QUALITY ASSURANCE POLICY

advertisement

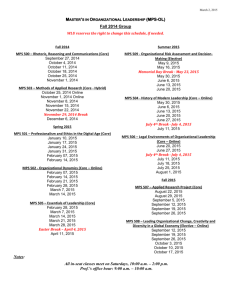

Meggitt Polymer Solutions QUALITY ASSURANCE POLICY MANUAL Meggitt Polymer Solutions UNCONTROLLED WHEN PRINTED 2010 Lafayette Avenue Post Office Box 887 McMinnville, Oregon 97128 USA Tel: (503) 472-0045 Fax: (503) 434-6454 www.meggitt.com 1 TABLE OF CONTENTS 1.0 REVISION RECORD 2.0 INTRODUCTION 3.0 QUALITY MANAGEMENT SYSTEM 4.0 MANAGEMENT RESPONSIBILITY 5.0 RESOURCE MANAGEMENT 6.0 PRODUCT REALIZATION 7.0 CONTROL OF MONITORING AND MEASURING DEVICES 8.0 MEASUREMENT, ANALYSIS AND IMPROVEMENT APPENDIX 1 CROSS REFERENCE CHART TO AS9100 AND PROCEDURE LISTING APPENDIX 2 ORGANIZATIONAL CHART APPENDIX 3 PROCESS FLOW CHARTS 2 1.0 REVISION RECORD REVISION LEVEL / DATE A: 02/08/01 B: 12/10/01 C: 6/17/02 D: 9/24/03 E: 6/7/04 F: 9/8/05 G: 12/14/07 SECTION(S) REVISED 1.1.2, 1.2.1, 1.4 ALL SECTIONS TO MEET AS9100 REV. A ADDED CROSS REFERENCE SHEET FOR AS9100 AT APPENDIX 1 ADDED PROCESS FLOW CHARTS FOR AS9100 REQUIREMENTS AT APPENDIX 3. ADDED NQA-1 REFERENCE TO 3.2 AND APPENDIX 1 REVISED SECTION TO 3.2 TO REFERENCE AS9100 REV.B REVISED SECTION 6.9 FOR CONTROL OF PRODUCTION EQUIPMENT TO INCLUDE NEW TOOL INSP PROGRAM UPDATED APPROVALS PAGE; REVISED SECTIONS 3.5, 4.2, 4.3, 4.7, 4.8, 6.7, 6.8, 6.10, 7.0, 8.1, 8.5, 8.6, 8.7, 8.8, 8.9, APP.2 3 QUALITY POLICY MANUAL APPROVALS __________________________ AL CALABRIA, PRESIDENT _____________ __________________________ JEFF BRYSON, QUALITY MANAGER 4 2.0 INTRODUCTION Meggitt Polymer Solutions (MPS), incorporated in 1981, manufactures silicone and rubber products in the form of calendared sheeting, extruded profiles and both simple and complex molded parts. Our highly trained and experienced staff of engineers and technicians provides development, testing and manufacturing of products for aerospace, government and the commercial sectors. The quality system requirements specified in this document are complementary (not alternative) to contractual and applicable regulatory requirements. 3.0 QUALITY MANAGEMENT SYSTEM 3.1 Purpose and Scope The purpose of this manual is to: • Specify quality management system requirements for use where the capacity to provide conforming product needs to be demonstrated; • Provide an overall knowledge and understanding of the processes employed by Meggitt Polymer Solutions, to assure customer satisfaction; • Describe, document and define the basic parameters required for Meggitt Polymer Solutions quality operations; • Establish a source of general policies, philosophy, procedures, responsibilities and authorities; • Document our commitment to quality and continuous improvement to our suppliers, customers, associates and employees. The scope of our quality system is the manufacture and delivery of silicone and rubber products. Meggitt Polymer Solutions provides products to customer designed drawings and specifications and therefore takes exception to the requirements under section 7.3. Meggitt Polymer Solutions does not provide service on our finished production items and therefore takes exception to the service provision requirements under 7.5.1, 7.5.1.5 and 7.5.2. 3.2 Quality System Structure This quality manual defines the quality policy with references to detailed quality procedures, outlined in MPS Quality Procedures, to comply with the following standards and requirements: SAE Aerospace Standard AS9100 ISO 9001-2000 Federal Aviation Regulation Part 21 Boeing D6-82479 & Addendum 1 NQA-1 5 A reference list indicated in Appendix 1 to this manual, shows the relationship between the requirements of the ISO9001 & AS9100 standard and the corresponding MPS Quality Procedures. The MPS company organizational chart is located in Appendix 2. Flow charts showing the interdepartmental relationships and process flow for key company processes are located in appendix 3. 3.3 Control of Documents General Documented procedures have been established and maintained for the control of all documents that relate to the requirements of this quality manual. Standards, manuals, procedures, etc. that relate to the quality system, as well as documents that define product, such as drawings and specifications, are controlled to ensure that employees always use the correct revision of any given document. NOTE: Controlled documents may be electronic or hard copy and may be of external or internal origin. Document approval and issue Documents are reviewed for adequacy and approved by appropriate personnel prior to issue or initial release. MPS maintains a master list that identifies current revisions for all controlled documents. This list is maintained to preclude the use of invalid or obsolete documents. “Satellite” document/drawing files are also maintained at the same revision as the master list. Further controls ensure that: • Appropriate documentation is available at points of use; • Invalid or obsolete documentation is not used; • Obsolete documentation is discarded or suitably identified. MPS maintains accountability for all drawings, specifications and digital media, and ensures that all drawings, process specifications, product specifications and other controlled media are maintained at the same revision as customers’ media. Where customer-supplied digital datasets that affect the quality of product are concerned, MPS maintains all appropriate controls of such master datasets, including documents and/or datasets issued to suppliers, and maintains a master list that establishes current revisions. Customer-supplied digital data used for production and/or inspection is controlled in accordance with customer requirements. Documentation changes Documentation changes are reviewed and approved by the same personnel, organization or functions that reviewed and approved the originals, unless specifically designated otherwise. Designated personnel, organization or functions have access to all pertinent information for the review and approval process. 6 MPS assesses the impact of documentation, process specification and/or digital media revisions, as necessary, prior to issue. Changes are summarized or suitably identified within the document or attachments when practical. Documentation change incorporation When specified, the implementation of changes, including revised drawings, process specifications and digital data, occurs within the time limits defined by the customer. Proposed changes to a customer’s design media, such as specification control drawings, design standards and digital media are implemented only after the customer-authorized documentation changes have been released. Documentation change activities affecting a customer are coordinated with that customer or regulatory agency. Effectivity points for incorporation and/or implementation are determined and mutually agreed upon with the customer. 3.4 Control of Records Records are maintained to demonstrate conformance to requirements and the effective operation of the quality system. MPS maintains documented procedures that detail the identification, storage, protection, retrieval and disposition of records, including pertinent records from suppliers. All records are legible and are retained in such a way that they are readily retrievable in an area that provide a suitable environment to prevent damage, deterioration and loss. They are maintained for a minimum of seven years or as contractually specified. Retention times are given in the MPS record procedure. Where agreed contractually, the customer or the customer’s representative makes records available for evaluation for an agreed period. Records are available for review by regulatory authorities, as required. All records are reviewed for completeness, accuracy and legibility and are stored in such a manner as to maintain their identification to the corresponding product. Records may be electronic or hard copy. Methods that prohibit tampering with or loss are defined for records that are maintained in forms other than hard copy (e.g., electronic media and microfiche). Changes and/or corrections to records are initialed and dated. Correction materials (such as “white-out,” “liquid paper,” “cover-up tape,” etc.) are not used. 3.5 Configuration Management MPS has established, documented and currently maintains a configuration management system appropriate to the product being supplied and which conforms to the customer’s requirements. The configuration is managed and controlled through either a document number with a revision letter, or by our internal “E” No, which, corresponds to the customer part number or internal MPS part number. The E No. dictates specific requirements for the configuration of each part produced. 