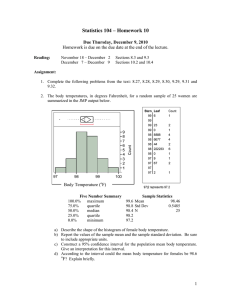

Steady Supplies or Stockpiles? Demand for

advertisement