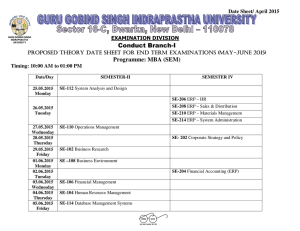

SYLLABUS (For the Academic year 2015 – 2016)

advertisement