Abstract

advertisement

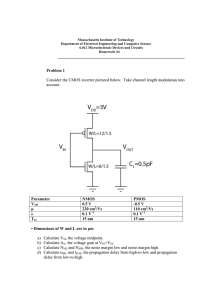

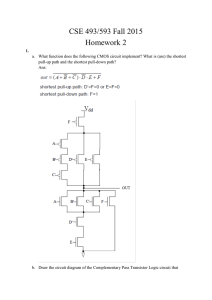

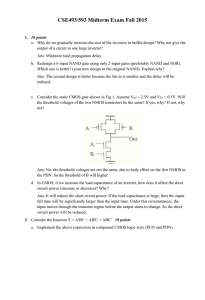

Implant Dose Sensitivity of 0.1µm CMOS Inverter Delay H. C. Srinivasaiah and Navakanta Bhat ECE Department, Indian Institute of Science, Bangalore−560 012, India e−mail:srinivas@protocol.ece.iisc.ernet.in or navakant@ece.iisc.ernet.in Abstract The simulation experiment is performed to characterize the impact of process level fluctuations on the circuit performance variation for the 0.1µm CMOS technology. The 0.1µm NMOS and PMOS transistors are optimized using four different ion implantation steps namely super steep retrograde channel (SSRC) implant, deep s/d implant, shallow s/d extension implant and halo implant. We demonstrate that the fluctuations in the nominal values of these implant doses result in the significant variation in DC (Ioff, Ion, Vt) and AC (Cgg) parameters of the transistors. The DC and AC parameter variations of these devices in turn have their effect on the performance of the inverter circuit. In particular, the halo implant has the maximum impact resulting in ∆Ioff=122% (97.48%) and ∆Ion=4.82% (5.29%) for NMOS (PMOS) transistor. The worst case delay variation is more than ±10% for a ±10% random variation in the implant dose parameters. 1. Introduction With the down scaling of MOSFET dimensions in the Deep Sub−micron (DSM) technology, the device and the circuit parameters are strongly nonlinear function of the process parameters [1]. The fluctuations in the process parameters have impact on the performance of the circuit and on the manufacturing yield. The transistor parameter fluctuations is caused by intrinsic and extrinsic process parameter variations [2, 3, 4]. The intrinsic variation includes random dopant number in the channel, interface state density, etc. and the extrinsic variations includes random variation in gate oxide thickness, channel length, implant dose etc. [2]. In the DSM technology, the increasing difficulty of improving manufacturing tolerance leads to the greater relative variation of the device parameters around the nominal technology point. In order to relate the process level fluctuations, to the circuit level fluctuations (delay fluctuation in the critical path), various statistical techniques are followed with different accuracy and complexity [1]. Here we have used the simplest approach of identifying the worst case corners (±3σ). One can Proceedings of the 15th International Conference on VLSI Design (VLSID’02) 0-7695-1441-3/02 $17.00 © 2002 IEEE relate the circuit delay fluctuation to some of the important SPICE parameter fluctuation using Monte− Carlo circuit simulation as, ∆τ = f1( ∆vt0, ∆γ, ∆Cj, ∆Tox . . .) where "f1" is a function to be determined by experiment, τ=circuit delay, vt0=threshold voltage, γ=body effect factor, Cj=junction capacitance, Tox=oxide thickness and ∆ indicates the fluctuation around the nominal value. However each of these SPICE parameters are controlled by multiple process parameters as, implant energy, anneal vt0 = f2(implant dose, temperature, oxidation temperature. . .), implant energy, anneal γ = f3(implant dose, temperature, oxidation temperature. . .) and Cj = f4(implant dose, implant energy, anneal temperature, oxidation temperature. . .) where "f2, f3 and f4 " are functions to be determined by experiment. In other words it becomes impossible to relate circuit level fluctuations to the underlying processes. In [5] an approximate functional relationship between process level to device level parameters has been established for 0.18µm technology, by the technique of statistical design of experiment. There are no generalized techniques to relate process level to circuit level fluctuations, applicable to all technology nodes, because of the strong nonlinearity that exists between process and circuit parameters in DSM regime [1]. This relationship becomes necessary in DSM regime to guide process engineering with respect to process control. We propose to perform mixed mode simulations which bring the process simulated devices directly into the netlist of a circuit wherein both circuit and device equations are solved