IPS-E-PM-385(2)

FOREWORD

The Iranian Petroleum Standards (IPS) reflect the

views of the Iranian Ministry of Petroleum and are

intended for use in the oil and gas production

facilities,

oil

refineries,

chemical

and

petrochemical plants, gas handling and processing

installations and other such facilities.

IPS is based on internationally acceptable

standards and includes selections from the items

stipulated in the referenced standards. They are

also supplemented by additional requirements

and/or modifications based on the experience

acquired by the Iranian Petroleum Industry and

the local market availability. The options which

are not specified in the text of the standards are

itemized in data sheet/s, so that, the user can select

his appropriate preferences therein.

The IPS standards are therefore expected to be

sufficiently flexible so that the users can adapt

these standards to their requirements. However,

they may not cover every requirement of each

project. For such cases, an addendum to IPS

Standard shall be prepared by the user which

elaborates the particular requirements of the user.

This addendum together with the relevant IPS

shall form the job specification for the specific

project or work.

The IPS is reviewed and up-dated approximately

every five years. Each standards are subject to

amendment or withdrawal, if required, thus the

latest edition of IPS shall be applicable

The users of IPS are therefore requested to send

their views and comments, including any

addendum prepared for particular cases to the

following address. These comments and

recommendations will be reviewed by the relevant

technical committee and in case of approval will

be incorporated in the next revision of the

standard.

Standards and Research department

No.19, Street14, North kheradmand

Karimkhan Avenue, Tehran, Iran .

Postal Code- 1585886851

Tel: 88810459-60 & 66153055

Fax: 88810462

Email: Standards@nioc.org

ﭘﻴﺶ ﮔﻔﺘﺎر

( ﻣﻨﻌﻜﺲ ﻛﻨﻨﺪه دﻳﺪﮔﺎﻫﻬﺎيIPS) اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮان

وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ و ﺑﺮاي اﺳﺘﻔﺎده در ﺗﺄﺳﻴﺴﺎت ﺗﻮﻟﻴﺪ ﻧﻔﺖ

، واﺣﺪﻫﺎي ﺷﻴﻤﻴﺎﺋﻲ و ﭘﺘﺮوﺷﻴﻤﻲ، ﭘﺎﻻﻳﺸﮕﺎﻫﻬﺎي ﻧﻔﺖ،و ﮔﺎز

ﺗﺄﺳﻴﺴﺎت اﻧﺘﻘﺎل و ﻓﺮاورش ﮔﺎز و ﺳﺎﻳﺮ ﺗﺄﺳﻴﺴﺎت ﻣﺸﺎﺑﻪ ﺗﻬﻴﻪ

.ﺷﺪه اﺳﺖ

ﺑﺮاﺳﺎس اﺳﺘﺎﻧﺪاردﻫﺎي ﻗﺎﺑﻞ ﻗﺒﻮل ﺑﻴﻦ،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

اﻟﻤﻠﻠﻲ ﺗﻬﻴﻪ ﺷﺪه و ﺷﺎﻣﻞ ﮔﺰﻳﺪهﻫﺎﺋﻲ از اﺳﺘﺎﻧﺪاردﻫﺎي ﻣﺮﺟﻊ

ﻫﻤﭽﻨﻴﻦ ﺑﺮاﺳﺎس ﺗﺠﺮﺑﻴﺎت ﺻﻨﻌﺖ ﻧﻔﺖ ﻛﺸﻮر و.ﻣﻲﺑﺎﺷﺪ

ﻣﻮاردي،ﻗﺎﺑﻠﻴﺖ ﺗﺄﻣﻴﻦ ﻛﺎﻻ از ﺑﺎزار داﺧﻠﻲ و ﻧﻴﺰ ﺑﺮﺣﺴﺐ ﻧﻴﺎز

.ﺑﻄﻮر ﺗﻜﻤﻴﻠﻲ و ﻳﺎ اﺻﻼﺣﻲ در اﻳﻦ اﺳﺘﺎﻧﺪارد ﻟﺤﺎظ ﺷﺪه اﺳﺖ

ﻣﻮاردي از ﮔﺰﻳﻨﻪﻫﺎي ﻓﻨﻲ ﻛﻪ در ﻣﺘﻦ اﺳﺘﺎﻧﺪاردﻫﺎ آورده ﻧﺸﺪه

اﺳﺖ در داده ﺑﺮگﻫﺎ ﺑﺼﻮرت ﺷﻤﺎره ﮔﺬاري ﺷﺪه ﺑﺮاي اﺳﺘﻔﺎده

.ﻣﻨﺎﺳﺐ ﻛﺎرﺑﺮان آورده ﺷﺪه اﺳﺖ

ﺑﺸﻜﻠﻲ ﻛﺎﻣﻼً اﻧﻌﻄﺎف ﭘﺬﻳﺮ ﺗﺪوﻳﻦ ﺷﺪه،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

.اﺳﺖ ﺗﺎ ﻛﺎرﺑﺮان ﺑﺘﻮاﻧﻨﺪ ﻧﻴﺎزﻫﺎي ﺧﻮد را ﺑﺎ آﻧﻬﺎ ﻣﻨﻄﺒﻖ ﻧﻤﺎﻳﻨﺪ

ﺑﺎ اﻳﻦ ﺣﺎل ﻣﻤﻜﻦ اﺳﺖ ﺗﻤﺎم ﻧﻴﺎزﻣﻨﺪيﻫﺎي ﭘﺮوژه ﻫﺎ را ﭘﻮﺷﺶ

در اﻳﻦ ﮔﻮﻧﻪ ﻣﻮارد ﺑﺎﻳﺪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﻧﻴﺎزﻫﺎي ﺧﺎص.ﻧﺪﻫﻨﺪ

اﻳﻦ اﻟﺤﺎﻗﻴﻪ.آﻧﻬﺎ را ﺗﺎﻣﻴﻦ ﻣﻲﻧﻤﺎﻳﺪ ﺗﻬﻴﻪ و ﭘﻴﻮﺳﺖ ﻧﻤﺎﻳﻨﺪ

ﻣﺸﺨﺼﺎت ﻓﻨﻲ آن ﭘﺮوژه و ﻳﺎ ﻛﺎر،ﻫﻤﺮاه ﺑﺎ اﺳﺘﺎﻧﺪارد ﻣﺮﺑﻮﻃﻪ

.ﺧﺎص را ﺗﺸﻜﻴﻞ ﺧﻮاﻫﻨﺪ داد

اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ ﺗﻘﺮﻳﺒﺎً ﻫﺮ ﭘﻨﺞ ﺳﺎل ﻳﻜﺒﺎر ﻣﻮرد ﺑﺮرﺳﻲ ﻗﺮار

در اﻳﻦ ﺑﺮرﺳﻲﻫﺎ ﻣﻤﻜﻦ اﺳﺖ.ﮔﺮﻓﺘﻪ و روزآﻣﺪ ﻣﻲﮔﺮدﻧﺪ

اﺳﺘﺎﻧﺪاردي ﺣﺬف و ﻳﺎ اﻟﺤﺎﻗﻴﻪاي ﺑﻪ آن اﺿﺎﻓﻪ ﺷﻮد و ﺑﻨﺎﺑﺮاﻳﻦ

.ﻫﻤﻮاره آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻧﻬﺎ ﻣﻼك ﻋﻤﻞ ﻣﻲ ﺑﺎﺷﺪ

درﺧﻮاﺳﺖ ﻣﻲﺷﻮد ﻧﻘﻄﻪ ﻧﻈﺮﻫﺎ و،از ﻛﺎرﺑﺮان اﺳﺘﺎﻧﺪارد

ﭘﻴﺸﻨﻬﺎدات اﺻﻼﺣﻲ و ﻳﺎ ﻫﺮﮔﻮﻧﻪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﺑﺮاي ﻣﻮارد

ﻧﻈﺮات و. ﺑﻪ ﻧﺸﺎﻧﻲ زﻳﺮ ارﺳﺎل ﻧﻤﺎﻳﻨﺪ،ﺧﺎص ﺗﻬﻴﻪ ﻧﻤﻮدهاﻧﺪ

ﭘﻴﺸﻨﻬﺎدات درﻳﺎﻓﺘﻲ در ﻛﻤﻴﺘﻪﻫﺎي ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ ﺑﺮرﺳﻲ و در

ﺻﻮرت ﺗﺼﻮﻳﺐ در ﺗﺠﺪﻳﺪ ﻧﻈﺮﻫﺎي ﺑﻌﺪي اﺳﺘﺎﻧﺪارد ﻣﻨﻌﻜﺲ

.ﺧﻮاﻫﺪ ﺷﺪ

ﻛﻮﭼﻪ، ﺧﺮدﻣﻨﺪ ﺷﻤﺎﻟﻲ، ﺧﻴﺎﺑﺎن ﻛﺮﻳﻤﺨﺎن زﻧﺪ، ﺗﻬﺮان،اﻳﺮان

19 ﺷﻤﺎره،ﭼﻬﺎردﻫﻢ

اداره ﺗﺤﻘﻴﻘﺎت و اﺳﺘﺎﻧﺪاردﻫﺎ

1585886851 : ﻛﺪﭘﺴﺘﻲ

66153055 و88810459 - 60 : ﺗﻠﻔﻦ

88810462 : دور ﻧﮕﺎر

Standards@nioc.org

:ﭘﺴﺖ اﻟﻜﺘﺮوﻧﻴﻜﻲ

GENERAL DEFINITIONS:

Throughout this Standard the following

definitions shall apply.

COMPANY :

Refers to one of the related and/or affiliated

companies of the Iranian Ministry of Petroleum

such as National Iranian Oil Company, National

Iranian Gas Company, National Petrochemical

Company and National Iranian Oil Refinery And

Distribution Company.

PURCHASER :

Means the “Company" where this standard is a

part of direct purchaser order by the “Company”,

and the “Contractor” where this Standard is a part

of contract documents.

VENDOR AND SUPPLIER:

Refers to firm or person who will supply and/or

fabricate the equipment or material.

CONTRACTOR:

Refers to the persons, firm or company whose

tender has been accepted by the company.

EXECUTOR :

Executor is the party which carries out all or part of

construction and/or commissioning for the project.

INSPECTOR :

The Inspector referred to in this Standard is a

person/persons or a body appointed in writing by

the company for the inspection of fabrication and

installation work

SHALL:

Is used where a provision is mandatory.

SHOULD:

Is used where a provision is advisory only.

WILL:

Is normally used in connection with the action by

the “Company” rather than by a contractor,

supplier or vendor.

MAY:

Is used where a provision is completely

discretionary.

: ﺗﻌﺎرﻳﻒ ﻋﻤﻮﻣﻲ

.در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺗﻌﺎرﻳﻒ زﻳﺮ ﺑﻪ ﻛﺎر ﻣﻲ رود

: ﺷﺮﻛﺖ

ﻣﺜﻞ،ﺑﻪ ﻳﻜﻲ از ﺷﺮﻛﺖ ﻫﺎي اﺻﻠﻲ و ﻳﺎ واﺑﺴﺘﻪ ﺑﻪ وزارت ﻧﻔﺖ

ﺷﺮﻛﺖ ﻣﻠﻲ، ﺷﺮﻛﺖ ﻣﻠﻲ ﮔﺎز اﻳﺮان،ﺷﺮﻛﺖ ﻣﻠﻲ ﻧﻔﺖ اﻳﺮان

ﺻﻨﺎﻳﻊ ﭘﺘﺮوﺷﻴﻤﻲ و ﺷﺮﻛﺖ ﻣﻠﻲ ﭘﺎﻻﻳﺶ و ﭘﺨﺶ ﻓﺮآوردهﻫﺎي

.ﻧﻔﺘﻲ اﻃﻼق ﻣﻲﺷﻮد

:ﺧﺮﻳﺪار

ﻳﻌﻨﻲ ﺷﺮﻛﺘﻲ ﻛﻪ اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﺳﻔﺎرش

ﺧﺮﻳﺪ ﻣﺴﺘﻘﻴﻢ آن ﺷﺮﻛﺖ ﻣﻲﺑﺎﺷﺪ و ﻳﺎ ﭘﻴﻤﺎﻧﻜﺎري ﻛﻪ اﻳﻦ

.اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﻗﺮارداد آن اﺳﺖ

:ﻓﺮوﺷﻨﺪه و ﺗﺎﻣﻴﻦ ﻛﻨﻨﺪه

ﺑﻪ ﻣﻮﺳﺴﻪ و ﻳﺎ ﺷﺨﺼﻲ ﮔﻔﺘﻪ ﻣﻲﺷﻮد ﻛﻪ ﺗﺠﻬﻴﺰات و ﻛﺎﻻﻫﺎي

.ﻣﻮرد ﻟﺰوم ﺻﻨﻌﺖ را ﺗﺎﻣﻴﻦ ﻣﻲﻧﻤﺎﻳﺪ

:ﭘﻴﻤﺎﻧﻜﺎر

ﻣﻮﺳﺴﻪ و ﻳﺎ ﺷﺮﻛﺘﻲ ﮔﻔﺘﻪ ﻣﻲﺷﻮد ﻛﻪ ﭘﻴﺸﻨﻬﺎدش،ﺑﻪ ﺷﺨﺺ

.ﺑﺮاي ﻣﻨﺎﻗﺼﻪ ﭘﺬﻳﺮﻓﺘﻪ ﺷﺪه اﺳﺖ

: ﻣﺠﺮي

ﻣﺠﺮي ﺑﻪ ﮔﺮوﻫﻲ اﻃﻼق ﻣﻲﺷﻮد ﻛﻪ ﺗﻤﺎم ﻳﺎ ﻗﺴﻤﺘﻲ از ﻛﺎرﻫﺎي

.اﺟﺮاﺋﻲ و ﻳﺎ راه اﻧﺪازي ﭘﺮوژه را اﻧﺠﺎم دﻫﺪ

:ﺑﺎزرس

ﮔﺮوه ﻳﺎ ﻣﻮﺳﺴﻪاي اﻃﻼق/در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺎزرس ﺑﻪ ﻓﺮد

ﻣﻲﺷﻮد ﻛﻪ ﻛﺘﺒﺎً ﺗﻮﺳﻂ ﻛﺎرﻓﺮﻣﺎ ﺑﺮاي ﺑﺎزرﺳﻲ ﺳﺎﺧﺖ و ﻧﺼﺐ

.ﺗﺠﻬﻴﺰات ﻣﻌﺮﻓﻲ ﺷﺪه ﺑﺎﺷﺪ

:ﺑﺎﻳﺪ

. اﺳﺘﻔﺎده ﻣﻲﺷﻮد،ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺟﺒﺎري اﺳﺖ

:ﺗﻮﺻﻴﻪ

. ﺑﻜﺎر ﻣﻲرود،ﺑﺮاي ﻛﺎري ﻛﻪ ﺿﺮورت اﻧﺠﺎم آن ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد

:ﺗﺮﺟﻴﺢ

ﻣﻌﻤﻮﻻً در ﺟﺎﻳﻲ اﺳﺘﻔﺎده ﻣﻲﺷﻮد ﻛﻪ اﻧﺠﺎم آن ﻛﺎر ﺑﺮاﺳﺎس

.ﻧﻈﺎرت ﺷﺮﻛﺖ ﺑﺎﺷﺪ

: ﻣﻤﻜﻦ اﺳﺖ

. ﺑﻜﺎر ﻣﻲرود،ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺧﺘﻴﺎري ﻣﻲﺑﺎﺷﺪ

IPS-E-PM-385(2)

0

ENGINEERING STANDARD

FOR

PROCESS MACHINERY PIPING

SECOND REVISION

AUGUST 2009

اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ

ﺑﺮاي

ﻟﻮﻟﻪﻛﺸﻲ ﻣﺎﺷﻴﻨﻬﺎي ﻓﺮآﻳﻨﺪي

وﻳﺮاﻳﺶ دوم

1388 ﺷﻬﺮﻳﻮر

This Standard is the property of Iranian Ministry of

Petroleum. All rights are reserved to the owner. Neither

whole nor any part of this document may be disclosed to any

third party, reproduced, stored in any retrieval system or

transmitted in any form or by any means without the prior

written consent of the Iranian Ministry of Petroleum.

ﺗﻤﺎم ﺣﻘﻮق آن ﻣﺘﻌﻠﻖ ﺑﻪ.اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﺘﻌﻠﻖ ﺑﻪ وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ

ﺗﻤﺎم ﻳﺎ ﺑﺨﺸﻲ،ﻣﺎﻟﻚ آن ﺑﻮده و ﻧﺒﺎﻳﺪ ﺑﺪون رﺿﺎﻳﺖ ﻛﺘﺒﻲ وزارت ﻧﻔﺖ اﻳﺮان

، اﻧﺘﻘﺎل، ذﺧﻴﺮه ﺳﺎزي، ﺑﻪ ﻫﺮ ﺷﻜﻞ ﻳﺎ وﺳﻴﻠﻪ ازﺟﻤﻠﻪ ﺗﻜﺜﻴﺮ،از اﻳﻦ اﺳﺘﺎﻧﺪارد

.ﻳﺎ روش دﻳﮕﺮي در اﺧﺘﻴﺎر اﻓﺮاد ﺛﺎﻟﺚ ﻗﺮار ﮔﻴﺮد

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

CONTENTS:

Page

No

IPS-E-PM-385(2)

:ﻓﻬﺮﺳﺖ ﻣﻄﺎﻟﺐ

0. INTRODUCTION ............................................. 2

2 ............................................................. ﻣﻘﺪﻣﻪ-0

1. SCOPE................................................................ 3

3 ...................................................... داﻣﻨﻪ ﻛﺎرﺑﺮد-1

2. REFERENCES .................................................. 3

3 ............................................................. ﻣﺮاﺟﻊ-2

3. UNITS................................................................. 6

6 ........................................................... واﺣﺪﻫﺎ-3

4. PIPING DESIGN FOR MACHINERIES ....... 6

6 ............... ﻃﺮاﺣﻲ ﻟﻮﻟﻪ ﻛﺸﻲ ﺑﺮاي ﻣﺎﺷﻴﻦ آﻻت دوار-4

4.1 General............................................................... 6

6 ...................................................... ﻋﻤﻮﻣﻲ1-4

4.2 Pumps........................................................... 8

8 ..................................................... ﺗﻠﻤﺒﻪ ﻫﺎ2-4

4.3 Compressors ................................................ 15

15 ................................................. ﻛﻤﭙﺮﺳﻮرﻫﺎ3-4

4.4 Steam Turbines ........................................... 20

20 ........................................... ﺗﻮرﺑﻴﻨﻬﺎي ﺑﺨﺎر4-4

5. TESTING ........................................................... 21

21 ........................................................... آزﻣﺎﻳﺶ-5

1

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

IPS-E-PM-385(2)

ﻣﻘﺪﻣﻪ-0

0. INTRODUCTION

This standard covers the basis for the overall

design of process and auxiliary piping within

limits of the packaged process machineries and

related facilities.

اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﺒﻨﺎي ﻛﻠﻲ ﻃﺮاﺣﻲ ﺧﻄﻮط ﻟﻮﻟﻪ ﻓﺮآﻳﻨﺪي و ﺟﺎﻧﺒﻲ

را در ﻣﺤﺪوده ﻣﺎﺷﻴﻦآﻻت ﻓﺮآﻳﻨﺪي و ﻣﻠﺤﻘﺎت ﺟﺎﻧﺒﻲ آن در ﺑﺮ

.ﻣﻲﮔﻴﺮد

This standard shall be used in conjunction with

the specific standard of each equipment and

general plant piping system standards as listed

in references.

اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺎﻳﺪ ﺑﻬﻤﺮاه اﺳﺘﺎﻧﺪارد ﻫﺮ ﺗﺠﻬﻴﺰ و اﺳﺘﺎﻧﺪاردﻫﺎي

ﻣﺮﺑﻮط ﺑﻪ ﻣﺼﺎرف ﻟﻮﻟﻪﻛﺸﻲ ﻋﻤﻮﻣﻲ ﻛﻪ در ﺑﺨﺶ اول ﻣﺮاﺟﻊ

. ﺑﻜﺎر ﮔﺮﻓﺘﻪ ﺷﻮد،آورده ﺷﺪهاﻧﺪ

2

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

IPS-E-PM-385(2)

داﻣﻨﻪ ﻛﺎرﺑﺮد-1

1. SCOPE

This standard contains minimum requirements

governing the design and installation of piping

systems associated with pumps compressors, and

turbines, as well as the auxiliary piping

associated with them for process services.

اﻳﻦ اﺳﺘﺎﻧﺪارد ﺣﺪاﻗﻞ اﻟﺰاﻣﺎت ﭘﻴﺮاﻣﻮن ﻃﺮاﺣﻲ و ﻧﺼﺐ ﺳﺎﻣﺎﻧﻪﻫﺎي

ﻛﻤﭙﺮﺳﻮرﻫﺎ و ﺗﻮرﺑﻴﻦﻫﺎ و ﻫﻤﭽﻨﻴﻦ،ﻟﻮﻟﻪﻛﺸﻲ ﻣﺮﺗﺒﻂ ﺑﺎ ﺗﻠﻤﺒﻪﻫﺎ

ﻟﻮﻟﻪﻛﺸﻲ ﺗﺠﻬﻴﺰات ﺟﺎﻧﺒﻲ ﻣﺮﺑﻮط ﺑﻪ آﻧﻬﺎ در ﻛﺎرﺑﺮدﻫﺎي ﻓﺮآﻳﻨﺪي

.را در ﺑﺮ ﻣﻲﮔﻴﺮد

:1 ﻳﺎدآوري

Note 1:

اﻳﻦ اﺳﺘﺎﻧﺪارد ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ در ﻣﺮداد ﻣﺎه ﺳﺎل

از اﻳﻦ.( ﻣﻨﺘﺸﺮ ﺷﺪه اﺳﺖ1) ﺑﺎزﻧﮕﺮي و ﺑﻪ ﺻﻮرت وﻳﺮاﻳﺶ1382

.( اﻳﻦ اﺳﺘﺎﻧﺪارد داراي اﻋﺘﺒﺎر ﻧﻴﺴﺖ0) ﭘﺲ وﻳﺮاﻳﺶ

This is a revised version of the standard

specification by the relevant technical committee

on Jul. 2003, which is issued as revision (1).

Revision (0) of the said standard specification is

withdrawn.

