Fall 2005 Seminar Series Size Matters!

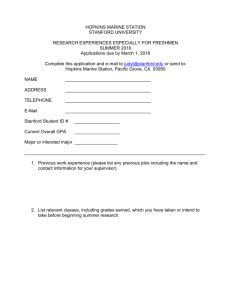

advertisement

Fall 2005 Seminar Series Size Matters! Smaller is Stronger: Strength and Plasticity at the Nanoscale William D. Nix Department of Materials Science and Engineering Stanford University, Stanford CA 94305-2205 Nanomechanical devices are certain to play an important role in future technologies. Already sensors and actuators based on MEMS technologies are commonplace and new devices based on NEMS are just around the corner. These developments are part of a decades-long trend to build useful engineering devices and structures on a smaller scale. Here we review recent advances in nanoindentation, a key technique for studying nanomechanical properties of materials, and examine some of the effects that arise when crystalline materials are mechanically deformed in small volumes. Size effects in plasticity are now well known. Plastic deformation in small volumes requires higher stresses than are needed for plastic flow of bulk materials. Here we review the various effects that appear to be responsible for this. The size dependence of the hardness of metals is described in terms of the geometrically necessary dislocations created in small indentations. But such accounts break down when the size of the deformation volume begins to approach the spacing of individual dislocations. Nanoindentation of epitaxial films at the nanometer depth scale reveals irregular loaddisplacement curves. In this domain the nucleation of dislocations appears to be more important than strain gradients. In an effort to shed additional light on these topics, uniaxial compression experiments on tiny samples made by focused ion beam machining have been conducted. These experiments involve small deformation volumes and minimal strain gradients, yet strong size effects are still observed. These size effects suggest that plasticity is dislocation sourcecontrolled, wherein smaller volumes are stronger because fewer sources of dislocations are available. The central idea is that for very small crystals dislocations leave the crystal more frequently than they multiply, forcing other, harder, sources of dislocations to be activated. Understanding and controlling the mechanical properties of materials on this scale is expected to lead to new, more robust, nanomechanical structures and devices. Bio: Professor Nix obtained his B.S. degree in Metallurgical Engineering from San Jose State College, and his M.S. and Ph.D. degrees in Metallurgical Engineering and Materials Science, respectively, from Stanford University. He joined the faculty at Stanford in 1963 and was appointed Professor in 1972. He was named the Lee Otterson Professor of Engineering at Stanford University in 1989 and served as Chairman of the Department of Materials Science and Engineering from 1991 to 1996. In 2001 he was awarded an Honorary Doctor of Engineering Degree by the Colorado School of Mines. Professor Nix received numerous awards during his career, including 1964 Western Electric Fund Award for Excellence in Engineering Instruction, 1970 Bradley Stoughton Teaching Award of ASM, 1998 ASM Gold Medal, 1993 Acta Metallurgica Gold Medal, 2001 Nadai Medal from the American Society of Mechanical Engineers. He was elected Fellow of the American Society for Metals in 1978 and elected Fellow of the Metallurgical Society of AIME in 1988. In 1987 he was elected to the National Academy of Engineering and in 2002 was elected as a Fellow of the American Academy of Arts and Sciences. Prof. Nix was elected to the National Academy of Sciences in 2003. Professor Nix is co-author of over 400 publications in these and related fields and he has trained 73 Ph.D. students in these subjects in his years at Stanford. He is co-author of "The Principles of Engineering Materials", published in 1973 by Prentice-Hall, Incorporated. This NECP Seminar is jointly sponsored by the Departments of Chemical and Materials Engineering, Mechanical Engineering, the NECP and the CeNSE. Refreshments will be served starting at 3:30 pm. Tuesday, November 29, 2005 CB 231, White Hall Class Room Building University of Kentucky, Lexington, KY 3:45 pm - 4:40 pm