﻴﺎرﻫﺎي ﻃﺮاﺣﻲ2-7

7.2 Design Criteria ....................................................14

27 ....................................................... ﺑﺮﮔﻪ ﻣﺸﺨﺼﺎت3-7

7.3 Specification Sheet .............................................27

28 ....................................... ﮔﺎز/ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻧﻔﺖ4-7

7.4 Oil/Gas Separators .............................................28

31 ......................... ﻣﺎﻳﻊ/ ﺟﺪاﻛﻨﻨﺪه ﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﮔﺎز-8

8. CENTRIFUGAL GAS/LIQUID

SEPARATORS ………………………………..31

31 ..................................................................... ﻋﻤﻮﻣﻲ1-8

8.1 General ...................................................................31

31 ...................................... ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﺳﻴﻜﻠﻮﻧﻲ2-8

8.2 Cyclone Separators ............................................31

35 ................................................. ﻇﺮوف ﻗﻄﺮه ﮔﻴﺮ ﻣﺸﻌﻞ-9

9. FLARE KNOCK-OUT DRUMS ..........................35

35 ..................................................................... ﻋﻤﻮﻣﻲ1-9

9.1 General ...................................................................35

36 ................................................... ﻣﻌﻴﺎرﻫﺎي ﻃﺮاﺣﻲ2-9

9.2 Design Criteria ....................................................36

36 .................................. ﻣﺎﻳﻊ/ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﺻﺎﻓﻲ ﮔﺎز-10

10. GAS/LIQUID FILTER SEPARATORS .........36

36 ..................................................................... ﻋﻤﻮﻣﻲ1-10

10.1 General ................................................................36

2

Jan. 2010/ 1388 ﺩﻱ

IPS-E-PR-880(1)

39................................................... ﻣﻌﻴﺎﺭﻫﺎﻱ ﻃﺮﺍﺣﻲ2-10

10.2 Design Criteria ..................................................39

:ﭘﻴﻮﺳﺖ ﻫﺎ

APPENDICES:

42 ................................................................ ﭘﻴﻮﺳﺖ ﺍﻟﻒ

APPENDIX A ..................................................................42

43.......... ﻣﺎﻳﻊ-ﭘﻴﻮﺳﺖ ﺏ ﻧﻤﻮﻧﻪ ﻣﺘﺪﺍﻭﻝ ﺟﺪﺍ ﻛﻨﻨﺪﻩ ﻫﺎﻱ ﮔﺎﺯ

APPENDIX B TYPICAL CONVENTIONAL

GAS-LIQUID SEPARATORS ...43

44............................................................................. ﭘﻴﻮﺳﺖ ﺝ

APPENDIX C ..................................................................44

45................... ﭘﻴﻮﺳﺖ ﺩ ﺍﺳﺘﺨﺮﺍﺝ ﻛﻨﻨﺪﻩ ﻗﻄﺮﻩ ﺍﺯ ﻧﻮﻉ ﭘﺮﻩ ﺍﻱ

APPENDIX D VANE TYPE MIST

EXTRACTOR ...................................45

ﭘﻴﻮﺳﺖ ﻫ ﻧﻤﻮﻧﻪ ﺍﻱ ﺍﺯ ﺟﺪﺍ ﻛﻨﻨﺪﻩ ﻫﺎﻱ ﺳﻴﻠﻜﻮﻧﻲ ﻭ ﻃﺮﺡ

ﺟﺪﺍ ﻛﻨﻨﺪﻩ ﭼﻨﺪ ﺳﻴﻜﻠﻮﻧﻲ ﻭ ﺟﺪﺍ ﻛﻨﻨﺪﻩ

47............................................... ﺳﻴﻜﻠﻮﻥ ﻣﺨﺮﻭﻁﻱ

APPENDIX E TYPICAL CYCLONE

SEPARATORS AND SKETCH OF

MULTI-CYCLONE SEPARATOR

AND A CONICAL CYCLONE

SEPARATOR ....................................47

50.............................................................................. ﭘﻴﻮﺳﺖ ﻭ

APPENDIX F ..................................................................50

51.............................................................................. ﭘﻴﻮﺳﺖ ﺯ

APPENDIX G..................................................................51

3

Jan. 2010/ 1388 دي

IPS-E-PR-880(1)

ﻣﻘﺪﻣﻪ-0

0. INTRODUCTION

"ﻃﺮاﺣﻲ ﻓﺮاﻳﻨﺪي ﺟﺪا ﻛﻨﻨﺪه ﻫﺎ" ﮔﺴﺘﺮده و ﺷﺎﻣﻞ ﻣﻮﺿﻮﻋﺎت

ﺑﻨﺎﺑﺮاﻳﻦ ﻳﻚ ﮔﺮوه از.ﻣﺨﺘﻠﻒ ﺑﺎ اﻫﻤﻴﺖ وﻳﮋه ﻣﻲ ﺑﺎﺷﻨﺪ

ﻣﺸﺨﺼﺎت اﺳﺘﺎﻧﺪارد ﻫﺎي ﻣﻬﻨﺪﺳﻲ ﺧﺎص ﺑﺮاي ﭘﻮﺷﺶ دادن

.ﻣﻮﺿﻮع ﺟﺪاﻛﻨﻨﺪهﻫﺎي ﻣﻜﺎﻧﻴﻜﻲ ﺗﻬﻴﻪ ﺷﺪه اﻧﺪ

:اﻳﻦ ﮔﺮوه ﺷﺎﻣﻞ اﺳﺘﺎﻧﺪاردﻫﺎي زﻳﺮ ﻣﻲ ﺑﺎﺷﻨﺪ

"Process Design of Separators" is broad and

contains various subjects of paramount

importance. Therefore a group of Process

Engineering Standard specifications are prepared

to cover the subject of mechanical separators.

This group includes the following standards:

STANDARD CODE

ﻋﻨﻮان اﺳﺘﺎﻧﺪارد

STANDARD TITLE

ﻛﺪ اﺳﺘﺎﻧﺪارد

IPS-E-PR- 850

“Engineering Standard

Process

Requirements

Vessels, and Separators”

for

of

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي اﻟﺰاﻣﺎت

"ﻓﺮآﻳﻨﺪي ﻣﺨﺎزن و ﺟﺪا ﻛﻨﻨﺪه ﻫﺎ

IPS-E-PR-850

IPS-E-PR-880

“Engineering Standard for

Process Design of Gas (Vapor)Liquid Separators”

IPS-E-PR-880

IPS-E-PR-895

“Engineering Standard for

Process Design of Solid-Liquid

Separators”

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي ﻃﺮاﺣﻲ

-(ﻓﺮاﻳﻨﺪي ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﮔﺎز)ﺑﺨﺎر

" ﻣﺎﻳﻊ

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي ﻃﺮاﺣﻲ

" ﻣﺎﻳﻊ-ﻓﺮاﻳﻨﺪي ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﺟﺎﻣﺪ

IPS-E-PR-895

:ﻣﺸﺨﺼﺎت اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ

This Standard Specification covers:

"PROCESS DESIGN OF GAS (VAPOR) LIQUID SEPARATORS"

ﻣﺎﻳﻊ" را ﭘﻮﺷﺶ-("ﻃﺮاﺣﻲ ﻓﺮاﻳﻨﺪي ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﮔﺎز)ﺑﺨﺎر

.ﻣﻲ دﻫﺪ

4

Jan. 2010/ 1388 دي

IPS-E-PR-880(1)

داﻣﻨﻪ ﻛﺎرﺑﺮد-1

1. SCOPE

اﻳﻦ ﻣﺸﺨﺼﺎت اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺣﺪاﻗﻞ اﻟﺰاﻣﺎت ﻃﺮاﺣﻲ

-ﻓﺮاﻳﻨﺪي )ﺷﺎﻣﻞ ﻣﻌﻴﺎرﻫﺎي اﻧﺘﺨﺎب ﻧﻮع( ﺟﺪا ﻛﻨﻨﺪه ﻫﺎ ﻣﺎﻳﻊ

ﭘﺎﻻﻳﺸﮕﺎه ﻫﺎ و ﺳﺎﻳﺮ،ﻳﺎ ﮔﺎز/ﮔﺎز)ﺑﺨﺎر( ﻛﻪ در ﺗﻮﻟﻴﺪ ﻧﻔﺖ و

ﻫﺪف.واﺣﺪﻫﺎي ﻓﺮاورش ﮔﺎز و ﭘﺘﺮوﺷﻴﻤﻲ را ﭘﻮﺷﺶ ﻣﻲ دﻫﺪ

اﻳﻦ اﺳﺘﺎﻧﺪارد ﺗﻌﻴﻴﻦ روﺷﻬﺎي ﺧﺎص ﺟﺪاﺳﺎزي ﺑﻪ ﻋﻨﻮان

ﻋﻤﻠﻴﺎﺗﻲ ﻛﻪ اﺟﺰاء اﻣﺘﺰاج ﻧﺎﭘﺬﻳﺮ ﻳﻚ ﻣﺨﻠﻮط را ﺑﺼﻮرت

ﻣﻜﺎﻧﻴﻜﻲ ﺗﻔﻜﻴﻚ ﻛﻨﺪ )ﺑﺪون ﻳﻚ واﻛﻨﺶ ﺷﻴﻤﻴﺎﻳﻲ ﻳﺎ ﻳﻚ

. ﻣﻲ ﺑﺎﺷﺪ،(ﻓﺮآﻳﻨﺪ اﻧﺘﻘﺎل ﺟﺮم

ﺑﺮاي ﻃﺮاﺣﻲ ﻧﺎزل ﻫﺎي ورودي و ﺧﺮوﺟﻲ و اﺟﺰاء داﺧﻠﻲ از

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ و ﻣﻮاد ﺑﺮايIPS-G-ME-150 اﺳﺘﺎﻧﺪارد

ﻇﺮوف ﺗﺤﺖ ﻓﺸﺎر و اﺟﺰاي داﺧﻠﻲ" اﺳﺘﻔﺎده، ﺑﺮﺟﻬﺎ راﻛﺘﻮرﻫﺎ

ﻣﮕﺮ ﺑﺼﻮرت دﻳﮕﺮي در اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﺸﺨﺺ ﺷﺪه،ﺷﻮد

.ﺑﺎﺷﺪ

This Engineering Standard Specification covers

minimum requirements for the process design

(including criteria for type selection) of gas

(vapor)-liquid separators used in the production of

the oil and/or gas, refineries and other gas

processing and petrochemical plants. For the

purpose of this Standard, separation techniques

are defined as, those operation, which isolate

specific immiscible ingredients of a mixture

mechanically, i.e., without a chemical reaction or

a mass transfer process taking place.

For design of inlet and outlet nozzles and vessel

internals refer to Engineering Standard IPS-GME-150, "Engineering and Material Standard for

Towers, Reactors, Pressure Vessels & Internals"

unless otherwise specified in this Standard.

:1 ﻳﺎدآوري

Note 1:

ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ1384 اﻳﻦ اﺳﺘﺎﻧﺪارد در دي ﻣﺎه ﺳﺎل

1 ﻣﺮﺑﻮﻃﻪ ﺑﺮرﺳﻲ و ﻣﻮارد ﺗﺄﻳﻴﺪ ﺷﺪه ﺑﻪ ﻋﻨﻮان اﺻﻼﺣﻴﻪ ﺷﻤﺎره

. اﺑﻼغ ﮔﺮدﻳﺪ276 ﻃﻲ ﺑﺨﺸﻨﺎﻣﻪ ﺷﻤﺎره

This standard specification is reviewed and

updated by the relevant technical committee on

Jan 2006, as amendment No. 1 by circular No.

276.

:2 ﻳﺎدآوري

Note 2:

اﻳﻦ اﺳﺘﺎﻧﺪارد دو زﺑﺎﻧﻪ ﻧﺴﺨﻪ ﺑﺎزﻧﮕﺮي ﺷﺪه ﻣﺸﺨﺼﻪ اﺳﺘﺎﻧﺪارد

ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ1388 ﻣﻲﺑﺎﺷﺪ ﻛﻪ در دي ﻣﺎه ﺳﺎل

از اﻳﻦ ﭘﺲ.( اراﻳﻪ ﻣﻲﮔﺮدد1) اﻧﺠﺎم و ﺑﻪ ﻋﻨﻮان وﻳﺮاﻳﺶ

.( اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﻨﺴﻮخ ﻣﻲﺑﺎﺷﺪ0) وﻳﺮاﻳﺶ

This bilingual standard is a revised version of the

standard specification by the relevant technical

committee on Jan 2010 which is issued as

revision (1). Revision (0) of the said standard

specification is withdrawn.

:3 ﻳﺎدآوري

Note 3:

ﻣﺘﻦ اﻧﮕﻠﻴﺴﻲ،در ﺻﻮرت اﺧﺘﻼف ﺑﻴﻦ ﻣﺘﻦ ﻓﺎرﺳﻲ و اﻧﮕﻠﻴﺴﻲ

.ﻣﻼك ﻣﻲﺑﺎﺷﺪ

In case of conflict between Farsi and English

languages, English language shall govern.

ﻣﺮاﺟﻊ-2

2. REFERENCES

در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﻪ آﻳﻴﻦ ﻧﺎﻣﻪﻫﺎ و اﺳﺘﺎﻧﺪاردﻫﺎي ﺗﺎرﻳﺦ دار و

ﺗﺎ ﺣﺪي ﻛﻪ در، اﻳﻦ ﻣﺮاﺟﻊ.ﺑﺪون ﺗﺎرﻳﺦ زﻳﺮ اﺷﺎره ﺷﺪه اﺳﺖ

ﺑﺨﺸﻲ از اﻳﻦ اﺳﺘﺎﻧﺪارد،اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﺸﺨﺺ ﺷﺪه اﺳﺖ

وﻳﺮاﻳﺶ ﮔﻔﺘﻪ ﺷﺪه، در ﻣﺮاﺟﻊ ﺗﺎرﻳﺦ دار.ﻣﺤﺴﻮب ﻣﻲﺷﻮﻧﺪ

ﻣﻼك ﺑﻮده و ﺗﻐﻴﻴﺮاﺗﻲ ﻛﻪ ﺑﻌﺪ از ﺗﺎرﻳﺦ وﻳﺮاﻳﺶ ذﻛﺮ ﺷﺪه در

ﭘﺲ از ﺗﻮاﻓﻖ ﺑﻴﻦ ﻛﺎرﻓﺮﻣﺎ و ﻓﺮوﺷﻨﺪه ﻗﺎﺑﻞ،آﻧﻬﺎ داده ﺷﺪه اﺳﺖ

آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻧﻬﺎ ﺑﻪ، در ﻣﺮاﺟﻊ ﺑﺪون ﺗﺎرﻳﺦ.اﺟﺮا ﻣﻲﺑﺎﺷﺪ

.اﻧﻀﻤﺎم ﻛﻠﻴﻪ اﺻﻼﺣﺎت و ﭘﻴﻮﺳﺖﻫﺎي آن ﻣﻼك ﻋﻤﻞ ﻣﻲﺑﺎﺷﻨﺪ

Throughout this Standard the following dated and

undated standards/codes are referred to. These

referenced documents shall, to the extent specified

herein, form a part of this standard. For dated

references, the edition cited applies. The

applicability of changes in dated references that

occur after the cited date shall be mutually agreed

upon by the Company and the Vendor. For

undated references, the latest edition of the

referenced documents (including any supplements

and amendments) applies.

5

Jan. 2010/ 1388 دي

ASME

(AMERICAN

SOCIETY

MECHANICAL ENGINEERS)

IPS-E-PR-880(1)

( )اﻧﺠﻤﻦ ﻣﻬﻨﺪﺳﺎن ﻣﻜﺎﻧﻴﻚ آﻣﺮﻳﻜﺎASME

OF

1 ﺑﺨﺶ، ﻗﺴﻤﺖ ﻫﺸﺘﻢASME

" آﻳﻴﻦ ﻧﺎﻣﻪ ﻇﺮوف ﺗﺤﺖ ﻓﺸﺎر و دﻳﮓ

2007 وﻳﺮاﻳﺶ:،"ﺑﺨﺎر

ASME Section VIII, Div.1

”Boiler and Pressure Vessel,

Code”. Edition 2007”

( ) ﻣﻮﺳﺴﻪ ﻧﻔﺖ آﻣﺮﻳﻜﺎAPI

API (AMERICAN PETROLEUM INSTITUTE)

API Spec. 12J "Specification for Oil and Gas

Separators", 7th. Ed., Oct. 1989

"ﻣﺸﺨﺼﺎت ﺑﺮاي ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي

1989 اﻛﺘﺒﺮ، وﻳﺮاﻳﺶ ﻫﻔﺘﻢ، ﮔﺎز،ﻧﻔﺖ

API Spec.12J

API 510

:"آﻳﻴﻦ ﻧﺎﻣﻪ ﺑﺎزرﺳﻲ ﻇﺮوف ﺗﺤﺖ ﻓﺸﺎر

ﺗﻌﻤﻴﺮات و، ﻃﺒﻘﻪ ﺑﻨﺪي،ﺑﺎزرﺳﻲ

ﺟﺎﻳﮕﺰﻳﻨﻲ ﺣﻴﻦ ﻛﺎر " وﻳﺮاﻳﺶ ﻧﻬﻢ

.2006 ژوﺋﻦ

API 510

“Pressure Vessel Inspection,

Code: In Service Inspection,

Rating, Repair, and Alteration”.

9th Ed., June 2006.

( )اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮانIPS

IPS (IRANIAN PETROLEUM STANDARDS)

IPS-E-GN-100 “Engineering

Units”

Standard

" " اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي واﺣﺪﻫﺎIPS-E-GN-100

for

IPS-E-PR-460 “Engineering Standard for

Process Design of Flare and

Blowdown Systems”

" اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي ﻃﺮاﺣﻲ

"ﻓﺮاﻳﻨﺪي ﺳﺎﻣﺎﻧﻪﻫﺎي ﻣﺸﻌﻞ و ﺗﺨﻠﻴﻪ

IPS-E-PR-460

IPS-G-ME-150 “Engineering and Material

Standard for Towers, Reactors,

Pressure Vessels & Internals”

" اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ و ﻣﻮاد ﺑﺮاي

ﺑﺮﺟﻬﺎ راﻛﺘﻮرﻫﺎ ﻣﺨﺎزن ﺗﺤﺖ ﻓﺸﺎر و

"اﺟﺰاء داﺧﻠﻲ

IPS-E-PR-150

ﺗﻌﺎرﻳﻒ و واژﮔﺎن-3

3. DEFINITIONS AND TERMINOLOGY

در زﻳﺮ ﻳﻚ واژه ﻧﺎﻣﻪ از اﺻﻄﻼﺣﺎت ﻣﻮرد اﺳﺘﻔﺎده در ﺟﺪا

ﻣﺎﻳﻊ و ﻓﻦ آوري ﺟﺪاﺳﺎزي آورده ﺷﺪه-(ﻛﻨﻨﺪهﻫﺎي ﮔﺎز)ﺑﺨﺎر

.اﺳﺖ

The following is a glossary of terms used in the

gas(vapor)-liquid separator and separation

technology.