:2 ﻳﺎدآوري

Note 2:

ﻧﺴﺨﻪ ﺑﺎزﻧﮕﺮي ﺷﺪه اﺳﺘﺎﻧﺪارد ﻓﻮق،اﻳﻦ اﺳﺘﺎﻧﺪارد دو زﺑﺎﻧﻪ

ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ1388 ﻣﻲﺑﺎﺷﺪ ﻛﻪ در ﺷﻬﺮﻳﻮر ﻣﺎه ﺳﺎل

از اﻳﻦ ﭘﺲ.( اراﻳﻪ ﻣﻲﮔﺮدد2) ﻣﺮﺑﻮﻃﻪ ﺗﺎﻳﻴﺪ و ﺑﻪ ﻋﻨﻮان وﻳﺮاﻳﺶ

.( اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﻨﺴﻮخ ﻣﻲﺑﺎﺷﺪ1) وﻳﺮاﻳﺶ

This bilingual standard is a revised version of the

standard specification by the relevant technical

committee on August 2009 which is issued as

revision (2). Revision (1) of the said standard

specification is withdrawn.

:3 ﻳﺎدآوري

Note 3:

ﻣﺘﻦ اﻧﮕﻠﻴﺴﻲ،در ﺻﻮرت اﺧﺘﻼف ﺑﻴﻦ ﻣﺘﻦ ﻓﺎرﺳﻲ و اﻧﮕﻠﻴﺴﻲ

.ﻣﻼك ﻣﻲﺑﺎﺷﺪ

In case of conflict between Farsi and English

languages, English language shall govern.

ﻣﺮاﺟﻊ-2

2. REFERENCES

Throughout this Standard the following dated and

undated standards/codes are referred to. These

referenced documents shall, to the extent

specified herein, form a part of this standard. For

dated references, the edition cited applies. The

applicability of changes in dated references that

occur after the cited date shall be mutually agreed

upon by the Company and the Vendor. For

undated references, the latest edition of the

referenced

documents

(including

any

supplements and amendments) applies.

ASME (AMERICAN

SOCIETY

MECHANICAL ENGINEERS)

در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﻪ آﻳﻴﻦ ﻧﺎﻣﻪﻫﺎ و اﺳﺘﺎﻧﺪاردﻫﺎي ﺗﺎرﻳﺦ دار و ﺑﺪون

ﺗﺎ ﺣﺪي ﻛﻪ در اﻳﻦ، اﻳﻦ ﻣﺮاﺟﻊ.ﺗﺎرﻳﺦ زﻳﺮ اﺷﺎره ﺷﺪه اﺳﺖ

ﺑﺨﺸﻲ از اﻳﻦ اﺳﺘﺎﻧﺪارد،اﺳﺘﺎﻧﺪارد ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﮔﺮﻓﺘﻪاﻧﺪ

وﻳﺮاﻳﺶ ﮔﻔﺘﻪ ﺷﺪه ﻣﻼك، در ﻣﺮاﺟﻊ ﺗﺎرﻳﺦ دار.ﻣﺤﺴﻮب ﻣﻲﺷﻮﻧﺪ

،ﺑﻮده و ﺗﻐﻴﻴﺮاﺗﻲ ﻛﻪ ﺑﻌﺪ از ﺗﺎرﻳﺦ وﻳﺮاﻳﺶ در آﻧﻬﺎ داده ﺷﺪه اﺳﺖ

در.ﭘﺲ از ﺗﻮاﻓﻖ ﺑﻴﻦ ﻛﺎرﻓﺮﻣﺎ و ﻓﺮوﺷﻨﺪه ﻗﺎﺑﻞ اﺟﺮا ﻣﻲﺑﺎﺷﺪ

آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻧﻬﺎ ﺑﻪ اﻧﻀﻤﺎم ﻛﻠﻴﻪ اﺻﻼﺣﺎت،ﻣﺮاﺟﻊ ﺑﺪون ﺗﺎرﻳﺦ

.و ﭘﻴﻮﺳﺖﻫﺎي آن ﻣﻼك ﻋﻤﻞ ﻣﻲﺑﺎﺷﻨﺪ

( )اﻧﺠﻤﻦ ﻣﻬﻨﺪﺳﺎن ﻣﻜﺎﻧﻴﻚ آﻣﺮﻳﻜﺎASME

OF

B 31.1 "Power Piping"

""ﻟﻮﻟﻪ ﻛﺸﻲ ﻧﻴﺮوﮔﺎﻫﻲ

B31.1

B 31.3 "Process Piping"

""ﻟﻮﻟﻪ ﻛﺸﻲ ﻓﺮآﻳﻨﺪي

B31.3

"اﺳﺘﺎﻧﺪارد آزﻣﻮن ﻋﻤﻠﻜﺮد ﻛﻤﭙﺮﺳﻮرﻫﺎيASME PTC-10

"ﮔﺮﻳﺰ از ﻣﺮﻛﺰ

ASME PTC-10 "Performance Test code on

Centrifugal Compressors"

( )ﻣﻮﺳﺴﻪ ﻧﻔﺖ آﻣﺮﻳﻜﺎAPI

API(AMERICAN PETROLEUM INSTITUTE)

610

"Centrifugal Pumps for Petroleum,

Petrochemical, and Natural Gas

Industries"

"ﺗﻠﻤﺒﻪﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﻣﻮرد ﻛﺎرﺑﺮد در

" ﭘﺘﺮوﺷﻴﻤﻲ و ﮔﺎز ﻃﺒﻴﻌﻲ، ﺻﻨﺎﻳﻊ ﻧﻔﺖ

3

610

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

IPS-E-PM-385(2)

611

"General Purpose steam Turbine for

Petroleum, Chemical and Natural Gas

Industry services"

، "ﺗﻮرﺑﻴﻨﻬﺎي ﺑﺨﺎر ﺑﺎ ﻛﺎرﺑﺮي ﻋﻤﻮﻣﻲ در ﺻﻨﺎﻳﻊ ﻧﻔﺖ611

"ﭘﺘﺮوﺷﻴﻤﻲ و ﮔﺎز ﻃﺒﻴﻌﻲ

612

"Petroleum, Petrochemical and Natural

Gas

Industries-Steam

TurbinesSpecial-purpose Applications"

، "ﺗﻮرﺑﻴﻨﻬﺎي ﺑﺨﺎر ﺑﺎ ﻛﺎرﺑﺮي ﺧﺎص در ﺻﻨﺎﻳﻊ ﻧﻔﺖ612

"ﭘﺘﺮوﺷﻴﻤﻲ و ﮔﺎز ﻃﺒﻴﻌﻲ

614

"Lubrication, Shaft Sealing and

Control Oil System and Auxiliaries for

Petroleum, Chemical and Natural Gas

Industry Services"

ﻧﺸﺖ ﺑﻨﺪي ﻣﺤﻮر و ﺳﺎﻣﺎﻧﻪ روﻏﻦ ﻛﻨﺘﺮل و، "رواﻧﻜﺎري614

ﭘﺘﺮوﺷﻴﻤﻲ و ﮔﺎز،ﺗﺠﻬﻴﺰات ﺟﺎﻧﺒﻲ در ﺻﻨﺎﻳﻊ ﻧﻔﺖ

"ﻃﺒﻴﻌﻲ

617

"Axial and Centrifugal Compressors

and

Expander-compressors

for

Petroleum,

Chemical

and

Gas

Industry"

"ﻛﻤﭙﺮﺳﻮرﻫﺎي ﻣﺤﻮري و ﮔﺮﻳﺰ از ﻣﺮﻛﺰ و ﺗﻮرﺑﻴﻦ617

" ﭘﺘﺮوﺷﻴﻤﻲ و ﮔﺎز ﻃﺒﻴﻌﻲ، اﻧﺒﺴﺎﻃﻲ – در ﺻﻨﺎﻳﻊ ﻧﻔﺖ

618

"Reciprocating

Compressors

for

Petroleum, Chemical and Gas Industry

Services"

"ﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ ﻣﻮرد اﺳﺘﻔﺎده در ﺻﻨﺎﻳﻊ618

" ﺷﻴﻤﻴﺎﻳﻲ و ﮔﺎز ﻃﺒﻴﻌﻲ، ﻧﻔﺖ

619

"Rotary-Type Positive-Displacement

Compressors

for

Petroleum,

Petrochemical and Natural Gas

Industries"

، "ﻛﻤﭙﺮﺳﻮرﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ ﭘﻴﭽﺸﻲ در ﺻﻨﺎﻳﻊ ﻧﻔﺖ619

"ﺷﻴﻤﻲ و ﮔﺎز ﻃﺒﻴﻌﻲ

672

"Packaged,

Integrally

Geared

Centrifugal Air Compressor for

Petroleum, Chemical and Gas Industry

Services"

"ﻣﺠﻤﻮﻋﻪ ﻛﻤﭙﺮﺳﻮرﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﻫﻮا ﺑﺎ ﭼﺮخ دﻧﺪه672

ﺷﻴﻤﻴﺎﻳﻲ و ﮔﺎز،داﺧﻠﻲ ﺟﻬﺖ اﺳﺘﻔﺎده در ﺻﻨﺎﻳﻊ ﻧﻔﺖ

"ﻃﺒﻴﻌﻲ

674

"Positive

Displacement

Reciprocating"

Pumps-

" "ﺗﻠﻤﺒﻪﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ رﻓﺖ و ﺑﺮﮔﺸﺘﻲ674

675

"Positive

Displacement

Controlled Volume"

Pumps-

" "ﺗﻠﻤﺒﻪﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ ﺑﺮاي ﺣﺠﻢ ﻛﻨﺘﺮل ﺷﺪه675

676

"Positive

Rotary"

Pumps-

" "ﺗﻠﻤﺒﻪﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ دوار676

682

"Pumps Shaft Sealing Systems for

Centrifugal and Rotary Pumps"

"ﺳﺎﻣﺎﻧﻪ ﻧﺸﺖ ﺑﻨﺪي ﻣﺤﻮر ﺗﻠﻤﺒﻪ ﺑﺮاي ﺗﻠﻤﺒﻪﻫﺎي دوار و682

"ﮔﺮﻳﺰ از ﻣﺮﻛﺰ

Displacement

( )اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮانIPS

IPS (IRANIAN PETROLEUM STANDARDS)

""اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي واﺣﺪﻫﺎ

IPS-E-GN-100

IPS-E-GN-100

"Engineering Standard for

Units"

IPS-E-PM-100

"Engineering Standard for

General Design Requirements

of Machineries"

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي اﻟﺰاﻣﺎتIPS-M-PM-100

IPS-E-PM-100

"ﻋﻤﻮﻣﻲ ﻃﺮاﺣﻲ ﻣﺎﺷﻴﻦ آﻻت

IPS-M-PM-105 "Material and Equipment

Standard for Centrifugal

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-105

ﺗﻠﻤﺒﻪﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﺑﺎ ﻛﺎرﺑﺮي

4

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

Pumps for Process Services"

IPS-E-PM-385(2)

"ﻓﺮآﻳﻨﺪي

IPS-M-PM-115 "Material and Equipment

Standard for Centrifugal

Pumps

for

Petroleum,

Petrochemical and Natural

Gas Industries "

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-115

ﺗﻠﻤﺒﻪﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ در ﺳﺮوﻳﺴﻬﺎي

"ﻋﻤﻮﻣﻲ

IPS-M-PM-125 "Material and Equipment

Standard for Centrifugal

Fire Water Pumps"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-125

"ﺗﻠﻤﺒﻪﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ آب آﺗﺶ ﻧﺸﺎﻧﻲ

IPS-M-PM-130 "Material and Equipment

Standard

for

Positive

Displacement

PumpsReciprocating"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-130

ﺗﻠﻤﺒﻪﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ رﻓﺖ و

"ﺑﺮﮔﺸﺖ

IPS-M-PM-140 "Material and Equipment

Standard

for

Positive

Displacement Pumps-Rotary"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-140

"ﺗﻠﻤﺒﻪﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ ﭘﻴﭽﺸﻲ

IPS-M-PM-150 "Material and Equipment

Standard

for

Positive

Displacement

PumpsControlled Volume"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-150

ﺗﻠﻤﺒﻪﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ ﺑﺮاي ﺣﺠﻢ

"ﻛﻨﺘﺮل ﺷﺪه

IPS-M-PM-170 "Material and Equipment

Standard for Axial and

Centrifugal

Compressors

and Expander Compressors

for Petroleum Chemical and

Gas Industry Services"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-170

ﮔﺮﻳﺰ از ﻣﺮﻛﺰ و،ﻛﻤﭙﺮﺳﻮرﻫﺎي ﻣﺤﻮري

ﺗﻮرﺑﻴﻦﻫﺎي اﻧﺒﺴﺎﻃﻲ ﺑﺮاي ﻣﺼﺎرف

" ﺷﻴﻤﻴﺎﻳﻲ و ﮔﺎز،ﺻﻨﺎﻳﻊ ﻧﻔﺖ

IPS-M-PM-180 "Material and Equipment

Standard for Packaged

Integrally

Geared

Centrifugal Compressors

for Utility and Instrument

Air Services"

" اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-180

ﻣﺠﻤﻮﻋﻪ ﻛﻤﭙﺮﺳﻮر ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﺑﺎ ﭼﺮخ

دﻧﺪه داﺧﻠﻲ در ﺗﺎﺳﻴﺴﺎت و ﻫﻮاي اﺑﺰار

"دﻗﻴﻖ

IPS-M-PM-200 "Material and Equipment

Standard for Reciprocating

Compressors for Process

Services"

" اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-200

ﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ ﺑﺎ ﻛﺎرﺑﺮي

"ﻓﺮآﻳﻨﺪي

IPS-M-PM-211 "Material and Equipment

Standard for Reciprocating

Compressors for Instrument

Air Services"

" اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-211

ﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ در

"ﺗﺎﺳﻴﺴﺎت و ﻫﻮاي اﺑﺰار دﻗﻴﻖ

IPS-M-PM-220 "Material and Equipment

Standard

for

Positive

Displacement Compressors

Rotary"

" اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-220

"ﻛﻤﭙﺮﺳﻮرﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ ﭘﻴﭽﺸﻲ

IPS-M-PM-240 "Material and Equipment

" اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-240

5

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

Standard

for

General

Purpose Steam Turbines"

IPS-E-PM-385(2)

"ﺗﻮرﺑﻴﻨﻬﺎي ﺑﺨﺎر ﺑﺎ ﻛﺎرﺑﺮي ﻋﻤﻮﻣﻲ

IPS-M-PM-250 "Material and Equipment

Standard

for

Special

Purpose Steam Turbines"

" اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-250

"ﺗﻮرﺑﻴﻨﻬﺎي ﺑﺨﺎر ﺑﺎ ﻛﺎرﺑﺮي ﺧﺎص

IPS-M-PM-320 "Material and Equipment

Standard for Lubrication,

Shaft Sealing and Control

Oil

Systems

and

Auxiliaries for Process

Services"

"اﺳﺘﺎﻧﺪارد ﻣﻮاد و ﺗﺠﻬﻴﺰات ﺑﺮايIPS-M-PM-320

ﻧﺸﺖ ﺑﻨﺪي ﻣﺤﻮر و،رواﻧﻜﺎري

ﺳﺎﻣﺎﻧﻪﻫﺎي روﻏﻦ ﻛﻨﺘﺮل ﺑﺎ ﻛﺎرﺑﺮي

"ﺧﺎص

IPS-G-PI-230

"General standards

Strainer and Filters"

for

"اﺳﺘﺎﻧﺪارد ﻋﻤﻮﻣﻲ ﺑﺮاي ﻓﻴﻠﺘﺮﻫﺎ و

"ﺻﺎﻓﻲﻫﺎ

IPS-G-PI-230

IPS-C-PI-350

"Construction Standard for

Plant

piping

System

Pressure Testing"

"اﺳﺘﺎﻧﺪارد ﺳﺎﺧﺘﻤﺎﻧﻲ ﺑﺮاي آزﻣﺎﻳﺶ

"ﻓﺸﺎر ﺳﺎﻣﺎﻧﻪ ﻟﻮﻟﻪ ﻛﺸﻲ ﻛﺎرﺧﺎﻧﻪ

IPS-C-PI-350

NEMA (NATIONAL ELECTRICAL

MANUFACTURERS ASSOCIATION)

( )اﻧﺠﻤﻦ ﻣﻠﻲ ﺳﺎزﻧﺪﮔﺎن ﺗﺠﻬﻴﺰات ﺑﺮﻗﻲNEMA

1

SM 23

2

"ﺗﻮرﺑﻴﻦ ﺑﺨﺎر در ﻛﺎرﺑﺮد ﺑﻪ ﻋﻨﻮان ﻣﺤﺮك

"ﺗﺠﻬﻴﺰات ﻣﻜﺎﻧﻴﻜﻲ

"Steam

Turbines

for

Mechanical

Drive

Services"

واﺣﺪﻫﺎ-3

3. UNITS

This standard is based on International System of

Units (SI), as per IPS-E-GN-100 except where

otherwise specified.

4. PIPING DESIGN

MACHINERIES

SM 23

FOR

ﻣﻨﻄﺒﻖ ﺑﺎ،(SI) ﺑﺮﻣﺒﻨﺎي ﻧﻈﺎم ﺑﻴﻦ اﻟﻤﻠﻠﻲ واﺣﺪﻫﺎ،اﻳﻦ اﺳﺘﺎﻧﺪارد

ﻣﮕﺮ آﻧﻜﻪ در ﻣﺘﻦ اﺳﺘﺎﻧﺪارد، ﻣﻲﺑﺎﺷﺪIPS-E-GN-100 اﺳﺘﺎﻧﺪارد

.ﺑﻪ واﺣﺪ دﻳﮕﺮي اﺷﺎره ﺷﺪه ﺑﺎﺷﺪ

ﻃﺮاﺣﻲ ﻟﻮﻟﻪﻛﺸﻲ ﺑﺮاي ﻣﺎﺷﻴﻦآﻻت ﻓﺮآﻳﻨﺪي-4

PROCESS

ﻋﻤﻮﻣﻲ1-4

4.1 General

4.1.1 Piping at pumps, compressors and steam

turbines shall be sufficiently flexible and

adequately supported to ensure that under no

circumstances the equipment nozzles will be

subject to any stress that could disturb the

alignment, internal clearances or otherwise affect

the equipment and jeopardize its trouble-free

operation.

ﻛﻤﭙﺮﺳﻮرﻫﺎ و ﺗﻮرﺑﻴﻦﻫﺎي ﺑﺨﺎر ﺑﺎﻳﺪ ﺑﻪ، ﻟﻮﻟﻪﻛﺸﻲ ﺗﻠﻤﺒﻪﻫﺎ1-1-4

ﻧﺤﻮ ﻛﺎﻓﻲ ﻗﺎﺑﻞ اﻧﻌﻄﺎف ﺑﻮده و ﺑﻪ ﻃﻮر ﻣﻨﺎﺳﺒﻲ در ﻧﻘﺎط ﺗﻜﻴﻪﮔﺎﻫﻲ

ﻧﮕﻬﺪاﺷﺘﻪ ﺷﻮد ﺗﺎ از ﺑﺮوز ﻫﺮﮔﻮﻧﻪ ﺗﻨﺶ ﺑﻪ ﻧﺎزلﻫﺎي ﺗﺠﻬﻴﺰات ﻛﻪ

ﻣﻲﺗﻮاﻧﺪ ﻫﻤﺮاﺳﺘﺎ ﺑﻮدن و ﻟﻘﻲﻫﺎي داﺧﻠﻲ را ﺗﺤﺖاﻟﺸﻌﺎع ﻗﺮار داده

ﺟﻠﻮﮔﻴﺮي،و ﻳﺎ ﻣﻨﺠﺮ ﺑﻪ اﻳﺠﺎد ﻣﺸﻜﻞ در ﻋﻤﻠﻜﺮد ﺗﺠﻬﻴﺰات ﺷﻮد

.ﻧﻤﺎﻳﺪ

In specifying the nozzle loads, the Contractor

shall ensure that they are sufficient for reasonably

expected piping loads but shall not specify them

so high that they require unnecessary nozzle

reinforcement. Piping shall be designed such that

the specified nozzle loads are not exceeded.

Where possible, the Contractor shall provide

more flexibility in the piping rather than require

additional nozzle reinforcement. If equipment

،ﭘﻴﻤﺎﻧﻜﺎر ﺑﺎﻳﺪ اﻃﻤﻴﻨﺎن ﺣﺎﺻﻞ ﻧﻤﺎﻳﺪ ﻛﻪ ﺑﺎرﻫﺎي اﻋﻤﺎل ﺷﺪه روي ﻧﺎزل

.ﻣﺘﻨﺎﺳﺐ ﺑﺎ ﺑﺎرﻫﺎي اﻋﻤﺎﻟﻲ ﻣﻮرد اﻧﺘﻈﺎر از ﻟﻮﻟﻪﻛﺸﻲ ﺗﻌﻴﻴﻦ ﺷﺪه ﺑﺎﺷﺪ

اﻟﺒﺘﻪ اﻳﻦ ﺑﺎرﻫﺎ ﻧﺒﺎﻳﺪ آﻧﭽﻨﺎن ﺑﺰرگ در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﻮﻧﺪ ﻛﻪ ﻣﻨﺠﺮ ﺑﻪ

ﻟﻮﻟﻪﻛﺸﻲ ﺑﺎﻳﺪ ﺑﻪ ﮔﻮﻧﻪاي ﻃﺮاﺣﻲ ﺷﻮد.ﺗﻘﻮﻳﺖ ﻏﻴﺮﺿﺮوري ﻧﺎزل ﮔﺮدد

ﻛﻪ ﺑﺎرﻫﺎي ﻧﺎﺷﻲ از آن ﻣﻨﺠﺮ ﺑﻪ اﻓﺰاﻳﺶ ﺑﺎرﻫﺎي وارده ﻣﻮرد اﻧﺘﻈﺎر ﺑﻪ

ﺣﺘﻲاﻻﻣﻜﺎن ﭘﻴﻤﺎﻧﻜﺎر ﺑﺎﻳﺪ ﻃﺮاﺣﻲ ﻟﻮﻟﻪﻛﺸﻲ را ﻗﺎﺑﻞ اﻧﻌﻄﺎف.ﻧﺎزل ﻧﮕﺮدد

6

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

IPS-E-PM-385(2)

flanges deviate from the standard sizes selected

from the piping classes, the matching pipe

flanges shall be ordered with the equipment.