simultaneously. This technique bypasses parameter extraction for the process simulated device. It is the mixed mode simulation technique that we have followed to characterize the delay parameter of an inverter chain. One can develop a functional relationship between circuit and process parameter by an appropriate choice of the design of experiment. For example: delay fluctuation, ∆τ can be related to the process as, ∆τ = f(∆implant dose, ∆implant energy, ∆anneal temperature, ∆oxidation temperature. . .) where "f" is a function to be determined by experiment. We have designed and optimized a "nominal" 0.1µm gate length NMOS and PMOS transistors using disposable spacer technique. The transistor performance variations are characterized as a function of the variations of the different implant doses around the nominal value. The two stage inverter circuits corresponding to nominal (C0), worst (C1) and best (C2) case process corners of the NMOS and PMOS transistors are simulated in mixed mode to assess the impact on circuit delay. Table 1: The process sequence for the nominal NMOS and PMOS device, D0 with important process parameter values. (Quantities in brackets are for PMOS device). 2. Transistors Design Methodology In realizing our devices, we have used standard TCAD tool from ISE (Integrated System Engineering) which has the process simulator DIOS−ISE and device simulator DESSIS−ISE. In simulating the I−V characteristics of the transistors, Hydrodynamic model has been used to account for the velocity overshoot, Vandort’s model has been used to account for carrier quantization in the channel [6]. The short channel effects in our 0.1µm transistor are suppressed with pocket halos, super steep retrograde channel and shallow source drain (s/d) extension. The process steps and the important parameter values for our nominal device are listed in Table 1, with the four implant steps being highlighted. Both NMOS and PMOS devices are optimized for Ioff=1.0 nA/µm and Ion for NMOS is 0.954mA/µm and that for PMOS is 0.397mA/µm in the saturation region (Vd=1.5V). Process simulated two dimensional cross sections for both NMOS and PMOS are shown in Figure 1. 3. Design of Experiment The four highlighted parameters in the Table 1 are varied ±10% from that of NMOS and PMOS nominal devices (D0). This results in total of 8 devices (D1−D8). Further we have included two more devices (D9 and D10) for both NMOS and PMOS, for the worst case current fluctuations corresponding to simultaneous variations in all the implant steps. The device label definitions are given in Table 2. Devices D1−D10 are process simulated for both NMOS and PMOS devices by DIOS−ISE. For all these devices DC and AC characteristics are extracted by DESSIS−ISE. The relative deviation of any parameter x, about its nominal value xnom is calculated as ∆x=(x− xnom)/xnom. Proceedings of the 15th International Conference on VLSI Design (VLSID’02) 0-7695-1441-3/02 $17.00 © 2002 IEEE Process Steps and Parameter values 1. In(Sb) SSRC: 5.7×1012 cm−2 /180 keV (5.7×1012 cm−2 /200 keV) 2. 20 Å Gate oxide @ 800o C. 3. 4. 0.1µm Gate Poly thickness. 2 nm Poly−reoxidation @ 800o C. 5. 96 nm Disposable Nitride spacer. 6. As(B) s/d: 6×1015 cm−2 /30 keV (1×1015 cm−2 / 5 keV) RTA: 1050o C, 20 sec. Etch the 96 nm disposable spacer 7. 8. 9. As (B) s/d extension:1×1015 cm−2 /7 keV (1×1014cm−2 /1.0 keV). 10. B(P) Halo:30o/6.65×1012 cm−2 /10 keV (30o /5.85×1012 cm−2 /25 keV). 11. Final RTA: 1050o C/4 sec. 12. 13. Deposit 40 nm final spacer. Cobalt Silicidation and Al metallization. Table 2: Device label definitions( − and + signs correspond to 10% decrease in dose and 10% increase in dose respectively) Devices D0 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 Definitions nominal Halo− Halo+ SSRC− SSRC+ Deep s/d implant− Deep s/d implant+ s/d extension implant− s/d extension implant+ Simultaneous deviations in the implant parameters causing decrease in the currents. Simultaneous deviations in the implant parameters causing increase in the currents. Doping Conc. /cm3 +2.792e+20 +1.922e+19 +1.323e+18 +9.110e+16 +6.272e+15 +4.260e+14 -5.436e+13 -1.219e+15 -1.774e+16 -2.577e+17 -3.743e+18 (a) Corresponding to a 10% deviation