ﻣﻨﻌﻘﺪ ﻛﻨﻨﺪ ه1-3

3.1 Coalescer

ﻳﻚ ﻇﺮف ﻓﺮاﻳﻨﺪي ﻣﻜﺎﻧﻴﻜﻲ ﻫﻤﺮاه ﺑﺎ ﻳﻚ ﭘﺮﻛﻨﻨﺪه ﻣﺮﻃﻮب ﺑﺎ

ﺳﻄﺢ زﻳﺎد ﻛﻪ در آن ﻗﻄﺮات ﻣﺎﻳﻊ ﺟﻤﻊ ﺷﺪه از ﻓﺎز دوم )ﺑﺮاي

ﻣﺜﺎل ﮔﺎز ﻳﺎ ﻣﺎﻳﻊ اﻣﺘﺰاج ﻧﺎﭘﺬﻳﺮ( ﺑﻮﺳﻴﻠﻪ ﻧﻴﺮوي ﮔﺮاﻧﺶ ﺟﺪا

.ﻣﻲﮔﺮدد

A mechanical process vessel with wettable, highsurface area packing on which liquid droplets

consolidate for gravity separation from a second

phase (for example gas or immiscible liquid).

ﺣﺠﻢ ﻛﻨﺘﺮﻟﻲ2-3

3.2 Control Volume

ﻳﻚ ﺣﺠﻢ ﻣﻌﻴﻨﻲ از ﻣﺎﻳﻊ ﻛﻪ ﺑﺮاي ﻫﺪف ﻛﻨﺘﺮل و ﺣﻔﻆ

ﻣﺤﺪودﻳﺖ ﺳﺮﻋﺖ ﺑﺮاي ﮔﺎز زداﻫﺎ و ﻣﻘﺎﺑﻠﻪ ﺑﺎ ﻛﻒ در ﺟﺪا

. ﻣﻲ ﺑﺎﺷﺪ،ﻛﻨﻨﺪهﻫﺎ

A certain liquid volume necessary for control

purposes and for maintaining the velocity limit

requirement for degassing and to counter foam in

separators.

ﻣﺎﻳﻊ- ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻣﺘﺪاول ﮔﺎز3-3

3.3 Conventional Gas-Liquid Separator

در اﻳﻦ اﺳﺘﺎﻧﺪارد واژه ﺟﺪا ﻛﻨﻨﺪه ﻣﺘﺪاول ﮔﺎز – ﻣﺎﻳﻊ ﺑﻪ

ﺟﺪاﻛﻨﻨﺪه ﻫﺎي ﻋﻤﻮدي و اﻓﻘﻲ ﮔﻔﺘﻪ ﻣﻲ ﺷﻮد ﻛﻪ ﮔﺎز و ﻣﺎﻳﻊ را

In this Standard, the term "Conventional GasLiquid Separator" is referred to vertical or

horizontal separators in which gas and liquid are

6

Jan. 2010/ 1388 دي

separated by means of gravity settling with or

without a mist eliminating device.

IPS-E-PR-880(1)

ﺑﻮﺳﻴﻠﻪ ﺗﻪ ﻧﺸﻴﻨﻲ ﺛﻘﻠﻲ ﻫﻤﺮاه ﻳﺎ ﺑﺪون ﻫﻤﺮاﻫﻲ دﺳﺘﮕﺎه ﻫﺎي

.ﻗﻄﺮه ﮔﻴﺮ ﺗﻔﻜﻴﻚ ﻣﻲ ﻛﻨﻨﺪ

ارﺗﻔﺎع ﺟﺪاﻳﺶ4-3

3.4 Disengaging Height

ارﺗﻔﺎﻋﻲ ﻛﻪ ﺑﻴﻦ ﭘﺎﻳﻴﻦ ﻻﻳﻪ ﺗﻮر ﺳﻴﻤﻲ و ﺳﻄﺢ ﻣﺎﻳﻊ در ﺟﺪا

.ﻛﻨﻨﺪه ﻫﺎي ﺑﺨﺎر ﻣﺎﻳﻊ ﻣﻲ ﺑﺎﺷﺪ

The height provided between bottom of the wiremesh pad and liquid level of a vapor-liquid

separator.

ﺻﺎﻓﻲ ﭘﺎرﭼﻪ اي5-3

3.5 Fabric Filter

ﺟﻤﻊ،واژه ﻋﻤﻮﻣﻲ ﺻﺎﻓﻲ ﻛﻴﺴﻪ اي ﻳﺎ ﻣﺤﻔﻈﻪ ﻫﺎي ﻛﻴﺴﻪ اي

ﻛﻨﻨﺪه ﻫﺎﻳﻲ ﻫﺴﺘﻨﺪ ﻛﻪ ﮔﺮد و ﺧﺎك از ﺟﺮﻳﺎن ﮔﺎز ﻏﺒﺎردار

.ﺑﻮﺳﻴﻠﻪ ﻋﺒﻮر از داﺧﻞ ﻧﻮﻋﻲ ﭘﺎرﭼﻪ از آن ﺟﺪا ﻣﻲ ﺷﻮد

Commonly termed "bag filters" or "baghouses",

are collectors in which dust is removed from the

gas stream by passing the dust-laden gas through a

fabric of some type.

ﻣﺨﺰن ﺗﺒﺨﻴﺮ آﻧﻲ6-3

3.6 Flash Tank

ﻇﺮﻓﻲ اﺳﺖ ﻛﻪ ﺑﺮاي ﺟﺪاﻛﺮدن ﮔﺎز آزاد ﺷﺪه در اﺛﺮ ﺗﺒﺨﻴﺮ آﻧﻲ

ﺣﺎﺻﻞ ﺷﺪه از اﻓﺖ ﻓﺸﺎر ﻣﺎﻳﻊ از ﻓﺸﺎر ﺑﺎﻻ ﺑﻪ ﻓﺸﺎر ﭘﺎﻳﻴﻦ ﺑﻜﺎر

.ﻣﻲ رود

A vessel used to separate the gas evolved from

liquid flashed from a higher pressure to a lower

pressure.

زﻣﺎن ﻣﺎﻧﺪ7-3

3.7 Hold-Up Time

زﻣﺎﻧﻲ اﺳﺖ ﻛﻪ در آن ﻣﻘﺪار ﻣﺎﻳﻊ ﺟﺪا ﺷﺪه در ﻳﻚ ﺟﺪا ﻛﻨﻨﺪه

ﻣﺎﻳﻊ ﺑﻪ ﻃﻮر واﻗﻌﻲ ﺑﺮاي اﻫﺪاف ﻛﻨﺘﺮﻟﻲ ﻳﺎ ﺟﺪاﺳﺎزي-ﮔﺎز

.ﺑﺨﺎرات در ﻇﺮف ﻣﻲ ﻣﺎﻧﺪ

A time period during which the amount of liquid

separated in a gas-liquid separator is actually in

the vessel for the purpose of control or vapor

separation.

ﻗﻄﺮه ﮔﻴﺮ8-3

3.8 Knock-Out

ﺟﺪاﺳﺎزي ﻛﻪ ﺑﺮاي ﺟﺪاﻛﺮدن ﻋﻤﺪه ﮔﺎز و ﻣﺎﻳﻊ ﻣﻮرد اﺳﺘﻔﺎده

: اﺳﺖ و ﻣﻲ ﺗﻮان آن را ﺑﻪ دو دﺳﺘﻪ زﻳﺮ ﺗﻘﺴﻴﻢ ﻛﺮد

A separator used for a bulk separation of gas and

liquid. It falls into one of two categories as below:

اﻟﻒ( ﻗﻄﺮه ﮔﻴﺮ آب آزاد ﻇﺮﻓﻲ اﺳﺖ ﻛﻪ ﺑﺮاي ﺟﺪاﺳﺎزي

a) The free water knock-out is a vessel used to

separate free water from a flow stream of gas,

oil, and water. The gas and oil usually leave

the vessel through the same outlet to be

processed by other equipment. The water is

removed for disposal.

ﮔﺎز و. ﻧﻔﺖ ﻳﺎ آب اﺳﺘﻔﺎده ﻣﻲ ﺷﻮد،آب آزاد ار ﺟﺮﻳﺎن ﮔﺎز

ﻧﻔﺖ اﻏﻠﺐ از ﻳﻚ ﺧﺮوﺟﻲ ﺑﺮاي ﻓﺮآورش در ﺗﺠﻬﻴﺰ دﻳﮕﺮ از

. آب ﺟﻬﺖ دﻓﻊ ﺟﺪا ﻣﻲ ﺷﻮد.ﻇﺮف ﺧﺎرج ﻣﻲ ﺷﻮﻧﺪ

ب( ﻗﻄﺮه ﮔﻴﺮ ﻛﻞ ﻣﺎﻳﻌﺎت ﻛﻪ ﻋﻤﻮﻣﺎً ﺑﺮاي ﺣﺬف ﻣﺎﻳﻌﺎت

b) The total liquid knock-out is normally used

to remove the combined liquids from a gas

stream.

.ﻫﻤﺮاه ﺟﺮﻳﺎن ﮔﺎز اﺳﺘﻔﺎده ﻣﻲ ﺷﻮد

آﺑﭽﻜﺎن ﺧﻂ9-3

3.9 Line Drip

دﺳﺘﮕﺎﻫﻲ ﻛﻪ ﻣﻌﻤﻮﻻً در ﺧﻄﻮط ﻟﻮﻟﻪ اي ﻛﻪ ﻧﺴﺒﺖ ﮔﺎز ﺑﻪ ﻣﺎﻳﻊ

ﺑﺎﻻﻳﻲ دارﻧﺪ ﺑﺮاي دﻓﻊ ﻣﺎﻳﻊ ﺟﺪا ﺷﺪه از ﺟﺮﻳﺎن ﮔﺎز ﻣﻮرد

.اﺳﺘﻔﺎده ﻗﺮار ﻣﻲ ﮔﻴﺮد و ﺑﺮاي ﻛﻠﻴﻪ ﻣﺎﻳﻌﺎت ﺿﺮوري ﻧﻴﺴﺖ

A device typically used in pipelines with very

high gas-to-liquid ratios to remove only free liquid

from a gas stream,and not necessarily all the

liquid.

( ﻗﻄﺮه ﮔﻴﺮ) اﺳﺘﺨﺮاج ﻛﻨﻨﺪه ﻗﻄﺮه10-3

3.10 Demister(Mist Extractor)

، ﺟﺪا ﻛﻨﻨﺪه ﻫﺎ،دﺳﺘﮕﺎﻫﻲ اﺳﺖ ﻛﻪ در ﺑﺎﻻي دﺳﺘﮕﺎه ﻋﺎري ﺳﺎز

ﺗﺎ ﻗﻄﺮات،ﻇﺮوف داراي ﺳﻴﻨﻲ ﻳﺎ ﭘﺮﻛﻦ و ﻏﻴﺮه ﻧﺼﺐ ﺷﺪه

.ﻣﺎﻳﻌﻲ ﻛﻪ ﻫﻤﺮاه ﺟﺮﻳﺎن ﮔﺎز ﻫﺴﺘﻨﺪ را ﺟﺪا ﻛﻨﺪ

A device installed in the top of scrubbers,

separators, tray or packed vessels, etc. to remove

liquid droplets entrained in a flowing gas stream.

7

Jan. 2010/ 1388 دي

IPS-E-PR-880(1)

ﻋﺎري ﺳﺎز11-3

3.11 Scrubber

ﻳﻚ ﻧﻮع ﺟﺪا ﻛﻨﻨﺪه اﺳﺖ ﻛﻪ ﺑﺮاي ﺟﺮﻳﺎﻧﻲ ﻛﻪ ﺑﻪ ﻃﻮر ﻏﻴﺮ

ﻣﻌﻤﻮل ﻧﺴﺒﺖ ﮔﺎز ﺑﻪ ﻣﺎﻳﻊ آﻧﻬﺎ ﺑﺎﻻﺳﺖ ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار

، واﺣﺪﻫﺎي اﺳﺘﺨﺮاج، و ﻣﻌﻤﻮﻻً در ﺗﺮﻛﻴﺐ ﺑﺎ ﻧﻤﮕﻴﺮﻫﺎ.ﻣﻲ ﮔﻴﺮد

اﺑﺰارآﻻت ﻳﺎ ﻛﻤﭙﺮﺳﻮرﻫﺎ ﺑﺮاي ﻣﺤﺎﻓﻈﺖ از ﻣﺎﻳﻌﺎت ﻫﻤﺮاه ﺑﻜﺎر

.ﻣﻲ رود

A type of separator which has been designed to

handle flow streams with unusually high gas-toliquid ratios. These are commonly used in

conjunction with dehydrators, extraction plants,

instruments, or compressors for protection from

entrained liquids.

ﻟﺨﺘﻪ ﮔﻴﺮ12-3

3.12 Slug Catcher

ﺟﺪا ﻛﻨﻨﺪه وﻳﮋه اي اﺳﺖ ﻛﻪ ﻗﺎدر ﺑﻪ ﺟﺬب ﺣﺠﻢ ﺑﺰرگ ﻣﺎﻳﻌﺎت

.ﻣﻮﺟﻮد در ﺟﺮﻳﺎن در ﻓﻮاﺻﻞ ﻧﺎﻣﻨﻈﻢ اﺳﺖ

A particular separator design able to absorb

sustained in-flow of large liquid volumes at

irregular intervals.

ﺑﺎزده ﻫﺪف13-3

3.13 Target Efficiency

،ﺑﺨﺸﻲ از ذرات ﻳﺎ ﻗﻄﺮات ﻫﻤﺮاه ﺳﻴﺎل ورودي ﺑﻪ ﺟﺪا ﻛﻨﻨﺪه

.ﻛﻪ ﺳﻴﺎل ﺑﺎ ﻋﺒﻮر از ﺷﻴﺊ دروﻧﻲ ﺑﻪ آن ﺑﺮﺧﻮرد ﻣﻲ ﻛﻨﺪ

The fraction of particles or droplets in the

entraining fluid of a separator, moving past an

object in the fluid, which impinge on the object.

ﺳﺮﻋﺖ ﻧﻬﺎﻳﻲ ﻳﺎ ﺳﺮﻋﺖ ﺳﻘﻮط14-3

3.14 Terminal Velocity or Drop-Out Velocity

ﺳﺮﻋﺘﻲ ﻛﻪ در ﻃﻮل آن ﻳﻚ ذره ﻳﺎ ﻗﻄﺮه ﻛﻮﭼﻚ ﻛﻪ ﺗﺤﺖ اﺛﺮ

ﻫﻨﮕﺎﻣﻲ ﻛﻪ ﻧﻴﺮوي،ﻧﻴﺮوي ﮔﺮاﻧﺶ در ﺣﺎل ﺳﻘﻮط اﺳﺖ

(ﭘﺲ راﻧﺶ)درگ( ﺑﺎ ﻧﻴﺮوي ﮔﺮاﻧﺶ ﻣﺘﻌﺎدل ﺷﻮد ذره )ﻳﺎ ﻗﻄﺮه

.ﺑﺎ ﺳﺮﻋﺖ ﺛﺎﺑﺖ ﻣﻲ اﻓﺘﺪ

The velocity at which a particle or droplet will fall

under the action of gravity, when drag force just

balances gravitational force and the particle (or

droplet) continues to fall at constant velocity.

ﻓﻀﺎي ﺑﺨﺎر15-3

3.15 Vapor Space

ﻣﺎﻳﻌﺎت ﻛﻪ در ﺑﺎﻻي ﺳﻄﺢ ﻣﺎﻳﻊ در-ﺣﺠﻤﻲ از ﺟﺪاﻛﻨﻨﺪه ﺑﺨﺎر

.ﺟﺪا ﻛﻨﻨﺪه اﺳﺖ

The volume of a vapor liquid separator above the

liquid level.

ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻛﺎري ﻣﺠﺎز16-3

3.16 Maximum Allowable Working Pressure

ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻣﺠﺎز در، (MAWP) ﺣﺪاﻛﺜﺮ ﻓﺸﺎر ﻛﺎري ﻣﺠﺎز

اﺳﺖ ﻛﻪ در ﺑﺎﻻي دﺳﺘﮕﺎه ﺟﺪا ﻛﻨﻨﺪه درASME آﻳﻴﻦ ﻧﺎﻣﻪ

.ﺷﺮاﻳﻂ ﻋﺎدي ﻋﻤﻠﻴﺎﺗﻲ در ﻳﻚ درﺟﻪ ﺣﺮارت ﻣﻌﻴﻦ ﻣﻲ ﺑﺎﺷﺪ

The maximum allowable working pressure

(MAWP) is the maximum pressure, permissible

by the ASME Code at the top of the separator in

its normal operating position for a designated

temperature.

ﻓﺸﺎر ﻋﻤﻠﻴﺎﺗﻲ17-3

3.17 Operating Pressure

ﻓﺸﺎر ﻋﻤﻠﻴﺎﺗﻲ ﻓﺸﺎري اﺳﺖ ﻛﻪ در ﻇﺮف در ﻃﻮل ﻋﻤﻠﻴﺎت

ﺑﻴﺸﺘﺮ ﺷﻮد وMAWP ﻓﺸﺎر ﻋﻤﻠﻴﺎﺗﻲ ﻧﺒﺎﻳﺪ از.وﺟﻮد دارد

ﻣﻌﻤﻮﻻً در ﺳﻄﺢ ﻣﻨﺎﺳﺒﻲ ﭘﺎﻳﻴﻦ ﺗﺮ از ﻓﺸﺎر ﺗﻨﻈﻴﻢ ﺗﺠﻬﻴﺰات

ﺗﺨﻠﻴﻪ ﻓﺸﺎر ﻧﮕﻪ داﺷﺘﻪ ﻣﻲ ﺷﻮد ﺗﺎ از ﺑﺎزﺷﺪن ﻣﺪاوم آﻧﻬﺎ

.ﺟﻠﻮﮔﻴﺮي ﻛﻨﺪ

The operating pressure is the pressure in the

vessel during normal operation. The operating

pressure shall not exceed the MAWP, and is

usually kept at a suitable level below the setting of

the pressure relieving devices to prevent their

frequent opening.

ﺧﻮردﮔﻲ18-3

3.18 Corrosion

ﺗﺨﺮﻳﺐ ﻓﻠﺰ ﺗﻮﺳﻂ واﻛﻨﺸﻬﺎي ﺷﻴﻤﻴﺎﻳﻲ ﻳﺎ،ﺧﻮردﮔﻲ

.اﻟﻜﺘﺮو ﺷﻴﻤﻴﺎﻳﻲ ﺑﺎ ﻣﺤﻴﻂ آن ﺗﻌﺮﻳﻒ ﻣﻲ ﺷﻮد

Corrosion is defined as the destruction of a metal

by chemical or electrochemical reaction with its

environment.