در ﺻﻮرﺗﻲ ﻛﻪ ﻓﻠﻨﺞﻫﺎي.اﻧﺠﺎم دﻫﺪ و از ﺗﻘﻮﻳﺖ ﺑﻴﺸﺘﺮ ﻧﺎزل اﺣﺘﺮاز ﻧﻤﺎﻳﺪ

ﻣﻮرد ﻧﻴﺎز ﺗﺠﻬﻴﺰات ﺑﺎ ﺳﺎﻳﺰﻫﺎي اﻧﺘﺨﺎب ﺷﺪه ﺑﺮاﺳﺎس ﻛﻼس ﻟﻮﻟﻪﻛﺸﻲ

ﻓﻠﻨﺞﻫﺎي ﻟﻮﻟﻪﻛﺸﻲ ﻣﻨﺎﺳﺐ ﺑﺎﻳﺪ ﺑﻬﻤﺮاه ﺗﺠﻬﻴﺰ ﺳﻔﺎرش،ﻣﺘﻔﺎوت ﺑﺎﺷﺪ

.داده ﺷﻮﻧﺪ

For general requirement on piping system see

IPS-E-PM-100.

ﺑﺮاي اﻃﻼﻋﺎت ﺑﻴﺸﺘﺮ در ﺧﺼﻮص اﻟﺰاﻣﺎت ﻋﻤﻮﻣﻲ ﺳﺎﻣﺎﻧﻪ ﻟﻮﻟﻪﻛﺸﻲ

. ﻣﺮاﺟﻌﻪ ﺷﻮدIPS-E-PM-100 ﺑﻪ اﺳﺘﺎﻧﺪارد

4.1.2 The surrounding piping and pipe supporting

structures shall be designed and routed so that

access is provided for maintenance or removal of

valves, in-line instruments, casing sections and

internal elements from the equipment and for

operational reasons (e.g. filter cleaning).

Removal or replacement of equipment shall be

possible with a minimum dismantling of piping.

ﻟﻮﻟﻪﻛﺸﻲ ﭘﻴﺮاﻣﻮﻧﻲ و ﺳﺎزهﻫﺎي ﺗﻜﻴﻪﮔﺎﻫﻲ ﻟﻮﻟﻪﻫﺎ ﺑﺎﻳﺪ ﺑﻪ2-1-4

Auxiliary piping shall be neatly routed along the

base-plate and shall not extend across the

operating floor. This piping shall not obstruct

inspection covers, bearing caps, upper halves of

casings or any other items which require access

for operation or maintenance.

ﻟﻮﻟﻪﻛﺸﻲﻫﺎي ﺟﺎﻧﺒﻲ ﺑﺎﻳﺪ ﺑﻪ ﻧﺤﻮ ﻣﻨﺎﺳﺒﻲ در ﻣﺤﺪوده ﺷﺎﺳﻲ

ﻫﻤﭽﻨﻴﻦ.ﺗﺠﻬﻴﺰ اﻧﺠﺎم ﺷﻮد و ﻧﺒﺎﻳﺪ ﺗﺎ ﻣﺤﻮﻃﻪ ﻋﻤﻠﻴﺎﺗﻲ اداﻣﻪ ﻳﺎﺑﺪ

، ﺳﺮﭘﻮش ﻳﺎﺗﺎﻗﺎنﻫﺎ،ﻟﻮﻟﻪﻛﺸﻲ ﻧﺒﺎﻳﺪ ﻣﺎﻧﻌﻲ ﺑﺮاي ﺑﺎزرﺳﻲ ﭘﻮﺷﺶﻫﺎ

ﻧﻴﻤﻪﻫﺎي ﺑﺎﻻﻳﻲ ﻣﺤﻔﻈﻪﻫﺎي ﺗﺠﻬﻴﺰات ﻳﺎ ﻫﺮ ﺟﺰء دﻳﮕﺮي ﻛﻪ در

. اﻳﺠﺎد ﻛﻨﺪ،ﺗﻌﻤﻴﺮات ﻳﺎ ﻋﻤﻠﻴﺎت دﺳﺘﺮﺳﻲ ﺑﻪ آﻧﻬﺎ اﻟﺰاﻣﻲ اﺳﺖ

4.1.3 The allowable forces and moments on

equipment nozzles shall be in accordance with

the relevant API/NEMA standards for this

equipment as listed in section 2, unless the

manufacturer states lower figures.

ﻣﻴﺰان ﻧﻴﺮوﻫﺎ و ﮔﺸﺘﺎورﻫﺎي وارده ﺑﻪ ﻧﺎزلﻫﺎي ﺗﺠﻬﻴﺰ3-1-4

4.1.4 Piping stress/strain (flexibility) analysis

shall be based on the design maximum and

minimum temperatures. These temperatures,

which are determined from the normal operating

temperature and the site temperatures, shall be

listed in the Line Designation Table.

ﻛﺮﻧﺶ )اﻧﻌﻄﺎف ﭘﺬﻳﺮي( ﻟﻮﻟﻪﻛﺸﻲ/ ﺗﺠﺰﻳﻪ و ﺗﺤﻠﻴﻞ ﺗﻨﺶ4-1-4

ﻧﺤﻮي ﻃﺮاﺣﻲ ﺷﻮﻧﺪ ﻛﻪ دﺳﺘﺮﺳﻲ ﻛﺎﻓﻲ ﺑﻪ ﻣﻨﻈﻮر ﺗﻌﻤﻴﺮات و ﻳﺎ

ﺑﺨﺶﻫﺎي ﻣﺨﺘﻠﻒ، اﺑﺰار دﻗﻴﻖ ﺧﻄﻮط،ﺟﺪا ﻛﺮدن ﺷﻴﺮآﻻت

ﻣﺤﻔﻈﻪ ﺗﺠﻬﻴﺰات و اﺟﺰاء داﺧﻠﻲ آﻧﻬﺎ و ﺳﺎﻳﺮ اﻫﺪاف ﻋﻤﻠﻴﺎﺗﻲ

ﺧﺎرج ﻛﺮدن و ﻳﺎ.)ﻣﺎﻧﻨﺪ ﺗﻤﻴﺰ ﻛﺮدن ﻓﻴﻠﺘﺮﻫﺎ( اﻣﻜﺎﻧﭙﺬﻳﺮ ﺑﺎﺷﺪ

ﺟﺎﻳﮕﺰﻳﻦ ﻧﻤﻮدن ﺗﺠﻬﻴﺰات ﺑﺎﻳﺪ ﺑﺎ ﺣﺪاﻗﻞ ﺟﺪاﺳﺎزي ﻟﻮﻟﻪﻛﺸﻲ

.اﻣﻜﺎن ﭘﺬﻳﺮ ﺑﺎﺷﺪ

ﻣﺘﻨﺎﻇﺮ آن ﺗﺠﻬﻴﺰ ﻛﻪ درAPI/NEMA ﺑﺎﻳﺪ ﻣﻄﺎﺑﻖ ﺑﺎ اﺳﺘﺎﻧﺪارد

ﺑﺎﺷﺪ ﻣﮕﺮ ﺳﺎزﻧﺪه ﻣﻘﺎدﻳﺮ ﻛﻤﺘﺮ از آن، درج ﮔﺮدﻳﺪه اﺳﺖ2 ﺑﺨﺶ

.را اﻋﻼم ﻧﻤﺎﻳﺪ

اﻳﻦ.ﺑﺎﻳﺪ ﺑﺮاﺳﺎس ﺣﺪاﻗﻞ و ﺣﺪاﻛﺜﺮ دﻣﺎي ﻃﺮاﺣﻲ اﻧﺠﺎم ﺷﻮد

دﻣﺎﻫﺎ ﻛﻪ ﺑﺮاﺳﺎس دﻣﺎي ﻋﻤﻠﻴﺎﺗﻲ ﻋﺎدي و دﻣﺎي ﻣﺤﻞ ﻣﺸﺨﺺ

.ﻣﻲﺷﻮﻧﺪ ﺑﺎﻳﺪ در ﺟﺪول ﻣﺸﺨﺼﺎت ﻟﻮﻟﻪ آورده ﺷﻮﻧﺪ

4.1.5 For computations of reactions on supports

and equipment the appropriate installation

temperature (See Notes 1 & 2) shall be used as a

reference. Proper temperature values for stress

ranges and reactions shall be derived from ANSI

B31.3, Paragraph 319.3.1.

ﺑﻪ ﻣﻨﻈﻮر ﻣﺤﺎﺳﺒﻪ ﻋﻜﺲاﻟﻌﻤﻠﻬﺎي وارده ﺑﻪ ﺗﻜﻴﻪﮔﺎﻫﻬﺎ و5-1-4

( در ذﻳﻞ ﻣﺮاﺟﻌﻪ ﺷﻮد2 و1 دﻣﺎي ﻧﺼﺐ ﻣﻨﺎﺳﺐ )ﺑﻪ ﻧﻜﺎت،ﺗﺠﻬﻴﺰ

ﻣﻘﺎدﻳﺮ دﻣﺎي ﻣﻨﺎﺳﺐ ﺑﺮاي.ﺑﺎﻳﺪ ﺑﻪ ﻋﻨﻮان ﻳﻚ ﻣﺮﺟﻊ اﺳﺘﻔﺎده ﺷﻮد

ANSI B31.3 ﻣﺤﺪوده دﺳﺘﺮﺳﻲ و ﻋﻜﺲاﻟﻌﻤﻠﻬﺎ ﺑﺎﻳﺪ از اﺳﺘﺎﻧﺪارد

. اﺳﺘﺨﺮاج ﺷﻮد319.3.1 ﺑﻨﺪ

:ﻳﺎدآوري ﻫﺎ

Notes:

1) The minimum installation temperature for

analysis of loads on equipment shall be the

minimum equipment design temperature or

the minimum site temperature, whichever is

lower.

( ﺣﺪاﻗﻞ دﻣﺎي ﻧﺼﺐ ﺑﺮاي ﺗﺠﺰﻳﻪ و ﺗﺤﻠﻴﻞ ﺑﺎرﻫﺎي وارده ﺑﻪ1

ﺗﺠﻬﻴﺰ ﺑﺎﻳﺪ ﺑﺮاﺑﺮ ﺑﺎ ﺣﺪاﻗﻞ دﻣﺎي ﻃﺮاﺣﻲ ﺗﺠﻬﻴﺰ ﻳﺎ ﺣﺪاﻗﻞ دﻣﺎي

. ﺑﺎﺷﺪ، ﻫﺮﻛﺪام ﻛﻪ ﻛﻤﺘﺮ ﺑﻮد،ﻣﺤﻞ

7

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

IPS-E-PM-385(2)

2) The maximum installation temperature for

analysis of loads on equipment shall be the

maximum equipment design temperature or

the maximum site temperature, whichever is

higher.

( ﺣﺪاﻛﺜﺮ دﻣﺎي ﻧﺼﺐ ﺑﺮاي ﺗﺠﺰﻳﻪ و ﺗﺤﻠﻴﻞ ﺑﺎرﻫﺎي وارده ﺑﻪ2

4.1.6 Auxiliary piping connected to pumps,

compressors or turbines shall be in accordance

with the relevant API Standards and IPS as listed

in section 2. Tapped holes for venting, etc., shall

have an NPT nipple, schedule 160 to which a

valve is connected. The requisitions and process

engineering flow schemes shall state when

flanged nozzles are required.

ﻳﺎ، ﻛﻤﭙﺮﺳﻮرﻫﺎ، ﻟﻮﻟﻪﻛﺸﻲ ﺟﺎﻧﺒﻲ ﻣﺘﺼﻞ ﺑﻪ ﺗﻠﻤﺒﻪﻫﺎ6-1-4

4.1.7 Lube oil and control oil lines shall be separated

ﺑﻪ ﻣﻨﻈﻮر ﻣﻤﺎﻧﻌﺖ از ﺧﻄﺮ آﺗﺶ ﺳﻮزي ﻣﺎﻧﻨﺪ اﺷﺘﻌﺎل7-1-4

from hot process and hot utility lines in order to

ﺧﻄﻮط، درﺟﻪ ﺳﺎﻧﺘﻴﮕﺮاد260-320 ﺧﻮد ﺑﻪ ﺧﻮدي در دﻣﺎي

اﻧﺘﻘﺎل روﻏﻦ ﻛﻨﺘﺮل و رواﻧﻜﺎري ﺑﺎﻳﺪ از ﺧﻄﻮط ﻓﺮآﻳﻨﺪي ﻳﺎ

ﺑﺮاي ﻛﺴﺐ اﻃﻼﻋﺎت ﺑﻴﺸﺘﺮ ﺑﻪ.ﺗﺄﺳﻴﺴﺎت داغ ﻣﺠﺰا ﺑﺎﺷﻨﺪ

. ﻣﺮاﺟﻌﻪ ﺷﻮدIPS-M-PM-320 اﺳﺘﺎﻧﺪارد

ﺗﺠﻬﻴﺰ ﺑﺎﻳﺪ ﺑﺮاﺑﺮ ﺑﺎ ﺣﺪاﻛﺜﺮ دﻣﺎي ﻃﺮاﺣﻲ ﺗﺠﻬﻴﺰ ﻳﺎ ﺣﺪاﻛﺜﺮ

. ﺑﺎﺷﺪ، ﻫﺮﻛﺪام ﻛﻪ ﺑﻴﺸﺘﺮ ﺑﻮد،دﻣﺎي ﻣﺤﻞ

درج ﺷﺪهIPS ﻣﺘﻨﺎﻇﺮ وAPI ﺗﻮرﺑﻴﻦﻫﺎ ﺑﺎﻳﺪ ﻣﻄﺎﺑﻖ ﺑﺎ اﺳﺘﺎﻧﺪارد

ﻣﺠﺎري رزوه دار ﺟﻬﺖ ﺗﺨﻠﻴﻪ ﮔﺎز و ﻏﻴﺮه ﺑﺎﻳﺪ. ﺑﺎﺷﺪ2 در ﻗﺴﻤﺖ

در. ﺑﻪ ﻫﻤﺮاه ﻳﻚ ﺷﻴﺮ ﺑﺎﺷﻨﺪ160 ﺑﺎ ردهNPT داراي ﻣﻐﺰي

در درﺧﻮاﺳﺖ ﺧﺮﻳﺪار،ﻣﻮاردي ﻛﻪ ﻧﺎزﻟﻬﺎي ﻓﻠﻨﺠﻲ ﻣﻮرد ﻧﻴﺎز ﺑﺎﺷﻨﺪ

.و ﻃﺮاﺣﻲ ﻣﻬﻨﺪﺳﻲ ﻓﺮآﻳﻨﺪ ﺑﺎﻳﺪ ﻟﺤﺎظ ﺷﻮد

avoid a fire hazard, e.g. auto ignition at 260-320°C.

For further information see IPS-M-PM-320.

4.1.8 Cooling water lines to pumps and

compressors shall not be less than DN 20 (¾ in.).

Lines DN 25 (1 in.) or less shall have the take-off

connection from the top of the water main line so

as to prevent plugging during operation.

ﺧﻄﻮط اﻧﺘﻘﺎل آب ﺧﻨﻚ ﻛﻨﻨﺪه ﺑﻪ ﺗﻠﻤﺒﻪﻫﺎ و ﻛﻤﭙﺮﺳﻮرﻫﺎ8-1-4

In all cases, drain and vent points which are

equipped with valves, shall be plugged or blinded

flange, which ever applicable.

ﻧﻘﺎط ﺧﺮوﺟﻲ ﮔﺎز و ﻣﺎﻳﻊ ﻛﻪ ﺑﻪ ﺷﻴﺮ ﻣﺠﻬﺰﻧﺪ ﺑﺎﻳﺪ،در ﻛﻠﻴﻪ ﻣﻮارد

.ﺑﺮﺣﺴﺐ اﻣﻜﺎن ﻛﻮر ﺷﺪه ﻳﺎ ﺑﺎ ﻓﻠﻨﺞ ﺑﺴﺘﻪ ﺷﻮﻧﺪ

ﺧﻄﻮط. اﻳﻨﭻ( ﺑـــﺎﺷﻨﺪ3 ) 20 ﻧﺒﺎﻳﺪ ﻛﻮﭼﻜــﺘﺮ از ﻗﻄﺮ اﺳﻤﻲ

4

اﻳﻨﭻ( ﻳﺎ ﻛﻤﺘﺮ ﺑﺎﻳﺪ داراي اﻣﻜﺎن ﺟﺪا ﺳﺎزي1) 25 ﻗﻄﺮ اﺳﻤﻲ

اﺗﺼﺎل از ﺑﺎﻻي ﺧﻂ اﺻﻠﻲ اﻧﺘﻘﺎل آب ﺑﺎﺷﻨﺪ ﺗﺎ از ﺑﺮوز ﻫﺮﮔﻮﻧﻪ

.ﮔﺮﻓﺘﮕﻲ در ﺣﻴﻦ ﻋﻤﻠﻴﺎت ﺟﻠﻮﮔﻴﺮي ﺷﻮد

ﺗﻠﻤﺒﻪﻫﺎ2-4

4.2 Pumps

ﻋﻤﻮﻣﻲ1-2-4

4.2.1 General

4.2.1.1 If the suction nozzle of a pump is smaller

in size than the connecting piping and a reducer

is required in a horizontal line, it shall be

eccentric, installed with the belly down. In

vertical pipes, eccentric or concentric reducers

may be used.

- در ﻣﻮاردي ﻛﻪ ﻧﺎزل ﻣﻜﺶ ﻳﻚ ﺗﻠﻤﺒﻪ ﻛﻮﭼﻜﺘﺮ از ﻟﻮﻟﻪ1-1-2-4

4.2.1.2 A block valve shall be in the suction line

of each pump upstream of the strainer. This

position enables the strainer to be cleaned

without draining the complete suction pipe. The

discharge line shall also have a block valve. A

non-return valve shall be installed in the

discharge line near the discharge nozzle of

centrifugal or rotary pumps, unless there is no

possibility of reversed flow or pressure surge

under any condition. This non-return valve shall

be installed upstream of the block valve to enable

در ﺧﻂ ﻣﻜﺶ ﻫﺮ ﺗﻠﻤﺒﻪ و ﻗﺒﻞ از ﺻﺎﻓﻲ ﺑﺎﻳﺪ از ﻳﻚ ﺷﻴﺮ2-1-2-4

ﻧﺼﺐ ﻳﻚ،ﻛﺸﻲ ﻣﺘﺼﻞ ﺷﺪه ﺑﻪ آن ﺑﻮده و ﻟﻮﻟﻪﻫﺎ اﻓﻘﻲ ﺑﺎﺷﻨﺪ

در.ﻛﺎﻫﻨﺪه ﻏﻴﺮﻫﻢ ﻣﺮﻛﺰ ﺑﺎ ﺷﻜﻢ رو ﺑﻪ ﭘﺎﻳﻴﻦ اﻟﺰاﻣﻲ ﻣﻲ ﺑﺎﺷﺪ

ﻟﻮﻟﻪﻫﺎي ﻋﻤﻮدي ﻣﻲﺗﻮان از ﻛﺎﻫﻨﺪهﻫﺎي ﻏﻴﺮﻫﻢ ﻣﺮﻛﺰ ﻳﺎ ﻫﻢ ﻣﺮﻛﺰ

.اﺳﺘﻔﺎده ﻧﻤﻮد

ﺗﻤﻴﺰ ﻧﻤﻮدن ﺻﺎﻓﻲ ﺑﺪون، ﺑﺪﻳﻦ ﺻﻮرت.ﻣﺴﺪودﻛﻨﻨﺪه اﺳﺘﻔﺎده ﻧﻤﻮد

ﺧﻂ ﺧﺮوﺟﻲ ﺗﻠﻤﺒﻪﻫﺎ ﻧﻴﺰ.ﺗﺨﻠﻴﻪ ﻛﺎﻣﻞ ﻟﻮﻟﻪ ﻣﻜﺶ اﻣﻜﺎﻧﭙﺬﻳﺮ ﺧﻮاﻫﺪ ﺑﻮد

ﻏﻴﺮ از ﻣﻮاردي ﻛﻪ اﺣﺘﻤﺎل.ﺑﺎﻳﺪ ﻳﻚ ﺷﻴﺮ ﻣﺴﺪودﻛﻨﻨﺪه داﺷﺘﻪ ﺑﺎﺷﻨﺪ

ﺟﺮﻳﺎن ﺑﺎزﮔﺸﺘﻲ ﻳﺎ اﻓﺰاﻳﺶ ﺳﺮﻳﻊ ﻓﺸﺎر ﺗﺤﺖ ﻫﻴﭻ ﺷﺮاﻳﻄﻲ وﺟﻮد

ﺑﺎﻳﺪ از ﺷﻴﺮ ﻳﻜﻄﺮﻓﻪ در ﺧﻂ ﺧﺮوﺟﻲ ﺗﻠﻤﺒﻪ و ﻧﺰدﻳﻚ ﺑﻪ،ﻧﺪاﺷﺘﻪ ﺑﺎﺷﺪ

اﻳﻦ.ﻧﺎزل ﺧﺮوﺟﻲ ﺗﻠﻤﺒﻪﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﻳﺎ ﮔﺮدﺷﻲ اﺳﺘﻔﺎده ﻧﻤﻮد

8

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

IPS-E-PM-385(2)

maintenance of the check valve without draining

the discharge pipe. The liquid volume between

the check valve and the pump discharge block

valve shall be as small as practical. Highly

corrosive or hazardous fluids shall have a drain

valve in the discharge line between the block and

the non-return valve.

ﺷﻴﺮ ﻳﻜﻄﺮﻓﻪ ﺑﺎﻳﺪ ﻗﺒﻞ از ﺷﻴﺮ ﻣﺴﺪود ﻛﻨﻨﺪه ﻧﺼﺐ ﺷﻮد ﺗﺎ ﺗﻌﻤﻴﺮ و

.ﻧﮕﻬﺪاري ﺷﻴﺮ ﻳﻜﻄﺮﻓﻪ ﺑﺪون ﺗﺨﻠﻴﻪ ﻟﻮﻟﻪ ﺧﺮوﺟﻲ ﺗﻠﻤﺒﻪ اﻣﻜﺎﻧﭙﺬﻳﺮ ﺑﺎﺷﺪ

ﺣﺠﻢ ﻣﺎﻳﻊ ﺑﻴﻦ ﺷﻴﺮ ﻳﻜﻄﺮﻓﻪ و ﺷﻴﺮ ﻣﺴﺪودﻛﻨﻨﺪه ﺧﺮوﺟﻲ ﺗﻠﻤﺒﻪ ﺑﺎﻳﺪ

ﺳﻴﺎﻻت ﺑﺎ ﺧﻮرﻧﺪﮔﻲ ﺑﺎﻻ و ﺧﻄﺮﻧﺎك ﺑﺎﻳﺪ.درﻛﻤﺘﺮﻳﻦ ﺣﺪ ﻣﻤﻜﻦ ﺑﺎﺷﺪ

ﻳﻚ ﺷﻴﺮ ﺗﺨﻠﻴﻪ در ﺧﻂ ﺧﺮوﺟﻲ ﺗﻠﻤﺒﻪ و ﻣﺎﺑﻴﻦ ﺷﻴﺮ ﻣﺴﺪودﻛﻨﻨﺪه و

.ﺷﻴﺮ ﻳﻜﻄﺮﻓﻪ داﺷﺘﻪ ﺑﺎﺷﻨﺪ

4.2.1.3 Suction piping to pumps handling at or

close to their vapor pressure shall require special

care to suppress flashing. Vertical drop as much

as possible shall be provided at the suction source

before starting the horizontal run to the pump.