in implant dose, percentage deviations in DC parameters (Ioff, Ion and Vt in the saturation region) are tabulated in Table 3 for both NMOS and PMOS devices. It can be seen that the halo implant step has the biggest impact on the variations, suggesting that this step has to be very tightly controlled in manufacturing. Figure 2 shows the Id−Vg characteristics for the nominal device (D0) and the worst and best case corner devices (D9 and D10) for both NMOS and PMOS. The AC extractions are performed at 100kHz over the full range of gate voltage from 0−1.5V. Figure 3 shows the Cgg−Vg characteristics for D0, D9 and D10 for both NMOS and PMOS devices in the saturation region. The percentage deviation in Cgg is tabulated in Table 4 and 5 in linear and saturation region for both NMOS and PMOS devices respectively. Both halo and SSRC implants are important in controlling the capacitance value. The variation in the gate capacitance Cgg is typically lower compared to the variation in DC parameters, since the gate capacitance is mainly dominated by the oxide thickness. However, for the accurate prediction of CMOS circuit delay, the CV/I metric is affected by the capacitance variations as well. Table 3: Percentage deviation in DC parameters in the saturation region for both the NMOS and PMOS devices. Doping Conc. /cm3 +2.891e+18 D1 D2 D3 NMOS NMOS NMOS PMOS PMOS PMOS ∆Ioff ∆Ion ∆Vt ∆Ioff ∆Ion ∆Vt Vds= Vds= Vds= Vds= Vds= Vds= 1.5V 1.5V 1.5V −1.5V −1.5V −1.5V 122 4.82 −13.55 97.48 5.29 −10.29 −52.7 −5.66 11.6 −47.2 −4.53 10.66 33.3 −2.41 −5.16 74.76 11.1 −9.84 D4 D5 D6 D7 −16.85 −5.03 −7.03 −1.36 7.87 1.26 −23.15 −2 2.58 1.29 −1.94 2.58 30.49 −23 33.7 −26.9 6.95 −3.02 3.02 −4 −5.74 6.1 −5.15 6.19 D8 D9 28.7 −71.3 2 −13.1 −4.52 19.35 35.83 3.78 −69.9 −11.59 −5.1 20.7 D10 203.52 7.97 −18.71 540.8 Devi −ces +1.854e+17 +1.189e+16 +7.589e+14 -2.286e+12 -7.947e+14 -1.244e+16 -1.940e+17 -3.026e+18 -4.719e+19 -7.360e+20 (b) Figure 1: Cross section of simulated (a) NMOS and (b) PMOS devices. ( approximate dopant concentration can be read from color palette given ). Proceedings of the 15th International Conference on VLSI Design (VLSID’02) 0-7695-1441-3/02 $17.00 © 2002 IEEE 24.18 −31.24 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 ∆Cgg@ Vds= 0.05V, and Vg=0.0V 0.02 0.01 0.53 −0.49 −0.26 0.28 −1.17 1.06 −1.91 1.36 ∆Cgg@ Vds= 0.05V, and Vg=1.5V 0.05 −0.01 −0.81 −8.07 −1.8 1.21 −0.05 −0.05 −9.21 1.29 ∆Cgg @ Vds= 1.5V, and Vg=0.0V −0.15 −0.16 −0.55 −0.84 −0.36 0 −1.57 1.21 −2.17 1.21 ∆Cgg @ Vds= 1.5V, and Vg=1.5V 0 −0.33 −4.56 7.5 −1 1 −0.58 0 −8.33 0.92 Table 5: Percentage deviation in total gate capacitance Cgg in the linear and saturation region for PMOS devices. D1 D2 ∆Cgg @ Vds= −0.05V, and Vg=0.0V −1.88 −2.86 ∆Cgg @ Vds= −0.05V, and Vg= −1.5V −0.91 0 ∆Cgg @ Vds= −1.5V, and Vg=0.0V 0.52 −0.45 ∆Cgg @ Vds= −1.5V, and Vg= −1.5V −0.09 −0.35 D3 D4 1.01 −0.14 −1.66 −2.87 2.41 1.29 0.18 −1.23 D5 D6 −3.03 1.44 −1.66 1.06 −0.69 0.69 −1.59 1.23 D7 D8 −4.76 0 0 0.08 −2.41 2.24 −0.79 0.7 D9 D10 −5.87 5.63 −1.66 0.08 −3.1 6.28 −3.17 2.95 Devi −ces Proceedings of the 15th International Conference on VLSI Design (VLSID’02) 0-7695-1441-3/02 $17.00 © 2002 IEEE Drain Current Id (Amp/Micron) Devi −ces 1E−2 1E−3 1E−4 1E−5 1E−6 D0_PMOS 1E−7 D9_PMOS D10_PMOS 1E−8 D0_NMOS 1E−9 D9_NMOS D10_NMOS 1E−10 −1 0 1 Gate Voltage(Volts) Figure 2: Id−Vg characteristics for D0, D9 and D10 for both NMOS and PMOS devices, in the saturation region (w=1µm). Total Gate Cap. Cgg(F/Micron) Table 4: Percentage deviation in total gate capacitance Cgg in the linear and saturation region for NMOS devices. 1.2e−15 1e−15 D0_PMOS 8e−16 D9_PMOS D10_PMOS D0_NMOS D9_NMOS 6e−16 D10_NMOS −1 0 1 Gate Voltage Vg(Volts) Figure 3: Cgg−Vg characteristics for D0, D9 and D10 for both NMOS and PMOS devices, in the saturation region (w=1µm) Vdd PMOS1 Vout1 PMOS2 Vout2 NMOS1 NMOS2 Voltage (Volts) Vin 1.5 C_Vin C0_Vout1 1 C0_Vout2 C1_Vout1 C1_Vout2 C2_Vout1 0.5 C2_Vout2 0 1e−11 2e−11 3e−11 4e−11 5e−11 Time (sec) (a) Figure 4: A two stage CMOS inverter Circuit. 