Reflective Materials for Safety and Emergency Signage

advertisement

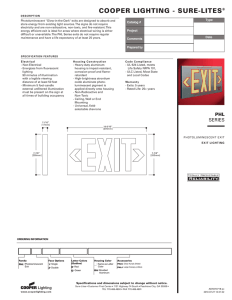

Reflective Materials for Safety and Emergency Signage Safety and emergency signage is crucial in workplaces, public areas, and many other settings to ensure that people are protected from potential hazards. These warnings are typically made of photoluminescent film, a reflective material intended for safety signage, code-compliant building signage, and more. Why Photoluminescent Film? 3M™ Scotch® Reflective Tape Photoluminescent film is typically a glossy, light yellow green color that glows in the dark. Signs in this vibrant hue are recognized as guides to safety or to follow other types of important information. 3M™’s Reflective This multilayered film is dimensionally stable and durable with excellent chemical and stain resistance. It has a pressure sensitive adhesive property that allows it to be attached to various substrates, including metals and building surfaces with a performance life that lasts for multiple years. nighttime brightness Reflective Material Design markers, boats, Images may be printed onto this photoluminescent film using 3M™ Scotchcal™ Screen Printing Inks 1900 and 9800 or thermal transfer methods. These images typically include text, such as “EXIT” and/or symbols depicting which action(s) to take or avoid. and more. The reflective material can be cut into various shapes in order to fit existing applications, or meet any specifications a user may need. Fabrico can offer various cutting services to create these designs, as well as provide the material in bulk or rewound onto smaller rolls. Materials Partner Spotlight Fabrico uses Photoluminescent Film 6900, and 3M™ Scotchcal™ Luminous Tape Rolls to create the best high-performance photoluminescent adhesive backed products. These 3M materials meet and exceed ASTM E207210, IMO A.752, OSHA 1910, 2000 IBC, and DIN-67510 Part 4. These popular materials have been proven to heighten the visibility of safety and emergency signage noticeably to prevent accidents from occurring. Tapes offer maximum for signs, driveway Selecting the Right Converter Quality Control Fabrico offers their design engineering expertise to help customers determine the specific requirements, select the best converting methods, and choose the most useful packaging option for their application. With a fully equipped test lab, Fabrico ensures that customer materials meet designed-in specs before they leave the factory floor, often eliminating the need to test materials on the customer end. Fabrico uses its laboratory to test adhesion, tensile, and dielectric strengths, as well as coat weight, resistance, and more. Fabrico’s test and measurement equipment is calibrated annually per the ISO standard. With the proper combination of those factors, reflective materials offer unlimited design and application possibilities to ensure the safety of individuals in any setting. With Fabrico’s extensive experience and converting capabilities, reflective materials can be slit, die-cut, rewound, stacked, or packaged. Additionally, Fabrico can laminate these materials with narrow or wide width films, and add carefully selected liner materials to provide optimum release characteristics required for the photoluminescent film adhesive backing. Factors to be considered for protective tape applications: • Visual appearance • Instant bonding and cure time • Conformability • Adherence to dissimilar materials • Design flexibility and assembly efficiency With more than 30 years of materials experience, Fabrico engineers understand the impact a material selection can have on the overall manufacturing process, therefore, material systems are designed to optimize production efficiency and improve overall cost-effectiveness. Headquarters 4175 Royal Drive, Suite 800 • Kennesaw, GA 30144 Phone: 844-FABRICO • Fax: 678-202-2702 Toll Free: 800-351-8273 • E-mail: info@fabrico.com About Fabrico Fabrico is the market leader in design and manufacturing services for flexible materials. Fabrico has developed a track record of solving unique challenges and providing sound customer solutions. The company offers a wide range of custom fabrication services including product engineering, material sourcing, prototyping, converting, laminating, complex printing, custom die-cutting, rotary die-cutting, water jet cutting, laser cutting, assembly, and performance packaging. Fabrico’s Advanced Assembly capabilities apply design-for-manufacturing principles to complex, high-value projects in demanding markets that include electrical/ electronics, medical, military/aerospace, and power generation. More information is available at www.fabrico.com or by calling (800)-351-8273. Fabrico is a trademark of EIS, Inc. www.fabrico.com Fabrico is a trademark of EIS, Inc. 3M is a trademark of 3M Company.