ﻧﺸﺎﻧﻪ ﻫﺎ و اﺧﺘﺼﺎرات-4

4. SYMBOLS AND ABBREVIATIONS

ﻓﻬﺮﺳﺖ ﻧﺸﺎﻧﻪ ﻫﺎ و اﺧﺘﺼﺎرات ﭘﺎراﻣﺘﺮﻫﺎي ﻣﻮرد اﺳﺘﻔﺎده،در زﻳﺮ

The following is the list of symbols and

8

Jan. 2010/ 1388 دي

abbreviations of parameters used in this Standard

and their units of measurement:

IPS-E-PR-880(1)

:در اﻳﻦ اﺳﺘﺎﻧﺪارد و واﺣﺪﻫﺎي اﻧﺪازه ﮔﻴﺮي آﻧﻬﺎ آورده ﺷﺪه اﺳﺖ

.(m2) = ﺳﻄﺢ ﻣﻘﻄﻊ ﺑﺮاي ﻋﺒﻮر ﺟﺮﻳﺎن ﮔﺎزA

.(( )ﻣﺘﺮ1 ﻣﺮﺑﻊ ورودي ﺳﻴﻜﻠﻮن)ﻧﻮع- = ﻃﻮل ﺿﻠﻊa

A

= Cross-sectional area for gas flow, (m²).

a

= Length of side, square cyclone inlet,

(type 1), (m).

C

= Drag coefficient of particle or droplet,

(dimensionless).

Df

= Filter element outside diameter, (m).

Dp

= Droplet or particle diameter, (m).

Dv

= Internal diameter of a separator vessel,

(m).

dn

= Nozzle diameter, (m).

dn1

= Feed nozzle

(m)

.( = ﻗﻄﺮ ﻧﺎزل )ﻣﺘﺮdn

.( = ﻧﺎزل ﺧﻮراك )ﻣﺘﺮdn1

dn2

= Gas outlet nozzle

(m)

.( = ﻧﺎزل ﺧﺮوﺟﻲ ﮔﺎز )ﻣﺘﺮdn2

dn3

= Liquid outlet nozzle (m)

.( = ﻧﺎزل ﺧﺮوﺟﻲ ﻣﺎﻳﻊ )ﻣﺘﺮdn3

d1

= Internal diameter of feed inlet, (m).

.( = ﻗﻄﺮ داﺧﻠﻲ ورودي ﺧﻮراك )ﻣﺘﺮd1

d2

= Internal diameter of gas outlet, (m).

.( = ﻗﻄﺮ داﺧﻠﻲ ﺧﺮوﺟﻲ ﮔﺎز )ﻣﺘﺮd2

d3

= Diameter of cylindrical cyclone baffle,

(m).

. = ﻗﻄﺮ ﺗﻴﻐﻪ ﺳﻴﻜﻠﻮن اﺳﺘﻮاﻧﻪ ايd3

g

= Local acceleration due to gravity,

(m/s²).

.( = ﺷﺘﺎب ﮔﺮاﻧﺶ ﻣﺤﻞ)ﻣﺘﺮ ﺑﺮ ﻣﺠﺬور ﺛﺎﻧﻴﻪg

H

= Height, (tangent to tangent) of vessel,

(m).

.( = ارﺗﻔﺎع )ﻣﻤﺎس ﺑﻪ ﻣﻤﺎس( ﻇﺮف )ﻣﺘﺮH

Hc

= Height of cyclone (from bottom plate to

outlet pipe), (m).

.( = ارﺗﻔﺎع ﺳﻴﻜﻠﻮن )از ﺻﻔﺤﻪ ﭘﺎﻳﻴﻦ ﺗﺎ ﻟﻮﻟﻪ ﺧﺮوﺟﻲ()ﻣﺘﺮHc

h

= Height of vessel required for hold-up,

(m).

.( = ارﺗﻔﺎع ﻣﻮرد ﻧﻴﺎز ﻇﺮف ﺑﺮاي زﻣﺎن ﻣﺎﻧﺪ)ﻣﺘﺮh

K

= Empirical constant for separator sizing,

(m/s).

.( = ﺛﺎﺑﺖ ﺗﺠﺮﺑﻲ ﺑﺮاي ﺗﻌﻴﻴﻦ اﺑﻌﺎد ﺟﺪا ﻛﻨﻨﺪه)ﻣﺘﺮK

KCR

= Proportionality constant.

.( = ﺿﺮﻳﺐ ﭘﺲ راﻧﺶ )درگ( ذره ﻳﺎ ﻗﻄﺮه )ﺑﻲ ﺑﻌﺪC

.( = ﻗﻄﺮ ﺑﻴﺮوﻧﻲ ﻋﺎﻣﻞ ﺻﺎﻓﻲ)ﻣﺘﺮDf

.( = ﻗﻄﺮ ذره ﻳﺎ ﻗﻄﺮه )ﻣﺘﺮDp

.( = ﻗﻄﺮ داﺧﻠﻲ ﻇﺮف ﺟﺪا ﻛﻨﻨﺪه )ﻣﺘﺮDv

= ﺛﺎﺑﺖ ﺗﻨﺎﺳﺐKCR

LA (L) = Level Alarm (Low)

.( = ﻫﺸﺪار ﺳﻄﺢ )ﭘﺎﻳﻴﻦLA (L)

LA (H) = Level Alarm (High)

.( = ﻫﺸﺪار ﺳﻄﺢ )ﺑﺎﻻLA (H)

.()ﻣﺘﺮ،ﻃﻮل ﻋﺎﻣﻞ ﺻﺎﻓﻲ

= Lf

ﻃﻮل ﻇﺮف اﻓﻘﻲ ﺟﺪا ﻛﻨﻨﺪه)ﻣﻤﺎس ﺑﻪ

= Lv

.()ﻣﺘﺮ،(ﻣﻤﺎس

Lf

= Filter element length, (m).

Lv

= Length of a horizontal separator vessel,

(tangent to tangent), (m).

Mg

= Mass flow rate of gas, (kg/s).

Ml

= Mass flow rate of liquid, (kg/s).

Pin

= Pressure at inlet, (kPa).

Pout

= Pressure at outlet, (kPa).

Q

= Volumetric load factor, (m³/s).

.( = ﻣﻴﺰان ﺟﺮﻳﺎن ﺟﺮﻣﻲ ﮔﺎز)ﻛﻴﻠﻮ ﮔﺮم در ﺛﺎﻧﻴﻪMg

.( = ﻣﻴﺰان ﺟﺮﻳﺎن ﺟﺮﻣﻲ ﻣﺎﻳﻊ)ﻛﻴﻠﻮ ﮔﺮم در ﺛﺎﻧﻴﻪMl

.( = ﻓﺸﺎر در ورودي )ﻛﻴﻠﻮ ﭘﺎﺳﻜﺎلPin

.( = ﻓﺸﺎر در ﺧﺮوﺟﻲ)ﻛﻴﻠﻮ ﭘﺎﺳﻜﺎلPout

.( = ﺿﺮﻳﺐ ﺣﺠﻤﻲ ﺑﺎر)ﻣﺘﺮﻣﻜﻌﺐ در ﺛﺎﻧﻴﻪQ

9

Jan. 2010/ 1388 دي

IPS-E-PR-880(1)

Qg

= Volumetric flow rate of gas, (m³/s).

Ql

= Volumetric flow rate of liquid, (m³/s).

Qmax

= Maximum value of Q, (m³/s).

R

= Radius of cyclone scroll f, (m).

Re

= Reynolds number, (dimensionless).

s

= Width of split between cyclone bottom

plate and wall, (m).

T

= Time (min).

t

= Thickness of demister pad, (m).

Vc

= Critical gas velocity necessary for

particles to drop or settle, (m/s).

Vg,in

= Gas velocity at inlet, (superficial),

(m/s).

Vg,out

= Gas velocity at outlet, (m/s).

.( = ﺳﺮﻋﺖ ﮔﺎز در ﺧﺮوﺟﻲ)ﻣﺘﺮ در ﺛﺎﻧﻴﻪVg,out

Vm

= Mixture velocity at inlet = (Qg +

Ql)/( dn²/4), (m/s).

.( = ﺳﺮﻋﺖ ﻣﺨﻠﻮط در ورودي)ﻣﺘﺮ در ﺛﺎﻧﻴﻪVm

Vt

= Terminal or free settling velocity of

particle or droplet and terminal rising

velocity of bubbles, in liquid phase, (m/s).

= ﺳﺮﻋﺖ ﺣﺪ ﻳﺎ ﺳﺮﻋﺖ آزاد ﺗﻪ ﻧﺸﻴﻨﻲ ذره ﻳﺎ ﻗﻄﺮه وVt

.(ﺳﺮﻋﺖ ﻧﻬﺎﻳﻲ ﺑﺎﻻ آﻣﺪن ﺣﺒﺎﺑﻬﺎ در ﻓﺎز ﻣﺎﻳﻊ)ﻣﺘﺮ در ﺛﺎﻧﻴﻪ

.( = ﻣﻴﺰان ﺟﺮﻳﺎن ﺣﺠﻤﻲ ﮔﺎز)ﻣﺘﺮﻣﻜﻌﺐ در ﺛﺎﻧﻴﻪQg

.( = ﻣﻴﺰان ﺟﺮﻳﺎن ﺣﺠﻤﻲ ﻣﺎﻳﻊ )ﻣﺘﺮﻣﻜﻌﺐ در ﺛﺎﻧﻴﻪQl

.()ﻣﺘﺮ ﻣﻜﻌﺐ در ﺛﺎﻧﻴﻪQ = ﺣﺪاﻛﺜﺮ ﻣﻘﺪارQmax

.( = ﺷﻌﺎع ﭘﻴﭽﺶ ﺳﻴﻜﻠﻮن )ﻣﺘﺮR

. = ﻋﺪد رﻳﻨﻮﻟﺪزRe

( = ﻋﺮض ﺷﻜﺎف ﻣﺎ ﺑﻴﻦ ﺻﻔﺤﻪ ﺗﺤﺘﺎﻧﻲ ﺳﻴﻜﻠﻮن و دﻳﻮاره)ﻣﺘﺮs

.( = زﻣﺎن )دﻗﻴﻘﻪT

( = ﺿﺨﺎﻣﺖ ﺻﻔﺤﻪ ذره ﮔﻴﺮ)ﻣﺘﺮt

= ﺳﺮﻋﺖ ﺑﺤﺮاﻧﻲ ﮔﺎز ﻛﻪ ﺟﻬﺖ اﻓﺘﺎدن ﻳﺎ ﺗﻪ ﻧﺸﻴﻨﻲ ذراتVc

.(ﻻزم اﺳﺖ )ﻣﺘﺮ در ﺛﺎﻧﻴﻪ

.( = ﺳﺮﻋﺖ ﮔﺎز در ورودي)ﻇﺎﻫﺮي()ﻣﺘﺮ در ﺛﺎﻧﻴﻪVg,in

:ﺣﺮوف ﻳﻮﻧﺎﻧﻲ

Greek Letters:

l (gamma)

cSt(mm²/s) )ﮔﺎﻣﺎ( = ﮔﺮاﻧﺮوي ﺳﻴﻨﻤﺎﺗﻴﻜﻲ ﻣﺎﻳﻊ

= Liquid kinematic viscosity,

cSt(mm²/s)

(cp) )ﻣﻮ( = ﮔﺮاﻧﺮوي دﻳﻨﺎﻣﻴﻜﻲ ﻓﺎز ﭘﻴﻮﺳﺘﻪ؛µ

µ (mu) = Dynamic viscosity of continuous phase,

cP(mPa.s).

µg (mu)

= Dynamic viscosity of gas,

cP(mPa.s).

g (rho)

= Gas phase density, (kg/m³).

l (rho)

= Liquid phase density, (kg/m³).

m (rho)

= Mixture density at inlet =

(Mg+Ml)/(Qg+Q), (kg/m³).

l

(cp) = ﮔﺮاﻧﺮوي دﻳﻨﺎﻣﻴﻜﻲ ﮔﺎز ؛µg

.( = ﭼﮕﺎﻟﻲ ﻓﺎز ﮔﺎز )ﻛﻴﻠﻮ ﮔﺮم ﺑﺮ ﻣﺘﺮﻣﻜﻌﺐ g

.( = ﭼﮕﺎﻟﻲ ﻓﺎز ﻣﺎﻳﻊ)ﻛﻴﻠﻮ ﮔﺮم ﺑﺮ ﻣﺘﺮﻣﻜﻌﺐ l

.( = ﭼﮕﺎﻟﻲ ﻣﺨﻠﻮط در ورودي)ﻛﻴﻠﻮ ﮔﺮم ﺑﺮ ﻣﺘﺮﻣﻜﻌﺐ m

واﺣﺪﻫﺎ-5

5. UNITS

،(SI) اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺮ ﻣﺒﻨﺎي ﺳﺎﻣﺎﻧﻪ ﺑﻴﻦ اﻟﻤﻠﻠﻲ واﺣﺪﻫﺎ

ﻣﻲ ﺑﺎﺷﺪ ﻣﮕﺮ آﻧﻜﻪ درIPS-E-GN-100 ﻣﻨﻄﺒﻖ ﺑﺎ اﺳﺘﺎﻧﺪارد

.ﻣﺘﻦ اﺳﺘﺎﻧﺪارد ﺑﻪ واﺣﺪ دﻳﮕﺮي اﺷﺎره ﺷﺪه ﺑﺎﺷﺪ

This Standard is based on International System of

Units, (SI) as per IPS-E-GN-100 except where

otherwise specified.

ﻋﻤﻮﻣﻲ-6

6. GENERAL

، ﻣﺎﻳﻊ ﻋﻤﻮﻣﺎً ﻣﻲ ﺗﻮان ﺑﻪ دو ﮔﺮوه ﻋﻤﺪه- ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﮔﺎز

ﻋﺎري،ﻧﺴﺒﺖ ﺑﺎﻻي ﮔﺎز ﺑﻪ ﻣﺎﻳﻊ )ﻣﺜﻞ ﻇﺮوف ﻗﻄﺮه ﮔﻴﺮ ﻣﺸﻌﻞ

ﺳﺎزﻫﺎ( و ﻧﺴﺒﺖ ﭘﺎﻳﻴﻦ ﮔﺎز ﺑﻪ ﻣﺎﻳﻊ) ﻣﺜﻞ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي

در اﻳﻦ اﺳﺘﺎﻧﺪارد. ﻣﺨﺎزن ﺗﺒﺨﻴﺮ آﻧﻲ( ﺗﻘﺴﻴﻢ ﻛﺮد،ﮔﺎز/ﻧﻔﺖ

Gas-Liquid Separators can be generally divided

into two main groups, high gas to liquid ratio (e.g.

flare knock-out drums, scrubbers), and low gas to

liquid ratio (e.g. oil/gas separators, flash tanks)

separators. In this Standard, process aspects of

10

Jan. 2010/ 1388 دي

three types of most frequently used gas (vapor)liquid separators are discussed more or less in

details, these three types are:

IPS-E-PR-880(1)

ﻣﺎﻳﻊ-(ﺟﻨﺒﻪ ﻫﺎي ﻓﺮاﻳﻨﺪي ﺳﻪ ﻧﻮع از ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﮔﺎز)ﺑﺨﺎر

ﻛﻪ اﻏﻠﺐ ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﻣﻲ ﮔﻴﺮﻧﺪ ﺑﺎ ﺟﺰﺋﻴﺎت ﺑﻴﺸﺘﺮ ﻳﺎ

: اﻳﻦ ﺳﻪ ﻧﻮع ﻋﺒﺎرﺗﻨﺪ از.ﻛﻤﺘﺮ ﺗﺸﺮﻳﺢ ﺷﺪه اﻧﺪ

ﻣﺎﻳﻊ )ﻛﻪ ﺷﺎﻣﻞ ﺟﺪا- ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻣﺘﺪاول ﮔﺎز(ﮔﺎز اﺳﺖ/ﻛﻨﻨﺪهﻫﺎي ﻧﻔﺖ

ﻣﺎﻳﻊ ﮔﺮﻳﺰ از ﻣﺮﻛﺰ- ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﮔﺎز ﻣﺎﻳﻊ- ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﺻﺎﻓﻲ دار ﮔﺎز-

-Conventional gas-liquid separators (including

oil/gas separators).

- Centrifugal gas-liquid separators.

- Gas-liquid filter separators.

ﻣﺨﺰن ﻗﻄﺮه ﮔﻴﺮ،ﻧﻮع دﻳﮕﺮي ﻛﻪ ﻣﻮرد اﺳﺘﻔﺎده آن زﻳﺎد اﺳﺖ

ﻣﺸﻌﻞ اﺳﺖ ﻛﻪ ﺑﻄﻮر ﻣﺨﺘﺼﺮ ﺑﺪان اﺷﺎره ﺷﺪه زﻳﺮا درﺑﺎره

" ﻃﺮاﺣﻲ ﻓﺮآﻳﻨﺪي ﻣﺸﻌﻞ وIPS-E-PR-460 ﺟﺰﺋﻴﺎت آن در

.ﺳﺎﻣﺎﻧﻪ ﻫﺎي ﺗﺨﻠﻴﻪ" ﺗﻮﺿﻴﺢ داده ﺷﺪه اﺳﺖ

ﭘﻴﻮﺳﺖ1-اﻧﻮاع ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻣﻜﺎﻧﻴﻜﻲ ﺑﻄﻮر ﻛﻠﻲ در ﺷﻜﻞ و

.)و( ﻧﺸﺎن داده ﺷﺪه اﻧﺪ

-(ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد اﻟﺰاﻣﺎت ﻓﺮآﻳﻨﺪي ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﮔﺎز)ﺑﺨﺎر

" اﻟﺰاﻣﺎت ﻓﺮآﻳﻨﺪيIPS-E-PR-850 1-6 ﻣﺎﻳﻊ ﻣﻄﺎﺑﻖ ﺑﻨﺪ

.ﺑﺮاي ﻇﺮوف و ﺟﺪا ﻛﻨﻨﺪه ﻫﺎ" ﺑﺎﺷﺪ

Another frequently used type i.e., flare knock-out

drum, is mentioned briefly since this type is

discussed in details in IPS-E-PR-460 Standard,

"Process Design of Flare and Blowdown

Systems".

Types of mechanical separators are generally

shown in Fig. F.1 of Appendix F.

The Process requirements of gas (vapor)-liquid

separators should be based on Item 6.1 of IPS-EPR-850, "Process Requirements of Vessels and

Separators".

ﻣﺎﻳﻊ- ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﮔﺎز1-6

6.1 Gas-Liquid Separators

ﻣﺎﻳﻊ ﻛﻪ اﻏﻠﺐ در ﻓﺮآﻳﻨﺪﻫﺎ اﺳﺘﻔﺎده-اﻧﻮاع ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﮔﺎز

:ﻣﻲ ﺷﻮﻧﺪ در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺗﺸﺮﻳﺢ ﺷﺪه اﻧﺪ ﻛﻪ ﻋﺒﺎرﺗﻨﺪ از

. ﻣﺎﻳﻊ- ﺟﺪا ﻛﻨﻨﺪه اي ﻣﺘﺪاول ﮔﺎز. ﺳﻴﻜﻠﻮﻧﻬﺎ.ﮔﺎز/ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻧﻔﺖ. ﻇﺮوف ﻗﻄﺮه ﮔﻴﺮ ﻣﺸﻌﻞ. ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﺻﺎﻓﻲ دار-

Gas-liquid separator types often used in processes

which are discussed in this Standard are:

- Conventional Gas/Liquid Separators.