7 4.0 MANAGEMENT RESPONSIBILITY 4.1 Management Commitment The senior management team of Meggitt Polymer Solutions is dedicated to creating a business focused on providing products that meet or exceed our customers’ requirements and expectations, thereby enhancing customer satisfaction. To do this, it is the senior management team’s responsibility to: • Communicate to employees the importance of meeting customer and regulatory requirements; • Establish the quality policy to direct efforts for continually improving MPS’s products and processes; • Create an organization that understands and implements this policy at all levels; • Develop and communicate specific quality objectives that are consistent with the quality policy and are measurable and ensure that they are understood by MPS employees and met; • Review the quality policy and quality objectives for continued suitability; • Review the quality system through scheduled management review meetings; • Enhance customer satisfaction through proactive and preventative measures. • Ensure resources are available to meet the needs of the quality system. 4.2 Customer Focus MPS’s senior management team is committed to ensuring that all customer requirements are met with the goal of improving customer satisfaction. Customer-supplied metrics are reviewed regularly, when available, to track performance. 4.3 Quality Policy and Mission Statement We are committed to becoming the pre-eminent polymer solutions provider through the review and continuous improvement of all of our processes, especially those related to quality. We define quality as conformance to customer requirements and measure our success by being the supplier of choice. We will obtain accurate and precise voice-of-the-customer information to fully define and document their requirements and expectations. Our distinct competencies are engineered design solutions, a diverse and wide product offering, and delivering our quality commitment. This requires the leadership team and all coworkers to drive for the following: • • • • • A process-oriented, results driven culture; A robust metrics process that identifies root causes of process inefficiencies; Setting challenging and achievable goals based on Meggitt targets and relevant external benchmarks for world-class performance; Establishing and communicating quality policies and procedures to comply with the requirements; Creating an organization that understands and implements these policies and procedures at all levels. 8 4.4 Planning MPS’s senior management team has planned the quality system to ensure that it meets customer and regulatory requirements and the company’s quality objectives. The management team also reviews changes to the quality system to ensure that the integrity of the system is not compromised by a change. When contractually required, MPS customers are notified of changes within the Quality Assurance Policy Manual or quality system. 4.5 Responsibility and Authority The senior management team ensures that all employees are aware of their responsibilities with regard to the quality system and that they know where their authority begins and ends. All employees have the authority and freedom to ensure product quality is not compromised for cost or schedule demands. Employees also have the authority to identify problems within a process or product to prevent further processing of nonconforming product. 4.6 Management Representative The Quality Manager, appointed to the position of management representative by the president of MPS, has been given the responsibility and authority to: • Ensure the MPS quality system is implemented and maintained in accordance with the company quality procedures; • Report on the performance of the quality system to the senior management team for review and improvements; • Promote the awareness of customer requirements and/or issues; • Resolve matters pertaining to quality; • Monitor and coordinate continual improvement activities; • Act as a liaison with external parties on matters relating to quality. When contractually specified, customers are notified of any changes in the management representative position. 4.7 Internal Communication MPS’s senior management team ensures that communication processes between departments are established. The team also ensures that the effectiveness of the quality system is adequately communicated through management review meetings, monthly management reports and internal audit results. Regular, scheduled staff and department meetings are conducted to communicate detailed information to enhance company performance. 4.8 Management Review The senior management team conducts reviews of the quality system to ensure the system is adequate and effective in meeting the stated company policy and objectives. A complete review is done annually, however meetings may occur more frequently. The management review meetings include the following discussion items: 9 • • • • • • • • Review of the company’s quality policy and objectives; Review of results from internal and external audits; Discussion of customer issues/feedback – positive and negative; Review of quality performance from monthly quality reports, including trends and changes; Review of the status of corrective and preventive actions from audits and discrepancy reports; Review of follow-up actions from previous management review meetings; Discussion of changes that could affect the quality system; Discussion for improvement recommendations. The Management Review form is used to record decisions and actions resulting from the management review meeting related to: • Quality system improvements; • Resource needs; • Product and process improvements related to customer requirements 5.0 RESOURCE MANAGEMENT 5.1 Provision of Resources The Meggitt Polymer Solutions management team is responsible for identifying resource requirements and providing adequate resources, including the assignment of trained personnel for management, performance of work and verification activities including internal audits and contractually agreed requirements of customers’ advanced quality systems activities. The team is also responsible for assigning appropriate resources for activities related to investigating, identifying and correcting the causes of product defects and process deficiencies and effecting appropriate corrective and preventive action. Resource requirements will be evaluated and implemented based on customer orders, management reviews and internal audit results. 5.2 Human Resources and Training MPS’s management team maintains documented procedures for identifying training needs and for providing for the training of all personnel performing activities affecting quality. Personnel performing specific assigned tasks are qualified on the basis of appropriate education, training and/or experience, as required. Records showing that employees are qualified to do these specific tasks are maintained. Training to achieve and maintain awareness and understanding of relevant procedures and instructions is also provided. Training needs are identified by means of customer order reviews, management reviews, corrective and preventive action reports, performance appraisals, employee requests and/or internal or external audit results. 