How Do You Spell Reliability? Kyle Distribution Switchgear Service Solutions

advertisement

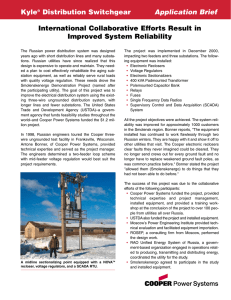

Kyle® Distribution Switchgear Service Solutions How Do You Spell Reliability? The ABC s of Power Distribution Reliability Reliability It’s not just a catch-phrase. It’s a commitment to a superior level of service. It’s the key to pleased customers, business opportunities, strategic growth, and satisfied regulatory agencies. It’s what makes you a trusted power supplier. What if there was a way to ensure premium reliability, guarantee continued TCC coordination, and provide optimal recloser mechanical operation? What if this assurance required only a minimal investment? There is a way to realize optimal system reliability, and it doesn’t involve making a purchase. The secret is simply performing scheduled maintenance on your Kyle® recloser. The Kyle reclosers that you already own are the best choice for providing reliable power distribution. Kyle quality, backed by over a half century experience as an industry leader in distribution switchgear, means that your system is using the most dependable products on the market. Preserving optimal performance is easy: simply follow the recloser maintenance guidelines recommended by Cooper Power Systems. The system reliability that your Kyle recloser provides, from TCC coordination to mechanical reliability, is guaranteed by keeping its components in prime condition. As with any mechanical device, repeated use takes a toll on even the best system. Regular maintenance preserves reliability of operation at peak efficiency, even during peak load demand periods, and protects system uptime. And uninterrupted service means a better financial bottom line. Regular maintenance will guarantee decades of reliable service from your Kyle distribution switchgear. You have already made a capital investment in superior products for reliable outage management. Make sure you collect the full dividends on that wise investment. Keep your distribution switchgear operating with the reliability that you and your customers depend on. The Kyle reclosers that you already own are an important part of your commitment to reliability. Establishing and following a regular maintenance routine will guarantee decades of reliable service from your Kyle distribution switchgear. You’ve already made the best decision for reliability, power quality, and efficiency. Protecting your investment is the next smart choice. The ABCs of Reliability Aesthetics Service Item Service Benefit External Hardware Inspect Paint Labels Inspect Inspect Minimize corrosion to maintain bushing and tank seals Avoid rust stains Maintain non-corrosive tank for oil reservoir Provide valuable environmental and hazard information Routine maintenance provides optimal operation. Routine maintenance is as easy as ABC. Simple inspections and basic care will keep your Kyle distribution switchgear operating at its prime. Proper maintenance includes the following basics: filtering or replacing the oil, and replacing the bushings gaskets, the head gasket, the series coil gasket, and the tank liner. For best performance reliability, Kyle also recommends inspecting all the components and the mechanism. Complete your maintenance program with a thorough test plan. Follow these ABC s of proper recloser maintenance to ensure your power distribution system’s optimal reliability. A esthetic concerns include hardware corrosion and paint scratches. Neglect of the exterior could lead to compromising the seal of the bushings and tank. During regular maintenance is an ideal time to verify that the non-PCB and hazard labels are still readable by the operating crews. Replace illegible labels. B oost mechanical reliability to ensure that the equipment itself is operating at peak levels. Mechanical components do exhibit wear after years of service and should be replaced as needed. Inspect the mechanism for proper operation to confirm correct tripping and closing. For oil interrupters, check moving and stationary interrupting contacts for erosion. If the contact surface shows wear, the part should be replaced. If the movable contact is replaced, the corresponding stationary contact should also be replaced to avoid excessive wear on the new moving contact. For vacuum interrupters, verify contact wear by the scribe mark wear indicator or by actual measurement of contact erosion. Check counters for proper alignment and operation to assure accurate system and maintenance planning information. It’s as easy as ABC to maintain your power distribution system’s optimal reliability. Contact your Cooper Power Systems Representative for additional information about maintenance and parts specials. Mechanical Reliability 2 Service Item Service Benefit