- Cyclones.

- Oil/Gas Separators.

- Flare Knock-out Drums.

- Filter Separators.

ﻣﻜﺎﻧﻴﺰم ﻫﺎي ﺟﺪاﺳﺎزي2-6

6.2 Separation Mechanisms

ﻣﺎﻳﻊ ﻛﻪ اﻏﻠﺐ در ﺻﻨﺎﻳﻊ ﻣﻮرد-اﻛﺜﺮ ﻓﺮآﻳﻨﺪﻫﺎي ﺟﺪاﺳﺎزﻫﺎي ﮔﺎز

اﺳﺘﻔﺎده ﻗﺮار ﻣﻲ ﮔﻴﺮﻧﺪ ﺑﺮ اﺳﺎس ﻳﻚ ﻳﺎ ﺗﺮﻛﻴﺒﻲ از ﻣﻜﺎﻧﻴﺰم

"ﺑﺮﺧﻮرد ﻛﺮدن" و "ﮔﺮﻳﺰ از،"ﻫﺎي "ﺗﻪﻧﺸﻴﻨﻲ ﺑﺎ ﻧﻴﺮوي ﺟﺎذﺑﻪ

ﺑﺮﺧﻲ از اﻧﻮاع "ﺻﺎف ﻛﺮدن" ﺑﻨﺪرت در اﻳﻦ.ﻣﺮﻛﺰ" ﻣﻲ ﺑﺎﺷﺪ

اﺻﻮل ﺟﺪاﺳﺎزي ﻣﻜﺎﻧﻴﻜﻲ.زﻣﻴﻨﻪ ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﻣﻲ ﮔﻴﺮﻧﺪ

و ﺻﺎف ﻛﺮدن، ﮔﺮاﻧﺶ،را ﻣﻲﺗﻮان ﺑﻄﻮر ﻛﻠﻲ ﺑﻪ اﻧﺪازه ﺣﺮﻛﺖ

.دﺳﺘﻪ ﺑﻨﺪي ﻛﺮد ﻛﻪ ﺑﻄﻮر ﺧﻼﺻﻪ در ﭘﺎﻳﻴﻦ ﺷﺮح داده ﻣﻲ ﺷﻮد

ﺑﻌﻨﻮان ﻳﻚ ﻗﺎﻋﺪه ﻛﻠﻲ ﺑﺎﻳﺪ ﺗﻮﺟﻪ داﺷﺖ ﺟﺪاﺳﺎزي ﻣﻜﺎﻧﻴﻜﻲ

ﻫﻨﮕﺎﻣﻲ اﺗﻔﺎق ﻣﻲ اﻓﺘﺪ ﻛﻪ ﭼﻨﺪﻳﻦ ﻓﺎز اﻣﺘﺰاج ﻧﺎﭘﺬﻳﺮ ﺑﺎ

.ﭼﮕﺎﻟﻲﻫﺎي ﻣﺘﻔﺎوت ﻣﻮﺟﻮد ﺑﺎﺷﻨﺪ

Gas-liquid separation processes most frequently

employed in industries are based on either one or

a

combination

of

"Gravity

Settling",

"Impingement"

and

"Centrifugation",

mechanisms. Some types of "Filtration" are

seldom employed in this field. The principles of

mechanical separation in general, can be classified

as momentum, gravity and filtration that are

briefly described in the following sections. Note

that as a general rule, mechanical separation

occurs only when the phases are immiscible and

have different densities.

ﺟﺪاﺳﺎزي ﻣﻜﺎﻧﻴﻜﻲ ﺗﻮﺳﻂ اﻧﺪازه ﺣﺮﻛﺖ1-2-6

6.2.1 Mechanical separation by momentum

ﻓﺎزﻫﺎي ﺳﻴﺎل ﺑﺎ ﭼﮕﺎﻟﻲ ﻫﺎي ﻣﺨﺘﻠﻒ داراي اﻧﺪازه ﺣﺮﻛﺖ ﻫﺎي

اﮔﺮ ﻳﻚ ﺟﺮﻳﺎن دو ﻓﺎز ﺑﺨﻮاﻫﺪ ﺑﻪ ﺗﻨﺪي ﺗﻐﻴﻴﺮ.ﻣﺘﻔﺎوت ﻫﺴﺘﻨﺪ

Fluid phases with different densities will have

different momentum. If a two phase stream

changes direction sharply, greater momentum will

11

Jan. 2010/ 1388 دي

not allow the particles of heavier phase to turn as

rapidly as the lighter fluid, so separation occurs.

Momentum is usually employed for bulk

separation of the two phases in a stream.

IPS-E-PR-880(1)

ﺟﻬﺖ ﺑﺪﻫﺪ اﻧﺪازه ﺣﺮﻛﺖ ﺑﻴﺸﺘﺮ ذرات ﻓﺎز ﺳﻨﮕﻴﻦ ﺗﺮ اﺟﺎزه

ﺑﻨﺎﺑﺮاﻳﻦ ﺟﺪاﺳﺎزي،ﻧﻤﻲدﻫﺪ ﻛﻪ ﺑﻪ ﺳﺮﻋﺖ ﻓﺎز ﺳﺒﻜﺘﺮ ﺑﭽﺮﺧﻨﺪ

اﻧﺪازه ﺣﺮﻛﺖ ﻣﻌﻤﻮﻻً در ﺟﺪاﺳﺎزي ﺗﻮده اي.اﺗﻔﺎق ﻣﻲ اﻓﺘﺪ

.ﺟﺮﻳﺎن دوﻓﺎز ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﻣﻲ ﮔﻴﺮد

ﺟﺪاﺳﺎزي ﻣﻜﺎﻧﻴﻜﻲ ﺗﻮﺳﻂ ﮔﺮاﻧﺶ2-2-6

6.2.2 Mechanical separation by gravity

ﻗﻄﺮات ﻣﺎﻳﻊ ﻳﺎ ذرات ﺟﺎﻣﺪ ﻫﻨﮕﺎﻣﻲ در ﻓﺎز ﮔﺎز ﺗﻪ ﻧﺸﻴﻦ

ﻣﻲﺷﻮﻧﺪ ﻛﻪ ﻧﻴﺮوي ﮔﺮاﻧﺶ ﻛﻪ ﺑﺮ روي ﻗﻄﺮه ﻳﺎ ذره ﻋﻤﻞ

ﻣﻲﻛﻨﺪ ﺑﺰرﮔﺘﺮ از ﻧﻴﺮوي ﭘﺲ راﻧﺶ )درگ( ﮔﺎزي ﺑﺎﺷﺪ ﻛﻪ

ﻫﻤﻴﻦ ﭘﺪﻳﺪه ﺑﺮاي ذرات.اﻃﺮاف ﻗﻄﺮه ﻳﺎ ذره ﺣﺮﻛﺖ ﻣﻲ ﻛﻨﺪ

ﺟﺎﻣﺪ ﻓﺎز ﻣﺎﻳﻊ و ﮔﻮي ﻣﺎﻳﻊ اﻣﺘﺰاج ﻧﺎﭘﺬﻳﺮ ﻛﻪ در ﻣﺎﻳﻊ دﻳﮕﺮ

ﺑﻠﻨﺪ ﺷﺪن ﺣﺒﺎﺑﻬﺎي ﺳﺒﻚ ﻣﺎﻳﻊ. اﺗﻔﺎق ﻣﻲ اﻓﺘﺪ،ﻏﻮﻃﻪ ور اﺳﺖ

ﻧﺘﺎﻳﺠﻲ ﻛﻪ از ﻋﻤﻞ ﻛﺮدن ﻧﻴﺮوي، ﻣﺜﻼ،ﻳﺎ ﮔﺎز در ﻓﺎز ﻣﺎﻳﻊ

در ﺧﺼﻮص ﺗﻪ.ﮔﺮاﻧﺸﻲ از ﻫﻤﻴﻦ ﻗﺎﻧﻮن ﭘﻴﺮوي ﻣﻲ ﻛﻨﻨﺪ

ﻧﺸﻴﻨﻲ ﮔﺮاﻧﺸﻲ ﻳﻚ ﺗﺼﻮﻳﺮ ﻛﻠﻲ از ﻣﺤﺪوده ﺗﻮزﻳﻊ اﻧﺪازه ذرات

و ﻫﻤﭽﻨﻴﻦ ﻗﻮاﻧﻴﻦ ﺣﺎﻛﻢ ﺑﺮ ﺗﻪ ﻧﺸﻴﻨﻲ ذرات در ﻫﺮ ﻣﺤﺪوده در

. ﭘﻴﻮﺳﺖ اﻟﻒ آﻣﺪه اﺳﺖ1.ﺷﻜﻞ اﻟﻒ

Liquid droplets or solid particles will settle out of

a gas phase if the gravitational force acting on the

droplet or particle is greater than the drag force of

the gas flowing around the droplet or particle. The

same phenomenon happens for solid particles in

liquid phase and immiscible sphere of a liquid

immersed in another liquid. Rising of a light

bubble of liquid or gas in a liquid phase also

follows the same rules, i.e. results from the action

of gravitational force. Regarding gravity settling,

an overall picture of the range and distribution of

particle sizes as well as the significant laws

governing the particle settling in each range are

shown in Fig. A.1 of Appendix A.

ﺟﺪاﺳﺎزي ﻣﻜﺎﻧﻴﻜﻲ ﺗﻮﺳﻂ ﺻﺎف ﻛﺮدن3-2-6

6.2.3 Mechanical separation by filtration

ﻣﺎﻳﻊ ﺑﺎ- ﺟﺎﻣﺪ ﻳﺎ ﮔﺎز- ﺟﺪاﺳﺎزي ﻣﺨﻠﻮط ﺳﻴﺎل،ﺻﺎف ﻛﺮدن

ﻋﺒﻮر ﻗﺴﻤﺖ ﻋﻤﺪه ﻣﺎﻳﻊ از ﻳﻚ ﻣﺎﻧﻊ ﻣﺘﺨﻠﺨﻞ ﻛﻪ ﺑﺴﻴﺎري از

ﻣﻲ،ذرات ﺟﺎﻣﺪ و ﻣﺎﻳﻊ ﻣﺨﻠﻮط را ﻫﻨﮕﺎم ﻋﺒﻮر ﻧﮕﻪ ﻣﻲ دارد

.ﺑﺎﺷﺪ

ﻓﺮاﻳﻨﺪﻫﺎي ﺻﺎف ﻛﺮدن را ﻣﻲ ﺗﻮان ﺑﻪ ﺳﻪ دﺳﺘﻪ ﻛﻠﻲ ﺗﻘﺴﻴﻢ

ﺻﺎف ﻛﺮدن ﻋﻤﻴﻖ و ﺻﺎف ﻛﺮدن، ﺻﺎف ﻛﺮدن ﻛﻴﻜﻲ:ﻛﺮد

.ﺳﻄﺤﻲ

Filtration is the separation of a fluid-solid or

liquid-gas mixture involving passage of most of

the fluid through a porous barrier which retains

most of the solid or liquid particulates contained

in the mixture.

Filtration processes can be divided into three

broad categories, cake filtration, depth filtration

and surface filtration.

ﻧﻜﺎت ﻋﻤﻮﻣﻲ در ﻟﻮﻟﻪ ﻛﺸﻲ ﺟﺪا ﻛﻨﻨﺪه3-6

6.3 General Notes on Separator Piping

ﺑﻪ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎ ﺑﺎﻳﺪ ﺗﺎ ﺣﺪ اﻣﻜﺎن ﻛﻤﺘﺮﻳﻦ/ﻟﻮﻟﻪ ﻛﺸﻲ از

ﺗﻮﺻﻴﻪ.ﻣﻤﺎﻧﻌﺖ را در ﻛﺎرﻛﺮد ﻣﻨﺎﺳﺐ ﺟﺪاﻛﻨﻨﺪه داﺷﺘﻪ ﺑﺎﺷﺪ

:ﻣﻲ ﺷﻮد ﻣﺤﺪودﻳﺖ ﻫﺎي زﻳﺮ رﻋﺎﻳﺖ ﺷﻮﻧﺪ

Piping to and from the separator shall interfere as

little as possible with the good working of the

separator. The following constraints should be

observed:

a) There should be no valves, pipe expansions

or contractions within 10 pipe diameters of the

inlet nozzle.

اﻓﺰاﻳﺶ ﻳﺎ ﻛﺎﻫﺶ اﻧﺪازه،اﻟﻒ( ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد ﻫﻴﭻ ﺷﻴﺮ

b) There should be no bends within 10 pipe

diameters of the inlet nozzle. except the

following:

ﺑﺮاﺑﺮ ﻗﻄﺮ10 ب( ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد ﻫﻴﭻ ﺧﻤﻲ در ﻓﺎﺻﻠﻪ

- For knock-out drums and demisters, a bend

in the feed pipe is permitted if this is in a

vertical plane through the axis of the feed

nozzle.

ﻳﻚ ﺧﻢ در ﻟﻮﻟﻪ، ﺑﺮاي ﻣﺨﺎزن ﻗﻄﺮه ﮔﻴﺮ ﻳﺎ ﻧﻢ ﮔﻴﺮﺧﻮراك ﻣﺠﺎز ﻣﻲ ﺑﺎﺷﺪ اﮔﺮ در ﻳﻚ ﺻﻔﺤﻪ ﻋﻤﻮدي ﺑﺮ

.ﻣﺤﻮر ﻧﺎزل ﺧﻮراك ﺑﺎﺷﺪ

ﺑﺮاي ﺳﻴﻜﻠﻮن ﻫﺎ ﻳﻚ ﺧﻢ در ﻟﻮﻟﻪ ﺧﻮراك ﻣﺠﺎز ﻣﻲﺑﺎﺷﺪاﮔﺮ در ﻳﻚ ﺻﻔﺤﻪ اﻓﻘﻲ ﺑﺎﺷﺪ و اﻧﺤﻨﺎء ﻫﻢ ﺟﻬﺖ ﺑﺎ ﮔﺮداب

ﺑﺮاﺑﺮ ﻗﻄﺮ ﻧﺎزل ورودي وﺟﻮد ﻧﺪاﺷﺘﻪ10 ﻟﻮﻟﻪ در ﻓﺎﺻﻠﻪ

.ﺑﺎﺷﺪ

: ﺑﺠﺰ ﻣﻮارد زﻳﺮ.ﻧﺎزل ورودي وﺟﻮد ﻧﺪاﺷﺘﻪ ﺑﺎﺷﺪ

- For cyclones a bend in the feed pipe is

permitted if this is in a horizontal plane and

the curvature is in the same direction as the

12

Jan. 2010/ 1388 دي

cyclone vortex.

IPS-E-PR-880(1)

.ﺳﻴﻜﻠﻮن ﺑﺎﺷﺪ

ج( اﮔﺮ ﻣﻄﻠﻮب ﺑﺎﺷﺪ ﻣﻤﻜﻦ اﺳﺖ ﻳﻚ ﻛﺎﻫﻨﺪه ﻟﻮﻟﻪ در ﺧﻂ

c) If desired, a pipe reducer may be used in the

vapor line leading from the separator, but it

should be no nearer to the top of the vessel

than twice the outlet pipe diameter.

اﻣﺎ ﺗﻮﺻﻴﻪ،ﺑﺨﺎر ﺧﺮوﺟﻲ از ﺟﺪا ﻛﻨﻨﺪه اﺳﺘﻔﺎده ﺷﻮد

ﻧﻤﻲﺷﻮد ﻧﺰدﻳﻜﺘﺮ از دو ﺑﺮاﺑﺮ ﻗﻄﺮ ﻟﻮﻟﻪ ﺧﺮوﺟﻲ ﺗﺎ ﺑﺎﻻي

.ﻇﺮف ﺑﺎﺷﺪ

اﮔﺮ اﻳﻦ ﺷﺮاﻳﻂ ﻣﻬﻴﺎ ﻧﺒﺎﺷﺪ ﻣﻘﺪاري ﻛﺎﻫﺶ در ﺑﺎزدﻫﻲ

.اﺗﻔﺎق ﻣﻲ اﻓﺘﺪ

اﮔﺮ از ﺷﻴﺮ ﺧﻂ ﺧﻮراك ﻧﺰدﻳﻚ ﺑﻪ ﻣﺨﺰن ﻧﺘﻮان اﺟﺘﻨﺎب

ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد ﺗﺮﺟﻴﺤﺎً از ﺷﻴﺮ دروازه اي ﻳﺎ ﺗﻮﭘﻲ.ﻛﺮد

از اﻓﺖ ﻓﺸﺎر ﺑﺎﻻ.ﻛﺎﻣﻼ ﺑﺎز در ﻋﻤﻠﻴﺎت ﻋﺎدي اﺳﺘﻔﺎده ﺷﻮد

ﻛﻪ ﻣﻨﺠﺮ ﺑﻪ ﺗﺒﺨﻴﺮ آﻧﻲ و ﭘﻮدري ﺷﺪن در ﺧﻂ ﺧﻮراك

اﮔﺮ ﻧﺘﻮان از ﺷﻴﺮ ﻛﺎﻫﺶ ﻓﺸﺎر.ﻣﻲﺷﻮد ﺑﺎﻳﺪ اﺟﺘﻨﺎب ﺷﻮد

ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد ﺗﺎ ﺣﺪ ﻣﻤﻜﻦ،در ﺧﻂ ﺧﻮراك اﺟﺘﻨﺎب ﻛﺮد

.در ﻓﺎﺻﻠﻪ ﺑﺎﻻدﺳﺖ ﻣﺨﺰن ﻗﺮار ﮔﻴﺮد

If these conditions cannot be complied with,

some loss of efficiency will result.

If a valve in the feed line near to the separator

cannot be avoided, it should preferably be of

the gate or ball type fully open in normal

operation. High pressure drops which cause

flashing and atomization should be avoided in

the feed pipe. If a pressure-reducing valve in

the feed pipe cannot be avoided, it should be

located as far upstream of the vessel as

practicable.

ﺟﻨﺲ ﺟﺪا ﻛﻨﻨﺪه4-6

6.4 Separator Material

ASME آﻳﻴﻦ ﻧﺎﻣﻪ1-4-6

6.4.1 ASME Code

Separators furnished to this specification shall

conform to the material requirements stipulated in

the latest edition of the ASME Code.

ﺟﺪا ﻛﻨﻨﺪه ﻫﺎﻳﻲ ﻛﻪ ﺑﺮ اﺳﺎس اﻳﻦ ﻣﺸﺨﺼﻪ اﺳﺘﺎﻧﺪارد ﺳﺎﺧﺘﻪ

ASME ﺷﺪه اﻧﺪ ﺑﺎﻳﺪ ﺑﺎ اﻟﺰاﻣﺎت آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻳﻴﻦ ﻧﺎﻣﻪ

.ﻣﻄﺎﺑﻖ ﺑﺎﺷﻨﺪ

6.4.2 Material selection for corrosive fluids should

be selected based on a review of related API or

NACE publications for materials that conform to

Paragraph 6.4.1. Consideration should be given to

material selection as it relates to weight loss,

sulphide stress cracking, chloride stress cracking,

or other forms of corrosion. It is the responsibility

of the user to determine what consideration for

corrosion should be made to the vessel during its

intended life.

ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد اﻧﺘﺨﺎب ﻣﻮاد ﺑﺮاي ﺳﻴﺎﻻت ﺧﻮرﻧﺪه ﺑﺮ2-4-6

ﻣﺮﺑﻮﻃﻪ ﺑﺮايNACE وAPI اﺳﺎس ﻳﻚ ﺑﺮرﺳﻲ از ﻧﺸﺮﻳﺎت

ﺗﻮﺻﻴﻪ. ﺑﺎﺷﺪ، ﻫﺴﺘﻨﺪ1-4-6 ﻣﻮادي ﻛﻪ ﻣﻄﺎﺑﻖ ﭘﺎراﮔﺮاف

ﻳﺎ ﺷﻜﺴﺖ ﺗﻨﺸﻲ،ﻣﻲ ﺷﻮد در اﻧﺘﺨﺎب ﻣﻮاد ﺑﻪ ﻛﺎﻫﺶ وزن

ﺷﻜﺴﺖ ﺗﻨﺸﻲ ﻛﻠﺮي ﻳﺎ دﻳﮕﺮ اﻧﻮاع ﺧﻮردﮔﻲ ﺗﻮﺟﻪ، ﮔﻮﮔﺮدي

ﻣﺴﺌﻮﻟﻴﺖ ﺗﻌﻴﻴﻦ ﻣﻼﺣﻈﺎت ﻻزم ﺑﺮاي ﺧﻮردﮔﻲ ﻇﺮف در.ﺷﻮد

.ﻃﻮل زﻣﺎن ﻛﺎرﻛﺮد ﺑﺮﻋﻬﺪه ﻛﺎرﺑﺮ اﺳﺖ

6.4.3 Corrosion consideration for separators

furnished to this specification shall be for the

pressure containing parts of the vessel only, and as

can be identified as falling within the

requirements of the applicable section of the

ASME Code.

ﻣﻼﺣﻈﺎت ﺧﻮردﮔﻲ ﺑﺮاي ﺟﺪاﻛﻨﻨﺪه ﻫﺎﻳﻲ ﻛﻪ ﺑﺮ3-4-6

Corrosion considerations for vessel internals (nonpressure parts) is by mutual agreement between

the purchaser and the manufacturer and not a part

of this specification.

ﻣﻼﺣﻈﺎت ﺧﻮردﮔﻲ ﺑﺮاي اﺟﺰاء داﺧﻠﻲ ﻇﺮف)ﻗﺴﻤﺘﻬﺎي ﻏﻴﺮ

ﻓﺸﺎري( ﺗﻮﺳﻂ ﻗﺮارداد ﻣﺘﻘﺎﺑﻞ ﺑﻴﻦ ﺧﺮﻳﺪار و ﺗﻮﻟﻴﺪ ﻛﻨﻨﺪه ﺑﻮده

.و ﺑﺨﺸﻲ از اﻳﻦ ﻣﺸﺨﺼﺎت ﻧﻤﻲ ﺑﺎﺷﺪ

اﺳﺎس اﻳﻦ ﻣﺸﺨﺼﺎت ﺳﺎﺧﺘﻪ ﻣﻲ ﺷﻮﻧﺪ ﻓﻘﻂ ﺑﺎﻳﺪ ﺑﻪ ﺑﺨﺸﻬﺎي

ﺗﺤﺖ ﻓﺸﺎر ﻇﺮف ﺑﻮده و ﻫﻤﺎﻧﻄﻮر ﻣﻲ ﺗﻮاﻧﻨﺪ ﺑﺎ اﻟﺰاﻣﺎت ﺑﺨﺶ

. ﺗﻌﻴﻴﻦ ﺷﻮﻧﺪASME ﻗﺎﺑﻞ اﻋﻤﺎل آﻳﻴﻦ ﻧﺎﻣﻪ

13

Jan. 2010/ 1388 دي

7.CONVENTIONAL

SEPARATORS

IPS-E-PR-880(1)

ﻣﺎﻳﻊ/ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻣﺘﺪاول ﮔﺎز-7

GAS/LIQUID

ﻋﻤﻮﻣﻲ1-7

7.1 General

The

Process

requirements

of

pressure,

temperature, corrosion and loading of separators

shall be based on Item 6.1 of IPS-E-PR-850,

"Process Requirements

of Vessels and

Separators".

دﻣﺎ ﺧﻮردﮔﻲ و ﺑﺎر ﺟﺪا ﻛﻨﻨﺪه ﻫﺎ ﺑﺎﻳﺪ ﺑﺮ،اﻟﺰاﻣﺎت ﻓﺮآﻳﻨﺪي ﻓﺸﺎر

"اﻟﺰاﻣﺎت ﻓﺮآﻳﻨﺪي ﺑﺮايIPS-E-PR-850 6,1 اﺳﺎس ﺑﻨﺪ

.ﻇﺮوف و ﺟﺪا ﻛﻨﻨﺪه ﻫﺎ" ﺑﺎﺷﺪ

Conventional gas/liquid separators are usually

characterized as vertical, horizontal, or spherical.

Horizontal separators can be single or double

barrel and can be equipped with sumps or boots.

اﻓﻘﻲ ﻳﺎ،ﻣﺎﻳﻊ ﻣﻌﻤﻮﻻً ﻋﻤﻮدي/ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻣﺘﺪاول ﮔﺎز

ﻛﺮوي ﻫﺴﺘﻨﺪ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي اﻓﻘﻲ ﻣﻲ ﺗﻮاﻧﻨﺪ ﻳﻚ ﻳﺎ دو

ﺑﺸﻜﻪاي ﺑﺎﺷﻨﺪ ﻛﻪ ﻣﻲ ﺗﻮاﻧﺪ ﺑﻪ ﭼﺎﻫﻚ ﻳﺎ ﭘﺎﺷﻨﻪ ﻫﺎ ﻣﺠﻬﺰ

ﻳﻚ اﺳﺘﺨﺮاج ﻛﻨﻨﺪه ﻗﻄﺮه ﻣﻴﺘﻮاﻧﺪ در اﻳﻦ ﻧﻮع از.ﺑﺎﺷﻨﺪ

.ﺟﺪاﺳﺎزﻫﺎ ﻧﺼﺐ ﮔﺮدد

Mist extractor can be installed in this type of

separators.

ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻋﻤﻮدي1-1-7

7.1.1 Vertical separators

(اﻟﻒ ﭘﻴﻮﺳﺖ ب را ﺑﺒﻴﻨﻴﺪ.1.ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻋﻤﻮدي )ﺷﻜﻞ ب

در.ﻫﻨﮕﺎﻣﻲ ﻛﻪ ﻧﺴﺒﺖ ﮔﺎز ﺑﻪ ﻣﺎﻳﻊ زﻳﺎد اﺳﺖ ﺑﺎﻳﺪ اﻧﺘﺨﺎب ﺷﻮﻧﺪ

ﻣﻮاردي ﻛﻪ ﻧﻮﺳﺎن ﻣﻜﺮر در ﺟﺮﻳﺎن ورودي ﻣﺎﻳﻊ ﺑﺎﺷﺪ ﻳﺎ ﻻزم

،ﺑﺎﺷﺪ از ﺗﺒﺨﻴﺮ ﻣﺠﺪد ﻳﺎ اﺧﺘﻼط دوﺑﺎره ﺳﻴﺎﻻت ﻣﻤﺎﻧﻌﺖ ﺷﻮد

.ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻋﻤﻮدي ﺗﺮﺟﻴﺢ داده ﺷﻮﻧﺪ

Vertical separators (see Fig. B.1-a of Appendix B)

shall be selected when the gas-liquid ratio is high.

In cases where there is a frequent fluctuation in

inlet liquid flow or where re-vaporization or

remixing of fluids in the vessel should be

prevented, vertical separators should be preferred.

ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي اﻓﻘﻲ2-1-7

7.1.2 Horizontal separators

)ب( را ﺑﺒﻴﻨﻴﺪ( زﻣﺎﻧﻲ ﻛﻪ1.ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي اﻓﻘﻲ)ﺷﻜﻞ ب

ﺣﺠﻢ زﻳﺎدي از ﺳﻴﺎل و ﻣﻘﺪار زﻳﺎدي ﮔﺎز ﻣﺤﻠﻮل در ﻣﺎﻳﻊ

آﻧﻬﺎ ﻫﻤﭽﻨﻴﻦ.ﻣﻮﺟﻮد ﺑﺎﺷﺪ ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﻣﻲ ﮔﻴﺮﻧﺪ

ﻣﺎﻳﻊ ﻛﻢ ﻣﻲ ﺷﻮد ﻳﺎ ﺟﺎﻳﻴﻜﻪ ﺟﺪاﺳﺎزي ﺳﻪ-ﺟﺎﻳﻴﻜﻪ ﻧﺴﺒﺖ ﺑﺨﺎر

. ﺗﺮﺟﻴﺢ داده ﻣﻲ ﺷﻮﻧﺪ،ﻓﺎزي ﻻزم اﺳﺖ

Horizontal separators (see Fig. B.1-b) are

practically used where large volumes of total

fluids and large amount of dissolved gas are

present with the liquid. They are also preferred

where the vapor-liquid ratio is small or where

three phase separation is required.

ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻛﺮوي3-1-7

7.1.3 Spherical separators

اﻳﻦ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎ ﮔﺎﻫﻲ در ﻛﺎرﺑﺮي ﻫﺎي ﻓﺸﺎر ﺑﺎﻻ ﻛﻪ اﻧﺪازه

اﺳﺘﻔﺎده ﻣﻲ،ﻣﺘﺮاﻛﻢ ﻣﺪ ﻧﻈﺮ اﺳﺖ و ﺣﺠﻢ ﻣﺎﻳﻊ ﻛﻢ اﺳﺖ

(ج دﻳﺪه ﺷﻮد-1-)ﺷﻜﻞ ب.ﺷﻮﻧﺪ

These separators are occasionally used for high

pressure service where compact size is desired and

liquid volumes are small, (see Fig. B.1-c).

ﻣﻌﻴﺎرﻫﺎي ﻃﺮاﺣﻲ2-7

7.2 Design Criteria

ﺟﺪاﻛﻨﻨﺪه ﻫﺎﻳﻲ ﻛﻪ ﺑﺎ اﻳﻦ ﻣﺸﺨﺼﺎت ﺳﺎﺧﺘﻪ ﺷﺪه اﻧﺪ ﻣﻤﻜﻦ

اﻓﻘﻲ ﻳﺎ ﻛﺮوي و در اﺑﻌﺎد و اﻧﺪازه ﻫﺎ و ﺣﺪاﻛﺜﺮ،اﺳﺖ ﻋﻤﻮدي

و1-4 ﻓﺸﺎر ﻛﺎري ﻣﺠﺎز ﻃﺒﻘﻪ ﺑﻨﺪي ﻧﺸﺎن داده ﺷﺪه در ﺟﺪول

اﻧﺪازه و. ﺑﺎﺷﺪAPI SPEC 12J اﺳﺘﺎﻧﺪارد3-4 و2-4

ﻓﺸﺎرﻫﺎي ﻛﺎرﻛﺮد ﻣﻮﺟﻮد ﻣﻤﻜﻦ از ﻣﺸﺨﺼﺎت ﻃﺒﻘﻪ ﺑﻨﺪي اﻋﻼم

ﻓﺸﺎر و، ﺳﺎﻳﺮ اﻧﺪازه.ﺷﺪه در ﺟﺪاول ﻣﺮﺟﻊ ﻣﺘﻔﺎوت ﺑﺎﺷﻨﺪ

ﻃﺒﻘﻪ ﺑﻨﺪي دﻣﺎ ﻣﻤﻜﻦ اﺳﺖ ﺑﺎ ﺗﻮاﻓﻖ ﺑﻴﻦ ﺧﺮﻳﺪار و ﺗﻮﻟﻴﺪ

.ﻛﻨﻨﺪه ﺳﺎﺧﺘﻪ ﺷﻮﻧﺪ

ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﺑﺪون اﺳﺘﺨﺮاج ﻛﻨﻨﺪه ﻗﻄﺮه ﻣﻌﻤﻮﻻً ﺑﺮاي

Separators furnished to this specification may be

vertical, horizontal, or Spherical, and are available

in sizes and maximum allowable working pressure

ratings shown in Tables 4.1,4.2 ,and 4.3 API

SPEC 12J. Available sizes and working pressures

may vary from the stated ratings in the referenced

tables. Other sizes, pressure, and temperature

ratings may be furnished by agreement between

purchaser and manufacturer.

Separators without mist extractors may be

14

Jan. 2010/ 1388 دي

designed for gravity settling using Stokes' law

equations.

IPS-E-PR-880(1)

ﺟﺪاﺳﺎزي ﺛﻘﻠﻲ ﺑﺎ اﺳﺘﻔﺎده از ﻗﻮاﻧﻴﻦ اﺳﺘﻮك ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار

.ﻣﻲ ﮔﻴﺮﻧﺪ

150 ﺑﻄﻮر ﻣﻌﻤﻮل ﺗﻌﻴﻴﻦ اﻧﺪازه ﺑﺮ اﺳﺎس ﺣﺬف ذرات ﺑﺎ ﻗﻄﺮ

.ﻣﻴﻜﺮوﻣﺘﺮ و ﺑﺰرﮔﺘﺮ اﺳﺖ

ﺑﺮاي ﻣﻘﺎﺻﺪ ﺗﺠﺮﺑﻲ ﻛﻪ در ﺣﺎﺷﻴﻪ ﻣﻄﻤﺌﻦ ﺑﺎﺷﺪ اﺳﺘﻔﺎده از

.روﺷﻬﺎي ﺑﻴﺎن ﺷﺪه در ﺑﻨﺪ زﻳﺮ ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد

Typically the sizing is based upon removal of 150

micrometers and larger diameter droplets.

For practical purposes, to be in safe side, use of

the methods presented in the following sections is

recommended.

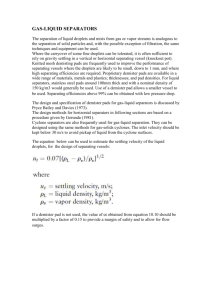

ﻣﻴﺰان ﺟﺮﻳﺎن ﻫﺎي ﻃﺮاﺣﻲ1-2-7

7.2.1 Design flow rates

ﻳﻚ ﺟﺪا ﻛﻨﻨﺪه ﻣﻤﻜﻦ اﺳﺖ در ﻳﻚ ﺑﺮﻧﺎﻣﻪ ﻓﺮاﻳﻨﺪ ﻛﻪ ﺷﺎﻣﻞ

در. ﻗﺮار داﺷﺘﻪ ﺑﺎﺷﺪ،ﭼﻨﺪﻳﻦ ﺣﺎﻟﺖ ﻓﺮآﻳﻨﺪي ﻣﺨﺘﻠﻒ ﻣﻲ ﺑﺎﺷﺪ

ﻃﺮاﺣﻲ ﺟﺪا ﻛﻨﻨﺪه ﺑﺎﻳﺪ ﻣﻨﻄﺒﻖ ﺑﺎ ﺷﺪﻳﺪﺗﺮﻳﻦ،اﻳﻦ ﺣﺎﻟﺖ

ﻣﺎﻳﻊ در ﻣﺨﺰن ﻗﻄﺮه/ ﺑﺮاي ﺟﺪاﺳﺎزي ﮔﺎز.ﺷﺮاﻳﻂ ﻋﻤﻠﻜﺮد ﺑﺎﺷﺪ

ﺷﺪﻳﺘﺮﻳﻦ ﺷﺮاﻳﻂ ﺑﺮاي ﺟﺪاﺳﺎزي در ﺑﻴﺸﺘﺮﻳﻦ،ﮔﻴﺮ ﻳﺎ ﻧﻢ ﮔﻴﺮ

: ﻛﻪ در ﻣﻌﺎدﻟﻪ ﭘﺎﻳﻴﻦ ﺗﻌﺮﻳﻒ ﻣﻲ ﺷﻮد، ﻣﻲ ﺑﺎﺷﺪQ ﻣﻘﺪار

A separator may be incorporated in a process

scheme for which there are different modes of

operation. In this case, the separator design shall

be based upon the operation mode with the

severest conditions. For the gas/liquid separation

in a knock-out drum or demister, the severest

condition is that with the highest value of Q,

where this is defined by: EMBED Equation

(Eq.1)

g

Q Qg

g

1

1

2 3

m /s

(EMBED)

(1 )ﻣﻌﺎدﻟﻪ

Q ﺑﺎ در ﻧﻈﺮ ﮔﺮﻓﺘﻦ اﻳﻨﻜﻪ ﺷﺪﻳﺪﺗﺮﻳﻦ ﺣﺎﻟﺖ از ﺑﻴﺸﺘﺮﻳﻦ ﻣﻘﺪار

Having identified the severest mode from the

highest value of Q, it is then necessary to add on a

margin to give the value on which the separator

design shall be based. This value, Qmax should

include margins for over design, safety or surging.

It represents the ’flooding’ condition.

ﻣﻲ ﺑﺎﺷﺪ در اﻳﻦ ﺣﺎﻟﺖ ﺿﺮوري اﺳﺖ ﻛﻪ ﻳﻚ ﻣﻘﺪار ﺣﺎﺷﻴﻪ اي

اﻳﻦ.ﺑﻪ آن اﺿﺎﻓﻪ ﮔﺮدد ﻛﻪ ﺑﺎﻳﺪ ﭘﺎﻳﻪ ﻃﺮاﺣﻲ ﺟﺪاﻛﻨﻨﺪه ﺑﺎﺷﺪ

ﺑﺎﻳﺪ ﺷﺎﻣﻞ ﻣﻘﺪار ﺣﺎﺷﻴﻪ اي ﺑﺮاي ﻃﺮاﺣﻲ اﺿﺎﻓﻲQmax ﻣﻘﺪار

"ﻛﻪ ﻧﺸﺎن دﻫﻨﺪه ﺷﺮاﻳﻂ "ﻃﻐﻴﺎن.اﻳﻤﻨﻲ و ﻳﺎ ﻧﻮﺳﺎﻧﺎت ﺑﺎﺷﺪ

.ﻣﻲﺑﺎﺷﺪ

(ﺣﺎﺷﻴﻪ ﺑﻜﺎر رﻓﺘﻪ ﺑﺮ روي ﻣﻴﺰان ﺟﺮﻳﺎن ﻋﺎدي)ﻃﺮاﺣﻲ ﻓﺮآﻳﻨﺪ

ﺑﺮاي ﻓﺮاﻳﻨﺪﻫﺎي ﻧﻔﺘﻲ ﻣﻴﺰان ﺣﺎﺷﻴﻪ.ﺑﻪ ﻛﺎرﺑﺮي ﺑﺴﺘﮕﻲ دارد

50 ﺑﺮاي ﺗﻮﻟﻴﺪ ﻧﻔﺖ ﺣﺎﺷﻴﻪ ﺗﺎ. درﺻﺪ ﻣﻌﻤﻮﻟﻲ اﺳﺖ25-15

.درﺻﺪ ﻧﻴﺰ ﻣﻤﻜﻦ اﺳﺖ ﻻزم ﺑﺎﺷﺪ

The margin to be applied over the normal (process

design) flow rate depends on the application. For

oil processing, a margin of 15-25% is common;

for oil production, margins up to 50% may be

required.