10 Training curricula are developed and maintained that describe required training for all personnel performing activities affecting quality. The following categories, as a minimum, are addressed as needed: • General (e.g. information about paperwork, parts, equipment) • Special techniques or capabilities; • Quality assurance standards (e.g., basic inspection techniques); • Contractually agreed requirements of customers’ advanced quality systems. The training program includes, as needed, special topics such as: familiarization with parts, components, equipment, systems, CAD and inspection and measuring equipment. Personnel are trained, as needed, in techniques and methods for purchasing, processing, fabrication, inspection, auditing, statistical process control, acceptance sampling, handling and packaging. The MPS training system provides a training matrix and guidelines that have been developed, implemented and updated as necessary. Training is provided internally or externally by any appropriate credible source. 5.3 Infrastructure MPS’s management team and the management team at Meggitt PLC ensure that MPS and its personnel have adequate buildings, work space, process equipment and the necessary support services to supply the customer with the required product in accordance with the customer’s contract. 5.4 Work Environment MPS provides for an adequate work environment to ensure that product conformity is not compromised. Planning the work environment is accomplished during the management review meetings or special meetings as required to meet the customers’ demands. Work environment issues include temperature and humidity control, lighting and cleanliness. . 6.0 PRODUCT REALIZATION 6.1 Planning for Product Realization Quality plans are developed by MPS to describe the activities necessary to satisfactorily complete the requirements of a product. Quality plans are an integral part of contract review and cost estimating which commence at the earliest phase of contract performance. The primary elements for a quality plan include, as required: • Quality objectives and product requirements to be achieved; • Elements of the processes that realize the objectives; • Specific allocation of resources to support all manufacturing phases of the product; • Detailed suitable inspection, test and verification requirements at appropriate stages and the records to be established; • Method for measuring the output of the quality to the quality objectives; • Any other pertinent information regarding activities required to meet the quality objectives, such as special provisions, drawing/product revision level, product configuration, etc. 11 As appropriate, consideration is given during the earliest possible phases of contract review to the following activities: • Identification and acquisition of any controls, processes, equipment (including inspection and test equipment), fixtures, resources and skills that may be needed to achieve the required quality; • The design, manufacture and use of tooling so that variable measurements can be taken, particularly for key characteristics, when required; • Updating, as necessary, of inspection and testing techniques; • Identification of all measurement requirements; • Identification of suitable verification at appropriate stages in the realization of product; • Clarification of standards of acceptability for all features and requirements, including those which contain a subjective element; • Identification and selection of suppliers capable of meeting quality requirements, including the appropriate flow-down of requirements; • Identification of or evaluation for statistical techniques, statistical process control and the contractually agreed requirements of customers’ advanced quality systems; • Establishment of appropriate process controls and development of control plans where key characteristics have been identified; • Risks associated with new technology and/or short delivery time scales have been evaluated. 6.2 Contract Review MPS maintains documented procedures for contract review. These procedures define the requirements and required activities for the review of contracts and contract amendments. Included in this are the following: • A review to ensure that the customers requirements are met, including delivery and post delivery activities; • Statutory and regulatory requirements; • Requirements necessary for the intended use of the product, but not stated • Any additional requirements deemed necessary by MPS Contracts are reviewed to be sure that requirements can be met and approved prior to acceptance. As a minimum, MPS performs a review of a request for quote, of a contract and of contract amendments. MPS determines requirements for departmental review of a request for quote based on the complexity of the product. Departmental review may include any combination of individuals, departments or organizations within MPS. Before submission of a quote, or acceptance of a contract or contract amendment, MPS reviews the quote, contract or amendment to ensure that: • Requirements are adequately defined and documented; • Verbal orders are understood and documented; • Differences between the contract requirements and those in the quote are resolved; • MPS has the capability to meet the contract requirements; • Risks associated with new technology and/or short delivery time scale has been evaluated. The reviewer documents any quote or contract that is disapproved, including the reason(s) for the disapproval. Amendments to contracts are reviewed and approved prior to acceptance. This includes incorporation or implementation of customer manufacturing requirements that modify engineering definitions. When a contract amendment is approved, MPS ensures that all functions concerned (such as Scheduling, Purchasing, etc.) are notified of the amendment and applicable additional requirements. Records of contract review are maintained. 12 6.3 Customer Communication Channels of communication, negotiations and interfaces with customers regarding contracts, product information, customer feedback and complaints are the responsibility of the MPS Sales Order Processing (SOP) team. The SOP team disperses the information from the customer to the perspective departments / individuals and is responsible for following up with the internal departments and corresponding back to the customer. The SOP team is also responsible for notifying the customer of changes that may affect quality, including changes in ownership, manufacturing location, processes or inspection techniques. 6.4 Purchasing General Documented procedures describing our purchasing processes are maintained. Through these procedures we ensure that products and materials purchased by MPS for manufacturing customers’ meet specified requirements. Responsibility MPS is responsible for the quality of all products, materials and services purchased for use in customers’ products, including products, materials and services from customer-designated sources. Evaluation of suppliers MPS evaluates and selects suppliers based on their ability to meet contract requirements, including any quality system requirements and any specific quality assurance requirements. MPS has the responsibility and authority for evaluating, selecting, approving, and, as necessary, disapproving suppliers who furnish product or processes for use on the customers’ product. This responsibility and authority extends to the quality system of all suppliers approved. When required by contract, suppliers and their subcontractors will be customerapproved and will select only those customer-approved process sources and manufacturer’s authorized distributors as required by the customer. The type and extent of control exercised over our suppliers and their subcontractors is defined in the “Right of entry and requirements flow-down” section following. To the extent these controls are enforced is dependent on the type of product, the impact of the supplier product on the quality of the final product, and, where applicable, on quality audit reports and/or quality records of the previously demonstrated capability and performance. Additional considerations may include such factors as: the degree of customer satisfaction with the final product relevant to the product or performance of the supplier, the review of such factors as product complexity, supplier’s capabilities and demonstrated process controls, our ability to inspect the product upon receipt and the supplier’s ability to provide appropriate evidence of inspection. MPS maintains an approved suppliers list. This list includes