در ﻟﻮﻟﻪﻛﺸﻲ ﺧﻂ ﻣﻜﺶ ﺗﻠﻤﺒﻪ ﻫﺎﻳﻲ ﻛﻪ در ﻓﺸﺎر ﺑﺨﺎر3-1-2-4

ﺳﻴﺎل و ﻳﺎ ﻧﺰدﻳﻚ ﺑﻪ آن ﻛﺎر ﻣﻲﻛﻨﻨﺪ ﺑﺎﻳﺪ ﺗﻤﻬﻴﺪاﺗﻲ در ﻧﻈﺮ ﮔﺮﻓﺘﻪ

ﻟﻮﻟﻪ اﻧﺘﻘﺎل ﻋﻤﻮدي.ﺷﻮد ﺗﺎ از ﺗﺒﺨﻴﺮ ﺳﻴﺎل ﻣﻤﺎﻧﻌﺖ ﺑﻪ ﻋﻤﻞ آﻳﺪ

ﻣﻨﺒﻊ ﻣﻜﺶ از ارﺗﻔﺎع ﺑﺎﻻ ﺑــﻪ ﺧﻂ اﻓﻘﻲ ﻣﺘﺼﻞ ﺑﻪ ﻧﺎزل ﻣﻜﺶ ﺗﻠﻤﺒﻪ

ﺑﺎﻳﺪ ﺣﺘﻲاﻻﻣﻜﺎن در دورﺗﺮﻳﻦ ﻓﺎﺻﻠﻪ ﺑﻪ ﻣﺠﺮاي ورودي ﺗﻠﻤﺒﻪ ﻗﺮار

.ﮔﻴﺮد

4.2.1.4 Permanent strainers shall be installed in

all pump suction lines.

در ﻛﻠﻴﻪ ﺧﻄﻮط ﻣﻜﺶ ﺗﻠﻤﺒﻪﻫﺎ ﺑﺎﻳﺪ ﺻﺎﻓﻲ داﺋﻤﻲ4-1-2-4

4.2.1.5 Y-type strainers are required for

permanent installation in vertical suction lines. In

horizontal suction lines Y-type or bucket- type

strainers may be used. Bucket-type strainers shall

be used for suction pipes DN 450 and larger.

ﺷﻜﻞ ﺑﻪY در ﺧﻄﻮط ﻣﻜﺶ ﻋﻤﻮدي ﺑﺎﻳﺪ از ﺻﺎﻓﻲﻫﺎي5-1-2-4

The installation of a Y-type strainer in the suction

of double-suction pumps shall not disturb an even

flow to the suction nozzle of the pump.

ﺷﻜﻞ در ﻣﻜﺶ ﺗﻠﻤﺒﻪﻫﺎي دوﻣﻜﺸﻲ ﻧﺒﺎﻳﺪ ﻣﻨﺠﺮ ﺑﻪY ﻧﺼﺐ ﺻﺎﻓﻲ

.اﻳﺠﺎد ﺗﻼﻃﻢ در ﺟﺮﻳﺎن آرام ﻧﺎزل ﻣﻜﺶ ﺗﻠﻤﺒﻪ ﺷﻮد

For carbon steel and alloy steel strainers, see IPSG-PI-230.

در ﺻﻮرت اﺳﺘﻔﺎده از ﺻﺎﻓﻲﻫﺎي ﻓﻮﻻد ﻛﺮﺑﻨﻲ و ﻓﻮﻻد آﻟﻴﺎژي ﺑﻪ

. ﻣﺮاﺟﻌﻪ ﺷﻮدIPS-G-PI-230 اﺳﺘﺎﻧﺪارد

The design and material for strainers in chemical

services and for special pumps shall fulfill the

process and pump requirements, e.g. metering

pumps.

ﻃﺮاﺣﻲ و اﻧﺘﺨﺎب ﻣﻮاد ﺻﺎﻓﻲﻫﺎﻳﻲ ﻛﻪ در ﻋﻤﻠﻴﺎت ﺷﻴﻤﻴﺎﻳﻲ و ﻳﺎ

ﺑﺎﻳﺪ اﻟﺰاﻣﺎت ﻓﺮآﻳﻨﺪي و ﺗﻠﻤﺒﻪ را،ﺗﻠﻤﺒﻪﻫﺎي ﺧﺎص اﻧﺠﺎم ﻣﻲﺷﻮﻧﺪ

ﻧﻴﺰ ﺗﺄﻣﻴﻦ ﻧﻤﺎﻳﺪ ﺑﻪ ﻋﻨﻮان ﻣﺜﺎل ﻣﻲﺗﻮان ﺑﻪ ﺗﻠﻤﺒﻪﻫﺎي ﺗﺰرﻳﻘﻲ ﻗﺎﺑﻞ

.ﺗﻨﻈﻴﻢ اﺷﺎره ﻧﻤﻮد

4.2.1.6 Pumps shall be protected by adding a

temporary conical suction strainer with a fine

screen mesh for initial start-up and

commissioning. Provision shall be made to

measure pressure difference between upstream

and downstream of the strainer and also to

protect it due to excess value.

در ﻣﺮﺣﻠﻪ ﺷﺮوع ﺑﻪ ﻛﺎر و راهاﻧﺪازي ﺑﻪ ﻣﻨﻈﻮر6-1-2-4

.ﻧﺼﺐ ﺷﻮﻧﺪ

Y در ﺧﻄﻮط ﻣﻜﺶ اﻓﻘﻲ ﻣﻴﺘﻮان از ﺻﺎﻓﻲﻫﺎي.ﻃﻮر داﺋﻢ اﺳﺘﻔﺎده ﻧﻤﻮد

ﺻﺎﻓﻲﻫﺎي ﺳﻄﻠﻲ ﺷﻜﻞ ﺑﺎﻳﺪ در.ﺷﻜﻞ ﻳﺎ ﺳﻄﻠﻲ ﺷﻜﻞ اﺳﺘﻔﺎده ﻧﻤﻮد

. ﻳﺎ ﺑﺰرﮔﺘﺮ ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﮔﻴﺮﻧﺪ450 ﻟﻮﻟﻪﻫﺎي ﻣﻜﺶ ﻗﻄﺮ اﺳﻤﻲ

ﻣﺤﺎﻓﻈﺖ از ﺗﻠﻤﺒﻪﻫﺎ ﺑﺎﻳﺪ از ﺻﺎﻓﻲﻫﺎي ﻣﻮﻗﺖ ﻣﺨﺮوﻃﻲ در ﻣﻜﺶ

ﭘﻴﺶ ﺑﻴﻨﻲﻫﺎي ﻻزم ﺑﻪ ﻣﻨﻈﻮر.ﺑﺎ ﺗﻮري ﺑﺴﻴﺎر رﻳﺰ اﺳﺘﻔﺎده ﻧﻤﻮد

اﻧﺪازهﮔﻴﺮي اﺧﺘﻼف ﻓﺸﺎر ﺑﻴﻦ ﺟﺮﻳﺎن ورودي و ﺧﺮوﺟﻲ ﺻﺎﻓﻲ

ﺑﺎﻳﺪ اﻧﺠﺎم ﺷﻮد ﺗﺎ در ﺻﻮرت زﻳﺎد ﺑﻮدن اﺧﺘﻼف ﻓﺸﺎر اﻣﻜﺎن

.ﻣﺤﺎﻓﻈﺖ از آن ﺻﻮرت ﭘﺬﻳﺮد

For conical screen strainers, see IPS-G-PI-230.

در ﺻﻮرت اﺳﺘﻔﺎده از ﺻﺎﻓﻲﻫــﺎي ﻣﺨﺮوﻃــﻲ ﺑــﻪ اﺳﺘﺎﻧﺪارد

. ﻣﺮاﺟﻌﻪ ﺷﻮدIPS-G-PI-230

4.2.1.7 A spade or spectacle blind shall be

inserted downstream of the suction valve and

upstream of the discharge valve to isolate pumps

from a common suction and discharge line during

ﺑﻪ ﻣﻨﻈﻮر ﻣﺠﺰا ﺳﺎﺧﺘﻦ ﺗﻠﻤﺒﻪ از ﺧﻂ ﻣﻜﺶ و ﺧﻂ7-1-2-4

ﺑﺎﻳﺪ از ﻳﻚ ﺻﻔﺤﻪ،ﺧﺮوﺟﻲ ﺗﻠﻤﺒﻪ در ﻃﻮل ﺗﻌﻤﻴﺮ و ﻧﮕﻬﺪاري

ﻣﺴﺪود ﻛﻨﻨﺪه و ﻳﺎ ﻣﺴﺪود ﻛﻨﻨﺪه ﻋﻴﻨﻜﻲ ﺑﻌﺪ از ﺷﻴﺮ ﻣﻜﺶ و ﻗﺒﻞ

9

)IPS-E-PM-385(2

ﺷﻬﺮﻳﻮرAug. 2009/ 1388

از ﺷﻴﺮ ﺗﺨﻠﻴﻪ اﺳﺘﻔﺎده ﻧﻤﻮد ﻣﮕﺮ اﻳﻦ ﻛﻪ ﺗﻠﻤﺒﻪ را ﺑﺘﻮان ﺑﺎ اﺳﺘﻔﺎده

از ﺳﺎﻳﺮ روﺷﻬﺎ ﻣﺠﺰا ﻧﻤﻮد.

maintenance, unless the pump can be isolated by

other means.

8-1-2-4در ﻛﺎرﺑﺮدﻫﺎﻳﻲ ﻛﻪ ﻋﻤﻠﻴﺎت در ﺧﻼء ﻳﺎ ﺑﺎ ﻣﺎﻳﻌﺎت

4.2.1.8 The pump vent shall be connected to the

vapor space of the suction vessel for operation

under vacuum or with hazardous liquids. This

allows of filling the system before the pump is

started without opening the discharge valve. The

vent line shall have two valves, one at the pump

and one at the vessel.

9-1-2-4در ﻛﺎرﺑﺮدﻫﺎﻳﻲ ﻛﻪ از ﺗﻠﻤﺒﻪ ﺑﺮاي ﺳﻴﺎﻻت ﺧﻄﺮﻧﺎك ﻳﺎ

4.2.1.9 To avoid spillage of hazardous or

expensive fluids when a pump is dismantled the

drain and vent connections shall be connected to

a drain or vacuum vessel for this purpose.

ﺧﻄﺮﻧﺎك اﻧﺠﺎم ﻣﻲﺷﻮد ،ﻣﺠﺎري ﺗﺨﻠﻴﻪ ﮔﺎز ﺗﻠﻤﺒﻪ ﺑﺎﻳﺪ ﺑﻪ ﻓﻀﺎي

ﺑﺨﺎر ﻣﺨﺰن ﻣﻜﺶ ﻣﺘﺼﻞ ﺷﻮد .اﻳﻦ اﻣﺮ ﻣﻨﺠﺮ ﺑﻪ ﭘﺮ ﺷﺪن ﺳﺎﻣﺎﻧﻪ

ﭘﻴﺶ از ﺷﺮوع ﺑﻜﺎر ﺗﻠﻤﺒﻪ ﺑﺪون ﺑﺎزﺷﺪن ﺷﻴﺮ ﺗﺨﻠﻴﻪ ﻣﻲﺷﻮد .ﻟﻮﻟﻪ

ﺗﺨﻠﻴﻪ ﮔﺎز ﺑﺎﻳﺪ ﻣﺠﻬﺰ ﺑﻪ دو ﺷﻴﺮ ﺑﺎﺷﺪ ﺑﻪ ﻃﻮري ﻛﻪ ﻳﻜﻲ روي

ﺗﻠﻤﺒﻪ و دﻳﮕﺮي روي ﻣﺨﺰن ﻗﺮار ﮔﻴﺮد.

ﮔﺮانﻗﻴﻤﺖ اﺳﺘﻔﺎده ﻣﻲﺷﻮد ،ﺑﺎﻳﺪ ﻣﺠﺎري ﺗﺨﻠﻴﻪ ﻣﺎﻳﻌﺎت و ﮔﺎزﻫﺎ ﺑﻪ

ﻣﺨﺎزن ﺗﺨﻠﻴﻪ ﻳﺎ ﻣﺨﺎزن ﺗﺤﺖ ﺧﻼء ﻣﺮﺗﺒﻂ ﺷﻮﻧﺪ ﺗﺎ از رﻳﺰش اﻳﻦ

ﻣﺎﻳﻌﺎت ﺑﻪ ﻫﻨﮕﺎم ﺟﺪاﺷﺪن ﺗﻠﻤﺒﻪ از اﺗﺼﺎﻻﺗﺶ ﻣﻤﺎﻧﻌﺖ ﺷﻮد.

4.2.1.10 Pumps handling fluids with a vapor

pressure exceeding 5 bar (g) shall have a vent

line to the flare system or shall discharge into the

process system, e.g. for LPG or naphtha. The

vent line shall have a spectacle or spade blind,

block-and bleeder and thermal relief valve.

Downstream of the relief valve shall be a flanged

valve for blinding. Pump vent connections for

toxic services shall discharge into closed systems.

10-1-2-4ﺗﻠﻤﺒﻪﻫـﺎﻳﻲ ﻛﻪ ﺳﻴﺎﻻﺗﻲ ﺑﺎ ﻓﺸﺎر ﺑﺨــﺎر ﺑﻴﺸﺘﺮ از 5

ﺑﺎر)ﻧﺴﺒﻲ( ﺑﻪ ﻋﻨﻮان ﻣﺜﺎل LPGﻳﺎ ﻧﻔﺘﺎ ﺟﺎﺑﺠﺎ ﻣﻲﻛﻨﻨﺪ ﺑﺎﻳﺪ ﻣﺠﻬﺰ ﺑﻪ

ﻟﻮﻟﻪ ﺗﺨﻠﻴﻪ ﺑﻪ ﺳﺎﻣﺎﻧﻪ ﻣﺸﻌﻞ ﺑﻮده ﻳﺎ در ﺳﺎﻣﺎﻧﻪ ﻓﺮآﻳﻨﺪي ﺗﺨﻠﻴﻪ ﺷﻮﻧﺪ.

ﻟﻮﻟﻪ ﺗﺨﻠﻴﻪ ﺑﺎﻳﺪ ﻣﺠﻬﺰ ﺑﻪ ﺻﻔﺤﻪ ﻣﺴﺪود ﻛﻨﻨﺪه ﻳﺎ ﺷﻴﺮ ﻣﺴﺪود ﻛﻨﻨﺪه دو

ﻃﺮﻓﻪ ﻣﺠﻬﺰ ﺑﻪ ﺷﻴﺮ ﺗﺨﻠﻴﻪ و ﺷﻴﺮ اﻃﻤﻴﻨﺎن ﺣﺮارﺗﻲ ﺑﺎﺷﺪ .ﺑﻌﺪ از ﺷﻴﺮ

اﻃﻤﻴﻨﺎن ﺑﺎﻳﺪ ﻳﻚ ﺷﻴﺮ ﺑﺎ اﺗﺼﺎل ﻓﻠﻨﺠﻲ ﺑﺮاي ﻗﻄﻊ ﺟﺮﻳﺎن در ﻧﻈﺮ ﮔﺮﻓﺘﻪ

ﺷﻮد .اﺗﺼﺎﻻت ﺗﺨﻠﻴﻪ ﮔﺎز در ﺗﻠﻤﺒﻪﻫﺎﻳﻲ ﻛﻪ در ﺳﺮوﻳﺴﻬﺎي ﺳﻤﻲ ﻛﺎر

ﻣﻲﻛﻨﻨﺪ ﺑﺎﻳﺪ ﺑﻪ ﺳﺎﻣﺎﻧﻪاي ﺑﺴﺘﻪ ﺗﺨﻠﻴﻪ ﺷﻮﻧﺪ.

11-1-2-4ﺗﻠﻤﺒﻪﻫﺎﻳﻲ ﻛﻪ ﺳﻴﺎﻻﺗﻲ در ﻓﺮآﻳﻨﺪ دﻣﺎ ﭘﺎﻳﻴﻦ را ﺟﺎﺑﺠﺎ

ﻣﻲﻛﻨﻨﺪ ﺑﺎﻳﺪ ﻟﻮﻟﻪ ﺗﺨﻠﻴﻪاي ﺑﻪ ﻣﺨﺰن ﻣﻜﺶ داﺷﺘﻪ ﺑﺎﺷﻨﺪ .ﻟﻮﻟﻪ ﺗﺨﻠﻴﻪ

ﺑﺎﻳﺪ ﺑﺼﻮرت ﻧﺎوداﻧﻲ ﺑﻮده و ﺣﺪاﻗﻞ ﻣﺴﻴﺮ ﻣﻤﻜﻦ را ﺗﺎ ﻣﺨﺰن ﻣﻜﺶ

ﻃﻲ ﻛﻨﺪ .ﻟﻮﻟﻪ ﺗﺨﻠﻴﻪ ﻧﺒﺎﻳﺪ ﻫﻴﭻ ﻣﺤﻠﻲ ﺑﺎ اﻣﻜﺎن ﺗﺠﻤﻊ ﮔﺎز داﺷﺘﻪ

ﺑﺎﺷﺪ .اﻳﻦ ﻟﻮﻟﻪ ﺗﺨﻠﻴﻪ ﺑﺎﻳﺪ ﺗﺎ ﺣﺪ ﻛﺎﻓﻲ ﺑﺰرگ اﻧﺘﺨﺎب ﺷﻮد ﺗﺎ ﻫﻤﺴﻄﺢ

ﺷﺪن ﺳﻴﺎل داﺧﻞ ﻟﻮﻟﻪ ﺑﺎ ﺳﻄﺢ ﺳﻴﺎل داﺧﻞ ﻣﺨﺰن ﻣﻜﺶ ﺑﺪون ﺷﻜﻞ

ﮔﻴﺮي و ﺗﺠﻤﻊ ﺑﺨﺎر در ﻟﻮﻟﻪ ﻣﻜﺶ ﺻﻮرت ﮔﻴﺮد.

4.2.1.11 Pumps handling cryogenic process fluids

shall have a vent pipe to the suction drum. The

vent pipe shall have a spading point and shall

follow the shortest practical route to the suction

drum. The vent pipe shall have no pockets. This

vent pipe shall be large enough to allow the

liquid level to equalize easily with the level in the

suction drum without creating vapor pockets in

the pipe.

12-1-2-4ﭘﻴﺶ ﺑﻴﻨﻲﻫﺎي ﻻزم در ﺧﺼﻮص ﻣﻨﺎﻓﺬ ﺗﺨﻠﻴﻪ

ﻣﺎﻳﻌﺎت در ﺧﻄﻮط ﻣﻜﺶ و ﺧﺮوﺟﻲ ﺑﺎﻳﺪ اﻧﺠﺎم ﺷﻮد .ﺧﻂ ﻣﻜﺶ

ﻣﻲﺗﻮاﻧﺪ از ﻃﺮﻳﻖ ﻣﺤﻔﻈﻪ ﺗﻠﻤﺒﻪ ﻧﻴﺰ ﺗﺨﻠﻴﻪ ﺷﻮد .در ﺻﻮرﺗﻲ ﻛﻪ

ﺧﻂ ﺧﺮوﺟﻲ ﻋﻤﻮدي ﺑﺎﺷﺪ ،ﺗﺨﻠﻴﻪ ﺧﻂ ﻣﺰﺑﻮر ﺑﺎﻳﺪ از ﻃﺮﻳﻖ

اﻧﺸﻌﺎب ﺣﻮل ﺷﻴﺮ ﻣﺴﺪود ﻛﻨﻨﺪه ﺧﺮوﺟﻲ ﺻﻮرت ﮔﻴﺮد .اﺗﺼﺎل

ﻓﺸﺎر ﺳﻨﺞﻫﺎ ﺑﺎﻳﺪ در ﺣﺪ ﻓﺎﺻﻞ ﻧﺎزل ﺗﻠﻤﺒﻪ و ﺷﻴﺮ ﺧﺮوﺟﻲ و روي

ﻟﻮﻟﻪ ﺗﻌﺒﻴﻪ ﺷﻮد .ﭘﻴﺶ ﺑﻴﻨﻲﻫﺎي ﻣﺸﺎﺑﻪ ﻧﻴﺰ ﺑﺎﻳﺪ در ﻧﺎزل ﻣﻜﺶ

اﻧﺠﺎم ﺷﻮد.

4.2.1.12 Provision shall be made for draining on

suction and discharge lines. Suction lines may be

drained through pump casing. If discharge line is

vertical, the line shall be drained by a bypass

around discharge block valve. Pressure gage

connection, shall be made in the piping between

pump nozzle and the discharge valve. The same

provision shall be made for suction nozzle.

2-2-4ﺗﻠﻤﺒﻪﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ

4.2.2 Centrifugal pumps

4.2.2.1 The length of the straight pipe from the

last elbow to the suction nozzle shall be sufficient

to ensure minimum turbulence at the centrifugal

1-2-2-4ﻃﻮل ﻟﻮﻟﻪ ﻣﺴﺘﻘﻴﻢ از آﺧﺮﻳﻦ زاﻧﻮﻳﻲ ﺑﻪ ﻧﺎزل ﻣﻜﺶ

ﺑﺎﻳﺪ ﺑﻪ اﻧﺪازه ﻛﺎﻓﻲ ﺑﻠﻨﺪ ﺑﺎﺷﺪ ﺗﺎ ﺗﻼﻃﻢ ﺟﺮﻳﺎن در ﻣﻜﺶ ﺗﻠﻤﺒﻪ

ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﺑﻪ ﺣﺪاﻗﻞ ﺑﺮﺳﺪ .ﺣﺪاﻗﻞ ﻃﻮل ﻣﺴﺘﻘﻴﻢ ﻟﻮﻟﻪاي ﻛﻪ ﺑﻪ

10

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

IPS-E-PM-385(2)

pump suction. Table (1) gives the minimum

straight pipe length upstream of the pump suction

nozzle, which shall not include any reducer,

strainer or stop-flow valve.