ﻣﺎﻫﻴﺖ ﺧﻮراك2-2-7

7.2.2 Nature of the feed

The type of flow in feed pipe to the separator,

transition from one flow regime to another,

formation of droplets, foaming tendency of the

liquid which may lead to carry over the liquid or

carry through of gas and other factors such as

existence of sands, rust, wax and other solids and

cocking tendency of the liquid are points which

should be taken into account when fixing design

conditions.

ﮔﺬر از ﻳﻚ،ﻧﻮع ﺟﺮﻳﺎن در ﻟﻮﻟﻪ ﺧﻮراك ورودي ﺑﻪ ﺟﺪا ﻛﻨﻨﺪه

ﺗﺸﻜﻴﻞ ﻗﻄﺮات و ﺗﻤﺎﻳﻞ ﺑﻪ ﻛﻒ،رژﻳﻢ ﺑﻪ رژﻳﻢ دﻳﮕﺮ ﺟﺮﻳﺎﻧﻲ

زاﻳﻲ ﻣﺎﻳﻊ ﻛﻪ ﻣﻨﺠﺮ ﺑﻪ ﻃﻐﻴﺎن ﻣﺎﻳﻊ ﻳﺎ ﺣﻤﻞ ﺑﻴﺶ از ﺣﺪ

،ﻣﺎﻳﻌﺎت در ﮔﺎز ﻣﻲ ﺷﻮد و ﻋﻮاﻣﻞ دﻳﮕﺮ ﻣﺎﻧﻨﺪ وﺟﻮد ﺳﻨﮕﺮﻳﺰه

ﻣﻮم و دﻳﮕﺮ ﺟﺎﻣﺪات و ﺗﻤﺎﻳﻞ ﺑﻪ ﻛﻚ ﺳﺎزي ﻣﺎﻳﻊ ﻧﻜﺎﺗﻲ،زﻧﮕﺎر

.اﺳﺖ ﻛﻪ در ﺗﺜﺒﻴﺖ ﺷﺮاﻳﻂ ﻃﺮاﺣﻲ ﺑﺎﻳﺪ ﻟﺤﺎظ ﺷﻮﻧﺪ

7.2.3 Efficiency and separator type

The efficiency of a separator is defined here as the

fraction (or percentage) of the liquid entering the

vessel that is separated off.

ﺑﺎزده و ﻧﻮع ﺟﺪاﻛﻨﻨﺪه3-2-7

ﻛﺴﺮي )ﻳﺎ درﺻﺪ( از ﻣﺎﻳﻊ،در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺎزده ﺟﺪاﻛﻨﻨﺪه

.اﺳﺖ ﻛﻪ ﺑﻪ داﺧﻞ ﻇﺮف وارد ﺷﺪه و ﺟﺪا ﻣﻲ ﺷﻮد

Table 1 gives the preferred choice of separator

اﻧﺘﺨﺎب ارﺟﺢ ﺟﺪا ﻛﻨﻨﺪه را ﺑﺎ ﺗﻮﺟﻪ ﺑﻪ ﻧﻮع ﺧﻮراك و1 ﺟﺪول

15

Jan. 2010/ 1388 دي

IPS-E-PR-880(1)

according to feed description and the approximate

efficiency expected:

16

.ﺑﺎزده ﺗﻘﺮﻳﺒﻲ ﻣﻮرد ﻧﻈﺮ ﻧﺸﺎن ﻣﻲ دﻫﺪ

TABLE 1 - EFFICIENCY VS TYPE OF FLOW OF SEPARATORS

ﺑﺎزده ﺑﺮ ﺣﺴﺐ ﻧﻮع ﺟﺮﻳﺎن ﺟﺪا ﻛﻨﻨﺪهﻫﺎ-1 ﺟﺪول

١٧

TYPE OF

FLOW

EFFICIENCY EXPECTED

ﻧﻮع ﺟﺮﻳﺎن

Bubbly

Stratified, smooth ﻻﻳﻪ اي،ﺣﺒﺎﺑﻲ آرام

Stratified, wavy

ﻻﻳﻪ اي،ﭘﺮﻣﻮج

Intermittent

Annular

ﻣﺘﻨﺎوب

>90%

<90%

Knock-Out drum

ﻣﺨﺰن ﻗﻄﺮه ﮔﻴﺮ ذرات

Knock-Out drum

ﻣﺨﺰن ﻗﻄﺮه ﮔﻴﺮ

Knock-Out drum

ﻣﺨﺰن ﻗﻄﺮه ﮔﻴﺮ ذرات

Knock-Out drum

ﻣﺨﺰن ﻗﻄﺮه ﮔﻴﺮ ذرات

ﺣﻠﻘﻮي

ﺑﺎزده ﻣﻮرد ﻧﻈﺮ

Demister or cyclone

ﻗﻄﺮه ﮔﻴﺮ ﻳﺎ ﺳﻴﻜﻠﻮن

Demister or cyclone

ﻗﻄﺮه ﮔﻴﺮ ﻳﺎ ﺳﻴﻜﻠﻮن

Demister or cyclone

ﻗﻄﺮه ﮔﻴﺮ ﻳﺎ ﺳﻴﻜﻠﻮن

ﻫﺮ ﭼﻨﺪ ﻳﻚ ﺟﺪا ﻛﻨﻨﺪه ﻗﻄﺮه ﮔﻴﺮ ﻫﻤﺮاه ﺑﺎ ﻻﻳﻪ ﻧﻢ ﮔﻴﺮ ﺗﻮري

ﺗﻮﺟﻪ، درﺻﺪ ﻣﻲ ﺑﺎﺷﺪ99 ﺳﻴﻤﻲ ﻏﺎﻟﺒﺎً داراي ﺑﺎزدﻫﻲ ﺑﻴﺸﺘﺮ از

ﻣﻴﻜﺮوﻣﺘﺮ20 ﺷﻮد ﻛﺴﺮ ﻗﺎﺑﻞ ﺗﻮﺟﻬﻲ از ﻗﻄﺮات ﺑﺎ ﻗﻄﺮ ﻛﻤﺘﺮ از

.ﻣﻤﻜﻦ اﺳﺖ از ﺟﺪا ﻛﻨﻨﺪه ﻗﻄﺮه ﮔﻴﺮ ﺗﻮري ﺳﻴﻤﻲ ﻋﺒﻮر ﻛﻨﺪ

Although a demister separator fitted with wire

mesh demister pad will often have efficiency

better than 99%, it should be noted that a

substantial fraction of droplets less than 20

micrometers in diameter, may pass through a wire

mesh demister.

اﻟﺰاﻣﺎت ﭘﺬﻳﺮش ﻣﺎﻳﻊ4-2-7

7.2.4 Liquid handling requirements

،ﺗﻮﺻﻴﻪ ﻣﻴﺸﻮد در ﺑﺮرﺳﻲ ﻇﺮﻓﻴﺖ ﭘﺬﻳﺮش ﻣﺎﻳﻊ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎ

.ﻧﻜﺎت زﻳﺮ ﻣﻮرد ﺗﻮﺟﻪ ﺑﺎﺷﺪ

In checking the capacity of the separator to handle

liquid, the following points should be considered.

ﮔﺎز زداﻳﻲ1-4-2-7

7.2.4.1 Degassing

ﺑﺮاي ﺟﻠﻮﮔﻴﺮي از ﺣﻤﻞ ﺣﺒﺎﺑﻬﺎي ﮔﺎز از ﻃﺮﻳﻖ ﺟﺮﻳﺎن ﻣﺎﻳﻊ

ﺳﺮﻋﺖ ﻣﺎﻳﻊ ﻛﻪ اﻟﺰاﻣﺎت ﻣﻮرد ﻧﻴﺎز،ﺧﺮوﺟﻲ در ﻣﺨﺎزن ﻋﻤﻮدي

:ذﻳﻞ را ﻓﺮاﻫﻢ ﻛﻨﺪ از ﻓﺮﻣﻮل زﻳﺮ ﺑﺪﺳﺖ ﻣﻲ آﻳﺪ

In order to prevent carry through of the gas

bubbles into the liquid outlet stream in vertical

vessels, the liquid velocity should satisfy the

following requirement: EMBED Equation

(Eq.2)

Qg

D V2

4

2.18 10

1

-2

1 g

1

(2 )ﻣﻌﺎدﻟﻪ

mm²/s ﮔﺮاﻧﺮوي ﺳﻴﻨﻤﺎﺗﻴﻜﻲ اﺳﺖ ﻛﻪ ﺑﺮ ﺣﺴﺐ

Where l, the liquid kinematic viscosity is in

mm²/s or cSt.

در اﻳﻨﺠﺎ

. اﺳﺖcSt ﻳﺎ

ﻣﺤﺪوده، ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد در ﻇﺮف اﻓﻘﻲ ﻛﻪ ﺗﺎ ﻧﺼﻒ ﭘﺮ ﺷﺪه

ﺑﻪ دﺳﺖ ﻣﻲ آﻳﺪ ﺑﻜﺎرQl/ (Dv.Lv) ﻓﻮق ﺑﻪ ﺳﺮﻋﺖ ﻛﻪ از راﺑﻄﻪ

. ﻃﻮل ﻇﺮف اﺳﺖLv ﻛﻪ،رود

In a horizontal vessel which is approximately half

full, the above limit should be applied to the

velocity Ql/ (Dv.Lv), where Lv is the vessel length.

l

:ﻳﺎدآوري

Note:

. زﻣﺎن ﻣﺎﻧﺪ ﻣﺎﻳﻊ ﻳﻜﻲ از ﻣﻌﻴﺎر ﻫﺎي ﮔﺎز زداﻳﻲ ﻣﻲ ﺑﺎﺷﺪ،اﻏﻠﺐ

روش زﻳﺮ ﻛﻪ ﺑﺮ اﺳﺎس ﻗﺎﻧﻮن اﺳﺘﻮك اﺳﺖ ﺗﺮﺟﻴﺢ داده

.ﻣﻲﺷﻮد

Often ’liquid residence time’ is used as a criterion

for de-gassing. The method given here, based on

Stokes’ law is preferred.

16

Jan. 2010/ 1388 دي

IPS-E-PR-880(1)

ﺣﺠﻢ ﻛﻨﺘﺮل2-4-2-7

7.2.4.2 Control volume

ﺑﺮاي ﮔﺎز زداﻳﻲ )و ﺑﻪ ﻋﻼوه ﺑﺮاي ﻣﻘﺎﺑﻠﻪ ﺑﺎ ﻛﻒ( ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد

ﻫﻨﮕﺎﻣﻲ ﻛﻪ ﺳﻄﺢ ﻣﺎﻳﻊ در ﺟﺪا.ﺳﺮﻋﺖ ﻣﺎﻳﻊ ﻣﺤﺪود ﺷﻮد

ﻛﻨﻨﺪه ﻣﻮرد ﻧﻴﺎز اﺳﺖ ﺣﺠﻢ ﻣﻌﻴﻨﻲ از ﻣﺎﻳﻊ ﺑﻪ ﻣﻨﻈﻮر ﻛﻨﺘﺮل

.ﺿﺮوري اﺳﺖ

:ﺗﻮﺻﻴﻪ ﻫﺎي زﻳﺮ ﺑﺮاي راﻫﻨﻤﺎﻳﻲ ﻣﻲ ﺑﺎﺷﺪ

For de-gassing (and also to counter foam), the

liquid velocity should be limited. When a liquid

level is required in the separator, a certain liquid

volume is necessary for control purposes.

The following recommendations are intended as a

guide:

اﻟﻒ( زﻣﺎن ﻣﺎﻧﺪ ﺑﺮاي ﻛﻨﺘﺮل

a) Hold-Up time for control

1- ﻛﻪ در ﺷﻜﻞ زLA(H) ، LA(L) ﺣﺪاﻗﻞ اﻟﺰاﻣﺎت ﺑﻴﻦ

در ﻧﺒﻮد دﻳﮕﺮ ﻣﻼﺣﻈﺎت ﻏﺎﻟﺐ،ﭘﻴﻮﺳﺖ ) ز( ﻧﺸﺎن داده ﺷﺪه

: ﺑﻪ ﺻﻮرت زﻳﺮ اﺳﺖ،ﻓﺮاﻳﻨﺪي اﻋﻤﺎل ﻣﻲ ﺷﻮد

The minimum requirement between LA(L) and

LA(H) shown in Fig. G.1 of Appendix G,

which should be applied in the absence of other

overriding process considerations, is as

follows:

ﻛﻨﺘﺮل ﺧﻮدﻛﺎر

Automatic control

دﻗﻴﻘﻪ ﺑﺮاي ﻣﺤﺼﻮل ﺑﻪ ﻣﺨﺰن4

دﻗﻴﻘﻪ ﺑﺮاي ﺧﻮراك ﻛﻮره5

دﻗﻴﻘﻪ ﺑﺮاي ﺳﺎﻳﺮ ﻛﺎرﺑﺮد ﻫﺎ4

4 minutes for product to storage

5 minutes for feed to a furnace

4 minutes for other applications

Manual control

ﻛﻨﺘﺮل دﺳﺘﻲ

20 minutes.

. دﻗﻴﻘﻪ20

ب( زﻣﺎن ﻣﺎﻧﺪ ﺑﺮاي دﺧﺎﻟﺖ ﻣﺘﺼﺪي واﺣﺪ

b) Hold-Up time for operator intervention

When operator action is necessary to avoid

upsets or a shutdown of plant operation, a

realistic estimate shall be made of the time

required.

زﻣﺎﻧﻲ ﻛﻪ اﻗﺪام ﻣﺘﺼﺪي واﺣﺪ ﺑﺮاي ﺟﻠﻮﮔﻴﺮي از ﺧﺮاﺑﻲ ﻳﺎ

ﺗﻮﻗﻒ ﻋﻤﻠﻴﺎت ﻻزم اﺳﺖ ﺑﺎﻳﺪ ﻳﻚ ﺗﺨﻤﻴﻦ واﻗﻊ ﺑﻴﻨﺎﻧﻪ از

.زﻣﺎن ﻣﻮرد ﻧﻴﺎز ﺑﻌﻤﻞ آﻳﺪ

For inside plot separators a minimum hold-up

of 5 minutes between pre-alarm and trip action

is recommended.

5 ﺑﺮاي ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي داﺧﻞ ﻣﺤﻮﻃﻪ واﺣﺪﻫﺎ زﻣﺎن ﻣﺎﻧﺪ

.دﻗﻴﻘﻪ ﺑﻴﻦ ﭘﻴﺶ ﻫﺸﺪار و از ﻛﺎر اﻓﺘﺎدن ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد

For off plot separators, the time the operator

needs to reach the equipment, should be added.

ﺗﻮﺻﻴﻪ،ﺑﺮاي ﺟﺪاﻛﻨﻨﺪ ﻫﺎي ﺧﺎرج از ﻣﺤﻮﻃﻪ واﺣﺪﻫﺎ

ﻣﻴﺸﻮد زﻣﺎن رﺳﻴﺪن ﻣﺘﺼﺪي واﺣﺪ ﺑﻪ ﺗﺠﻬﻴﺰات ﻧﻴﺰ اﺿﺎﻓﻪ

ﺑﺮاي ﻛﻠﻴﺪﻫﺎﻳﻲ ﻛﻪ ﻣﺴﺘﻘﻴﻤﺎً ﺑﺮ ﻋﻤﻠﻜﺮد ﻛﺎرﺧﺎﻧﻪ اﺛﺮ.ﮔﺮدد

، ﺑﺮاي ﻣﺜﺎل ﺷﺮوع ﺧﻮدﻛﺎر ﺗﻠﻤﺒﻪ ﻫﺎي آﻣﺎده ﺑﻜﺎر، ﻧﺪارﻧﺪ

در اﻳﻦ ﺣﺎﻟﺖ ﭘﻴﺶ ﻫﺸﺪار.زﻣﺎن ﻣﺎﻧﺪ ﺿﺮوري ﻧﻴﺴﺖ

.ﻣﻤﻜﻦ اﺳﺖ ﺣﺬف ﺷﻮد

No hold-up is required for switches which do

not directly affect plant operation, e.g.,

automatic starting of standby pump. The prealarm may then be omitted.

ﻟﺨﺘﻪ ﻫﺎي ﻣﺎﻳﻊ3-4-2-7

7.2.4.3 Liquid slugs

در ﺻﻮرﺗﻲ ﻛﻪ ﺧﻮراك داراي ﻟﺨﺘﻪ ﻫﺎي ﻣﺎﻳﻊ ﺑﺎﺷﺪ زﻣﺎن ﻣﺎﻧﺪ

در ﺻﻮرت ﻛﻤﺒﻮد ﺳﺎﻳﺮ اﻃﻼﻋﺎت.زﻳﺎدﺗﺮي ﻣﻄﺮح ﻣﻲ ﺑﺎﺷﺪ

5-2 ﺣﺠﻢ ﻟﺨﺘﻪ ﻣﺎﻳﻊ ﺑﺮاي ﺟﺮﻳﺎن در زﻣﺎن،ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮد

ﺛﺎﻧﻴﻪ ﺑﺎ ﺳﺮﻋﺖ ﻋﺎدي ﺧﻮراك و ﭘﺮ ﺑﻮدن ﻟﻮﻟﻪ ﺧﻮراك ﺑﻪ ﻣﻘﺪار

. درﺻﺪ ﻣﺎﻳﻊ ﺑﺎﺷﺪ100

وNL ﺟﺪاﻛﻨﻨﺪه ﻫﺎ ﺑﺎﻳﺪ ﻗﺎدر ﺑﻪ ﺟﺎ دادن اﻳﻦ ﻟﺨﺘﻪ ﻣﺎﻳﻊ ﻣﺎﺑﻴﻦ

If the feed contains slugs of liquid, extra hold-up

volume is required. In the absence of other

information, the slug volume should be taken as 25 seconds of flow with the normal feed velocity

and 100% liquid filling of the feed pipe.

The separator should be able to accommodate this

slug volume between NL and LA (H) or between

17

Jan. 2010/ 1388 دي

NL and LA (HH), depending on whether it is

required for the arrival of a slug to sound the highlevel alarm, or not. To increase the volume for

accommodation of the slug the NL may be set

closer to LA (L). (For an explanation of liquid

level control terms, see Fig. G.1 of Appendix G.)

