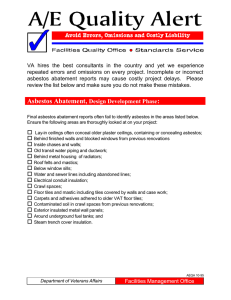

ASBESTOS OPERATIONS and MAINTENANCE PROGRAM

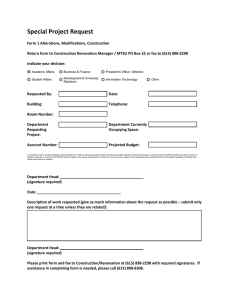

advertisement