( ﻣﺸﺨﺺ ﺷﺪه1) ﻧﺎزل ﻣﻜﺶ ﺗﻠﻤﺒﻪ ﻣﻨﺘﻬﻲ ﻣﻲﺷﻮد در ﺟﺪول

ﺻﺎﻓﻲ و ﻳﺎ ﺷﻴﺮ ﻗﻄﻊ ﺟﺮﻳﺎن، اﻳﻦ ﻃﻮل ﻧﺒﺎﻳﺪ ﺷﺎﻣﻞ ﻛﺎﻫﻨﺪه.اﺳﺖ

.ﺑﺎﺷﺪ

Suction piping shall be as short and as direct as

possible, avoiding high spots where pockets of

gas or air could accumulate. However, if this is

unavoidable, venting facilities shall be provided.

ﻟﻮﻟﻪ ﻣﻜﺶ ﺑﺎﻳﺪ ﺗﺎ ﺣﺪ اﻣﻜﺎن ﻛﻮﺗﺎه و ﻣﺴﺘﻘﻴﻢ ﺑﻮده و ﺷﺎﻣﻞ ﻧﻘﺎط

.ﻣﺮﺗﻔﻊ ﻛﻪ اﻣﻜﺎن ﺗﺠﻤﻊ ﮔﺎز ﻳﺎ ﻫﻮا در آن وﺟﻮد دارد ﻧﺒﺎﺷﺪ

TABLE .1- MINIMUM STRAIGHT LENGTH REQUIREMENTS AT UPSTREAM OF THE PUMP

SUCTION NOZZLE. "D" STANDS FOR PIPE DIAMETER.

.“ ﻧﻤﺎﻳﺎﻧﮕﺮ ﻗﻄﺮ ﻟﻮﻟﻪ اﺳﺖD” . ﺣﺪاﻗﻞ ﻃﻮل ﻣﺴﺘﻘﻴﻢ ﻟﻮﻟﻪ ﻣﻨﺘﻬﻲ ﺑﻪ ﻧﺎزل ﻣﻜﺶ ﺗﻠﻤﺒﻪ-1 ﺟﺪول

TYPE OF PUMP

POSITION OF SUCTION PIPING

ﻧﻮع ﺗﻠﻤﺒﻪ

ﻣﻮﻗﻌﻴﺖ ﻟﻮﻟﻪ ﻛﺸﻲ ﻣﻜﺶ

MINIMUM STRAIGHT

LENGTH

ﺣﺪاﻗﻞ ﻃﻮل ﻣﺴﺘﻘﻴﻢ ﻟﻮﻟﻪ

Vertical close-coupled

in same plan as pump shaft

ﻋﻤﻮدي ﺑﺎ ﺟﻔﺖ ﺷﺪﮔﻲ ﻧﺰدﻳﻚ

1.5 D *

ﻣﻮﻗﻌﻴﺖ در ﺻﻔﺤﻪاي ﻛﻪ درﺑﺮدارﻧﺪه ﻣﺤﻮر ﺗﻠﻤﺒﻪ اﺳﺖ

perpendicular to pump shaft

4D

ﻋﻤﻮد ﺑﺮ وﺿﻌﻴﺖ ﻣﺤﻮر ﺗﻠﻤﺒﻪ

Single suction,

end suction type

not applicable

4D

ﻏﻴﺮﻗﺎﺑﻞ ﻛﺎرﺑﺮد

ﻣﻜﺶ از اﻧﺘﻬﺎ،ﺗﻚ ﻣﻜﺸﻲ

Single suction,

top-top connection

at top of pump

4D

ﺑﺎﻻي ﺗﻠﻤﺒﻪ

ﺗﻚ ﻣﻜﺶ

ﻧﺎزﻟﻬﺎي رو ﺑﻪ ﺑﺎﻻ

in same plan as pump shaft

1.5 D

ﻣﻮﻗﻌﻴﺖ در ﺻﻔﺤﻪاي ﻛﻪ درﺑﺮدارﻧﺪه ﻣﺤﻮر ﺗﻠﻤﺒﻪ اﺳﺖ

Double suction

perpendicular to pump shaft (preferred situation)

دو ﻣﻜﺸﻲ

3D

ﺗﺮﺟﻴﺤﺎً ﻋﻤﻮد ﺑﺮ ﻣﺤﻮر ﺗﻠﻤﺒﻪ

any position other than perpendicular **

5 D to 10 D

** ﻫﺮ وﺿﻌﻴﺘﻲ ﻏﻴﺮ از ﻋﻤﻮدي

* For vertical close coupled pumps with

1.5 D straight length, eccentric reducers

(bottom flat) are preferred.

ﻛﻪ ﻃﻮل،در ﺗﻠﻤﺒﻪﻫﺎي ﻋﻤﻮدي ﺑﺎ ﺟﻔﺖ ﺷﺪﮔﻲ ﻧﺰدﻳﻚ

ﺑﻬﺘﺮ، ﺑﺮاﺑﺮ ﻗﻄﺮ ﻟﻮﻟﻪ دارﻧﺪ1/5 ﻟﻮﻟﻪ ﻣﺴﺘﻘﻴﻤﻲ ﻣﻌﺎدل

.اﺳﺖ از ﻛﺎﻫﻨﺪهﻫﺎي ﻏﻴﺮ ﻫﻢ ﻣﺮﻛﺰ اﺳﺘﻔﺎده ﺷﻮد

** It shall be studied how unequal flow to

the impeller eye can best be avoided.

The advice of the pump Manufacturer

should be sought in this respect.

** ﺑﻬﺘﺮﻳﻦ ﻧﺤﻮه ﻣﻤﺎﻧﻌﺖ از ورود ﺟﺮﻳﺎن ﻏﻴﺮﻳﻜﻨﻮاﺧﺖ ﺑﻪ

ﺗﻮﺻﻴﻪ.ﭼﺸﻤﻲ ﭘﺮواﻧﻪ ﺑﺎﻳﺪ ﻣﻮرد ﻣﻄﺎﻟﻌﻪ ﻗﺮار ﮔﻴﺮد

.ﻣﻲﺷﻮد ﻧﻈﺮ ﺳﺎزﻧﺪه در اﻳﻦ ﻣﻮرد اﺧﺬ ﺷﻮد

*

4.2.2.2 Removable pipe spools shall be provided

between the block valves and the pumps or

drivers. The piping to the suction end of a pump

shall be arranged so that the pump impeller may

be removed while the suction block valve is in

place. Where pump discharge piping goes to an

overhead pipe way, the block and check valves

shall be installed in the vertical piping section

above the pump.

در ﺣﺪ ﻓﺎﺻﻞ ﺷﻴﺮ ﻣﺴﺪودﻛﻨﻨﺪه و ﺗﻠﻤﺒﻪ ﻳﺎ ﻣﺤﺮﻛﻬﺎ2-2-2-4

4.2.2.3 Suction lines carrying sensitive fluids

ﺗﻮﺻﻴﻪ ﻣﻴﺸﻮد ﺧﻄﻮط ﻣﻜﺶ ﻛﻪ ﺳﻴﺎﻻت ﺣﺴﺎس3-2-2-4

ﻟﻮﻟﻪﻛﺸﻲ اﻧﺠﺎم ﺷﺪه ﺑﻪ.ﺑﺎﻳﺪ از ﻟﻮﻟﻪ اﺗﺼﺎل ﻓﻠﻨﺠﻲ اﺳﺘﻔﺎده ﻧﻤﻮد

اﻧﺘﻬﺎي ﻣﻜﺶ ﺗﻠﻤﺒﻪ ﺑﺎﻳﺪ ﺑﻪ ﮔﻮﻧﻪاي ﺑﺎﺷﺪ ﻛﻪ ﺑﺘﻮان ﭘﺮواﻧﻪ ﺗﻠﻤﺒﻪ را

ﺧﺎرج،در ﻣﻮاﻗﻌﻲ ﻛﻪ ﺷﻴﺮ ﻣﺴﺪودﻛﻨﻨﺪه در ﻣﺤﻞ ﺧﻮد ﻗﺮار دارد

در ﻣﻮاﻗﻌﻲ ﻛﻪ ﻟﻮﻟﻪﻛﺸﻲ ﺗﺨﻠﻴﻪ ﺗﻠﻤﺒﻪ ﺑﻪ ﻟﻮﻟﻪ ﺑﺎﻻﺳﺮي.ﻧﻤﻮد

ﺷﻴﺮﻫﺎي ﻣﺴﺪودﻛﻨﻨﺪه و ﻳﻜﻄﺮﻓﻪ ﺑﺎﻳﺪ در ﺑﺨﺶ،ﻣﺘﺼﻞ اﺳﺖ

.ﻋﻤﻮدي ﻟﻮﻟﻪﻛﺸﻲ و در ﺑﺎﻻي ﺗﻠﻤﺒﻪ ﻧﺼﺐ ﺷﻮﻧﺪ

11

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

IPS-E-PM-385(2)

such as hot oil, boiler feed water, and the like

must be sloped downward to the pump to

provide venting of flashed vapors back to the

fluid source.

آب ﺗﻐﺬﻳﻪ دﻳﮓ ﺑﺨﺎر و ﻏﻴﺮه را اﻧﺘﻘﺎل ﻣﻲدﻫﻨﺪ،ﻣﺎﻧﻨﺪ روﻏﻦ داغ

داراي ﺷﻴﺒﻲ ﺑﻪ ﺳﻤﺖ ﭘﺎﻳﻴﻦ ﺑﻪ ﻃﺮف ﺗﻠﻤﺒﻪ ﺑﻮده ﺗﺎ ﺑﺨﺎرات ﺑﻪ

.وﺟﻮد آﻣﺪه ﺑﻪ ﻣﻨﺒﻊ ﺳﻴﺎل ﺑﺎز ﮔﺮدﻧﺪ

4.2.2.4 Pumps shall be spaced to allow

minimum clearance of 915 mm between flanges

of piping and other projections of an adjacent

pump.

ﺗﻠﻤﺒﻪﻫﺎ ﺑﺎﻳﺪ ﺑﻪ ﮔﻮﻧﻪاي ﻗﺮار داده ﺷﻮﻧﺪ ﻛﻪ ﺣﺪاﻗﻞ4-2-2-4

4.2.2.5 The discharge valve as well as the

suction strainer and suction valve may be of the

same size as the pump nozzles for economic

reasons and also to avoid comparatively heavy

attachments, unless the pressure drop is too

high. The pressure rating of the suction valve

and piping between this valve and the suction

nozzle shall be equal to the rating of the

discharge piping in order to accommodate

overpressure due to backflow from the

discharge side.

ﺷﻴﺮ ﺗﺨﻠﻴﻪ و ﺻﺎﻓﻲ ﻣﻜﺶ و ﺷﻴﺮ ﻣﻜﺶ را ﻣﻲﺗﻮان ﺑﺎ5-2-2-4

4.2.2.6 For spared centrifugal pumps which

have common suction and discharge pipes, a

flow across the pump discharge non-return

valve is required to keep the spare pump at

operating temperature, ready for immediate

start-up. That small flow also allows for a

controlled warming (or cooling) of the pump

and therefore avoids undesirable thermal effects

on pipes and equipment during this heating

(cooling) process. Plugging of spare pump

piping connections will also be avoided.

در ﺗﻠﻤﺒﻪﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﻳﺪﻛﻲ ﻛﻪ داراي ﻟﻮﻟﻪﻫﺎي6-2-2-4

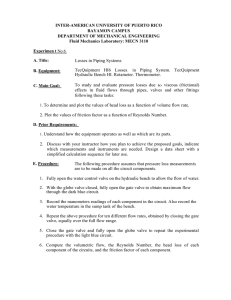

A bypass with a throttling valve around the

discharge non-return valve shall be installed in

the following cases:

در ﺻﻮرت ﻣﻮاﺟﻬﻪ ﺑﺎ ﺷﺮاﻳﻂ ذﻳﻞ ﺑﺎﻳﺪ روي ﻟﻮﻟﻪ ﻛﻨﺎرﮔﺬر ﺷﻴﺮ

.ﻳﻜﻄﺮﻓﻪ ﺧﺮوﺟﻲ از ﻳﻚ ﺷﻴﺮ ﻓﺸﺎر ﺷﻜﻦ اﺳﺘﻔﺎده ﻧﻤﻮد

ﻣﻴﻠﻴﻤﺘﺮ ﺑﻴﻦ ﻓﻠﻨﺞ ﻟﻮﻟﻪﻛﺸﻲ و ﺑﺮآﻣﺪﮔﻴﻬﺎي ﺗﻠﻤﺒﻪ ﻣﺠﺎور915

.ﻓﺎﺻﻠﻪ ﺑﺎﺷﺪ

ﺗﻮﺟﻪ ﺑﻪ ﻣﻼﺣﻈﺎت اﻗﺘﺼﺎدي و ﻫﻤﭽﻨﻴﻦ ﺟﻠﻮﮔﻴﺮي از اﺳﺘﻔﺎده از

، ﻫﻢ اﻧﺪازه ﺑﺎ ﻧﺎزل ﺗﻠﻤﺒﻪ در ﻧﻈﺮ ﮔﺮﻓﺖ،ﻣﻠﺤﻘﺎت ﻧﺴﺒﺘﺎً ﺳﻨﮕﻴﻦ

ﻓﺸﺎر ﻧﺎﻣﻲ ﺷﻴﺮ.ﻣﮕﺮ در ﻣﻮاردي ﻛﻪ اﻓﺖ ﻓﺸﺎر ﺑﺴﻴﺎر زﻳﺎد ﺑﺎﺷﺪ

ﻣﻜﺶ و ﻟﻮﻟﻪ ﻛﺸﻲ ﺑﻴﻦ اﻳﻦ ﺷﻴﺮ و ﻧﺎزل ﻣﻜﺶ ﺑﺎﻳﺪ ﺑﺎ ﻓﺸﺎر ﻧﺎﻣﻲ

ﻟﻮﻟﻪ ﻛﺸﻲ ﺗﺨﻠﻴﻪ ﺑﺮاﺑﺮ ﺑﺎﺷﺪ ﺗﺎ ﺷﺮاﻳﻂ ﺑﺮاي ﺗﺤﻤﻞ اﻓﺰاﻳﺶ ﻓﺸﺎر

.ﻧﺎﺷﻲ از ﺑﺮﮔﺸﺖ ﺟﺮﻳﺎن از ﻗﺴﻤﺖ ﺗﺨﻠﻴﻪ ﻓﺮاﻫﻢ ﺷﻮد

ﺟﺮﻳﺎﻧﻲ در ﻃﻮل ﺧﻂ ﺷﻴﺮ،ﻣﻜﺶ و ﺗﺨﻠﻴﻪ ﻣﺸﺘﺮك ﻫﺴﺘﻨﺪ

ﺑﺮﮔﺸﺖ ﻧﺎﭘﺬﻳﺮ ﺗﺨﻠﻴﻪ ﺗﻠﻤﺒﻪ ﺑﺎﻳﺪ ﺑﺮﻗﺮار ﺑﺎﺷﺪ ﺗﺎ ﺗﻠﻤﺒﻪ ﻳﺪﻛﻲ در

دﻣﺎي ﻋﻤﻠﻴﺎﺗﻲ ﻧﮕﻪ داﺷﺘﻪ ﺷﻮد و ﺑﺮاي ﺷﺮوع ﺑﻪ ﻛﺎر ﻧﺎﮔﻬﺎﻧﻲ آﻣﺎده

اﻳﻦ ﺟﺮﻳﺎن ﻛﻢ ﻫﻤﭽﻨﻴﻦ ﺑﻪ ﮔﺮﻣﺎﻳﺶ ﻳﺎ ﺳﺮﻣﺎﻳﺶ ﻛﻨﺘﺮل.ﺑﺎﺷﺪ

ﺷﺪه ﺗﻠﻤﺒﻪ و ﻫﻤﭽﻨﻴﻦ ﺟﻠﻮﮔﻴﺮي از اﺛﺮات ﻧﺎﻣﻨﺎﺳﺐ ﺣﺮارﺗﻲ ﺑﺮ

ﻟﻮﻟﻪﻫﺎ و ﺗﺠﻬﻴﺰات در ﻃﻮل ﻓﺮآﻳﻨﺪ ﮔﺮﻣﺎﻳﺶ ﻳﺎ ﺳﺮﻣﺎﻳﺶ ﻛﻤﻚ

ﺑﻪ اﻳﻦ ﻃﺮﻳﻖ از ﺑﺴﺘﻪ ﺷﺪن اﺗﺼﺎﻻت ﻟﻮﻟﻪ ﻛﺸﻲ ﺗﻠﻤﺒﻪ.ﻣﻲﻛﻨﺪ

.ﻳﺪﻛﻲ ﻧﻴﺰ ﻣﻤﺎﻧﻌﺖ ﻣﻲﺷﻮد

- If discharge and suction pipe operating

temperatures are above 150 °C;

150 اﮔﺮ دﻣﺎي ﻋﻤﻠﻴﺎﺗﻲ ﺧﻄﻮط ﻣﻜﺶ و ﺗﺨﻠﻴﻪ ﺑﻴﺸﺘﺮ از.درﺟﻪ ﺳﺎﻧﺘﻴﮕﺮاد ﺑﺎﺷﺪ

- If the pumped fluid can solidify at

ambient temperature, e.g. water pipes in

freezing climates;

اﮔﺮ اﻣﻜﺎن ﺟﺎﻣﺪ ﺷﺪن ﺳﻴﺎل ﭘﻤﭗ ﺷﻮﻧﺪه در دﻣﺎي ﻣﺤﻴﻂ ﺑﻄﻮر ﻣﺜﺎل ﻣﻲﺗﻮان از ﻟﻮﻟﻪﻫﺎي آب در.وﺟﻮد داﺷﺘﻪ ﺑﺎﺷﺪ

.ﺷﺮاﻳﻂ دﻣﺎﻳﻲ ﻳﺦ زدن ﻧﺎم ﺑﺮد

- If discharge/suction pipe operating

temperature is below -10 °C;

-10 اﮔﺮ دﻣﺎي ﻋﻤﻠﻴﺎﺗﻲ ﺧﻄﻮط ﻣﻜﺶ ﻳﺎ ﺗﺨﻠﻴﻪ ﻛﻤﺘﺮ از.درﺟﻪ ﺳﺎﻧﺘﻴﮕﺮاد ﺑﺎﺷﺪ

- For pumps handling highly volatile

liquids at pumping temperatures, e.g.

LPG service

ﺗﻠﻤﺒﻪﻫﺎﻳﻲ ﻛﻪ ﺳﻴﺎﻻت ﺑﺴﻴﺎر ﻓﺮار را در دﻣﺎي ﻋﻤﻠﻴﺎﺗﻲLPG ﺑﻪ ﻋﻨﻮان ﻣﺜﺎل ﻣﻲﺗﻮان از ﻛﺎرﺑﺮدﻫﺎي.اﻧﺘﻘﺎل ﻣﻲدﻫﻨﺪ

.ﻧﺎم ﺑﺮد

12

)IPS-E-PM-385(2

ﺷﻬﺮﻳﻮرAug. 2009/ 1388

When a bypass with a throttling valve around

the discharge non-return valve is required,

following criteria for sizing shall be followed.

ﻫﻨﮕﺎﻣﻲﻛﻪ اﺳﺘﻔﺎده از ﻳﻚ ﻣﺴﻴﺮ ﻛﻨﺎر ﮔﺬر ﻣﺠﻬﺰ ﺑﻪ ﺷﻴﺮ ﻓﺸﺎر ﺷﻜﻦ

روي ﺧﻂ ﻣﺮﺑﻮط ﺑﻪ ﺷﻴﺮ ﻳﻜﻄﺮﻓﻪ ﺧﺮوﺟﻲ ،ﻣﻮرد ﻧﻴﺎز اﺳﺖ ،ﺑﺎﻳﺪ

ﻣﻌﻴﺎرﻫﺎي زﻳﺮ روي ﻧﺤﻮه اﻧﺪازهﮔﺬاريﻫﺎي ﻣﺮﺑﻮﻃﻪ رﻋﺎﻳﺖ ﺷﻮد:

-Iﻟﻮﻟﻪ ﺑﺎ ﻗﻄﺮ اﺳﻤﻲ 20ﺑﻪ ﻫﻤﺮاه ﺷﻴﺮ ﻓﺸﺎر ﺷﻜﻦ ﺑﺎﻳﺪ ﺑﻪ

ﺻﻮرت اﺳﺘﺎﻧﺪارد اﺳﺘﻔﺎده ﺷﻮد ﻣﮕﺮ در ﻣﻮارد IIو III؛

(I) DN 20 pipe with a throttling valve shall

be used as a standard except as specified for

;)(II) and (III

-IIدر ﺳﺎﻣﺎﻧﻪﻫﺎﻳﻲ ﺑﺎ دﻣﺎي ﻋﻤﻠﻴﺎﺗﻲ ﺑﻴﺸﺘﺮ از 150درﺟﻪ

ﺳﺎﻧﺘﻴﮕﺮاد و در ﺷﺮاﻳﻂ ذﻳﻞ ﺑﺎﻳﺪ از ﻟﻮﻟﻪ ﺑﺎ ﻗﻄﺮ اﺳﻤﻲ 25و

ﻳﻚ ﺷﻴﺮ ﻓﺸﺎر ﺷﻜﻦ ﺑﻪ ﻣﻨﻈﻮر اﻃﻤﻴﻨﺎن از ﺟﺮﻳﺎن ﻛﺎﻓﻲ ﺳﻴﺎل

ﮔﺮم و ﺗﻮزﻳﻊ ﺣﺮارت ﻳﻜﻨﻮاﺧﺖ در ﺗﻠﻤﺒﻪ و ﻟﻮﻟﻪ ﻛﺸﻲ ورودي و

ﺧﺮوﺟﻲ آن اﺳﺘﻔﺎده ﻧﻤﻮد:

(II) For systems operating at temperatures

above 150 °C, DN 25 pipe with a throttling

valve shall be used in the following cases to

ensure sufficient flow of hot fluid to allow

uniform warming of the pump and its suction

and discharge piping:

در ﺗﻠﻤﺒﻪﻫﺎي ﺑﺰرگ

)ﻟﻮﻟﻪ ﻛﺸﻲ ﻣﻜﺶ ﻗﻄﺮ اﺳﻤﻲ (400

- For large pumps (suction piping ≥ DN

;)400

در ﺻﻮرﺗﻴﻜﻪ ﻟﻮﻟﻪ ورودي و ﻳﺎ ﺧﺮوﺟﻲ داراي ﻃﻮل

ﻣﻌﺎدل" " Lﺑﻴﺸﺘﺮ از 25ﻣﺘﺮ ﺑﺎﺷﺪ) .ﺑﻪ ﺷﻜﻞ 1ﻣﺮاﺟﻌﻪ

ﺷﻮد(

در ﺻﻮرﺗﻴﻜﻪ ﻟﻮﻟﻪ ﻛﻨﺎرﮔﺬر ﺑﺎ رده 80ﻳﺎ ﺑﺎﻻﺗﺮ ﺑﺎﺷﺪ.