IPS-E-PR-880(1)

ﺑﺎﺷﻨﺪ ﻛﻪ ﺑﺴﺘﮕﻲ ﺑﻪ ﻟﺰوم ﻳﺎ ﻋﺪمLA(HH) وNL ﻳﺎLA(H)

ﺑﺮاي.ﻟﺰوم ﻫﺸﺪار ﺳﻄﺢ ﺑﺎﻻ در اﺛﺮ رﺳﻴﺪن ﻟﺨﺘﻪ ﻣﺎﻳﻊ دارد

LA ﺑﻪNL اﻓﺰاﻳﺶ دادن ﻓﻀﺎي ﻟﺨﺘﻪ ﻣﺎﻳﻊ ﻣﻤﻜﻦ اﺳﺖ ﺗﻨﻈﻴﻢ

) ﺑﺮاي ﺗﻮﺿﻴﺢ ﺷﺮاﻳﻂ ﻛﻨﺘﺮل ﺳﻄﺢ ﻧﺰدﻳﻚ.ﻧﺰدﻳﻚ ﺗﺮ ﺷﻮد

(. در ﭘﻴﻮﺳﺖ )ز( ﻣﺮاﺟﻌﻪ ﺷﻮد1-ﻣﺎﻳﻊ ﺑﻪ ﺷﻜﻞ ز

:ﻳﺎدآوري

Note:

ﻫﻨﮕﺎﻣﻲ ﻛﻪ ﻟﺨﺘﻪ ﻫﺎي ﻣﺎﻳﻊ در ﺟﺮﻳﺎن ﺧﻮراك ﻣﻮﺟﻮد ﺑﺎﺷﻨﺪ

ﻣﻼﺣﻈﺎﺗﻲ ﺑﺮاي ﺗﻘﻮﻳﺖ ﺗﺠﻬﻴﺰات ورودي و ﻟﻮﻟﻪ ﻛﺸﻲ )اﮔﺮ ﻫﺮ

.ﻳﻚ ﻻزم ﺑﺎﺷﺪ( ﺑﺎﻳﺪ ﻣﻮرد ﺗﻮﺟﻪ ﻗﺮار ﮔﻴﺮﻧﺪ

When slugs are expected in the feed,

consideration should be given to strengthening the

piping and feed inlet device, if one is to be fitted.

روﺷﻬﺎي ﻃﺮاﺣﻲ ﺟﺪاﻛﻨﻨﺪه5-2-7

7.2.5 Separator design methods

Recommended methods for basic (process) design

of conventional Gas-Liquid Separators are

presented in the following sections. Although

general references are available in literature. For

symbols and abbreviations see Section 4.

روﺷﻬﺎي ﭘﻴﺸﻨﻬﺎدي ﺑﺮاي ﻃﺮاﺣﻲ ﭘﺎﻳﻪ )ﻓﺮآﻳﻨﺪي( ﺟﺪا

.ﻣﺎﻳﻊ در ﺑﺨﺸﻬﺎي زﻳﺮ آﻣﺪه اﺳﺖ-ﻛﻨﻨﺪهﻫﺎي ﻣﺘﺪاول ﮔﺎز

ﺑﺮاي ﻋﻼﺋﻢ و.اﮔﺮﭼﻪ ﻣﻨﺎﺑﻊ ﻋﻤﻮﻣﻲ در ﻣﻘﺎﻻت ﻣﻮﺟﻮد ﻫﺴﺘﻨﺪ

. ﻣﺮاﺟﻌﻪ ﺷﻮد4 اﺧﺘﺼﺎرات ﺑﻪ ﺑﺨﺶ

7.2.5.1 Conventional separators without mist

extractors

ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻣﺘﺪاول ﺑﺪون اﺳﺘﺨﺮاج1-5-2-7

This type of separator vessel utilize gravity as the

main mechanism for separating the liquid and gas

phases.

اﺳﺘﻔﺎده از ﮔﺮاﻧﺶ اﺻﻠﻲ ﺗﺮﻳﻦ، در اﻳﻦ ﻧﻮع ﻇﺮف ﺟﺪا ﻛﻨﻨﺪه

.ﻧﻮع راﻫﻜﺎر ﺑﺮاي ﺟﺪا ﻛﺮدن ﻓﺎزﻫﺎي ﻣﺎﻳﻊ و ﮔﺎز اﺳﺖ

ﻛﻤﺘﺮﻳﻦ، ﺑﺮاي ﻃﺮاﺣﻲ ﺟﺪا ﻛﻨﻨﺪه ﺑﺪون اﺳﺘﺨﺮاج ﻛﻨﻨﺪه ﻗﻄﺮه

ﻛﻪ ﺑﻄﻮر.ﻗﻄﺮ ﻗﻄﺮه اي ﻛﻪ ﺣﺬف ﻣﻲ ﺷﻮد ﺑﺎﻳﺴﺘﻲ ﺗﻌﻴﻴﻦ ﺷﻮد

ﺑﺎ وﺟﻮد. ﻣﻴﻜﺮوﻣﺘﺮ اﺳﺖ2000 ﺗﺎ150 ﻧﻤﻮﻧﻪ اﻳﻦ ﻣﺤﺪوده ﺑﻴﻦ

اﻳﻨﻜﻪ روش ﻣﺤﺎﺳﺒﻪ ﺗﻪ ﻧﺸﻴﻨﻲ ﮔﺮاﻧﺸﻲ ﺑﺮاي اﻳﻦ ﻧﻮع ﻣﻌﺘﺒﺮ

روﺷﻬﺎي ﺑﻴﺎن ﺷﺪه در ﺑﺨﺶ ﺑﻌﺪي ﻧﻴﺰ ﻣﻨﺠﺮ ﺑﻪ ﻃﺮاﺣﻲ،اﺳﺖ

.ﭘﺎﻳﻪ ﻣﻄﻤﺌﻦ ﻣﻲ ﺷﻮﻧﺪ

ﻛﻨﻨﺪهﻫﺎي ﻗﻄﺮه

To design a separator without a mist extractor, the

minimum size diameter droplet to be removed

must be set. Typically this diameter is in the range

of 150 to 2000 micrometers. Although the

calculation method for gravity settling is valid for

this type, the methods given in the following

sections can also yield to a safe basic design.

ﻇﺮف ﻗﻄﺮه ﮔﻴﺮ ﻋﻤﻮدي ﺑﺪون اﺳﺘﺨﺮاج1-1-5-2-7

7.2.5.1.1 Vertical knock-out drum without mist

extractors

ﻛﻨﻨﺪهﻫﺎي ﻗﻄﺮه

a) Diameter

اﻟﻒ( ﻗﻄﺮ

The vessel diameter, Dv, can be estimated

from: EMBED Equation

(Eq. 3 )

Q max

/ 4.D v 2

EMBED را ﻛﻪ ﻣﻲ ﺗﻮان ﺑﻮﺳﻴﻠﻪ ﻣﻌﺎدﻟﻪDv ﻗﻄﺮ ﻇﺮف

.ﻣﺤﺎﺳﺒﻪ ﻛﺮد

0. 07

(3 )ﻣﻌﺎدﻟﻪ

:ﻛﻪ

Where:

ﻣﻴﺰان ﺟﺮﻳﺎن ﻃﺮاﺣﻲ ﻓﺮاﻳﻨﺪ ﺑﻌﻼوه ﺣﺎﺷﻴﻪ

Qmax

is the process design value of Q

plus margin (see 7.2.1).

Qmax

.ﻣﻲﺑﺎﺷﺪ

ب( ارﺗﻔﺎع

b) Height

، ارﺗﻔﺎع ﻇﺮف ﻣﻮرد ﻧﻴﺎز ﺑﺮاي زﻣﺎن ﻣﺎﻧﺪ ﻣﺎﻳﻊ ﺑﺎﺷﺪh اﮔﺮ

( ﺑﻨﺎﺑﺮاﻳﻦ ارﺗﻔﺎع ﻛﻠﻲ2-4-2-7 )ﻣﺮاﺟﻌﻪ ﺷﻮد ﺑﻪ

If h is the height of vessel required for liquid

hold-up (see 7.2.4.2), then the total vessel

18

Jan. 2010/ 1388 دي

height (tangent to tangent) is

IPS-E-PR-880(1)

.ﻇﺮف)ﻣﻤﺎس ﺗﺎ ﻣﻤﺎس( از روش زﻳﺮ ﻣﺤﺎﺳﺒﻪ ﻣﻲ ﮔﺮدد

(Eq. 4)

H = h + dn + X + Y

(4 )ﻣﻌﺎدﻟﻪ

:ﻛﻪ

Where:

dn

is Inlet nozzle diameter, in m;

X

Y

is 0.3 Dv with a minimum of 0.3 m;

is 0.9 Dv with a minimum of 0.9 m.

ﻗﻄﺮ ﻧﺎزل ورودي؛dn

ﻣﺘﺮ؛0/3 اﺳﺖ ﺑﺎ ﺣﺪاﻗﻞ0/3 Dv X

. ﻣﺘﺮ0/9 اﺳﺖ ﺑﺎ ﺣﺪاﻗﻞ0/9 Dv Y

ج( ﻧﺎزل ﻫﺎ

c) Nozzles

( ﻧﺎزل ﺧﻮراك1

1) Feed nozzle

ﻧﺎزل ﺧﻮراك ﺑﺎﻳﺪ ﺑﻪ ﻟﻮﻟﻪ ﻧﻴﻤﻪ ﺑﺎز ﻳﺎ دﺳﺘﮕﺎه ﻣﻨﺤﺮف

dn ﻗﻄﺮ ﻧﺎزل.ﻛﻨﻨﺪه ﺟﺮﻳﺎن در ورودي ﻣﺠﻬﺰ ﮔﺮدد

ﻣﻤﻜﻦ اﺳﺖ ﺑﺎ ﻗﻄﺮ ﻟﻮﻟﻪ ﺧﻮراك ﺑﺮاﺑﺮ ﺑﺎﺷﺪ اﻣﺎ ﻧﺒﺎﻳﺪ

ﻛﻴﻠﻮ ﮔﺮم ﺑﺮ ﻣﺘﺮ ﻣﺠﺬور ﺛﺎﻧﻴﻪ1500 ازV2m× m

.ﺗﺠﺎوز ﻛﻨﺪ

The feed nozzle shall be fitted with a half

open pipe or a flow diverting box inlet device.

The nozzle diameter, dn, may be taken equal

to that of the feed pipe but the product m ×

V2m shall not exceed 1500 kg/m.s².

( ﻧﺎزل ﺧﺮوﺟﻲ ﮔﺎز2

2) Gas outlet nozzle

ﻗﻄﺮ ﻧﺎزل ﺧﺮوﺟﻲ ﮔﺎز ﻣﻌﻤﻮﻻً ﺑﺎ ﻗﻄﺮ ﻟﻮﻟﻪ ﺧﺮوﺟﻲ ﺑﺮاﺑﺮ

ﻣﺤﺼﻮل ﺧﺮوﺟﻲVg²× g ﻣﻲ ﺑﺎﺷﺪ وﻟﻲ ﻧﺒﺎﻳﺪ ﻣﻘﺪار

. ﺗﺠﺎوز ﻛﻨﺪ3750 kg/m.s²از

The diameter of the gas outlet nozzle should

normally be taken equal to that of the outlet

pipe, but the product g × Vg²,out shall not

exceed 3750 kg/m.s².

( ﻧﺎزل ﺧﺮوﺟﻲ ﻣﺎﻳﻊ3

3) Liquid outlet nozzle

ﻗﻄﺮ ﻧﺎزل ﺧﺮوﺟﻲ ﻣﺎﻳﻊ ﺑﺎﻳﺪ ﻃﻮري اﻧﺘﺨﺎب ﮔﺮدد ﻛﻪ

اﻣﺎ ﺗﻮﺻﻴﻪ ﻣﻲ، ﻣﺘﺮ ﺑﺮ ﺛﺎﻧﻴﻪ ﺗﺠﺎوز ﻧﻜﻨﺪ1 ﺳﺮﻋﺖ در آن از

ﻧﺎزل ﺑﺎﻳﺪ ﺑﻪ ﮔﺮداب ﺷﻜﻦ ﻣﺠﻬﺰ.ﺷﻮد ﺳﺮﻋﺖ ﻛﻤﺘﺮ ﺑﺎﺷﺪ

.ﺷﻮد

The diameter of the liquid outlet nozzle shall

be choosen such that the velocity in it does

not exceed 1 m/s, but should preferably be

lower. The nozzle shall be equipped with a

vortex breaker.

d) Pressure drop

د( اﻓﺖ ﻓﺸﺎر

The pressure differential between inlet

and vapor outlet is:

( Eq. 5 )

: اﺧﺘﻼف ﻓﺸﺎر ﻣﺎﺑﻴﻦ ورودي و ﺧﺮوﺟﻲ ﮔﺎز ﺑﺮاﺑﺮ اﺳﺖ ﺑﺎ

Pin - Pout = 8 × 10-4 × g × V2g,out

kPa

(5 )ﻣﻌﺎدﻟﻪ

7.2.5.1.2 Horizontal knock-out drum without

mist extractor

ﻇﺮف ﻗﻄﺮه ﮔﻴﺮ اﻓﻘﻲ ﺑﺪون اﺳﺘﺨﺮاج2-1-5-2-7

For a horizontal knock-out drum, the following

design method can be applied:

ﺑﺮاي ﻃﺮاﺣﻲ ﻇﺮف ﻗﻄﺮه ﮔﻴﺮ اﻓﻘﻲ روش ﻃﺮاﺣﻲ زﻳﺮ اﺳﺘﻔﺎده

:ﻣﻲﺷﻮد

ﻛﻨﻨﺪه ﻗﻄﺮه

اﻟﻒ( اﻧﺪازه

a) Size

از ﻓﺮﻣﻮل زﻳﺮ ﭘﻴﺮوي،ﺳﻄﺢ ﻣﻘﻄﻊ ﺑﺮاي ﻋﺒﻮر ﺟﺮﻳﺎن ﮔﺎز

:ﻣﻲ ﻛﻨﺪ

The cross-sectional area for gas flow, A,

follows from:

(Eq. 6 )

Qmax

0.1 m/s

A

19

(6 )ﻣﻌﺎدﻟﻪ

Jan. 2010/ 1388 دي

IPS-E-PR-880(1)

ﻣﻘﺪارQmax ﺳﻄﺢ ﻣﺎﻳﻊ ﺑﺎﺷﺪ وLA ﺑﺎﻻيA در ﺟﺎﻳﻲ ﻛﻪ

ﻣﺮاﺟﻌﻪ1-2-7 )ﺑﻪ.ﻃﺮاﺣﻲ ﻓﺮآﻳﻨﺪي ﺑﻪ اﺿﺎﻓﻪ ﺣﺎﺷﻴﻪ اﺳﺖ

ﺷﻮد( ﻇﺮوف اﻓﻘﻲ ﻣﻌﻤﻮﻻً ﺑﻴﻦ ﻳﻚ ﺳﻮم و ﻳﻚ دوم ارﺗﻔﺎع ﻣﺎﻳﻊ

.ﻃﺮاﺣﻲ ﻣﻲ ﮔﺮدﻧﺪ

Where A is taken above the LA (HH) liquid

level and Qmax is the process design value of Q

plus a margin, (see7.2.1). Horizontal vessels

are usually designed to be between about one

third and one half-full of liquid.

:ﻳﺎدآوري

Note:

)ﺑﻪ،ﺣﺠﻢ ﻣﺎﻧﺪ ﻣﺎﻳﻊ ﺗﻮﺳﻂ ﻣﻼﺣﻈﺎت دﻳﮕﺮ ﺗﻌﻴﻴﻦ ﻣﻲ ﺷﻮد

Lv . روش ﻃﺮاﺣﻲ ﺷﺎﻣﻞ ﺣﺪس و ﺧﻄﺎ اﺳﺖ.( را ﺑﺒﻴﻨﻴﺪ4-2-7

ﺛﺎﺑﺖ ﻫﺴﺘﻨﺪ و ﭘﺮﺷﺪن ﺟﺰﺋﻲ ﺑﺮاي ﺟﺒﺮان اﻟﺰاﻣﺎت زﻣﺎنDv و

ﺳﭙﺲ ﻻزم اﺳﺖ ﺑﺮرﺳﻲ ﺷﻮد ﻛﻪ ﻧﺴﺒﺖ.ﻣﺎﻧﺪ اﻧﺘﺨﺎب ﻣﻲ ﺷﻮد

ﺣﺪس اوﻟﻴﻪ ﺑﺮاي. ﻣﺘﺮ ﺑﺮﺛﺎﻧﻴﻪ ﺗﺠﺎوز ﻧﻨﻤﺎﻳﺪ0/1 ازQmax/A

ﺑﺮاي اﻳﻦ6/0 ﺗﺎ2/5 ﻣﻘﺎدﻳﺮ، ﻓﺮض ﻣﻲ ﺷﻮد3 Lv/Dv ﻧﺴﺒﺖ

ﻳﺎ ﺑﺰرﮔﺘﺮ ﺑﺮاي ﻛﺎرﺑﺮدﻫﺎي6/0 ﻣﻘﺎدﻳﺮ،ﻧﺴﺒﺖ ﻋﺎدي ﻫﺴﺘﻨﺪ

.ﻓﺸﺎر ﺑﺎﻻ ﺗﻮﺻﻴﻪ ﻣﻲ ﺷﻮﻧﺪ

The liquid hold-up volume is determined by other

considerations, (See 7.2.4). The design method

involves trial and error. Lv and Dv are fixed, and a

fractional filling chosen to satisfy liquid hold-up

requirements. It is then necessary to check that

Qmax/A does not exceed 0.1 m/s. A starting value

for the ratio Lv/Dv of 3.0 is suggested; values of

2.5 to 6.0 for this ratio are normal; values of 6.0 or

higher are recommended for high-pressure

applications.

ب( ﻧﺎزﻟﻬﺎ

b) Nozzles

( ﻧﺎزل ﺧﻮراك1

1) Feed Nozzle

ﻣﻤﻜﻦ اﺳﺖ ﺑﺎ ﻗﻄﺮ ﻟﻮﻟﻪ ورودي ﺧﻮراك ﺑﺮاﺑﺮdn ﻗﻄﺮ ﻧﺎزل

1000 از m × V2m ﺑﺎﺷﺪ اﻣﺎ ﻧﺒﺎﻳﺪ ﺣﺎﺻﻠﻀﺮب

. ﺗﺠﺎوز ﻛﻨﺪkg/m.s²

The nozzle diameter, dn, may be taken

equal to that of the feed pipe, but the

product

(Eq. 7)

m × V2m

(7 )ﻣﻌﺎدﻟﻪ

shall not exceed 1000 kg/m.s².

( ﻧﺎزل ﺧﺮوﺟﻲ ﮔﺎز2

2) Gas Outlet Nozzle

ﻫﻤﺎن روش ﻣﻮرد اﺳﺘﻔﺎده در،ﺑﺮاي ﻧﺎزل ﮔﺎز ﺧﺮوﺟﻲ

ﻣﺮاﺟﻌﻪ1-1-5-2-7 )ﺑﻪ،ﻇﺮف ﻋﻤﻮدي ﺑﻜﺎر ﻣﻲ رود

.(ﺷﻮد

For gas outlet nozzle, the same method can be

applied as for a vertical vessel, (see 7.2.5.1.1).

