Cryogenic Life Support System NASA - Biomedical Engineering

advertisement

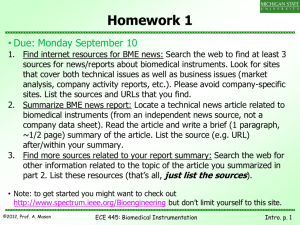

Doerr-BO-Mining-02222012 John F. Kennedy Space Center BIOMEDICAL ENGINEERING Cryogenic Life Support System Donald F. Doerr LABTECH Inc. dsquare@cfl.rr.com 321-258-7052 (formerly) NASA - Biomedical Engineering Kennedy Space Center, FL 32899 John F. Kennedy Space Center BIOMEDICAL ENGINEERING • • • • • • How did we get to cryo life support? Rocket engines need fuel + oxidizer (atmospheric air is not available in upper atmosphere and space) For shuttle – supply 1,359,142 lb of oxygen to 3 shuttle engines for 8.5 minutes. Gaseous, compressed oxygen tank would be too heavy Solution go to cryogenic form of oxygen Liquid O2 – 53 lb/ft3, - 297°F, store at 22 psi. Total tank weight (empty – 66000 lb) 154’ long, 27.6’ dia. Oxygen tank at top 2 John F. Kennedy Space Center Why cryos for life support? BIOMEDICAL ENGINEERING • • Similar challenges with gas supplies faced ground crews: – Whole body protective suit for toxic propellant handling – lengthy operations (e.g. hypergol load = 10 workers x 30 hrs) – Pad rescue of 7 crewman from outside blast danger – No commercially available alternatives By same process, determined that cryogenic air (or oxygen) could power long duration life support equipment – At least twice the duration of compressed air – Store at 22 psi, operate at 150 psi (max) – Storage vessels (dewars) much lighter – Avoid hazards of high pressure gas (air or oxygen) – Body cooling a by-product 3 John F. Kennedy Space Center Mollier Chart for AIR BIOMEDICAL ENGINEERING 4 John F. Kennedy Space Center BIOMEDICAL ENGINEERING • • Advantages of cryogenics Advantages of liquid air – More useable air per volume • (53 lb/ft3 liquid vs. 22 lb/ft3 4500psi compressed air) – Much lower, safer, storage pressure (22 psi vs 4500 psi) – Body cooling is secondary product Advantages of storing oxygen in liquid form – Large respirable “air” supply created by adding only O2 to system and scrubbing CO2 such as rebreather – Considerable duration for minimal supply volumes 5 John F. Kennedy Space Center Physical Properties BIOMEDICAL ENGINEERING Compressed Air Liquid Air Supercritical Air (gas) Liquid Oxygen Temperature ambient -321°F -321°F -297°F Temperature ambient 77°K 77°K 90°K Density 22 lb/ft3 @ 4500psi 53 lb/ft3 53 lb/ft3 75 lb/ft3 Density ~0.35 gm/cm3 0.85 gm/cm3 0.85 gm/cm3 1.14 gm/cm3 Pressure 60 min. cyl. 4500 psi > 14.7 psi < 575 psi > 575 psi < 950 psi > 14.7 psi < 737 psi 728 x 728 x 861 x Expansion Rate 6 John F. Kennedy Space Center BIOMEDICAL ENGINEERING Disadvantages of cryogenic air/O2 • Disadvantages • Typical standby time is 24 hr, so use for planned ops • Stored liquid air can become oxygen rich over time • Nitrogen (colder) boils off first leaving oxygen • Dewars can be attitude sensitive • Quantity indicators are more difficult 7 John F. Kennedy Space Center How do you make liquid air? BIOMEDICAL ENGINEERING • Two basic ways to make liquid air • Cool gaseous, dry air to condensation point (- 320°F) • Mix liquid oxygen and liquid nitrogen Can adjust oxygen/nitrogen ratio as desired -Oxygen rich – e.g. NOAA II (36% O2) - Applications in diving - Applications for rebreathers 8 John F. Kennedy Space Center Liquid Air Storage BIOMEDICAL ENGINEERING Liquid Air Trailer – 150 gallon (also available in 158 gal and 600 gal.) Liquid Air Pack fill Station (in shop) 9 John F. Kennedy Space Center BIOMEDICAL ENGINEERING How does liquid air pack work? Pressure demand SCBA mask Buildup loop (pressurizes system) Dewar holds 6 lb liquid air (vacuum jacketed vessel) Heat exchanger for buildup loop Accumulator Heat exchanger for supply loop 10 John F. Kennedy Space Center BIOMEDICAL ENGINEERING • Long term cryogenic gas storage Zero loss cryogenic storage vessel (dewar) – Store cryogenic air, oxygen, or nitrogen for extended time periods – Use electric power to operate cryo-cooler – Combination of commercially available components 300 liter storage vessel Commercially available cryo-cooler. Recuperator mounted in storage vessel 11 John F. Kennedy Space Center BIOMEDICAL ENGINEERING Zero loss liquid air storage data 1 50.00 Liquid Evaporated <---Dwell Time <---Pump Run Tim 0.00 Average power consumption = 396 W -50.00 End of Test Start Vent 1.55 Pump cycles -100.00 Lost Data ~2L Sample taken from liquid side. -150.00 -200.00 Temp Low F -250.00 Temp Mid Low F Temp Mid High F Temp High F -300.00 T-0 @ 0937 8/15/2011 Data by Dave Bush Tank Press PSIG Time in minutes CryoCooler Current A -350.00 0 1440 2880 4320 5760 7200 12 8640 10080 11520 12960 14400 15840 17280 18720 John F. Kennedy Space Center BIOMEDICAL ENGINEERING Zero-loss Liquid Air Dewar Test 2 Summary • Test conducted for 90 days • Digital pressure control for cryocooler activation • Entire 300 liter dewar and liquid air on digital platform scale • Sampled once per month for oxygen concentration which used about ~10 lb air each time • Conclusion • Lost less than 1 lb liquid air over 90 days (except samples) • Oxygen sample within 0.1 % start to finish 13 John F. Kennedy Space Center BIOMEDICAL ENGINEERING Cryogenic Air Systems in use Propellant Handlers Ensemble -2 hr totally encapsulated suit - body cooling - 5000 uses per year Liquid Air Pack -1 hr positive pressure demand SCBA - Used by pad rescue and SAR teams - 38 units in use each shuttle launch/landing Portable Liquid Air Ventilator – used by astronauts to cool flight suit prior to launch 14 John F. Kennedy Space Center BIOMEDICAL ENGINEERING Prototype cryogenic systems Supercritical Air Pack -1 hr pos. pres. SCBA - Liquid Cooled garment - For use by pad rescue team - 2 hr unit in development 15 Supercritical SCUBA -equiv. to 90 ft3 tank -Buoyancy compensator - full face dive mask John F. Kennedy Space Center BIOMEDICAL ENGINEERING 16