- If the suction and/or discharge pipe has

a length L of more than 25 m (see

;)Figure 1 below

- If the bypass pipe is schedule 80 or

;heavier

در ﺳﺮوﻳﺲﻫﺎﻳﻲ ﻛﻪ رﺳﻮبﮔﺬاري ﺑﺴﻴﺎر ﺷﺪﻳﺪ ﻣﻮرد

اﻧﺘﻈﺎر اﺳﺖ.

- For services where severe fouling is

expected.

III) For systems operating at temperatures

above 150 °C, DN 40 pipe with a throttling

valve shall be used for pumps with a suction

diameter equal to or greater than DN 600.

-IIIدر ﺳﺎﻣﺎﻧﻪﻫﺎﻳﻲ ﻛﻪ ﺑﺎ دﻣﺎي 150درﺟﻪ ﺳﺎﻧﺘﻴﮕﺮاد ﻳﺎ

ﺑﻴﺸﺘﺮ ﻛﺎر ﻣﻴﻜﻨﻨﺪ و ﻗﻄﺮ ﻣﻜﺶ ﺗﻠﻤﺒﻪ آﻧﻬﺎ ﺑﺰرﮔﺘﺮ ﻳﺎ ﻣﺴﺎوي ﺑﺎ

ﻗﻄﺮ اﺳﻤﻲ 600اﺳﺖ ،ﺑﺎﻳﺪ از ﺧﻂ ﻛﻨﺎرﮔﺬر ﺑﺎ ﻟﻮﻟﻪ ﺑﻪ ﻗﻄﺮ

اﺳﻤﻲ 40ﻣﺠﻬﺰ ﺑﻪ ﺷﻴﺮ ﻓﺸﺎر ﺷﻜﻦ اﺳﺘﻔﺎده ﻧﻤﻮد.

13

ﺷﻬﺮﻳﻮرAug. 2009/ 1388

)IPS-E-PM-385(2

RO

LO

PI

Pump A

ﺗﻠﻤﺒﻪ اﻟﻒ

RO

LO

L

PI

Pump B

L

ﺗﻠﻤﺒﻪ ب

FIG. 1-BYPASS AROUND NON-RETURN VALVE OF

SPARED PUMPS.

RO, STANDS FOR RESTRICTION ORIFICE. LO

STANDS FOR LOCKED OPEN.

ﺷﻜﻞ -1ﻛﻨﺎرﮔﺬر ﭘﻴﺮاﻣﻮن ﺷﻴﺮ ﺑﺮﮔﺸﺖ ﻧﺎﭘﺬﻳﺮ ﺗﻠﻤﺒﻪﻫﺎي ﻳﺪﻛﻲ.

ROﻧﻤﺎﻳﺎﻧﮕﺮ اورﻳﻔﻴﺲ ﻣﺤﺪود ﻛﻨﻨﺪه و LOﻧﻤﺎﻳﺎﻧﮕﺮ ﻟﺰوم ﺑﺎز ﺑﻮدن

ﻣﻲﺑﺎﺷﺪ.

4.2.2.7 Cooling water connections and the hookup of required water lines, if specified on the

data/requisition sheets and shown on the

diagrams and flow schemes, are generally in

accordance with API 610, with the following

additional requirements:

7-2-2-4در ﻣﻮاردي ﻛﻪ در داده ﺑﺮﮔﻬﺎ ﻳﺎ درﺧﻮاﺳﺖ ﺧﺮﻳﺪ و

در ﺷﻤﺎﺗﻴﻜﻬﺎي ﺟﺮﻳﺎن و دﻳﺎﮔﺮام ﻫﺎ ﻣﺸﺨﺺ ﺷﺪه ﺑﺎﺷﺪ ،اﺗﺼﺎﻻت

آب ﺧﻨﻚ ﻛﻨﻨﺪه و ﻧﻤﺎﻳﺶ ارﺗﺒﺎط ﺧﻄﻮط اﻧﺘﻘﺎل آب ﺑﺎﻳﺪ ﻣﻄﺎﺑﻖ ﺑﺎ

اﺳﺘﺎﻧﺪارد API 610و اﻟﺰاﻣﺎت اﺿﺎﻓﻲ ذﻳﻞ ﺑﺎﺷﻨﺪ:

در ﺻﻮرت ﻛﺎرﺑﺮدي ﺑﻮدن ﺧﻄﻮط ،آب ﺧﻨﻚ ﻛﻨﻨﺪه را ﻣﻲﺗﻮان ﺑﻪ

ﺻﻮرت ﺳﺮي ﺑﺮاي ﺗﻠﻤﺒﻪﻫﺎﻳﻲ ﻛﻪ ﻋﻤﻠﻜﺮد ﻳﻜﺴﺎﻧﻲ دارﻧﺪ ،در ﻧﻈﺮ

ﮔﺮﻓﺖ .ﻫﻤﭽﻨﻴﻦ ﺧﻄﻮط آب ﺧﻨﻚ ﻛﻨﻨﺪه ﻣﻨﺘﻬﻲ ﺑﻪ ﻣﺤﻔﻈﻪ آب

ﺑﻨﺪي و ﻣﺤﻔﻈﻪ ﻳﺎﺗﺎﻗﺎن ،ﺗﻠﻤﺒﻪﻫﺎ را ﻣﻴﺘﻮان ﺑﻪ ﺻﻮرت ﺳﺮي ﻗﺮار

داد .ﻫﺮﭼﻨﺪ در ﺗﻠﻤﺒﻪﻫﺎﻳﻲ ﻛﻪ در دﻣﺎي ﺑﺎﻻي 300درﺟﻪ

ﺳﺎﻧﺘﻴﮕﺮاد ﻛﺎر ﻣﻴﻜﻨﻨﺪ ﺑﺎﻳﺪ ﺑﻪ ﺻﻮرت ﻣﻮازي ﻗﺮار داده ﺷﻮﻧﺪ.

If applicable, cooling water lines may be

connected in series for pumps with the same

function. Also cooling water lines to stuffing

boxes and pump bearing houses can be lined up

in series. However, for pumps operating above

300°C this shall be in parallel.

آب ﺧﻨﻚ ﻛﻨﻨﺪه ﺑﺎﻳﺪ داراي ﻳﻚ ﺷﻴﺮ اﻃﻤﻴﻨﺎن ﺣﺮارﺗﻲ ﺑﺎﺷﻨﺪ ﺗﺎ از

ﻣﺠﺮاي آب ﺧﻨﻚ ﻛﻨﻨﺪه ﺗﻠﻤﺒﻪﻫﺎي ﺧﺎرج از ﺳﺮوﻳﺲ ﻣﺎﻧﻨﺪ ﺗﻠﻤﺒﻪﻫﺎي

ﻳﺪﻛﻲ ﻛﻪ در ﻣﺤﻴﻂ ﻫﺎي ﮔﺮﻣﺴﻴﺮي ﻣﻲ ﺑﺎﺷﻨﺪ .ﻣﺤﺎﻓﻈﺖ ﺑﻪ ﻋﻤﻞ آﻳﺪ.

Cooling water lines shall have a thermal relief

valve to safeguard the cooling jackets of pumps

standing idle in a hot climate, e.g. spare pumps.

Fresh water is preferred as cooling water.

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد از آب ﺗﺎزه ﺑﻪ ﻋﻨﻮان آب ﺧﻨﻚ ﻛﻨﻨﺪه اﺳﺘﻔﺎده ﺷﻮد.

در ﻣﻮرد آب درﻳﺎ ﻳﺎ ﺳﺎﻳﺮ آﺑﻬﺎﻳﻲ ﻛﻪ ﻋﻤﻠﻴﺎت ﺗﺼﻔﻴﻪ روي آﻧﻬﺎ

اﻧﺠﺎم ﻧﺸﺪه ﺑﺎﻳﺪ از ﺻﺎﻓﻲ دوﻗﻠﻮ در ﺗﺄﻣﻴﻦ آب ﺧﻨﻚ ﻛﻨﻨﺪه

اﺳﺘﻔﺎده ﻧﻤﻮد.

For sea water or other untreated water a duplex

strainer shall be installed in the cooling water

supply header.

8-2-2-4در ﺧﺼﻮص ﺳﺎﻣﺎﻧﻪ ﻫﺎي ﻟﻮﻟﻪ ﻛﺸﻲ ﺷﺴﺘﺸﻮ دﻫﻨﺪه و

4.2.2.8 Requirements of API 682 on flushing

14

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

IPS-E-PM-385(2)

plans shall be complied whenever it is

applicable.

API در ﻣﻮاردي ﻛﻪ ﻛﺎرﺑﺮد داﺷﺘﻪ ﺑﺎﺷﻨﺪ ﺑﺎﻳﺪ اﻟﺰاﻣﺎت اﺳﺘﺎﻧﺪارد

4.2.2.9 Sealing systems of Pumps for vacuum

service require a sealing liquid and a vent line to

the process system to secure against dryrunning.

در ﺳﺎﻣﺎﻧﻪﻫﺎي آب ﺑﻨﺪي ﺗﻠﻤﺒﻪﻫﺎ در ﻛﺎرﺑﺮد ﺧﻼء9-2-2-4

. در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﻮﻧﺪ682

ﺑﺎﻳﺪ از ﻣﺎﻳﻊ آب ﺑﻨﺪي ﻛﻨﻨﺪه و ﺧﻂ ﺗﺨﻠﻴﻪ ﮔﺎز ﺑﻪ ﺳﺎﻣﺎﻧﻪ ﻓﺮآﻳﻨﺪي

.اﺳﺘﻔﺎده ﻧﻤﻮد ﺗﺎ در ﻣﻘﺎﺑﻞ ﻋﻤﻠﻜﺮد ﺧﺸﻚ ﻣﺤﺎﻓﻈﺖ ﺷﻮد

ﺗﻠﻤﺒﻪﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ3-2-4

4.2.3 Positive displacement pumps

ﺑﺎﻳﺪ ﺗﻠﻤﺒﻪﻫﺎي ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ را در ﻣﻘﺎﺑﻞ وﻗﻮع اﻧﺴﺪاد1-3-2-4

4.2.3.1 Positive displacement pumps shall be

safeguarded against a blocked outlet with a

reliable pressure-relief device. This shall not be

an integrated part of the pump and be in

accordance with IPS-E-IN-170. The relief valve

should be installed in a bypass between the

discharge line upstream of the block valve and

the suction vessel. Alternatively the relief valve

may be installed in a bypass between the

discharge line upstream of the block valve and

the suction line downstream of the block valve.

However, this may not create an over pressure

of the suction system.

در ﺧﺮوﺟﻲ آﻧﻬﺎ ﺗﻮﺳﻂ ﻳﻚ وﺳﻴﻠﻪ ﺗﺨﻠﻴﻪ ﻓﺸﺎر ﻗﺎﺑﻞ اﻃﻤﻴﻨﺎن ﻣﺤﺎﻓﻈﺖ

اﻳﻦ وﺳﻴﻠﻪ ﻧﺒﺎﻳﺪ ﺑﺎ ﺑﺪﻧﻪ ﺗﻠﻤﺒﻪ ﻳﻜﭙﺎرﭼﻪ ﺑﻮده و ﺑﺎﻳﺪ ﻣﻨﻄﺒﻖ ﺑﺎ.ﻧﻤﻮد

ﺗﻮﺻﻴﻪ ﻣﻴﺸﻮد اﻳﻦ ﺷﻴﺮ. ﺑﺎﺷﺪIPS-E-IN-170 اﻟﺰاﻣﺎت اﺳﺘﺎﻧﺪارد

اﻃﻤﻴﻨﺎن روي ﺧﻂ ﻛﻨﺎرﮔﺬري ﻛﻪ از ﻗﺒﻞ از ﺷﻴﺮ ﻣﺴﺪودﻛﻨﻨﺪه ﺧﻂ

.دﻫﺶ ﺷﺮوع ﺷﺪه و ﺑﻪ ﻣﺨﺰن ﻣﻜﺶ ﻣﻨﺘﻬﻲ ﻣﻲﮔﺮدد ﻗﺮار ﮔﻴﺮد

ﻫﻤﭽﻨﻴﻦ اﻳﻦ ﺷﻴﺮ اﻃﻤﻴﻨﺎن ﻣﻲﺗﻮاﻧﺪ روي ﺧﻂ ﻛﻨﺎرﮔﺬري ﻛﻪ از ﻗﺒﻞ از

ﺷﻴﺮ ﻣﺴﺪودﻛﻨﻨﺪه ﺧﻂ ﺗﺨﻠﻴﻪ ﺷﺮوع ﺷﺪه و ﺑﻪ ﺑﻌﺪ از ﺷﻴﺮ

درﺻﻮرﺗﻴﻜﻪ ﺑﺎﻋﺚ،ﻣﺴﺪودﻛﻨﻨﺪه ﺧﻂ ﻣﻜﺶ ﻣﻨﺘﻬﻲ ﻣﻲﮔﺮدد ﻗﺮار ﮔﻴﺮد

.اﻳﺠﺎد ﻓﺸﺎر زﻳﺎد از ﺣﺪ در ﺳﺎﻣﺎﻧﻪ ﻣﻜﺶ ﻧﮕﺮدد

ﻛﻤﭙﺮﺳﻮرﻫﺎ3-4

4.3 Compressors

4.3.1 General

ﻋﻤﻮﻣﻲ1-3-4

4.3.1.1 To prevent fatigue failure of compressor

piping, the effect of vibrations and pressure

surge shall be considered.

ﺑﺮاي ﺟﻠﻮﮔﻴﺮي از ﺑﺮوز ﺷﻜﺴﺖ ﻧﺎﺷﻲ از ﺧﺴﺘﮕﻲ ﻟﻮﻟﻪ ﻛﺸﻲ1-1-3-4

Piping shall have a minimum of overhung

weight.

ﻟﻮﻟﻪ ﻛﺸﻲ ﺑﺎﻳﺪ ﺑﻪ ﮔﻮﻧﻪاي اﻧﺠﺎم ﮔﻴﺮد ﻛﻪ ﺣﺪاﻗﻞ وزن ﻣﻌﻠﻖ را

.داﺷﺘﻪ ﺑﺎﺷﺪ

4.3.1.2 Pipe and butt-welding fitting shall be

lined up accurately and welds shall be internally

ground smooth.

ﺟﻔﺖ ﺷﺪﮔﻲ و اﺗﺼﺎﻻت ﺟﻮش ﻟﺐ ﺑﻪ ﻟﺐ ﺑﺎﻳﺪ ﺑﻪ دﻗﺖ2-1-3-4

4.3.1.3 Inter-stage and discharge piping shall be

sufficiently flexible to allow of expansion, due

to compression heat.

ﻟﻮﻟﻪﻛﺸﻴﻬﺎي ﺑﻴﻦ ﻣﺮاﺣﻞ و ﻟﻮﻟﻪ ﻛﺸﻲ دﻫﺶ ﺑﺎﻳﺪ ﺑﻪ3-1-3-4

ﻗﺪر ﻛﺎﻓﻲ اﻧﻌﻄﺎف ﭘﺬﻳﺮ ﺑﺎﺷﻨﺪ ﺗﺎ اﻣﻜﺎن اﻧﺒﺴﺎط در اﺛﺮ ﺣﺮارت

.ﻧﺎﺷﻲ از ﻣﺘﺮاﻛﻢ ﺷﺪن ﮔﺎز وﺟﻮد داﺷﺘﻪ ﺑﺎﺷﺪ

4.3.1.4 Block valves shall be installed in the

suction and discharge lines, except for

atmospheric air compressors, which shall have

block valves in the discharge lines only.

ﺑﻪ اﺳﺘﺜﻨﺎء ﻛﻤﭙﺮﺳﻮرﻫﺎي ﻫﻮاﻳﻲ ﻛﻪ ﻣﻜﺶ آﻧﻬﺎ از4-1-3-4

. ﺑﺎﻳﺪ اﺛﺮات ارﺗﻌﺎﺷﺎت و ﻧﻮﺳﺎن ﺳﺎز در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﻮﻧﺪ،ﻛﻤﭙﺮﺳﻮرﻫﺎ

.ﻫﻤﺮاﺳﺘﺎ ﺷﻮﻧﺪ و ﺟﻮﺷﻬﺎ ﺑﺎﻳﺪ از داﺧﻞ ﺻﺎف و ﻳﻜﻨﻮاﺧﺖ ﺷﻮﻧﺪ

ﺑﺎﻳﺪ ﻓﻘﻂ ﺷﻴﺮ ﻣﺴﺪودﻛﻨﻨﺪه در ﺧﻂ دﻫﺶ داﺷﺘﻪ،ﻣﺤﻴﻂ ﻣﻲﺑﺎﺷﺪ

در ﺳﺎﻳﺮ ﻣﻮارد ﺷﻴﺮﻫﺎي ﻣﺴﺪودﻛﻨﻨﺪه ﺑﺎﻳﺪ ﻓﻘﻂ در ورودي،ﺑﺎﺷﻨﺪ

.و ﺧﺮوﺟﻲ ﻧﺼﺐ ﺷﻮد

4.3.1.5 Except for reciprocating compressors,

compressor discharge lines shall have a check

valve between the block valve and the discharge

nozzle as close as practical to the compressor.

ﺧﻄﻮط دﻫﺶ، ﺑﻪ اﺳﺘﺜﻨﺎء ﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ5-1-3-4

ﻛﻤﭙﺮﺳﻮرﻫﺎ ﺑﺎﻳﺪ ﻣﺠﻬﺰ ﺑﻪ ﻳﻚ ﺷﻴﺮ ﻳﻜﻄﺮﻓﻪ ﻗﺒﻞ از ﺷﻴﺮ ﻣﺴﺪودﻛﻨﻨﺪه و

.در ﻧﺰدﻳﻜﺘﺮﻳﻦ ﻣﺤﻞ ﺑﻪ ﻧﺎزل ﺧﺮوﺟﻲ ﻛﻤﭙﺮﺳﻮر ﺑﺎﺷﺪ

15

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

4.3.1.6 A suction strainer shall be installed in all

compressor suction lines located downstream of

the block valve of the compressor and as close

as possible to the compressor suction nozzle.

Screens and filters shall be reinforced to prevent

their collapse or failure and subsequent entry of

debris into the compressor, see IPS-G-PI-230.

Provision shall be made to measure the pressure

difference across the strainer in order to monitor

fouling, if it exceeds the certain value.

IPS-E-PM-385(2)

ﻳﻚ ﺻﺎﻓﻲ ﺑﺎﻳﺪ در ﺧﻄﻮط ﻣﻜﺶ ﻛﻠﻴﻪ ﻛﻤﭙﺮﺳﻮرﻫﺎ6-1-3-4

ﺑﻌﺪ از ﺷﻴﺮ ﻣﺴﺪودﻛﻨﻨﺪه و در ﻧﺰدﻳﻜﺘﺮﻳﻦ ﻣﺤﻞ ﺑﻪ ﻧﺎزل ﻣﻜﺶ

ﺻﻔﺤﺎت ﻣﺸﺒﻚ و اﻟﻤﺎن ﻓﻴﻠﺘﺮﻫﺎ ﺑﺎﻳﺪ ﺑﻪ.ﻛﻤﭙﺮﺳﻮر ﻧﺼﺐ ﺷﻮد

ﻣﻨﻈﻮر ﺟﻠﻮﮔﻴﺮي از ﻣﭽﺎﻟﻪ ﺷﺪن ﻳﺎ ﺑﺮوز ﻧﻘﺺ در آﻧﻬﺎ و در ﻧﺘﻴﺠﻪ

)ﺑﻪ اﺳﺘﺎﻧﺪارد.ورود ذرات ﺑﻪ ﻛﻤﭙﺮﺳﻮر ﺗﻘﻮﻳﺖ ﺷﻮﻧﺪ

ﺑﻪ ﭘﺎﻳﺶ ﻣﻴﺰان رﺳﻮب در ﺻﺎﻓﻲ.( ﻣﺮاﺟﻌﻪ ﺷﻮدIPS-G-PI-230

ﺑﺎﻳﺪ ﺗﻤﻬﻴﺪات ﻻزم ﺑﺮاي اﻧﺪازه ﮔﻴﺮي اﺧﺘﻼف ﻓﺸﺎر دو ﻃﺮف

.ﺻﺎﻓﻲ دﻳﺪه ﺷﻮد ﺗﺎ از ﻣﻴﺰان ﻣﺸﺨﺼﻲ ﺑﻴﺸﺘﺮ ﻧﺸﻮد

4.3.1.7 The suction line between a knock-out

drum and the compressor shall be as short as

practicable, without pockets, and slope towards

the knock-out drum. When a continuous slope is

not possible, low points shall be provided with a

drain to remove any possible accumulation of

liquid.

ﺧﻂ ﻣﻜﺶ ﺑﻴﻦ ﻣﺨﺰن ﻣﺎﻳﻊ ﮔﻴﺮ و ﻛﻤﭙﺮﺳﻮر ﺑﺎﻳﺪ ﺑﺎ7-1-3-4

ﻛﻮﺗﺎﻫﺘﺮﻳﻦ ﻃﻮل ﻣﻤﻜﻦ اﻧﺠﺎم و ﺑﺪون ﻧﻘﻄﻪ ﺗﺠﻤﻊ ﻣﺎﻳﻌﺎت ﺑﻮده و

در ﻣﻮاردي ﻛﻪ.ﺷﻴﺒﻲ ﺑﻪ ﺳﻤﺖ ﻣﺨﺰن ﻣﺎﻳﻊ ﮔﻴﺮ داﺷﺘﻪ ﺑﺎﺷﺪ

اﻋﻤﺎل ﺷﻴﺐ ﻳﻜﻨﻮاﺧﺖ ﻣﻤﻜﻦ ﻧﻴﺴﺖ ﻧﻘﺎط ﺗﺤﺘﺎﻧﻲ ﺑﺎﻳﺪ داراي

.ﻣﺠﺮاي ﺧﺮوﺟﻲ ﺑﺮاي ﺗﺨﻠﻴﻪ ﻣﺎﻳﻌﺎت اﺣﺘﻤﺎﻟﻲ ﺟﻤﻊ ﺷﺪه ﺑﺎﺷﻨﺪ

4.3.1.8 The pressure rating of the suction block

valve and piping between this valve and the

suction nozzle shall be equal to the rating of the

discharge line.