all approved suppliers that furnish product or processes required for successfully completing a contract for a customer. Conditionally approved suppliers may also be included on the list for approved suppliers provided the approval conditions are clearly annotated on the list. MPS maintains records that include performance documentation for approved suppliers, conditionally approved suppliers and, as appropriate, disqualified/disapproved suppliers. This performance documentation includes compliance to special customer/contract requirements, as 13 required. MPS maintains records of periodic supplier review and assessment. These records are used to determine the frequency of supplier audits or evaluations, the level of product inspection (contingent on customer inspection requirements), appropriate corrective actions as necessary, and whether to offer future bid opportunities. The MPS Quality Department has the responsibility and authority to take appropriate corrective action when a supplier’s performance, product history and/or unsatisfactory quality system constitute such action. Unacceptable supplier performance is any performance deficiency that adversely affects the operation of MPS or ability to satisfy the customer. Appropriate corrective action may include such actions as: supplier’s written plans of corrective action, providing technical and training assistance, limited or conditional approval, or disapproval. Purchasing data Purchasing documents clearly describe the product ordered, including where applicable: • Positive and precise identification such as type, class and grade; • All relevant technical data including applicable issues of specifications, drawings and process requirements; • Other relevant information, as appropriate, including acceptance criteria, inspection instructions, requirements for approval, qualification, verification or validation of product, procedures, process equipment and personnel; • Other applicable data, such as: design, manufacturing, testing, reliability and customer acceptance requirements; • Identification of the quality system standard to be applied; • Right of entry provisions and requirements flow-down; • Requirements for samples or test specimens (production method, number, storage conditions, etc.) for design approval, process approval, inspection, investigation or auditing; • Requirements relative to the notification of anomalies, changes in definition, changes in type design and the approval of their processing; • Verification arrangements and the method of product release. MPS reviews and approves purchasing documents for accuracy and adequacy of the specified requirements prior to release, including review to assure contracts are released to approved sources, as required. Right of entry and requirements flow-down Purchasing documents contain right of entry provisions and requirements flow-down for our customers, our customers’ representatives, our customers’ agents and regulatory agencies. All suppliers and sub-tier suppliers must allow for right of entry for MPS agents, customers or customers’ agents for product verification, process verification, quality audit or any other quality evaluation necessary to ensure our customer’s satisfaction. MPS may request suppliers to assign appropriate personnel to visit MPS’s facility or a customer’s facility, to assist with activities necessary for effecting corrective and preventive actions resulting from a nonconformity where the root cause is determined to be the primary 14 responsibility of the supplier. MPS flows down quality system requirements to suppliers to the extent necessary to ensure that characteristics that are not verifiable upon receipt are controlled. Unless relieved of the responsibility by the customer, MPS flows down statistical process control requirements and customers’ advanced quality systems requirements when the supplier controls a critical feature or key characteristic. 6.5 Verification of Purchased Product General MPS maintains procedures to verify purchased products. This verification may include: • Obtaining and reviewing objective evidence of the quality of the product from suppliers (e.g., accompanying documentation, certificates of conformity, test reports, statistical records, records of process control); • Inspection and audit at source; • Inspection of products on receipt; • Delegation of verification to the supplier, MPS periodically validates test reports for raw materials to ensure the accuracy of the data from the supplier. For customer-delegated verification authority at MPS, MPS does not further delegate this authority to a supplier without prior written approval from the customer. Purchased product is not released for production use until the product has been verified as conforming to the specified requirements. Product may be released prior to completion of all inspection and testing requirements under the positive recall system in order to meet customer schedule requirements. The finished product is held at final inspection until all tests and inspections have been completed prior to shipping. Verification at the supplier’s premises Verification of product at the supplier’s facility is performed when required. The customer or MPS may define the requirement for such source inspections. Where MPS intends to verify purchased product at the supplier’s premises, the verification arrangements and the method of product release are specified in the purchasing documents. Customer verification of product Where specified in the contract, the customer or the customer’s representative is afforded the right to verify at our facility or at a supplier’s premises that purchased product conforms to specified requirements. Verification by the customer or the customer’s representative does not absolve MPS of the responsibility to provide acceptable product, nor does it preclude subsequent rejection by the customer. Customer verifications are not used as a means of determining effectiveness of process controls, as a means of determining the product’s complete compliance to specifications, as evidence of effective control of quality, or as a means of measuring customer satisfaction. Delegation of verification to suppliers 15 When delegation is used, MPS defines the requirements for delegation and maintains a list of delegations. Purchased product verification authority is only delegated to a supplier that has demonstrated a high level of system and product quality, and, as required, with a written approval from the customer. Objective evidence of a high level of system and product quality performance is maintained for any supplier that has delegated product verification authority. This delegated product verification authority is removed when the supplier’s quality performance deteriorates. Procedures are written and submitted, as required, to customers for review when verification of purchased product is delegated to a supplier. These procedures define the requirements for delegating verification of purchased products to suppliers including the method for monitoring performance and the requirement for removing delegation authority from a supplier when quality performance deteriorates. 