4. Transient simulations Two stage inverter circuit as shown in Figure 4 is simulated at Vdd=1.5V. According to the circuit label definition of Table 6, three, two stage inverter circuits C0, C1, C2 were configured by generating SPICE−netlist and mixed mode simulated for an input pulse. Input pulse had a width of 150 ps and rise and fall time of 5 ps. The output waveforms for all the three circuits, nominal (C0), worst (C1), and best (C2) are superimposed at the rising and falling edges of the input pulse as shown in Figure 5 (a) and 5 (b) respectively. This figure gives a comparison of delay for all the three circuits in both rising and falling edge of the input pulse. Various terminal voltages as defined in Figure 4 alongwith the circuit label give the identification of the corresponding curve. Table 7 consolidates the percentage deviation in delays relative to the nominal circuit, for both the rising and falling edge for the first stage loaded with an identical inverter. Significant deviation in the circuit delay is evident from these results. Also the variations will get amplified with the complexity of the circuit as is evident from the difference in the first and second stage outputs of the inverter chain. Proceedings of the 15th International Conference on VLSI Design (VLSID’02) 0-7695-1441-3/02 $17.00 © 2002 IEEE Voltage (Volts) 1.5 C_Vin C0_Vout1 1 C0_Vout2 C1_Vout1 C1_Vout2 0.5 C2_Vout1 C2_Vout2 0 1.6e−10 1.7e−10 1.8e−10 1.9e−10 Time (sec) (b) Figure 5: Transient waveforms of the two stage inverter circuit (a) at the rising edge and (b) at the falling edge of the input pulse. underlying processes for the DSM technology. This would facilitate guidelines for process engineering to improve the manufacturing yield. Table 6: Circuit label definitions Circuit C0 C1 C2 Definitions Nominal delay circuit built by device D0 from both NMOS and PMOS Worst delay circuit built by device D9 from both NMOS and PMOS Best delay circuit built by device D10 from both NMOS and PMOS Table 7: Percentage deviation in circuit delay (∆T) parameters. The reference is the rising or falling edge of the input pulse. Acknowledgments We express our gratitude to Prof. T. S. Vedavathy, ECE department, Indian Institute of Science, Bangalore, for her support, right through this work. We also thank her for providing the computing facility, which enabled this work. References 1. ∆Tvout1 @ ∆Tvout1 @ rising edge falling edge of Vin of Vin Circ uits Vout1 delay @ rising edge of Vin (ps) Vout1 delay @ falling edge of Vin (ps) C0 8.97 8.35 −− −− C1 9.82 9.3 9.48 11.38 C2 7.5 8.02 −16.4 −3.95 2. 3. 5. Conclusions Among the four implant parameters namely SSRC dose, deep s/d dose, shallow extension dose and halo dose, the pocket halo has the significant effect on the transistor leakage and saturation currents, which finally have effect on circuit delays. This process step has to be tightly controlled in manufacturing to decrease mismatch effect. The device mismatch in turn results in circuit delay variation which has implications on the yield of the circuit. A proper physical model is necessary to correlate the circuit performance to Proceedings of the 15th International Conference on VLSI Design (VLSID’02) 0-7695-1441-3/02 $17.00 © 2002 IEEE 4. 5. 6. Michael Orshansky, James C. Chen, and Chenming Hu, "Direct Sampling Methodology for Statistical Analysis of Scaled CMOS Technologies", IEEE Semiconductor Manufacturing. Vol. 12. NO. 4 November 1999. p. 403. Keith A. Bowman, Xinghai Tang, John C. Eble and James D. Meindl, "Impact of Extrinsic and Intrinsic Parameter Fluctuation on CMOS Circuit Performance", IEEE SSC. Vol. 35. NO. 8. August 2000. p. 1186. Tomohisa Mizuno, Jun−ichi Okamura, and Akira Toriumi, "Experimental Study of Threshold Voltage Fluctuation Due to Statistical Variation of Channel Dopant Number in MOSFET’s" IEEE ED, Vol. 41. NO. 11. November 1994. p. 2216. P. A. Stolk and D. B. M. Klaassen, "The Effect Statistical Fluctuation on MOS Device Performance", IEDM 96. p. 627. P. M. Zeitzoff, A. F. Tasch, W. E. Moore, S. A. Khan, and D. Angelo, "Modeling of Manufacturing Sensitivity and of Statistically Based Process Control Requirement for a 0.18 µm NMOS Device", International Conference on Characterization and Metrology for ULSI Technology, American Institute of Physics, 1998, pp 73−81. DESSIS−ISE, ISE TCAD Release 6.1 Manual, 1999.