ﻧﺮخ ﻓﺸﺎر ﻧﺎﻣﻲ ﺷﻴﺮ ﻣﺴﺪودﻛﻨﻨﺪه ﻣﻜﺶ و ﻟﻮﻟﻪ ﻛﺸﻲ8-1-3-4

4.3.1.9 If two or more compressors are

combined, their suction lines shall be connected

to the top of the header, except that suction lines

at least one pipe size smaller than the header

may be connected concentrically at the side of

the header.

در ﺻﻮرﺗﻲ ﻛﻪ دو ﻛﻤﭙﺮﺳﻮر ﻳﺎ ﺑﻴﺸﺘﺮ ﺑﻪ ﺻﻮرت9-1-3-4

4.3.1.10 Compressor lube oil and seal oil piping

over the full length shall be of austenitic

stainless steel, including valve trim and flange

bolting. See IPS-M-PM-320.

ﻛﻞ ﻟﻮﻟﻪ ﻛﺸﻲ ﻫﺎي ﺳﺎﻣﺎﻧﻪ روﻏﻦ رواﻧﻜﺎري و آب10-1-3-4

.ﺑﻴﻦ اﻳﻦ ﺷﻴﺮ و ﻧﺎزل ﻣﻜﺶ ﺑﺎﻳﺪ ﺑﺎ ﻓﺸﺎر ﺧﻂ ﺧﺮوﺟﻲ ﺑﺮاﺑﺮ ﺑﺎﺷﺪ

ﺧﻄﻮط ﻣﻜﺶ آﻧﻬﺎ ﺑﺎﻳﺪ ﺑﻪ ﺑﺎﻻي،ﺗﺮﻛﻴﺒﻲ ﻗﺮار داده ﺷﺪه ﺑﺎﺷﻨﺪ

ﻣﮕﺮ در ﻣﻮاردي ﻛﻪ ﺧﻄﻮط ﻣﻜﺶ،ﺟﻤﻊ ﻛﻨﻨﺪه ﻣﺘﺼﻞ ﺷﻮﻧﺪ

ﻣﻴﺘﻮان،ﺣﺪاﻗﻞ ﺑﻪ اﻧﺪازه ﻳﻚ ﻗﻄﺮ ﻟﻮﻟﻪ ﻛﻮﭼﻜﺘﺮ از ﻟﻮﻟﻪ ﻣﻘﺴﻢ ﺑﺎﺷﺪ

.ﺑﻪ ﺻﻮرت ﻫﻢ ﻣﺮﻛﺰ ﺑﻪ ﻛﻨﺎر ﻟﻮﻟﻪ ﻣﻘﺴﻢ ﻣﺘﺼﻞ ﻧﻤﻮد

ﺑﻨﺪي ﻛﻤﭙﺮﺳﻮر ﺑﻪ ﻫﻤﺮاه ﺳﺎﻗﻪ ﺷﻴﺮآﻻت ﺑﻪ ﺟﺰ ﻣﺘﺤﺮك ﺷﻴﺮآﻻت

و ﭘﻴﭻ و ﻣﻬﺮه ﻫﺎي ﻓﻠﻨﺞ ﺑﺎﻳﺪ از ﺟﻨﺲ ﻓﻮﻻد زﻧﮓ ﻧﺰن آﺳﺘﻴﻨﻴﺘﻲ

. ﻣﺮاﺟﻌﻪ ﺷﻮدPS-M-PM-320 ﺑﻪ.ﺑﺎﺷﺪ

4.3.1.11 Flow straightening devices to reduce

the required straight length of compressor inlet

piping, such as vaned elbows or other piping

internals, may be used only with the approval of

the Company.

ﺑﻪ ﻣﻨﻈﻮر ﻛﺎﻫﺶ ﻃﻮل ﻣﺴﺘﻘﻴﻢ ﻣﻮرد ﻧﻴﺎز ﻟﻮﻟﻪ ﻛﺸﻲ11-1-3-4

4.3.1.12 Compressors in hydrocarbon or toxic

service shall have purge facilities. Possibility of

spading shall be provided by spectacle blinds,

removable spool pieces or elbows.

ﻛﻤﭙﺮﺳﻮرﻫﺎﻳﻲ ﻛﻪ در ﺳﺮوﻳﺲﻫﺎي ﻫﻴﺪروﻛﺮﺑﻨﻲ ﻳﺎ12-1-3-4

4.3.2

ورودي ﻛﻤﭙﺮﺳﻮر ﻣﻴﺘﻮان از وﺳﺎﻳﻠﻲ ﺑﺮاي ﻳﻜﺮاﺳﺘﺎ ﻛﺮدن ﺟﺮﻳﺎن

ﻣﺎﻧﻨﺪ زاﻧﻮﻳﻲﻫﺎي ﺗﻴﻐﻪ دار و ﺳﺎﻳﺮ اﺟﺰاي داﺧﻠﻲ ﻟﻮﻟﻪ ﻛﺸﻲ در

.ﺻﻮرت ﺗﺄﻳﻴﺪ ﺷﺮﻛﺖ اﺳﺘﻔﺎده ﻧﻤﻮد

اﻣﻜﺎن.ﺳﻤﻲ ﻛﺎر ﻣﻲﻛﻨﻨﺪ ﺑﺎﻳﺪ ﻣﺠﻬﺰ ﺑﻪ ادوات ﮔﺎز زداﻳﻲ ﺑﺎﺷﻨﺪ

،ﻗﻄﻊ ﻣﺴﻴﺮ ﺟﺮﻳﺎن ﺑﺎﻳﺪ از ﻃﺮﻳﻖ ﻣﺴﺪود ﻛﻨﻨﺪهﻫﺎي ﻋﻴﻨﻜﻲ

.ﻟﻮﻟﻪ ﻫﺎي واﺳﻂ ﻓﻠﻨﺠﻲ ﻳﺎ زاﻧﻮﻳﻲ ﻓﺮاﻫﻢ ﺷﻮد

ﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ2-3-4

Reciprocating compressors

4.3.2.1 The piping shall have as much free

clearance as possible around each machine.

ﻟﻮﻟﻪ ﻛﺸﻲ اﻃﺮاف ﺗﺠﻬﻴﺰ ﺑﺎﻳﺪ ﺣﺘﻲاﻻﻣﻜﺎن ﺑﻪ ﮔﻮﻧﻪاي1-2-3-4

.ﺑﺎﺷﺪ ﻛﻪ ﺣﺪاﻛﺜﺮ ﻓﻀﺎي دﺳﺘﺮﺳﻲ در ﭘﻴﺮاﻣﻮن ﺗﺠﻬﻴﺰ ﻣﻬﻴﺎ ﺑﺎﺷﺪ

16

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

4.3.2.2 In order to prevent transmission of

vibrations to a compressor, compressor piping

shall not be supported or connected to the

compressor foundation, the building structure

and other equipment foundation that may have

vibration.

IPS-E-PM-385(2)

، ﺑﻪ ﻣﻨﻈﻮر ﺟﻠﻮﮔﻴﺮي از اﻧﺘﻘﺎل ارﺗﻌﺎﺷﺎت ﺑﻪ ﻛﻤﭙﺮﺳﻮر2-2-3-4

ﻟﻮﻟﻪ ﻛﺸﻲ ﻛﻤﭙﺮﺳﻮر ﻧﺒﺎﻳﺪ ﺑﻪ ﻓﻮﻧﺪاﺳﻴﻮن و ﺳﺎزه ﺳﺎﺧﺘﻤﺎن

ﻛﻤﭙﺮﺳﻮر و ﻓﻮﻧﺪاﺳﻴﻮن ﺳﺎﻳﺮ ﺗﺠﻬﻴﺰات ﻛﻪ ﻣﻤﻜﻦ اﺳﺖ ارﺗﻌﺎش

. ﻣﺘﺼﻞ ﻳﺎ ﺗﻜﻴﻪ داده ﺷﻮد،داﺷﺘﻪ ﺑﺎﺷﻨﺪ

4.3.2.3 Detrimental pulsations and vibrations

shall be controlled for satisfactory levels of

piping vibration, compressor performance, valve

life, and operation of equipment sensitive to

flow pulsation. Following basic techniques shall

be used:

ﺑﻪ ﻣﻨﻈﻮر رﺳﻴﺪن ﺑﻪ ﻣﻘﺎدﻳﺮ ﻗﺎﺑﻞ ﻗﺒﻮل در ارﺗﻌﺎﺷﺎت3-2-3-4

ﻋﻤﺮ ﺷﻴﺮآﻻت و ﻋﻤﻠﻜﺮد ﺗﺠﻬﻴﺰات ﺣﺴﺎس، ﻛﺎرآﻳﻲ ﻛﻤﭙﺮﺳﻮر،ﻟﻮﻟﻪ

.ﺑﻪ ﻧﻮﺳﺎﻧﺎت ﺟﺮﻳﺎﻧﻲ ﺑﺎﻳﺪ ﻧﻮﺳﺎﻧﺎت و ارﺗﻌﺎﺷﺎت ﻣﻀﺮ ﻛﻨﺘﺮل ﺷﻮﻧﺪ

:روﺷﻬﺎي اﺳﺎﺳﻲ ذﻳﻞ ﺑﺎﻳﺪ ﺑﻪ ﻛﺎر ﮔﺮﻓﺘﻪ ﺷﻮﻧﺪ

I. System design based on analysis of the

interactive effects of pulsations and the

attenuation requirements;

ﻃﺮاﺣﻲ ﺳﺎﻣﺎﻧﻪ ﺑﺮاﺳﺎس ﺗﺤﻠﻴﻞ اﺛﺮات ﻣﺘﻘﺎﺑﻞ ﻧﻮﺳﺎﻧﺎت و-I

II. Utilization of pulsation suppression

devices; (such as: pulsation filters and

attenuators; volume bottles, with or

without internals; choke tubes; orifice

systems;

and

selected

piping

configurations);

اﺳﺘﻔﺎده از اﺑﺰار ﺗﻌﺪﻳﻞ ﻧﻮﺳﺎﻧﺎت )ﻣﺎﻧﻨﺪ ﻓﻴﻠﺘﺮ و ﺗﻀﻌﻴﻒ-II

اﻟﺰاﻣﺎت دﺳﺘﻴﺎﺑﻲ ﺑﻪ ﻣﻴﺮاﻳﻲ آﻧﻬﺎ ﺑﺎﺷﺪ؛

ﻣﺨﺰن داراي دﻳﻮارهﻫﺎي داﺧﻠﻲ ﻳﺎ ﻓﺎﻗﺪ،ﻛﻨﻨﺪه ﻧﻮﺳﺎﻧﺎت

ﺳﺎﻣﺎﻧﻪﻫﺎي اورﻳﻔﻴﺲ و، ﻟﻮﻟﻪﻫﺎي ﻣﺴﺪود ﻛﻨﻨﺪه،دﻳﻮاره

اﺳﺘﻔﺎده از ﭼﻴﺪﻣﺎن ﻣﻨﺎﺳﺐ در ﻟﻮﻟﻪﻛﺸﻲ(؛

III. Mechanical restraint design; including

type, location, and number of pipe and

equipment clamps and supports.

ﻣﺤﻞ و ﺗﻌﺪاد، ﺷﺎﻣﻞ ﻧﻮع، ﻃﺮاﺣﻲ ﻗﻴﻮد ﻣﻜﺎﻧﻴﻜﻲ-III

.ﺑﺴﺖﻫﺎ و ﺗﻜﻴﻪﮔﺎﻫﻬﺎي ﻟﻮﻟﻪﻫﺎ و ﺗﺠﻬﻴﺰات

4.3.2.4 The design of a compressor inlet system

for operation with a gas at or near saturation

shall consider the following factors:

در ﻃﺮاﺣﻲ ﺳﺎﻣﺎﻧﻪ ورودي ﺑﻪ ﻛﻤﭙﺮﺳﻮري ﻛﻪ ﺑﺎ4-2-3-4

ﮔﺎزﻫﺎي اﺷﺒﺎع ﻳﺎ ﻧﺰدﻳﻚ ﺑﻪ اﺷﺒﺎع ﻛﺎر ﻣﻴﻜﻨﺪ ﺑﺎﻳﺪ ﺑﻪ ﻣﻮارد ذﻳﻞ

:ﺗﻮﺟﻪ ﻧﻤﻮد

the

ﻧﺰدﻳﻜﻲ ﺟﺪاﻛﻨﻨﺪه ﻣﺎﻳﻊ ﺑﻪ ﻣﺤﻞ ﻣﻜﺶ ﻛﻤﭙﺮﺳﻮر ؛

─ Separator efficiency over the operating

flow range;

راﻧﺪﻣﺎن ﺟﺪاﻛﻨﻨﺪه در ﻣﺤﺪوده ﺟﺮﻳﺎن ﻋﻤﻠﻴﺎﺗﻲ؛

─ Liquid separator

compressor suction;

close

to

ﺣﺠﻢ ﻛﺎﻓﻲ ﺟﺪاﻛﻨﻨﺪه ﺑﺮاي ﻧﺎﺧﺎﻟﺼﻲﻫﺎي ورودي؛

─ Sufficient separator volume to handle

incoming slugs;

─ Sufficient gas velocity in the line from

the separator to the cylinder to minimize

liquid dropout;

ﺳﺮﻋﺖ ﻛﺎﻓﻲ ﮔﺎز در ﺧﻂ از ﺟﺪاﻛﻨﻨﺪه ﺗﺎ ﺳﻴﻠﻨﺪر ﺑﺮاي ﺑﻪﺣﺪاﻗﻞ رﺳﺎﻧﺪن ﻗﻄﺮان ﻣﻴﻌﺎﻧﺎت؛

ﺣﺬف ﻧﻘﺎط ﭘﺎﻳﻴﻦ در ﺣﺪ ﻓﺎﺻﻞ ﺟﺪاﻛﻨﻨﺪه و ﺳﻴﻠﻨﺪر ؛

─ Elimination of low points between the

separator and cylinder;

ﺷﻴﺐ ﺧﻄﻮط؛

─ Slope of lines;

ﻋﺎﻳﻖﻛﺎري ﺑﻪ ﻣﻨﻈﻮر ﺣﺪاﻗﻞ ﻧﻤﻮدن اﻓﺖ ﺣﺮارﺗﻲ؛

─ Insulation to minimize heat loss;

اﺳﺘﻔﺎده از ﭘﻮﺷﺶ ﺣﺮارﺗﻲ ﺑﺮاي ﻧﮕﻬﺪاري دﻣﺎي ﮔﺎز در

.ﻧﻘﻄﻪ ﺷﺒﻨﻢ ﻳﺎ ﺑﺎﻻﺗﺮ از آن

─ Heat tracing to maintain the gas at or

above the dew point.

17

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

IPS-E-PM-385(2)

:1 ﻳﺎدآوري

Note 1:

During certain atmospheric conditions, air can

be at or close to saturated conditions; also,

multi-stage air or hydrocarbon gas compressors

will usually have saturated conditions following

inter-cooling.

ﻫﻮا ﻣﻲﺗﻮاﻧﺪ در ﺷﺮاﻳﻂ اﺷﺒﺎع ﻳﺎ ﻧﺰدﻳﻚ ﺑﻪ،در ﺷﺮاﻳﻂ اﺗﻤﺴﻔﺮﻳﻚ

ﻫﻤﭽﻨﻴﻦ ﻛﻤﭙﺮﺳﻮرﻫﺎي ﭼﻨﺪ ﻣﺮﺣﻠﻪاي ﻫﻮا ﻳﺎ ﮔﺎزﻫﺎي.آن ﺑﺎﺷﺪ

ﻫﻴﺪروﻛﺮﺑﻨﻲ ﻣﻌﻤﻮﻻ ﭘﺲ از ﻣﺮﺣﻠﻪ ﺧﻨﻚ ﻛﺎري در ﺷﺮاﻳﻂ اﺷﺒﺎع

.ﻗﺮار ﻣﻲﮔﻴﺮﻧﺪ

:2 ﻳﺎدآوري

Note 2:

The purchaser should ensure that the quantity

of liquid carried into the inlet system is

minimized and that any such carry-over does

not collect in the inlet system and form slugs.

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد ﺧﺮﻳﺪار از ﺣﺪاﻗﻞ ﺑﻮدن ﻣﻘﺪار ﻣﺎﻳﻊ در ﺳﺎﻣﺎﻧﻪ

ورودي و ﻫﻤﭽﻨﻴﻦ از ﺗﺸﻜﻴﻞ ﻧﺸﺪن ﻣﻴﻌﺎﻧﺎت در ﺳﺎﻣﺎﻧﻪ ورودي

.اﻃﻤﻴﻨﺎن ﺣﺎﺻﻞ ﻧﻤﺎﻳﺪ

4.3.2.5 No cast iron valves shall be used on

compressor process piping.

در ﻟﻮﻟﻪﻛﺸﻲ ﻓﺮآﻳﻨﺪي ﻛﻤﭙﺮﺳﻮر ﻧﺒﺎﻳﺪ از ﺷﻴﺮ ﭼﺪﻧﻲ5-2-3-4

4.3.2.6 Crank case vents and distance piece

vents shall be piped to the outside of the

compressor building. See IPS-M-PM-200.

ﻣﻨﺎﻓﺬ ﺧﺮوﺟﻲ ﮔﺎز ﻣﺤﻔﻈﻪ ﻟﻨﮓ و ﻗﻄﻌﻪ ﻓﺎﺻﻠﻪ اﻧﺪاز6-2-3-4

.ﺑﺎﻳﺪ ﺗﻮﺳﻂ ﻟﻮﻟﻪ ﺑﻪ ﺧﺎرج از ﺳﺎﺧﺘﻤﺎن ﻛﻤﭙﺮﺳﻮر ﻫﺪاﻳﺖ ﺷﻮﻧﺪ

. ﻣﺮاﺟﻌﻪ ﺷﻮدIPS-M-PM-200 ﺑﺮاي اﻃﻼﻋﺎت ﺑﻴﺸﺘﺮ ﺑﻪ

4.3.2.7 The design approach choices

specified by API 618 shall be followed:

ﺑﺎﻳﺪ از ﻣﻮاردAPI 618 ﺷﻴﻮهﻫﺎي ﻃﺮاﺣﻲ ﺑﺮاﺳﺎس7-2-3-4

.اﺳﺘﻔﺎده ﻧﻤﻮد

as

:ذﻳﻞ ﭘﻴﺮوي ﻧﻤﺎﻳﺪ

a. Design Approach 1: Empirical Pulsation

Suppression Device Sizing.

اﻧﺪازه ﻛﺮدن ﺗﺠﺮﺑﻲ ادوات ﻣﻤﺎﻧﻌﺖ:1 اﻟﻒ( ﺷﻴﻮه ﻃﺮاﺣﻲ

b. Design Approach 2: Acoustic Simulation

and Piping Restraint Analysis.

ﺷﺒﻴﻪ ﺳﺎزي ﺻﻮﺗﻲ و ﺗﺤﻠﻴﻞ ﻗﻴﻮد ﻟﻮﻟﻪ:2 ب( ﺷﻴﻮه ﻃﺮاﺣﻲ

c. Design Approach 3: Acoustic Simulation

and Piping Restraint Analysis plus

Mechanical Analysis (with Forced

Mechanical Response Analysis if

necessary).

ﺷﺒﻴﻪ ﺳﺎزي ﺻﻮﺗﻲ و ﺗﺤﻠﻴﻞ ﻗﻴﻮد ﻟﻮﻟﻪ:3 ج( ﺷﻴﻮه ﻃﺮاﺣﻲ

.ﻛﻨﻨﺪه از ﻧﻮﺳﺎن

.ﻛﺸﻲ

ﻛﺸﻲ ﺑﻪ ﻫﻤﺮاه ﺗﺤﻠﻴﻞ ﻣﻜﺎﻧﻴﻜﻲ )در ﺻﻮرت ﻟﺰوم ﺑﻪ

(ﻫﻤﺮاه ﺗﺤﻠﻴﻞ واﻛﻨﺶ ﻣﻜﺎﻧﻴﻜﻲ ﺗﺤﻤﻴﻠﻲ

4.3.2.8 Suction and discharge volume bottles

greater than 750 mm diameter shall have a 200

mm minimum blinded opening for cleaning and

bottle inspection.

750 ﻣﺤﻔﻈﻪﻫﺎي ﻣﻜﺶ و ﺧﺮوﺟﻲ ﺑﺎ ﻗﻄﺮ ﺑﻴﺸﺘﺮ از8-2-3-4

200 ﻣﻴﻠﻴﻤﺘﺮ ﺑﺎﻳﺪ داراي دﻫﺎﻧﻪ ﻛﻮر ﺷﺪهاي ﺑﺎ ﻗﻄﺮ ﺣﺪاﻗﻞ

ﻣﻴﻠﻴﻤﺘﺮ ﺑﺎﺷﻨﺪ ﺗﺎ ﺑﺮاي ﺗﻤﻴﺰ ﻛﺮدن و ﺑﺎزرﺳﻲ ﻣﺤﻔﻈﻪﻫﺎ ﺑﻜﺎر ﮔﺮﻓﺘﻪ

.ﺷﻮﻧﺪ

4.3.2.9 Reciprocating compressors shall be

safeguarded against a blocked outlet with a

reliable pressure-reliving device, installed in

upstream of the discharge block valve. Interstage sections shall also be protected by relief

valves See IPS-G-ME-250.

ﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ ﺑﺎﻳﺪ ﺗﻮﺳﻂ اﺑﺰار ﻓﺸﺎرﺷﻜﻦ9-2-3-4

ﻗﺎﺑﻞ اﻃﻤﻴﻨﺎﻧﻲ ﻛﻪ در ﺑﺎﻻ دﺳﺖ ﺷﻴﺮ ﻣﺴﺪود ﻛﻨﻨﺪه ﺧﺮوﺟﻲ ﻧﺼﺐ ﻣﻲ

. ﺟﻬﺖ ﺟﻠﻮﮔﻴﺮي از ﻣﺴﺪود ﺷﺪن ﻣﺴﻴﺮ ﺧﺮوﺟﻲ ﻣﺤﺎﻓﻈﺖ ﺷﻮﻧﺪ،ﺷﻮﻧﺪ

ﻗﺴﻤﺖﻫﺎي ﺑﻴﻦ ﻣﺮﺣﻠﻪاي ﻧﻴﺰ ﺑﺎﻳﺪ ﺗﻮﺳﻂ ﺷﻴﺮﻫﺎي ﻓﺸﺎر ﺷﻜﻦ ﻣﺤﺎﻓﻈﺖ

. ﻣﺮاﺟﻌﻪ ﻛﻨﻴﺪIPS-G-ME-250 ﺑﻪ اﺳﺘﺎﻧﺪارد.ﮔﺮدﻧﺪ

4.3.2.10 The pressure rating of the suction

piping, valves and suction pulsation dampeners

of a reciprocating compressor shall have the

same rating as the discharge of that stage.