6.6 Control of Production MPS identifies and plans the production processes that directly affect quality and ensures that these processes are carried out under controlled conditions. Controlled conditions include: 1) Documented procedures defining the manner of production, where the absence of such procedures could adversely affect quality; 2) Manufacturing plans that contain: • Clear, concise, detailed and complete instructions for work that affects product quality; • Provisions to implement the requirements set forth in the quality plan; • Reference to process specifications and document requirements by specific callout on the plan; • Appropriate inspection points; • Drawing revision level and accurate description of the “as-built” configuration of the product; • Accurate accountability of product entered into the manufacturing process (e.g., parts quantities, split orders, nonconformities); • Evidence of completion, inspection acceptance or disposition; • Statistical process control requirements; • Specific procedures and work instructions to be applied; • Detailed inspection and test requirements; 3) A production planning system that includes lot tracking as well as tracking when a part is initially manufactured and provides a schedule, which includes completion dates for: • Raw materials; • Tool design and fabrication; • Component parts including purchased or fabricated parts; • standards; • Subcontracted operations; • Finishing process operations; • Assembly operations; • First article inspection; • Final inspection; • Customer source inspection, as required; 16 • • • • • • • • • • • • • Shipping operations; In-process delays such as flow-time between operations and scheduled downtime; Use of suitable production equipment and a suitable working environment (e.g., temperature, humidity, lighting and cleanliness); Compliance with reference standards/codes, quality plans and documented procedures; Compliance with applicable government safety and environmental regulations; Compliance with required drawings and specifications Monitoring and control of suitable process parameters and product characteristics and monitoring and control of key characteristics where required by contract; Approval of processes and equipment, as appropriate; Criteria for workmanship, stipulated in the clearest practical manner (e.g., written standards, representative samples or illustrations); Suitable maintenance of equipment to ensure continuing process capability; Evidence that all manufacturing and inspection operations have been completed as planned, or as otherwise documented and authorized; Provision for the prevention, detection, and removal of foreign objects; Control of utilities and supplies such as water, compressed air, electricity and chemical products to the extent they affect product quality. MPS reviews and approves manufacturing plans to ensure incorporation of all quality requirements. 6.7 Production Documentation Production operations are carried out in accordance with approved data. This data contains, as necessary: • Drawings and parts lists, • Production documents (e.g., Detailed Manufacturing Instructions and routers); • Inspection documents; acceptance test plans; • A list of specific or non-specific tools and numerical control (NC) machine programs; • Documents associated with specific tools enabling the tools to be designed, produced, validated, controlled, used and maintained. 6.8 Control of Production Process Changes Engineering and quality personnel are authorized to approve changes to production processes. MPS identifies those changes, which require customer acceptance in accordance with contractual requirements prior to making any change. Changes affecting processes, production equipment, tools and programs are documented. Procedures are available to control their implementation. The results of changes to production processes are assessed to confirm that the desired effect has been achieved without adverse effects to product quality. 6.9 Control of Production Equipment Production equipment, tools and programs are checked prior to use. Validation prior to 17 production use will include verification of the first article produced to the design data/specification. Production tooling will be verified prior to use. Storage requirements, including periodic preservation/condition checks, are established for production equipment and tooling in storage. 6.10 Control of Work Performed Outside MPS’s Facility When planning to carry out work at a location other than its normal facilities, MPS defines the process to control and validate the quality of the work through supplier controls including supplier audits/surveys, performance, purchase order notes and details and receiving inspection. 6.11 Special Processes Where the results of processes cannot be fully verified by subsequent inspection and testing of the product and where, for example, processing deficiencies may become apparent only after the product is in use, the processes are carried out by qualified operators and/or require continuous monitoring and control of process parameters to ensure that the specified requirements are met. Such processes are known as special processes. The requirements for any qualification of process operations, including associated equipment and personnel is specified and records of these qualifications are maintained. Processes that cannot be fully verified by subsequent testing may be controlled through the use of certified operators, statistical process control, quality assurance monitoring and/or other methods acceptable to the customer. Special processes that require pre-qualification by the customer or customer’s agent are qualified prior to processing. When production operations call for special processes, the following requirements apply: • The special processes to be implemented are reviewed and qualified prior to use; • Equipment and personnel and approved prior to implementation of the process • Applicable aspects of special processes, as defined by the process specifications, including special process changes are controlled; • The significant operations and parameters in the process to be controlled during production are defined. • Records of the special processing, including equipment, inspection documents and personnel training are maintained; • Revalidation of the special process is conducted in accordance with the specification or customer requirements. MPS may elect to send the product to an MPS-approved source to complete the special processing if the requirements are beyond the capabilities at MPS. 6.12 Identification and Traceability MPS maintains documented procedures for identifying the product by suitable means from 18 receipt and during all stages of production and delivery, including the product’s inspection and test status. When stamps or passwords are used as product acceptance media, MPS documents controls for the media. MPS also maintains documented procedures for the unique identification of individual product or lots. MPS maintains records that provide traceability to applicable materials. According to the level of traceability required by contract, regulatory, or other established requirement, MPS’s system provides for: • Identification to be maintained throughout the product life; • All the products manufactured from the same batch of raw material or from the same manufacturing batch to be traced, as well as the destination (delivery, scrap) of all products of the same batch; • The identity of an assembly, its components and those of the next higher assembly to be traced; • The sequential record of a given product’s production (manufacture, assembly, inspection) to be retrieved. When identification or traceability of material or product is lost, that product or material is processed as nonconforming product. MPS maintains the identification of the configuration of the product in order to identify any differences between the actual configuration and the agreed configuration. 6.13 Customer Property All product, raw material and tooling received from a customer for use in the customer’s finished product is verified for drawing and specification conformance against the purchase contract, at receiving inspection. Customer property also includes data furnished by the customer for MPS’s use in design, production and inspection. Customer property is subject to the same inspection criteria as vendor received product. Any customer property, which is damaged, deteriorated or lost are promptly reported to the Sales Department in order to notify the customer of the discrepancies; records of the event are maintained. Disposition of nonconforming product occurs by customer authorization only. MPS maintains the customer property in a controlled area, properly identified and controlled to prevent damage or deterioration. 6.14 Preservation of Product General MPS maintains documented procedures for handling, storage, packaging, preservation and delivery of product. When applicable in accordance with product specifications and/or applicable regulations, these procedures include specific requirements for: • Cleaning; • Prevention, detection and removal of foreign objects; • Special handling for sensitive products; • Marking and labeling including safety warnings; • Shelf life control and stock rotation; • Hazardous materials. 