Metalux

advertisement

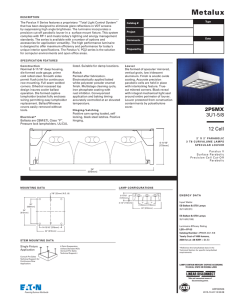

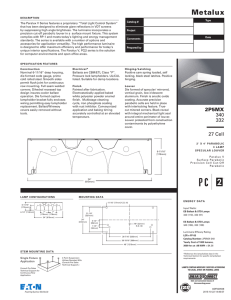

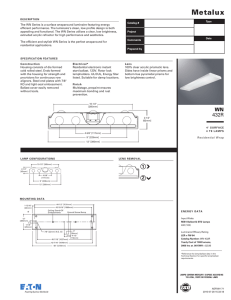

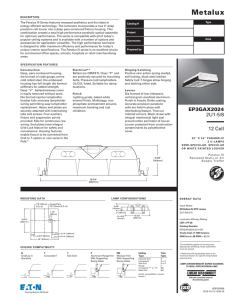

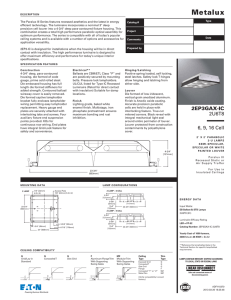

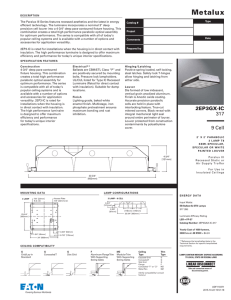

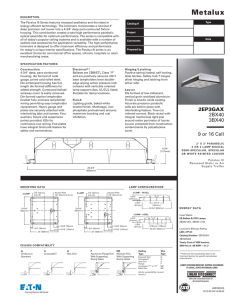

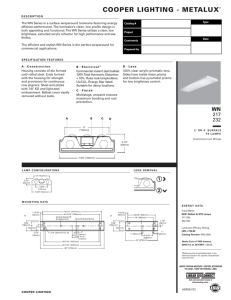

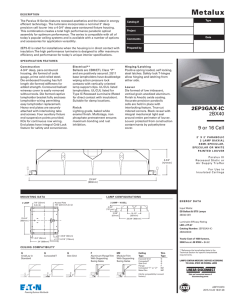

Metalux D ES C R IPTION The Paralux V Series features a proprietary “Total Light Control System” that has been designed to eliminate glare reflections in VDT screens by suppressing high angle brightness. The luminaire incorporates a precision cut-off parabolic louver in a surface mount fixture. This system complies with RP-1 and meets today’s lighting and energy management standards. The series is available with a number of options and accessories for application versatility. The high performance luminaire is designed to offer maximum efficiency and performance for today’s unique interior specifications. The Paralux V, PC|2 series is the solution for computer environments and open office areas. Type Catalog # Project Date Comments Prepared by SPE C IFIC A TION FEA T U R E S Construction Nominal 6-11/16" deep housing, die formed code gauge, prime cold rolled steel. Smooth sides permit flush joint for continuous row mounting. Full seam welded corners. Dihedral recessed top design insures cooler ballast operation. Die formed captive lampholder bracket fully encloses wiring permitting easy lampholder replacement. Ballast/Wireway covers easily removed without tools. have double-edge wiping action pressure lock contacts with lamp support clips. UL/CUL listed. Suitable for damp locations. Louver F in ish Painted after fabrication. Electrostatically applied baked white polyester powder enamel finish. Multistage cleaning cycle, iron phosphate coating with rust inhibitor. Conveyorized application and baking timing accurately controlled at an elevated temperature. El e c t r i c a l * Ballasts are CBM/ETL Class “P”. 2G11 base lampholders locking, black steel latches. Positive hinging. Die formed of specular/ mirrored, vertical grain, low iridescent aluminum. Finish is anodic oxide coating. Accurate precision parabolic cells are held in place with interlocking feature. Truecut mitered corners. Black reveal with integral mechanical light seal around entire perimeter of louver. Louver protected from construction contaminants by polyethylene cover. 2P5MX 3BX40 Hin g in g /L a tch in g Positive cam spring loaded, self 12 Cell 6-11/16" [170mm] 2' X 2' PARABOLIC 3 BIAXIAL LAMPS SPECULAR LOUVER Paralux V Surface Parabolic Precision Cell Cut-Off Parabolic 24" [610mm] ENERGY DATA MOUNTING D A TA L A MP CONF IGURA T IONS 7/8" [22mm] K.O. (6) 6-11/16" [170mm] 4-1/2" [114mm] 20" [508mm] 7" 7" [178mm] [178mm] 24" [610mm] 24" [610mm] Input Watts: EB Ballast & STD Lamps 3BX40 (110) STD Ballast & STD Lamps 3BX40 (128) Luminaire Efficacy Rating LER = FP-53 Catalog Number: 2P5MX-3BX40 Yearly Cost of 1000 lumens, 3000 hrs at .08 KWH = $4.53 14-15/16" [379mm] 24" [610mm] *Reference the lamp/ballast data in the Technical Section for specific lamp/ballast requirements. S TEM M OUNTING D A T A Single Fixture Application Consult Pre Sales Technical Support for Continuous Row Application. 