Interrupting Contacts Main Latch Assembly Counters Inspect Inspect Inspect Prevent interrupting, mechanical or thermal failure Maintain proper closing of mechanism Obtain information and planned maintenance Service Solutions Coordination Reliability Service Item Service Benefit Series Coil Pump Piston Series Coil Gaskets Insulating Oil Inspect Inspect Replace Filter, Replace Correct minimum trip values Obtain proper sequencing and TCC timing Avoid oil leakage paths that affect TCC timing Maintain consistant TCC timing C oordination reliability is maintained through the proper functioning of various parts within the individual 1800 20 1200 10 600 8 480 6 360 5 300 4 240 3 180 2 120 1 60 .8 48 .6 36 .5 30 .4 24 .3 18 .2 12 C .1 6.0 .08 4.8 D .06 3.6 .05 3.0 .04 2.4 .03 1.8 A 40000 50000 20000 30000 8000 5000 6000 CURRENT (as a percent of minimum trip) 10000 2000 3000 4000 500 600 800 1000 200 .01 1.2 300 .02 400 Reliability . 2400 30 80 for your valuable power distribution equipment. Using genuine Cooper replacement parts protects your system’s quality. By investing the time to keep your reclosers operating at their prime, you are guaranteeing that your system delivers 3000 40 100 These few simple checks offer cheap insurance 3600 50 TIME (sec) inspecting the dielectric components on a regular basis. Avoid moisture ingress and oil degradation through the replacement of fiber liners and inspection of bushings, bushing gaskets, and tank head gaskets. Fiber liners retain moisture and should be replaced with every oil change. Cracked or chipped bushings lead to external flashovers, resulting in increased damage and system outages. Regular care easily prevents these problems. 60 60 ielectric integrity is maintained by servicing the oil and 50 D TIME [cycles (60 hertz basis)] reclosers. The series coil and its gaskets, the pump piston, and the oil all play important roles in the TCC timing and operation of the recloser. Neglecting these components will prevent proper system coordination and service reliability. Keep your system well coordinated to avoid lost crew time locating and troubleshooting faulted areas. 0.6 Dielectric Integrity Service Item Service Benefit Oil Head Gasket Bushings Bushing Gaskets Liner Tank Filter, Replace Inspect Inspect Replace Replace Inspect Maintain dielectric integrity Avoid moisture ingress, maintaining dielectric integrity Avoid external flashover and high radio noise Avoid moisture ingress path Avoid dielectric failure due to moisture Verify tank is maintaining oil reservoir and not leaking 3 Kyle® Distribution Switchgear Service, Our Mission Switchgear Support Group Kyle Distribution Switchgear Service provides our utility customers the finest service on the most technically advanced distribution equipment in the world. We offer training, Kyle replacement parts/kits, and repair/maintenance services at the factory or at one of our factory trained Authorized Repair shop locations throughout the U.S. Our focus is on safety, quality, and reliability. Immediate solutions for customers application questions are available through our experts in the Switchgear Support Group (SSG). The SSG is dedicated to providing answers to your technical questions. • Overcurrent, overvoltage, and reliability seminars taught by qualified engineers in the area of coordination and system quantities. • Specialized Hands-On Service Training Classes • Factory and Regional Authorized Service Shops • Worldwide Field Service • 24-hour Emergency Spare Parts Shipment Contact Kyle directly: 1-800-497-KYLE (1-800-497-5953) For International calls: 1-414-768-8203 or 1-414-768-8205 SSG Contact hours: Standard hours 7:00 am to 5:00 pm Central Standard Time Emergency support is also available 24 hours, 7 days a week. Contact Kyle Switchgear Support Group at ssg@cooperpower.com Expanded Website Support at www.cooperpower.com Contact Kyle Service at kyleservice@cooperpower.com Additional Service Information at www.cooperpower.com/Services/KyleDistribution.asp • Software Training • Interface Software Downloads • Expanded Literature Database • E-mail Help-Site • Newsletter E-mail After 60 years of continued customer service growth, Kyle® has an unmatched history as the leader in the distribution switchgear industry. Even as we look to the future, we remain committed to that legacy. Innovative Products Exceptional Customer Service Contact your Cooper Power Systems Representative for additional information. The Quality System at Cooper Power Systems, Kyle Distribution Switchgear is ISO 9001 certified. ©2002 Cooper Industries, Inc. Kyle® is a registered trademark of Cooper Industries, Inc. Bulletin 02037 • October 2002 • New Issue P.O. Box 1640, Waukesha, WI 53187 USA Phone: 1-262-524-3300 Fax: 1-262-524-3313 www.cooperpower.com KPP 10/02