19 Where handling, storage, packaging, preservation or delivery is subcontracted, the appropriate requirements for suppliers will apply. Handling Product is handled in a manner that prevents damage and deterioration. When appropriate, methods of handling product include provisions for the detection and removal of foreign objects. This may include the removal of superfluous oils, greases or extraneous packaging materials that inhibit the visibility of the finished product and/or adversely affect the ability to safely handle the product. Storage Storage areas that prevent damage and deterioration of product are designated. Processes for authorized receipt to and issuance from these areas are in effect. Raw materials are identified and traceable to test results, including those for chemical and physical characteristics. Issuance from inventory follows “first-in, first-out” methods. Inventories of customer proprietary product are controlled to prevent product from being sold or otherwise provided to any third party without the customer’s authorization. Inventory controls include a system that precludes deterioration of time- or temperature-sensitive materials and minimizes the impact of design and configuration changes. MPS audits storage areas at least annually. Packaging Packing, packaging and marking processes, including materials used, are controlled to the extent necessary to ensure conformance to specified requirements. Preservation Appropriate methods of preservation and segregation of product are applied. These practices include periodic maintenance, cleaning and minor rework as necessary. Delivery The quality of the product is protected after final inspection and test. As required, this protection is extended to include delivery to destination. Final inspection operations are verified as complete (i.e., completeness of manufacture is verified) on all products prepared for delivery. Shipping documents MPS ensures that the accompanying documents such as completed packing sheets for the product are present at delivery as specified in the contract/order and are protected against loss and deterioration. 7.0 CONTROL OF MONITORING AND MEASURING DEVICES MPS maintains documented procedures to control, calibrate and maintain inspection, 20 measuring and test equipment to demonstrate the conformance of product to the specified requirements. Inspection, measuring and test equipment is used in a manner that ensures that the measurement uncertainty is known and is consistent with the required measurement capability. The accuracy requirements for selection and use of measuring and test equipment are defined. Where comparative references such as test hardware are used as suitable forms of inspection, they are checked to prove that they are capable of verifying the acceptability of product, prior to release for use during production, and are rechecked at prescribed intervals. MPS establishes the extent and frequency of such checks and maintains records as evidence of control. Where the availability of technical data pertaining to the inspection, measuring and test equipment is a specified requirement, such data is made available to the customer or customer’s representative for verification that the inspection, measuring and test equipment is functionally adequate. All inspection, measuring and test equipment or comparative references, including test hardware, automated test equipment, and reference hardware, personally owned or company owned, are subject to the requirements of the calibration system. All such equipment is checked for suitable capabilities prior to release for use and is rechecked at prescribed intervals. Calibrations are conducted upon receipt of the device, independent of the manufacturer’s certification. Calibration of inspection, measuring and test equipment is traceable to the National Institute of Standards and Technology (NIST) or equivalent. Where a nationally or internationally recognized standard does not exist, the basis used for calibration is documented. The extent and frequency of calibration is established, with records maintained as evidence of control. Intervals of calibration may be adjusted through the use of historical data collected for the individual tool or tool types. MPS maintains a list of inspection, measuring and test equipment, including equipment supplied by the customer. The processes employed for the calibration of inspection, measuring and test equipment, including details of equipment type, unique identification, location, frequency of checks, recall method, check method, acceptance criteria and the action to be taken when results are unsatisfactory, are defined. The calibration status of equipment is shown with a suitable indicator or approved identification record. MPS assesses and documents the validity of previous inspection and test results when inspection, measuring or test equipment is found to be out of calibration. When the assessment indicates that the product may be nonconforming, MPS takes appropriate action on the product. MPS ensures that the environmental conditions are suitable for the calibrations, inspections, measurements and tests being carried out and that the handling and storage of equipment is such that its accuracy and fitness for use is maintained. MPS safeguards inspection, measuring and test equipment from adjustments, which would invalidate the calibration setting. 21 Calibrated tooling is exclusively used for the final inspection of the product. All other measuring instruments, which are not used for final inspection or delegated inspection are not required to be calibrated. These instruments may include tools in production and maintenance, unless specifically required by the work instructions. 8.0 MEASUREMENT, ANALYSIS AND IMPROVEMENT 8.1 Customer Satisfaction MPS determines customer satisfaction by customer feedback in the form of customer metrics and customer communication in the form of e-mails, customer visits, and other written and verbal correspondence. The management team reviews this information uses it to determine strategic continual improvement projects. 8.2 Internal Audit MPS maintains documented procedures for planning and implementing internal quality audits to verify whether quality activities and related results comply with planned arrangements and to determine the effectiveness of the quality system. Internal quality audits are scheduled on the basis of the status and importance of the activity to be audited and are carried out by personnel independent of those having direct responsibility for the activity being audited. Audit personnel are familiar with written procedures and standards applicable to the areas being audited and are trained in audit techniques. Audit results are recorded and brought to the attention of the managers of the areas audited who are responsible for taking timely corrective action on findings. As required, corrective action plans are disclosed at the request of the customer. Follow-up audit activities verify the implementation and effectiveness of the corrective action taken; these activities are recorded. Checklists are developed and used as an aid to conducting internal audits. The acceptability of the checklists is measured against the effectiveness of the internal audit process and the overall performance. The results of internal quality audits form an integral part of the input to management review activities. 8.3 Monitoring and Measurement of Processes MPS monitors various manufacturing and non-manufacturing processes to determine whether the processes are achieving planned results. Monitoring of manufacturing processes may include the use of statistical process control, results from in-process and final inspection, pressure testing, and material testing. Monitoring of non-manufacturing processes may include analyses of engineering costs; quote functions, and customer satisfaction as it relates to the effectiveness of the Sales Order Processing Department. If a nonconformity is determined to exist in a process, corrective action is implemented to correct the process. If an evaluation has determined that nonconforming product exists as a result of the process nonconformity, then that product will be identified and controlled as 22 specified in section 8.7. 