4 Point Suspension Utilizes Standard KOs (Consult Pre Sales Technical Support.) LAMPS CONTAIN MERCURY. DISPOSE ACCORDING TO LOCAL, STATE OR FEDERAL LAWS Safe and convenient means of disconnecting power. ADF020507 2015-10-22 13:18:50 2 P5 M X PH OTOM ETR IC S Coefficients of Utilization 2P5MX-3BX40S34MI Electronic Ballast F40BX/SPX35/RS Lamps 3150 Lumens Spacing criterion: (II) 1.2 x mounting height, (⊥) 1.2 x mounting height Efficiency 65.0% Test Report: rc rw RCR 0 1 2 3 4 5 6 7 8 9 10 Candela Effective floor cavity reflectance 80% 70% 70 50 30 10 70 50 30 10 77 74 70 66 62 58 55 51 48 45 42 77 72 66 61 57 52 49 45 41 37 34 77 70 64 58 53 48 44 40 37 33 30 77 68 61 55 50 45 41 37 34 30 27 76 72 68 64 61 57 54 51 47 44 41 76 70 65 60 56 52 48 44 41 37 34 76 69 63 57 52 48 44 40 36 33 30 76 67 61 55 50 45 41 37 34 30 27 20% 50% 50 30 10 30% 50 30 10 10% 50 30 10 0% 0 72 68 63 59 55 50 47 43 40 36 33 69 65 61 57 53 49 46 43 39 36 33 66 63 59 56 52 48 45 42 39 35 32 65 60 56 51 47 43 39 36 32 29 26 72 66 61 56 51 47 43 40 36 33 30 72 65 59 54 49 45 41 37 33 30 27 69 64 60 55 51 46 43 39 36 32 29 69 63 58 53 48 44 41 37 33 30 27 Zonal Lumen Summary Ty p i c a l VC P Pe r c e n t a g e s Zone 0-30 0-40 0-60 0-90 0-180 Room Size (Ft.) 20 x 20 30 x 30 30 x 60 60 x 30 60 x 60 Lumens %Lamp %Fixture 3227 4982 6127 6140 6140 34.1 52.7 64.8 65.0 65.0 52.6 81.1 99.8 100.0 100.0 2P5MX3BX40S34MI.IES Height Along 8.5’ 10.0’ 91 87 85 87 86 88 86 88 86 88 66 62 58 54 50 46 42 39 35 32 29 66 62 57 52 48 44 40 37 33 30 27 Height Across 8.5’ 10.0’ 95 97 95 97 95 97 95 97 96 97 Angle 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 Along II 3990 3981 3938 3813 3641 3421 3149 Across ⊥ 3990 3995 3933 4004 4142 4181 3715 45° 3990 3980 3927 3834 3787 3735 3560 2804 3186 2333 2322 1491 857 206 15 8 5 3 0 0 0 2316 1279 571 202 17 8 5 3 1 0 0 1156 886 400 29 13 9 6 3 2 0 0 Luminance Data LER = FP-53 Angle in Deg 45 55 65 75 85 Yearly Cost of 1000 lumens, 3000 hrs at .08 KWH = $4.53 Average 0-Deg cd/sm fL 7433 2170 1266 369 67 19 41 11 0 0 Average 45-Deg cd/sm fL 6376 1861 1242 362 67 19 41 11 0 0 Average 90-Deg cd/sm fL 4417 1289 178 52 75 21 41 11 0 0 ORDER ING INFOR M A TION SAMPLE NUMBER: 2P5MX-3BX40S34MI-120V-EB81-U Width 2=2' width Number of Lamps 3 lamps P=Paralux Louver (Not included) 5=5" Louver Depth Wattage (Length) BX40=40W Biaxial (24") Voltage (2) 120V=120 Volt 277V=277 Volt 347V=347 Volt UNV=Universal Voltage 120-277 Ballast Type (2) Blank=Standard Magnetic Ballast (Biax & 20W) EB5 =T5 Biax Electronic Instant Start. Total Harmonic Distortion < 20% (3) No. of Ballast 1, 2 or 3 Options TEB5 =T5 Biax Electronic Instant Start. Total Harmonic Distortion < 10% GL=Single Element Fuse GM=Double Element Fuse No. of Ballast 1, 2 or 3 WTR=White Reveal Flex=Flex Installed EL=Emergency Installed MX=Surface Mount/Floating Door Louver Color S=Silver Cell Configuration 34=3 Row of 4, 12 Cell Louver Finish MI=Specular/Mirrored (Low Iridescent) VDT=VDT Soft Semi-Specular/Haze (Low Iridescent) (1) NOTES: An EQ Grid Clip is recommended for all 9/16" ceiling systems. Four required per fixture. (3) international markets. Not available when specifying emergencies, voltage must be specific. (2) Options FR=Suitable for Fire Rated Applications MEP=Modified End Plate/ For End Filler Applications (See Accessory Section) 20REP=20 Gauge Riveted Endplates. For use in New York City. (Additional options available. See Accessory Section) Packaging U=Unit Pack PAL=Job Pack, out of carton PALC=Job Pack, in carton Products also available in non-US voltages and frequencies for For complete product data, reference the Fluorescent Specification binder. Specifications & dimensions subject to change without notice. Consult your Cooper Lighting Representative for availability and ordering information. ACCESSORIES EQ-CLIP-U=T-BAR Safety Earthquake Clips (1) SH IP P ING D A T A Catalog No. 2P5MX-3BX40S34MI Eaton 1121 Highway 74 South Peachtree City, GA 30269 P: 770-486-4800 www.eaton.com/lighting Specifications and dimensions subject to change without notice. Wt. 28 lbs. ADF020507 2015-10-22 13:18:50 Eaton 1121 Highway 74 South Peachtree City, GA 30269 P: 770-486-4800 www.eaton.com/lighting Specifications and dimensions subject to change without notice.