( ﻧﺎزل ﺧﺮوﺟﻲ ﻣﺎﻳﻊ3

3) Liquid Outlet Nozzle

ﺑﺮاي ﻧﺎزل ﺧﺮوﺟﻲ ﻣﺎﻳﻊ ﻫﻤﺎن روش ﻣﻮرد اﺳﺘﻔﺎده در

( ﻣﺮاﺟﻌﻪ1-1-5-2-7 )ﺑﻪ،ﻇﺮف ﻋﻤﻮدي ﺑﻜﺎر ﻣﻲ رود

.ﺷﻮد

For Liquid outlet nozzle, the same method

can be applied as for a vertical vessel, (see

7.2.5.1.1).

ج( اﻓﺖ ﻓﺸﺎر

c) Pressure Drop

اﻓﺖ ﻓﺸﺎر را ﻫﻢ ﻣﻲ ﺗﻮان ﺑﻪ روش ﻇﺮف ﻋﻤﻮدي ﻣﺤﺎﺳﺒﻪ

(1-1-5-2-7 )ﻣﺮاﺟﻌﻪ ﺷﻮد ﺑﻪ.ﻛﺮد

The pressure drop can be calculated as for a

vertical vessel (see 7.2.5.1.1).

7.2.5.2 Conventional gas-liquid separators with

wire mesh mist extractors

Wire mesh pads are frequently used as

entrainment separators for the removal of very

small liquid droplets and, therefore, a higher overall percentage removal of liquid. Removal of

droplets down to 10 micrometers or smaller may

be possible with these pads. Typical wire mesh

installation in gas-liquid separators is illustrated in

ﻣﺎﻳﻊ ﻫﻤﺮاه ﺑﺎ- ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻣﺘﺪاول ﮔﺎز2-5-2-7

اﺳﺘﺨﺮاج ﻛﻨﻨﺪهﻫﺎي ﻗﻄﺮه از ﻧﻮع ﺗﻮري ﺳﻴﻤﻲ

ﻻﻳﻪ ﻫﺎي ﺗﻮر ﺳﻴﻤﻲ اﻏﻠﺐ ﺑﺮاي ﺟﺬب ذرات و ﻗﻄﺮات ﺑﺴﻴﺎر

ﺣﺬف.رﻳﺰ ﻣﺎﻳﻊ ﺑﻜﺎر ﻣﻲ رود و درﺻﺪ ﺣﺬف ﻣﺎﻳﻊ آﻧﻬﺎ ﺑﺎﻻﺳﺖ

. ﻣﻴﻜﺮوﻣﺘﺮ ﺑﺎ اﻳﻦ ﻻﻳﻪ ﻫﺎ اﻣﻜﺎن ﭘﺬﻳﺮ اﺳﺖ10 ذرات ﻛﻮﭼﻜﺘﺮ از

ﻧﻤﻮﻧﻪ ﻧﺼﺐ ﻧﻮع ﺗﻮر ﺳﻴﻤﻲ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﮔﺎز – ﻣﺎﻳﻊ در

20

Jan. 2010/ 1388 دي

Fig. B.1 of Appendix B.

In plants where fouling or hydrate formation is

possible or expected, mesh pads are typically not

used. In these services vane or centrifugal type

separators are generally more appropriate.

. در ﭘﻴﻮﺳﺖ ب ﻧﺸﺎن داده ﺷﺪه اﺳﺖ1-ﺷﻜﻞ ب

در ﻛﺎرﺧﺎﻧﺠﺎت ﻛﻪ اﻳﺠﺎد رﺳﻮﺑﺎت ﻳﺎ ﻫﻴﺪراﺗﻬﺎ ﻣﻤﻜﻦ ﺑﻮده ﻳﺎ

ﺗﻮرﻫﺎي ﺳﻴﻤﻲ ﻣﻌﻤﻮﻻً ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار،اﻧﺘﻈﺎر ﻣﻲ رود

در اﻳﻦ ﻧﻮع ﻛﺎرﺑﺮي ﻫﺎ ﻫﻤﻮاره ﺟﺪاﻛﻨﻨﺪه ﻫﺎي ﻧﻮع.ﻧﻤﻲﮔﻴﺮﻧﺪ

.ﭘﺮه اي ﻳﺎ ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﻣﻲ ﮔﻴﺮﻧﺪ

ﻣﻴﻠﻴﻤﺘﺮ ﻫﻤﺮاه ﺑﺎ ﭼﮕﺎﻟﻲ150 اﻛﺜﺮ ﺗﺄﺳﻴﺴﺎت از ﻻﻳﻪ ﺑﺎ ﺿﺨﺎﻣﺖ

. ﻛﻴﻠﻮ ﮔﺮم ﺑﺮ ﻣﺘﺮ ﻣﻜﻌﺐ اﺳﺘﻔﺎده ﻣﻲ ﻛﻨﻨﺪ190-145 ﺗﻮدهاي

. ﻣﻴﻠﻴﻤﺘﺮ ﻣﻲ ﺑﺎﺷﺪ100 ﻛﻤﺘﺮﻳﻦ ﺿﺨﺎﻣﺖ ﺗﻮﺻﻴﻪ ﺷﺪه ﻻﻳﻪ

ﺑﺮاي ﻃﺮﺣﻬﺎي ﺧﺎص ﺗﻮﺻﻴﻪ ﻣﻴﺸﻮد ﺑﻪ ﺗﻮﻟﻴﺪ ﻛﻨﻨﺪﮔﺎن ﻣﺮاﺟﻌﻪ

.ﺷﻮد

در ﺻﻮرﺗﻲ ﻛﻪ ﻳﻚ ﻗﻄﺮه ﮔﻴﺮ ﺑﺎ اﻧﺪازه ﺑﺴﻴﺎر ﺑﺰرگ ﻣﺪﻧﻈﺮ ﺑﺎﺷﺪ

.ﻇﺮف ﺑﺎﻳﺪ ﺑﺼﻮرت اﻓﻘﻲ ﻃﺮاﺣﻲ ﮔﺮدد

Most installations will use a 150 mm thick pad

with 145-190 kg/m³ bulk density. Minimum

recommended pad thickness is 100 mm.

Manufacturers should be contacted for specific

designs.

If the mist eliminators need to be designed for an

excessively large size, the vessels shall be

designed for a horizontal type.

7.2.5.2.1 Vertical demister separators

Most vertical separators that employ mist

extractors are sized using equations that are

derived from gravity settling equations . The most

common equation used is the critical velocity

equation:

Vc K

(Eq. 8)

IPS-E-PR-880(1)

ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻗﻄﺮه ﮔﻴﺮ ﻋﻤﻮدي1-2-5-2-7

اﻛﺜﺮ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻋﻤﻮدي ﻛﻪ داراي اﺳﺘﺨﺮاج ﻛﻨﻨﺪه ﻗﻄﺮه

ﻫﺴﺘﻨﺪ ﺑﺎ اﺳﺘﻔﺎده از ﻣﻌﺎدﻻت ﻣﺸﺘﻖ ﺷﺪه از ﻣﻌﺎدﻻت رﺳﻮب

ﻋﻤﻮﻣﻲ ﺗﺮﻳﻦ ﻣﻌﺎدﻟﻪ.ﮔﺬاري ﮔﺮاﻧﺸﻲ ﺗﻌﻴﻴﻦ اﻧﺪازه ﻣﻲ ﺷﻮﻧﺪ

:ﻣﻮرد اﺳﺘﻔﺎده ﻣﻌﺎدﻟﻪ ﺳﺮﻋﺖ ﺑﺤﺮاﻧﻲ زﻳﺮ اﺳﺖ

1 g

(8 )ﻣﻌﺎدﻟﻪ

g

Some typical values of the separator sizing factor,

K, are given in Table 2. Note that this equation

actually gives the size of the separation element

(mist extractor), and does not size the actual

separator containment vessel. That means the

vessel may be selected larger than the element,

(e.g., for surge requirements).

درK ، ﺑﺮﺧﻲ ﻣﻘﺎدﻳﺮ ﻧﻤﻮﻧﻪ ﻋﺎﻣﻞ ﺗﻌﻴﻴﻦ اﻧﺪازه ﺟﺪا ﻛﻨﻨﺪه

ﺗﻮﺟﻪ ﺑﺎﻳﺪ داﺷﺖ ﻛﻪ اﻳﻦ ﻣﻌﺎدﻟﻪ. آورده ﺷﺪه اﺳﺖ2 ﺟﺪول

اﻧﺪازه ﻋﻨﺼﺮ ﺟﺪاﺳﺎزي )اﺳﺘﺨﺮاج ﻛﻨﻨﺪه ﻗﻄﺮه( را ﻣﻲ دﻫﺪ و ﻧﻪ

اﻳﻦ ﺑﺪان ﻣﻌﻨﻲ اﺳﺖ ﻛﻪ.اﻧﺪازه ﺣﻘﻴﻘﻲ ﻇﺮف ﺟﺪا ﻛﻨﻨﺪه را

ﻣﻤﻜﻦ اﺳﺖ )ﻣﺜﻼً ﺑﺮاي اﻟﺰاﻣﺎت ﻧﻮﺳﺎن( ﻇﺮف ﺑﺰرﮔﺘﺮ از ﻋﺎﻣﻞ

.ﺻﺎﻓﻲ اﻧﺘﺨﺎب ﮔﺮدد

TABLE 2 - TYPICAL K FACTORS FOR SIZING WIRE MESH DEMISTERS

ﺑﺮاي ﺗﻌﻴﻴﻦ اﻧﺪازه ﻗﻄﺮه ﮔﻴﺮﻫﺎي از ﻧﻮع ﺗﻮري ﺳﻴﻤﻲK ﻧﻤﻮﻧﻪ ﺿﺮاﻳﺐ-2 ﺟﺪول

23

SEPARATOR TYPE

ﻧﻮع ﺟﺪاﻛﻨﻨﺪه

Horizontal (with vert. pad)

Spherical

Vertical or horizontal (with horiz. pad)

K. FACTOR m/s

(اﻓﻘﻲ )ﺑﺎ ﻻﻳﻪ ﻋﻤﻮدي

ﻛﺮوي

At 2100 kPa

At 4100 kPa

At 10300 kPa

Wet steam

Most vapors under vacuum

Salt and caustic evaporators

0.107

0.101

در

در

در

0.091

ﺑﺨﺎر ﻣﺮﻃﻮب

اﻛﺜﺮ ﺑﺨﺎرات ﺗﺤﺖ ﺷﺮاﻳﻂ ﺧﻸ

0.076

4100

6200

10300

At 6200 kPa

0.061 to 0.107

0.055 to 0.107

(اﻓﻘﻲ ﻳﺎ ﻋﻤﻮدي )ﺑﺎ ﻻﻳﻪ اﻓﻘﻲ

در ﻓﺸﺎر اﺗﻤﺴﻔﺮ

2100 kPa در

At atm. press.

K ﺿﺮﻳﺐ

0.122 to 0.152

0.082

0.064

0.061

0.046

ﺗﺒﺨﻴﺮ ﻛﻨﻨﺪه ﻫﺎي ﺳﻮد ﺳﻮز آور و ﻧﻤﻚ

21

Jan. 2010/ 1388 دي

IPS-E-PR-880(1)

:ﻳﺎدآوري ﻫﺎ

Notes:

700 ﺑﻪ ازاء ﻫﺮ- ﻛﻴﻠﻮﭘﺎﺳﻜﺎل700 درK = 0.107 (1

ﻛﻢ0/003 ، ﻛﻴﻠﻮ ﭘﺎﺳﻜﺎل700 ﻛﻴﻠﻮ ﭘﺎﺳﻜﺎل ﺑﺎﻻي

.ﺷﻮد

ﺗﺎ0/6 را درK ،( ﺑﺮاي ﻣﺤﻠﻮﻟﻬﺎي ﮔﻼﻳﻜﻮل و آﻣﻴﻦ2

. ﺿﺮب ﻛﻨﻴﺪ0/8

ذﻛﺮ ﺷﺪه در ﺑﺎﻻ را ﺑﺮايK ( ﻋﻤﻮﻣﺎ ﻧﺼﻒ ﻣﻘﺎدﻳﺮ3

ﺗﻌﻴﻴﻦ اﻧﺪازه ﺗﻘﺮﻳﺒﻲ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎي ﻋﻤﻮدي ﺑﺪون

.ﺗﻮر ﺳﻴﻤﻲ ﻗﻄﺮه ﮔﻴﺮ اﺳﺘﻔﺎده ﺷﻮد

( ﺑﺮاي ﻋﺎري ﺳﺎزﻫﺎي ﻣﻜﺶ ﻛﻤﭙﺮﺳﻮر و ﺟﺪاﻛﻨﻨﺪه4

0/8 ﺗﺎ0/7 را درK ﻫﺎي ورودي ﻣﻨﺒﺴﻂ ﻛﻨﻨﺪه

.ﺿﺮب ﻛﻨﻴﺪ

روش زﻳﺮ ﻳﻚ روش ﺗﻘﺮﻳﺒﻲ اﺳﺖ وﻟﻲ روش ﻣﻄﻤﺌﻦ ﺑﺮاي

.ﺗﻌﻴﻴﻦ اﻧﺪازه ﺟﺪاﻛﻨﻨﺪه ﻫﺎي ﻗﻄﺮه ﮔﻴﺮي ﻋﻤﻮدي اﺳﺖ

1) K = 0.107 at 700 kPa - Subtract 0.003 for

every 700 kPa above 700 kPa.

2) For glycol and amine solutions, multiply K

by 0.6 to 0.8.

3) Typically use one-half of the above K values

for approximate sizing of vertical separators

without wire mesh demisters.

4)For compressor suction scrubbers and

expander inlet separators multiply K by 0.7 0.8.

The following is a rough, but safe sizing method

for vertical demister separators:

اﻟﻒ( ﻗﻄﺮ

a) Diameter

: از ﻓﺮﻣﻮل زﻳﺮ ﭘﻴﺮوي ﻣﻲ ﻛﻨﺪDv ﻗﻄﺮ ﻇﺮف

The vessel diameter, Dv follows from:

Q max

(Eq. 9 )

D 2v / 4

0.105m / s

وﻗﺘﻲ ﻛﻪ ﻳﻚ ﺣﻠﻘﻪ ﻧﮕﻬﺪارﻧﺪه اﺳﺘﺎﻧﺪارد ﺑﺮاي ﺣﺼﻴﺮ ﻗﻄﺮه

Dv ﻋﺮض ﺣﻠﻘﻪ ﻗﺎﺑﻞ اﻏﻤﺎض ﺑﻮده و،ﮔﻴﺮ ﻃﺮاﺣﻲ ﻣﻲ ﺷﻮد

ﻣﺤﺎﺳﺒﻪ،از ﻣﻌﺎدﻟﻪ ﺑﺎﻻ ﻛﻪ ﻗﻄﺮ داﺧﻠﻲ ﻇﺮف ﻣﻲ ﺑﺎﺷﺪ

.ﺧﻮاﻫﺪ ﺷﺪ

When a standard support ring for the demister

mat is designed, then the width of the ring is

considered to be negligible and Dv calculated

from the above formula will be the vessel

internal diameter.

:ﻳﺎدآوريﻫﺎ

Notes:

( ﺑﺮاي ﻣﺎﻳﻌﺎت ﮔﺮاﻧﺮو ﺣﺪاﻛﺜﺮ ﻇﺮﻓﻴﺖ ﻳﻚ ﺣﺼﻴﺮ ﻗﻄﺮه1

1) For viscous liquids, the maximum capacity

of a horizontal demister mat is less.

.ﮔﻴﺮ اﻓﻘﻲ ﻛﻤﺘﺮ اﺳﺖ

10 ﻣﺘﺮ در ﺛﺎﻧﻴﻪ را0/105 ﻣﻘﺪارµg =100 cP ﺑﺮاي

.درﺻﺪ ﻛﺎﻫﺶ داده ﺷﻮد

. درﺻﺪ ﻛﺎﻫﺶ اﻋﻤﺎل ﺷﻮد20 ، µg =1000 cPﺑﺮاي

For µg =100 cP reduce the value 0.105 m/s by

10%.

For µg =1000 cP, apply 20% reduction.

2) Maximum capacity of the mat decreases as

the rate of liquid fed to it increases. The above

values apply to a lightly loaded mat, as

encountered in most separators.

( ﺣﺪاﻛﺜﺮ ﻇﺮﻓﻴﺖ ﺻﻔﺤﻪ ﺗﻮري ﻫﺎ ﺑﺎ اﻓﺰاﻳﺶ ﻣﻴﺰان ورود2

ﻣﻘﺎدﻳﺮ ذﻛﺮ ﺷﺪه در ﺑﺎﻻ ﺑﺮاي ﺻﻔﺤﻪ.ﻣﺎﻳﻊ ﻛﺎﻫﺶ ﻣﻲ ﻳﺎﺑﺪ

. ﺑﻜﺎر ﻣﻲ رود، ﺗﻮري ﻛﻢ ﺑﺎر ﻣﺎﻧﻨﺪ اﻛﺜﺮ ﺟﺪا ﻛﻨﻨﺪه ﻫﺎ

ب( ارﺗﻔﺎع

b) Height

ارﺗﻔﺎع ﻻزم ﻇﺮف ﺑﺮاي زﻣﺎن ﻣﺎﻧﺪ ﻣﺎﻳﻊ ﻣﻲ ﺑﺎﺷﺪh

ﺑﻨﺎﺑﺮاﻳﻦ ﻣﻌﺎدﻟﻪ ارﺗﻔﺎع ﻛﻞ ﻇﺮف.( را ﺑﺒﻴﻨﻴﺪ2-4-2-7 )ﺑﻨﺪ

:)ﻣﻤﺎس ﺗﺎ ﻣﻤﺎس( ﺑﻪ ﺻﻮرت زﻳﺮ اﺳﺖ

Let h be the height of vessel required for liquid

hold-up (see 7.2.4.2). Then the total vessel

height (tangent to tangent)is

(Eq. 10)

(9 )ﻣﻌﺎدﻟﻪ

H = h + dn + t + X + Y + 0.15 Dv

22

(10 )ﻣﻌﺎدﻟﻪ

Jan. 2010/ 1388 دي

IPS-E-PR-880(1)

:ﻛﻪ

Where:

dn = diameter of inlet nozzle

:ﻗﻄﺮ ﻧﺎزل ورودي

t = thickness of demister mat,

usually 0.1 m

ﻣﺘﺮ0/1 ًﺿﺨﺎﻣﺖ ﺣﺼﻴﺮ ﻗﻄﺮ ﮔﻴﺮ ﻣﻌﻤﻮﻻ

X = 0.3 Dv with a minimum of 0.3 m ﺑﺎ ﺣﺪاﻗﻞ

ﻣﺘﺮ0/3 0.3 Dv

for a vessel equipped with half-open pipe

inlet device ﺑﺮاي ﻇﺮف ﻣﺠﻬﺰ ﺑﻪ دﺳﺘﮕﺎه ورودي

Y = 0.45 Dv with a minimum of 0.9 m ﺑﺎ ﺣﺪاﻗﻞ

ﻣﺘﺮ0/9 0/45 Dv

ﻟﻮﻟﻪ ﻧﻴﻢ ﺑﺎز

ج( ﻧﺎزﻟﻬﺎ