8.4 Monitoring and Measurement of Product General MPS maintains documented procedures for inspection and testing activities in order to verify that the specified requirements, including key characteristics, for the product have been met. The required inspection and testing and the accompanying records are detailed in the quality plan or documented procedures. These procedures specify the inspection/test methods to be used, including: • Methods of recording inspection/test results; • Identification of authorized personnel; • Limits of authorization; • Training and qualification requirements. As required, the customer, prior to use, approves acceptance sampling plans and procedures. When 100% inspection is conducted, all of the characteristics with design requirements are inspected on every part. Inspection and testing MPS: • Inspects and tests product-in-process in accordance with the product’s manufacturing plan and/or documented procedures and • Holds product until the required inspection and tests have been completed or necessary reports have been received and verified, except when product is released under positive recall procedures. All in-process inspections and tests are made at appropriate times in the manufacturing process and are performed to verify compliance with engineering requirements. Final inspection and testing The primary purpose of final inspection and test is to ensure that all specified receiving and inprocess tests and inspections have been performed and that the results meet the specified requirements. As a minimum, the following are implemented as part of the final inspection system: • A check to ensure that all first article inspection requirements are current; • A review of manufacturing plans to ensure that all quality requirements have been accurately implemented; • A check to ensure that all changes have been incorporated for the units being shipped • A final review of recorded nonconformance’s to ensure that they are all corrected, and / or have customer approval to ship (i.e., advanced rejection tag, open reject notice); • A review of the applicable specifications, special instructions, etc., to ensure that all contractual requirements are complete and accurately implemented; • A visual inspection or test of the product. MPS carries out all final inspection and testing in accordance with the manufacturing plan and/or documented procedures to complete the evidence of conformance of the finished product to the specified requirements. 23 No product is shipped until all activities specified in the manufacturing plan and/or procedures have been satisfactorily completed and the associated data and documentation are available and authorized. Use of customer’s digital datasets as authority for design and/or inspection Use of a customer’s digital data or dataset as authority for design and/or inspection will comply with that customer’s standards or contractual requirements. Digital datasets are used for reference only (no design or inspection authority) unless otherwise approved, authorized or compliant with customer requirements for dataset usage. 8.5 Inspection Documentation Inspection documentation is maintained and controlled by MPS. These documents include the following information: • Criteria for acceptance and rejection; • Where in the sequence inspection and testing operations are performed; • Identification of inspector and date • Record of the inspection results MPS maintains inspection and test records, which provide evidence that the product has been inspected and/or tested. These records show clearly whether the product has passed or failed the inspections and tests according to the defined acceptance criteria and, when required, show actual test result data. These records also identify the inspection authority responsible for the release of product. Where the product fails to pass any inspection and/or test, the procedures for control of nonconforming product apply. When practical, these records will display variable data rather than attribute data. When required by specification or acceptance test plan, test records will show actual test results data. Where required to demonstrate product qualification, MPS ensures that test and inspection records provide evidence that the product meets the defined requirements. 8.6 First Article Inspection MPS’s procedures provide a process, as appropriate, for the inspection, verification and documentation of the first production article. Detailed data showing complete results of the inspections of the first production units manufactured are recorded and maintained (also known as: FAI, first article report or first article inspection reports). First article inspection documentation includes a list of the characteristics required by the design data and any required tolerances, the actual test results, the material and process specifications, special purchase order requirements and drawing revision. The first article inspection records are updated to include production process changes or configuration changes. These record updates will include the delta changes whenever there is a change to the contract, drawing, specification, supplier or manufacturing process that could result in a change to the product configuration. 8.7 Control of Nonconforming Product General 24 MPS maintains documented procedures to ensure that product that does not conform to specified requirements is prevented from unintended use. This control provides for identification, documentation, evaluation, segregation (when practical), and disposition of nonconforming product, and for notification to the functions concerned. The procedures established by MPS also take into account product returned to MPS from a customer, as well as process nonconformities. These procedures define as a minimum: • Action taken to eliminate the detected nonconformity • Controls for use of nonconforming products in finished products; • The formal authority process including the defined scope for all personnel approving the use of alternate materials and/or nonconforming product; • The process for control and disposal of scrapped product, including rendering it unusable. The nonconforming product process provides for timely reporting (within 1 business day) of nonconformities that may affect product already delivered. Notification consists of a clear description of the nonconformance, which includes, as necessary, parts affected, customer and/or MPS part numbers, quantity, date(s) delivered, date codes, and corrective action for the nonconformity. Parties requiring notification of nonconforming product may include: • Internal organizations; • Customers; • Suppliers; • Regulatory agencies. Nonconforming product is not sold, delivered, given or otherwise used by or for any other customer without the customer’s authorization. Review and disposition of nonconforming product MPS’s documented procedures define the personnel approved to conduct material reviews and make nonconforming product disposition decisions. The allowable nonconforming product dispositions are: • Rework to required specifications; • Scrap; • Return to the supplier; • Use-as-is; (accepted by customer approval only). Where required by the contract, the proposed use or rework of product, which does not conform to specified requirements is reported for concession to the customer or customer’s representative. The description of the nonconformity that has been accepted is recorded to denote the actual condition. Rework instructions are sufficiently detailed and include in-process inspection points, as necessary. Reworked products require re-inspection. 