ﺷﻴﺮﻫﺎ و ﺗﻀﻌﻴﻒ، ﻓﺸﺎر ﻧﺎﻣﻲ ﻟﻮﻟﻪ ﻛﺸﻲ ﻣﻜﺶ10-2-3-4

ﻛﻨﻨﺪهﻫﺎي ﻧﻮﺳﺎن در ﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ ﺑﺎﻳﺪ ﻓﺸﺎر

.ﻧﺎﻣﻲ ﻣﻌﺎدل ﺑﺎ ﺧﺮوﺟﻲ آن ﻣﺮﺣﻠﻪ داﺷﺘﻪ ﺑﺎﺷﻨﺪ

18

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد ﻛﻤﭙﺮﺳﻮرﻫﺎي رﻓﺖ و ﺑﺮﮔﺸﺘﻲ ﻣﻮرد11-2-3-4

4.3.2.11 Onshore reciprocating compressors and

integral piping should be supported on a

common slab to avoid differences in settlement

between the compressor body and the connected

piping.

اﺳﺘﻔﺎده در ﺧﺸﻜﻲ و ﻟﻮﻟﻪﻛﺸﻲﻫﺎي ﻣﺘﺼﻞ ﺑﻪ آﻧﻬﺎ داراي ﺻﻔﺤﻪ

ﺗﻜﻴﻪﮔﺎﻫﻲ ﻣﺸﺘﺮﻛﻲ ﺑﺎﺷﻨﺪ ﺗﺎ از ﺑﺮوز اﺧﺘﻼف ﺳﻄﺢ ﺑﻴﻦ ﺑﺪﻧﻪ ﻛﻤﭙﺮﺳﻮر

.و ﻟﻮﻟﻪﻛﺸﻲ ﻣﺘﺼﻞ ﺑﻪ آن در ﺻﻮرت ﻧﺸﺴﺖ ﺗﻜﻴﻪ ﮔﺎه ﺟﻠﻮﮔﻴﺮي ﺷﻮد

در دوره ﭘﻴﺶ راهاﻧﺪازي و ﺷﺮوع ﺑﻜﺎر ﻛﻤﭙﺮﺳﻮرﻫﺎي12-2-3-4

4.3.2.12 For the pre-commissioning and start-up

period, temporary start-up strainers for

reciprocating compressors shall be provided

with maximum screen of 75 micron particles

(200 mesh SWG 47 with an open area of

approximately 34%).

4.3.3

IPS-E-PM-385(2)

رﻓﺖ و ﺑﺮﮔﺸﺘﻲ ﺑﺎﻳﺪ از ﺻﺎﻓﻲﻫﺎي ﻣﻮﻗﺖ راه اﻧﺪازي ﺑﺎ ﻗﺎﺑﻠﻴﺖ

200 )ﺗﻮري. ﻣﻴﻜﺮون اﺳﺘﻔﺎده ﻧﻤﻮد75 ﻏﺮﺑﺎﻟﮕﺮي ذرات ﺣﺪاﻛﺜﺮ ﺗﺎ

.(%34 و ﺳﻄﺢ ﺑﺎز ﺣﺪود47 SWG ﺑﺎ

ﻛﻤﭙﺮﺳﻮرﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ3-3-4

Centrifugal compressors

4.3.3.1 For piping requirements on centrifugal

compressor see IPS-M-PM-170.

در ﻣﻮرد اﻟﺰاﻣﺎت ﻟﻮﻟﻪﻛﺸﻲ در ﻛﻤﭙﺮﺳﻮرﻫﺎي ﮔﺮﻳﺰ از1-3-3-4

4.3.3.2 Straight length Requirements of tables 1

and 2 shall be considered in centrifugal

compressor inlet and outlet piping design.

ﺑﺎﻳﺪ در ﻃﺮاﺣﻲ2 و1 ﻃﻮل ﻣﺴﺘﻘﻴﻢ ﻻزم در ﺟﺪاول2-3-3-4

. ﻣﺮاﺟﻌﻪ ﺷﻮدIPS-M-PM-170 ﻣﺮﻛﺰ ﺑﻪ اﺳﺘﺎﻧﺪارد

ﻟﻮﻟﻪﻛﺸﻲ ورودي و ﺧﺮوﺟﻲ ﺑﻪ ﻛﻤﭙﺮﺳﻮر ﮔﺮﻳﺰ از ﻣﺮﻛﺰ ﻣﺪ ﻧﻈﺮ

.ﮔﺮﻓﺘﻪ ﺷﻮد

:ﻳﺎدآوري

Note:

ASME PTC-10 ﺑﺮاي اﻃﻼﻋﺎت ﺑﻴﺸﺘﺮ در اﻳﻦ ﺧﺼﻮص ﺑﻪ

For further information on this subject see

ASME PTC-10, section 4.3.

. ﻣﺮاﺟﻌﻪ ﺷﻮد4.3 ﻗﺴﻤﺖ

TABLE 2- MINIMUM STRAIGHT LENGTH REQUIREMENTS AT CENTRIFUGAL

COMPRESSORS INLET LINE. "D" STANDS FOR PIPE DIAMETER.

.“ ﻧﻤﺎﻳﺎﻧﮕﺮ ﻗﻄﺮ ﻟﻮﻟﻪ ﻣﻲﺑﺎﺷﺪD” . ﺣﺪاﻗﻞ ﻃﻮل ﻣﺴﺘﻘﻴﻢ ﻻزم در ﺧﻂ ورودي ﻛﻤﭙﺮﺳﻮر ﮔﺮﻳﺰ از ﻣﺮﻛﺰ-2 ﺟﺪول

Inlet Opening Preceded By:

Minimum Straight Length Before Inlet

ﺗﺠﻬﻴﺰ ﻗﺮار ﮔﺮﻓﺘﻪ ﭘﻴﺶ از دﻫﺎﻧﻪ ورودي

ﺣﺪاﻗﻞ ﻃﻮل ﻣﺴﺘﻘﻴﻢ ﭘﻴﺶ از ورودي

straight pipe

3D

ﻟﻮﻟﻪ ﻣﺴﺘﻘﻴﻢ

Elbow

3D

زاﻧﻮﻳﻲ

Reducer

5D

ﻛﺎﻫﻨﺪه

10 D

Valve

ﺷﻴﺮ

Flow Device

5D

ادوات ﺟﺮﻳﺎﻧﻲ

19

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

IPS-E-PM-385(2)

TABLE 3- MINIMUM STRAIGHT LENGTH REQUIREMENTS AT CENTRIFUGAL

COMPRESSORS OUTLET LINE. "D" STANDS FOR PIPE DIAMETER.

.“ ﻧﻤﺎﻳﺎﻧﮕﺮ ﻗﻄﺮ ﻟﻮﻟﻪ ﻣﻲﺑﺎﺷﺪD” . ﺣﺪاﻗﻞ ﻃﻮل ﻣﺴﺘﻘﻴﻢ ﻻزم در ﺧﻂ ﺧﺮوﺟﻲ ﻛﻤﭙﺮﺳﻮر ﮔﺮﻳﺰ از ﻣﺮﻛﺰ-3 ﺟﺪول

Outlet Opening Followed By:

Minimum Straight Length After Outlet

ﺗﺠﻬﻴﺰ ﻗﺮار ﮔﺮﻓﺘﻪ ﭘﺲ از دﻫﺎﻧﻪ ﺧﺮوﺟﻲ

ﺣﺪاﻗﻞ ﻃﻮل ﻣﺴﺘﻘﻴﻢ ﭘﺲ از ﺧﺮوﺟﻲ

straight pipe

3D

ﻟﻮﻟﻪ ﻣﺴﺘﻘﻴﻢ

Elbow

3D

زاﻧﻮﻳﻲ

Reducer

5D

ﻛﺎﻫﻨﺪه

Valve

5D

ﺷﻴﺮ

Flow Device

10 D

ادوات ﺟﺮﻳﺎﻧﻲ

4.3.3.3 Volume of gas entrapped between suction

and discharge block valves of centrifugal

compressors shall be as less as practical to prevent

system surge at shut-down condition. This may be

reached by reducing the piping length between

suction and discharge block valves.

ﺑﻪ ﻣﻨﻈﻮر ﺟﻠﻮﮔﻴﺮي از اﻓﺰاﻳﺶ ﺳﺮﻳﻊ ﻓﺸﺎر ﺳﺎﻣﺎﻧﻪ در3-3-3-4

ﺷﺮاﻳﻂ ﺗﻮﻗﻒ ﻋﻤﻠﻴﺎت ﺑﺎﻳﺪ ﺣﺠﻢ ﮔﺎز ﺣﺒﺲ ﺷﺪه ﺑﻴﻦ ﺷﻴﺮﻫﺎي

ﻣﺴﺪودﻛﻨﻨﺪه ﻣﻜﺶ و ﺧﺮوﺟﻲ در ﻛﻤﭙﺮﺳﻮر ﮔﺮﻳﺰ از ﻣﺮﻛﺰ در ﺣـﺪاﻗـﻞ

ﺑﺪﻳﻦ ﻣﻨﻈﻮر ﻣﻲﺗﻮان ﻃــﻮل ﻟﻮﻟﻪﻛﺸﻲ ﺑﻴﻦ.ﻣﻤﻜﻦ ﻧﮕﻬﺪاﺷﺘﻪ ﺷﻮد

.ﺷﻴﺮﻫﺎي ﻣﺴﺪود ﻛﻨﻨﺪه ﻣﻜﺶ و ﺧﺮوﺟﻲ را ﻛﻢ ﻛﺮد

4.3.3.4 For the pre-commissioning and start-up

period, temporary start-up strainers for

centrifugal compressors shall be provided with a

40 mesh, SWG 32 to 60.

در دوره ﭘﻴﺶ راهاﻧﺪازي و ﺷﺮوع ﺑﻪ ﻛﺎر ﺑﺎﻳﺪ از4-3-3-4

ﺻﺎﻓﻲﻫﺎي ﻣﻮﻗﺖ ﺑﺮاي ﻛﻤﭙﺮﺳﻮرﻫﺎي ﮔﺮﻳﺰ از ﻣﺮﻛﺰ اﺳﺘﻔﺎده ﻧﻤﻮد

. ﺑﺎﺷﻨﺪ60 ﺗﺎ32 SWG ﺑﺎ40 ﻛﻪ داراي ﺗﻮري

ﺗﻮرﺑﻴﻦﻫﺎي ﺑﺨﺎر4-4

4.4 Steam Turbines

4.4.1 If the exhaust side of a turbine cannot

withstand the supply steam pressure, a relief

valve of adequate capacity shall be installed

directly downstream of the turbine.

در ﺻﻮرﺗﻲ ﻛﻪ ﺧﺮوﺟﻲ ﺗﻮرﺑﻴﻦ ﺗﺤﻤﻞ ﻓﺸﺎر ﺑﺨﺎر را1-4-4

ﻧﺪاﺷﺘﻪ ﺑﺎﺷﺪ ﺑﺎﻳﺪ از ﺷﻴﺮ اﻃﻤﻴﻨﺎﻧﻲ ﺑﺎ ﻇﺮﻓﻴﺖ ﻣﻨﺎﺳﺐ و ﺑﻼﻓﺎﺻﻠﻪ

.ﭘﺲ از ﺗﻮرﺑﻴﻦ اﺳﺘﻔﺎده ﻛﺮد

4.4.2 Warming-up provisions for the turbine

inlet piping and the turbine shall be made. This

is less important for the impulse-type turbine,

but stringent for the reaction-type turbine.

ﭘﻴﺶ ﺑﻴﻨﻲﻫﺎي ﻻزم ﺑﻪ ﻣﻨﻈﻮر ﮔﺮم ﻛﺮدن ﺗﻮرﺑﻴﻦ و2-4-4

4.4.3 The set pressure of the relief valve shall

exceed neither the turbine design pressure nor

that of the exhaust piping.

ﻣﻴﺰان ﻓﺸﺎر ﺗﻨﻈﻴﻢ ﺷﺪه ﺷﻴﺮ اﻃﻤﻴﻨﺎن ﻧﺒﺎﻳﺪ از ﻓﺸﺎر3-4-4

The calculation for the relief valve orifice shall

be based on the turbine inlet nozzle.

ﻣﺤﺎﺳﺒﺎت ﺷﻴﺮ اﻃﻤﻴﻨﺎن اورﻳﻔﻴﺲ ﺑﺎﻳﺪ ﺑﺮاﺳﺎس ﻧﺎزل ورودي

.ﺗﻮرﺑﻴﻦ ﺑﺎﺷﺪ

4.4.4 A suitable strainer shall be installed in the

steam inlet line close to the turbine, if not

supplied with the turbine.

در ﻣﻮاردي ﻛﻪ ﺻﺎﻓﻲ ﺑﻬﻤﺮاه ﺗﻮرﺑﻴﻦ ﺗﻬﻴﻪ ﻧﺸﻮد ﺑﺎﻳﺪ از4-4-4

اﻳﻦ اﻣﺮ در ﺗﻮرﺑﻴﻦ ﻧﻮع.ﻟﻮﻟﻪﻛﺸﻲ ورودي آن ﺑﺎﻳﺪ اﻧﺠﺎم ﺷﻮد

.واﻛﻨﺸﻲ ﺑﺴﻴﺎر ﻣﻬﻢﺗﺮ از ﺗﻮرﺑﻴﻦ ﻧﻮع ﺿﺮﺑﻪاي اﺳﺖ

.ﻃﺮاﺣﻲ ﺗﻮرﺑﻴﻦ و ﻓﺸﺎر ﻃﺮاﺣﻲ ﻟﻮﻟﻪ ﺧﺮوﺟﻲ ﺗﻮرﺑﻴﻦ ﺑﻴﺸﺘﺮ ﺑﺎﺷﺪ

ﻳﻚ ﺻﺎﻓﻲ ﻣﻨﺎﺳﺐ در ﺧﻂ ورودي ﺑﺨﺎر و ﻧﺰدﻳﻚ ﺑﻪ ﺗﻮرﺑﻴﻦ

.اﺳﺘﻔﺎده ﻧﻤﻮد

4.4.5 Piping shall be designed to permit steamblowing up to the inlet and outlet flanges of the

turbine before start-up.

ﻃﺮاﺣﻲ ﻟﻮﻟﻪﻛﺸﻲ ﺑﺎﻳﺪ ﺑﻪ ﻧﺤﻮي ﺑﺎﺷﺪ ﻛﻪ ﭘﻴﺶ از راه5-4-4

اﻣﻜﺎن ﻓﺮﺳﺘﺎدن ﺟﺮﻳﺎن ﺑﺨﺎر ﺑﻪ ﻓﻠﻨﺞﻫﺎي ورودي و،اﻧﺪازي

.ﺧﺮوﺟﻲ وﺟﻮد داﺷﺘﻪ ﺑﺎﺷﺪ

20

Aug. 2009/ 1388ﺷﻬﺮﻳﻮر

IPS-E-PM-385(2)

4.4.6 Steam vents shall be routed to a safe

location and shall not be combined with any

lubricating oil, seal oil or process vent.

ﻣﻨﺎﻓﺬ ﺧﺮوﺟﻲ ﺑﺨﺎر ﺑﺎﻳﺪ ﻣﻨﺘﻬﻲ ﺑﻪ ﻣﺤﻠﻬﺎي اﻣﻨﻲ ﺑﺎﺷﺪ و6-4-4

4.4.7 Turbine lube oil and seal oil piping should

over the full length be of austenitic stainless

steel, including valve trim and flange bolting.

See IPS-M-PM-320.

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد ﻟﻮﻟﻪﻛﺸﻲ روﻏﻦ رواﻧﻜﺎري و آب ﺑﻨﺪي و7-4-4

4.4.8 For general and specific requirements

for steam turbines See IPS-M-PM-240 and

IPS-M-PM-250.

ﺑﺮاي ﻛﺴﺐ اﻃﻼﻋﺎت ﺑﻴﺸﺘﺮ در ﺧﺼﻮص اﻟﺰاﻣﺎت ﻋﻤﻮﻣﻲ8-4-4

روﻏﻦ آب ﺑﻨﺪي ﻳﺎ ﻓﺮآﻳﻨﺪ،ﺑﺎ ﻣﻨﺎﻓﺬ ﺧﺮوﺟﻲ روﻏﻦ رواﻧﻜﺎري

.ﺗﺮﻛﻴﺐ ﻧﺸﻮﻧﺪ

ﻗﻄﻌﺎت داﺧﻠﻲ ﺷﻴﺮ و ﭘﻴﭻ ﻫﺎي ﻓﻠﻨﺞ ﺳﺮﺗﺎﺳﺮ از ﺟﻨﺲ ﻓﻮﻻد زﻧﮓ

ﻣﺮاﺟﻌﻪIPS-M-PM-320 ﺑﻪ اﺳﺘﺎﻧﺪارد.ﻧﺰن آﺳﺘﻴﻨﻴﺘﻲ ﺑﺎﺷﺪ

.ﺷﻮد

و

IPS-M-PM-240

ﺑﻪ

و ﺧﺎص ﺗﻮرﺑﻴﻦﻫﺎي ﺑﺨﺎر

. ﻣﺮاﺟﻌﻪ ﺷﻮدIPS-M-PM-250

آزﻣﺎﻳﺶ-5

5. TESTING

5.1 Prior to initial operation, installed piping

shall be pressure tested to assure tightness.

ﭘﻴﺶ از ﺷﺮوع ﻋﻤﻠﻴﺎت، ﺟﻬﺖ ﺣﺼﻮل اﻃﻤﻴﻨﺎن از ﻋﺪم ﻧﺸﺘﻲ1-5

In the event repairs or additions are made

following the test, the affected piping shall be

retested, except that in the case of minor repairs

or additions, the Company may waive retest

requirements, or may request alternate methods

of determining the "soundness" of fabrication.

- ﺗﻌﻤﻴﺮاﺗﻲ ﺻﻮرت ﮔﺮﻓﺖ ﻳﺎ ﺑﺨﺶ، در ﺻﻮرﺗﻲ ﻛﻪ ﭘﺲ از اﻧﺠﺎم آزﻣﻮن

ﻫﺎﻳﻲ ﺑﻪ ﻣﺠﻤﻮﻋﻪ اﺿﺎﻓﻪ ﮔﺮدد ﺑﺨﺶﻫﺎﻳﻲ از ﻟﻮﻟﻪﻛﺸﻲ ﻛﻪ ﺑﻪ آن ﺑﺨﺶ

ﻣﮕﺮ در ﻣﻮاردي ﻛﻪ،ﻣﺮﺑﻮط ﻫﺴﺘﻨﺪ ﺑﺎﻳﺪ ﻣﻮرد آزﻣﻮن ﻣﺠﺪد ﻗﺮار ﮔﻴﺮﻧﺪ

ﺷﺮﻛﺖ ﻣﻲﺗﻮاﻧﺪ اﻧﺠﺎم آزﻣﻮن ﻣﺠﺪد را.ﺗﻌﻤﻴﺮات ﻳﺎ اﺿﺎﻓﺎت ﻧﺎﭼﻴﺰ ﺑﺎﺷﻨﺪ

ﻟﻐﻮ ﻧﻤﺎﻳﺪ و ﻳﺎ روش ﻫﺎي دﻳﮕﺮي را ﺑﺮاي ﺣﺼﻮل اﻃﻤﻴﻨﺎن از درﺳﺘﻲ

.ﻣﺠﻤﻮﻋﻪ درﺧﻮاﺳﺖ ﻧﻤﺎﻳﺪ

5.2 Inspection and testing shall be in accordance

with Chapter VI of "ASME B31.3, Latest Revision,

Process Piping" and IPS-C-PI-350 "Plant piping

System Pressure Testing". Requirements of

individual IPS standards on specific rotating

equipment shall also be followed.

از وﻳﺮاﻳﺶ آﺧﺮVI ﺑﺎزرﺳﻲ و آزﻣﻮنﻫﺎ ﺑﺎﻳﺪ ﻣﻄﺎﺑﻖ ﺑﺎ ﻓﺼﻞ2-5

IPS-C-PI-350 "ﻟﻮﻟﻪﻛﺸﻲ ﻓﺮآﻳﻨﺪي" وASME B31.3 اﺳﺘﺎﻧﺪارد

ﻫﻤﭽﻨﻴﻦ اﻟﺰاﻣﺎت."آزﻣﻮن ﻓﺸﺎر ﺳﺎﻣﺎﻧﻪ ﻟﻮﻟﻪﻛﺸﻲ ﻛﺎرﺧﺎﻧﻪ" اﻧﺠﺎم ﺷﻮد

. روي ﻫﺮ ﺗﺠﻬﻴﺰ دوار ﺧﺎص ﻧﻴﺰ ﺑﺎﻳﺪ ﻣﺪﻧﻈﺮ ﻗﺮار ﮔﻴﺮدIPS اﺳﺘﺎﻧﺪارد

5.3 All piping other than open drain lines,

sewers and air lines less than DN 20 OD shall

be pressure tested.

ﻓﺎﺿﻼب و، ﻛﻠﻴﻪ ﻟﻮﻟﻪﻛﺸﻴﻬﺎ ﻏﻴﺮ از ﺧﻄﻮط ﺗﺨﻠﻴﻪ ﻣﺎﻳﻌﺎت3-5

5.4 All tape shall be removed from flanges at

conclusion of testing.

ﻛﻠﻴﻪ ﻧﻮارﻫﺎي ﭼﺴﺒﻴﺪه ﺷﺪه ﺑﻪ ﻓﻠﻨﺞﻫﺎ ﭘﺲ از ﺑﻪ اﻧﺠﺎم4-5

. ﻟﻮﻟﻪﻛﺸﻲ ﻧﺼﺐ ﺷﺪه ﺑﺎﻳﺪ ﺗﺤﺖ آزﻣﻮن ﻓﺸﺎر ﻗﺮار ﮔﻴﺮد،اوﻟﻴﻪ

ﻣﻲﺑﺎﺷﻨﺪ ﺑﺎﻳﺪ20 ﺧﻄﻮط ﻫﻮا ﻛﻪ ﻛﻮﭼﻜﺘﺮ از ﻗﻄﺮ اﺳﻤﻲ ﺧﺎرﺟﻲ

.ﺗﺤﺖ آزﻣﻮن ﻓﺸﺎر ﻗﺮار ﮔﻴﺮﻧﺪ

.رﺳﻴﺪن آزﻣﺎﻳﺶ ﺑﺎﻳﺪ ﺟﺪا ﺷﻮﻧﺪ

21