8.8 Analysis of Data MPS collects and analyzes performance measures within the Quality and Sales Departments to 25 track and assess our customer’s satisfaction and assist in determining what continual improvement projects should be initiated. The Quality and Sales Departments gather information for these measures from inspection reports and customer data to give an indication of: • Customer satisfaction; • Conformity to product requirements; • Process and product trends that can prompt preventive action; • Supplier performance. Advanced quality system activities, including control plans and control charts, may be used as an improvement activity for CI projects. The senior management staff reviews completed projects and determines actual benefit to use as a reference for future CI projects and activities. 8.9 Continual Improvement The senior management team of MPS ensures that continual quality improvements are implemented in an effort to reduce the variation of key characteristics called out on MPS or customer drawings, to prevent defects, reduce waste, increase profit, and to improve product quality and delivery. Measurement goals are determined for key quality and customer service parameters at management meetings through the review of quality policies and objectives, audit results, preventive actions and from data collected for continual improvement projects. 8.10 Corrective and Preventive Action General MPS maintains documented procedures for implementing corrective and preventive action and makes the appropriate changes to documented procedures resulting from corrective and preventive actions. Corrective action Customer complaints, single significant product or process non-conformances and minor-butrepetitive product or process non-conformances (even those product non-conformances that are dispositioned use-as-is) can cause the initiation of a corrective action. MPS’s corrective action process includes: • Root cause analysis of the problem and recording the results of the analysis; • Determining and implementing the corrective action needed to eliminate this cause; • Recording the results of the corrective action taken, and • Ensuring that the corrective action taken is effective. When timely and/or effective corrective actions are not achieved, the issue is escalated to senior management staff. Corrective action response format Unless otherwise specified by a customer, corrective action responses are documented on the 26 MPS corrective action form and include: • • • • • The immediate correction; The root cause of the problem; The corrective action that addresses the root cause; The corrective action verification plan; The follow-up that was done to check for the effectiveness of the action. Records of the corrective actions are maintained. Preventive action MPS takes into consideration information from four sources for potential preventive action: • • • • Internal audit observations; Customer feedback from day-to-day conversations with Sales rep’s Customer feedback from customer visits; Review of incoming materials for variation MPS’s preventive action process includes: • Determining the cause of the potential problem; • Determining and implementing the action needed; • Recording the results of the preventive action taken; • Ensuring that the preventive action taken is effective. Historical data and problem-solving tools are used to analyze and eliminate potential causes of nonconformities. 27 APPENDIX 1 A - Cross Reference Sheet - AS9100 to MPS Quality Procedures AS9100 / NQA-1 MPS Quality Procedure AS9100 / NQA1 MPS Quality Procedure 4.2.2 No Reference 5.5.2b,c,d 4.2.2a No Reference 5.5.3 No Reference 4.2.2b No Reference 5.6.1 8.1 4.2.2c No Reference 5.6.2 8.2 4.2.3 01QP0026 5.6.3 8.3 4.2.3a “ 6.1a,b 7.1 & 7.2 4.2.3b “ 6.2.1 4.2.3c “ 4.2.3d “ 4.2.3e MPS Quality Procedure AS9100 / NQA-1 MPS Quality Procedure 7.4.1d 2.1.5 8.2.1 7.4.1e / REQ.4 2.2.3 8.2.2a,b 7.4.2a,b,c /REQ.4 2.1.5 8.2.2 / REQ.2 & 18 7.4.2d /REQ.4 2.1.5 8.2.3 7.4.2e,f /REQ.4 2.1.5 8.2.3a,b,c / REQ 7.4.2g,h /REQ.4 2.1.5 8.2.4 /REQ.10 01QP0016 7.4.2i /REQ.4 2.1.5 6.2.2a No Reference 7.4.2j /REQ.4 2.1.5 8.2.4.1a,b,c,d /REQ.14 01QP0006 6.2.2b No Reference 7.4.2 /REQ.4 2.1.6 8.2.4.2 /REQ.10 01QP0005 “ 6.2.2c No Reference 7.4.3 /REQ.4 & 7 01QP0002 8.3 /REQ.15 01QP0017 4.2.3f “ 6.2.2d No Reference 7.4.3a,b,c,d,e /REQ.4 & 7 4.0, 6.0, 8.0 8.4 01QP0009 4.2.3g “ 6.3a,b,c No Reference 7.5.1 / REQ.5 01QP0022 8.4a,b,c,d 4.2.3g “ 6.4 No Reference 7.5.1a,b,c,d,e,f / REQ.5 2.1.3 8.5.1 4.2.3 “ 7.1 01QP0023 sec.2.2 7.5.1g,h /REQ.5 2.1.3 8.5.2 /REQ.16 4.2.4 /REQ.17 9.1 AS9100 / NQA-1 01QP0009 sec. 5.0 & 6.0 01QP0024 2.1 to 2.4 01QP0014 No Reference 01QP0024 2.15 to 2.21 01QP0003 01QP0004 01QP0009 sec. 4.0 & 10 01QP0018 sec. 2.1 to 2.7 & 01QP0014 sec. 2.15 to 2.20 01QP0007 7.1a 2.2.5 7.5.1.1 /REQ.9 01QP0026 5.1a 01QP0009 sec. 4.1 7.1b 2.2.5 7.5.1h / REQ.5 01QP0022 sec. 2.1.3 8.5.2g /REQ.16 5.1b 2.1 7.1c 2.2.5 7.5.1.2 /REQ.9 2.2 8.5.2h /REQ.16 2.7 5.1c 3.1 7.1d 2.2.5 7.5.1i,j,k 2.1.3 & 01QP0019 sec. 2.17 8.5.2a /REQ.16 01QP0018 sec. 2.8 to 2.17 5.1d 8.1 7.1e No Reference 7.5.1.3 / REQ.9 7.5.2 01QP0022 5.1e 4.1 5.2 01QP0009 sec. 5.1 to 6.2 5.3a No Reference 5.3b 01QP0009 sec. 2.1 5.3c 3.1 to 3.3 5.3d 01QP0009 sec. 4.1 5.3e No Reference 01QP0018 2.8 to 2.17 7.6 / REQ.12 01QP0008 sec. 3.2 5.4.1 01QP0023 01QP0009 sec. 6.0 7.6a /REQ.12 3.1, 4.0, 5.3 5.4.1a 01QP0009 sec. 4.1 5.4.1b 4.3 7.4.1a / REQ.4 01QP0024 sec. 2.1.2 5.5.1 4.2 7.4.1b /REQ.4 2.3.1 5.5.2a 9.1 7.4.1c /REQ.4 7.2.1a 7.2.1b,c,d 01QP0023 sec. 2.3.2 No Reference 2.5 7.5.3 /REQ.8 01QP0027 7.5.3a,b,c,d /REQ.8 01QP0027 7.2.2a,b,c,d 2.3.1 7.5.4 01QP0015 7.2.2 2.3.5 7.5.5 /REQ.13 01QP0019 7.2.3a,b,c 01QP0023 sec. 2.4 7.5.5a,b,c,d,e,f /REQ.13 7.6b,c /REQ.12 2.3.3 to 2.3.6 2.1 to 2.5 5.4 7.6d,e /REQ.12 6 7.6f /REQ.12 4 8.1a,b,c 28 No Reference 8.5.2a to f /REQ.16 10.2 8.5.3 8.5.3a,b,c,d,e 2.1 to 2.7 2.18 01QP0018 sec. 2.21 No Reference APPENDIX 1 B QUALITY PROCEDURE MASTER LISTING 01QP0001 QUALITY PROCEDURE INDEX 01QP0002 RECEIVING INSPECTION 01QP0003 FINAL INSPECTION 01QP0005 FIRST ARTICLE INSPECTION 01QP0006 INSPECTION AND TEST STATUS 01QP0007 RECORD CONTROL 01QP0008 CALIBRATION PROCEDURE 01QP0009 MANAGEMENT RESPONSIBILITY 01QP0010 SHIPPING CONTROL 01QP0013 LABORATORY PROCEDURE 01QP0014 INTERNAL AUDITING PROCEDURE 01QP0015 CUSTOMER SUPPLIED MATERIAL PROCEDURE 01QP0016 TRAINING PROCEDURE 01QP0017 NON-CONFORMING MATERIAL AND MRB PROCEDURE 01QP0018 CORRECTIVE ACTION PROCEDURE 01QP0019 HANDLING, STORAGE AND PACKAGING PROCEDURE 29 01QP0020 STATISTICAL SAMPLING PROCEDURE 01QP0021 ADVANCED QUALITY SYSTEM PROCEDURE 01QP0022 PROCESS CONTROL PROCEDURE 01QP0023 CONTRACT REVIEW AND QUALITY PLANNING PROCEDURE 01QP0024 PURCHASE ORDER & SUPPLIER AUDIT PROCEDURE 01QP0026 DRAWING AND DOCUMENT CONTROL PROCEDURE 01QP0027 IDENTIFICATION AND TRACEABILITY PROCEDURE 01QP0028 CUSTOMER RETURN PROCEDURE 01QP0029 DEFECT CODES AND DEFINITIONS 01QP0030 EQUIPMENT CALIBRATION PROCEDURE 01QP0031 CUSTOMER DELEGATED INSPECTION PROCEDURE 01QP0032 MPS DELEGATED OPERATOR PROCEDURE 01QP0033 FAA-DMIR PROCEDURE 01QP0034 SUPPLIER DELEGATED SOURCE INSPECTION PROCEDURE 01QP0035 FOREIGN OBJECT DEBRIS PREVENTION 01QP0036 NDT QUALIFICATION AND CERTIFICATION PROCEDURE 01QP0037 EYE EXAMINATION PROCEDURE FOR NDT PERSONNEL 01QP0038 DIGITAL PRODUCT DEFINITION QUALITY PROCEDURE 01QP0039 EYE EXAMINATION PROCEDURE FOR QUALITY INSPECTORS 01QP0040 CONTINUOUS IMPROVEMENT PROCEDURE 01QP0041 FIRST PART INSPECTION PROCEDURE 30 APPENDIX 2 Key Personnel ORGANIZATION CHART President V.P. Operations Controller Quality Manager V.P. sales and marketing Maintenance Manager Materials Manager Engineering Manager Personnel Manager IT Manager Internal Audit Coordinator Al Calabria Steve Fackler Bill Chomko Jeff Bryson Mike Gardner Ernie Rymer Paul Jongedyk Andy Smith Urmilla Jhattu Ray Hodge Alex Vasquez Board of Directors President Controller Quality Manager Materials Manager Operations Manager Sales Manager Accounting Supervisor Inspectors Purchasing Maintenance Supervisor Sales Order Processing Document Control Payroll QA Laboratory Supervisor Receiving/Stores Maintenance Personnel Call Center Drafting Accounts Receivable Laboratory Personnel Shipping Module Leaders Accounts Payable QA Engineer Manufacturing Cells Receptionist Internal Auditors Tooling Personnel Manager Engineering Manager Manufacturing Engineers 31 IT Manager APPENDIX 3 FLOW CHARTS 32 33 34 35 36