FCB Flashing Red Beacon Instruction Manual

advertisement

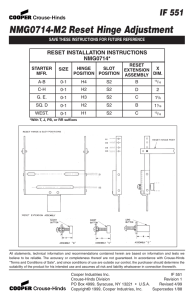

FCB Flashing Red Beacon Instruction Manual IF 1557 SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE LIMITED PRODUCT WARRANTY THE FOLLOWING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER EXPRESS, IMPLIED OR STATUTORY, INCLUDING, BUT NOT BY WAY OF LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. Cooper Crouse-Hinds (“the Company”) warrants to each original Buyer of Products manufactured by the Company that such Products are, at the time of delivery to the Buyer, free of material and workmanship defects, provided that no warranty is made with respect to: (a) any Product which has been repaired or altered in such a way, in Company’s as to affect the Product adversely; judgment, (b) any Product which has, in Company’s judgment, been subject to negligence, accident or improper storage; (c) any Product which has not been operated and maintained in accordance with normal practice and in conformity with recommendations and published specification of Company; and, (d) any Products, component parts or accessories manufactured by others but supplied by Company (any claims should be submitted directly to the manufacturer thereof). Cooper Crouse-Hinds obligation under this warranty is limited to use reasonable effects to repair or, at its option, replace, during normal business hours at any authorized service facility of Company, any Products which in its judgment proved not to be as warranted within the applicable warranty period. All costs of transportation of Products claimed not to be as warranted and of repaired or replacement Products to or from such service facility shall be borne by Purchaser. Company may require the return of any Product claimed not to be as warranted to one of its facilities as designed by Company, transportation prepaid by Purchaser, to establish a claim under this warranty. The cost of labor for installing a repaired or replacement product shall be borne by Purchaser. Replacement parts provided under the terms of this warranty are warranted for the remainder of the warranty period of the Products upon which they are installed to the same extent as if such parts were original components thereof. Warranty services provided under the Agreement do not assure uninterrupted operations of Products; Company does not assume any liability for damages caused by any delays involving warranty service. The warranty period for the Products is 24 months from date of shipment or 12 months from date of first use whichever occurs first. Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 1 IF 1557 Rev 1 New 02/08 SAFETY NOTICES This equipment is normally used or connected to circuits that may employ voltages which are dangerous and may be fatal if accidentally contacted by operating or maintenance personnel. Extreme caution should be exercised when working with this equipment. While practical safety precautions have been incorporated in this equipment, the following rules must be strictly observed: KEEP AWAY FROM LIVE CIRCUITS Operating and maintenance personnel must at all times observe all safety regulations. Do not perform maintenance on internal components or re-lamp with power ON. RESUSCITATION Maintenance personnel should familiarize themselves with the technique for resuscitation found in widely published manuals of first aid instructions. Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 2 IF 1557 Rev 1 New 02/08 TABLE OF CONTENTS Title Page................................................................................................... 1 Limited Product Warranty.......................................................................... 1 Safety Notices............................................................................................. 2 Table of Contents....................................................................................... 3 General Description - Section 1.0 ……………………….…………………3 Installation Instructions – Model 41257G – Section 2.0..…………………. 4 Installation Insturctions – Model 41257G-H – Section 3.0 ………………. 5 Installation Instructions – Model 41257C-TH – Section 4.0 ……………… 6 Figure 1 -Model G …….............................................................................. 7 Figure 2 - Model -H...................................................................................... 8 Figure 3 - Model C FCB-12 with Thompson Hanger................................... 9 Figure 4 - Canopy Detail, Detail B, & Detail A..................................…… 10 Figure 5 - 3 Wire Feed and 2 Wire Feed 115 Volts or 230 Volts ..…........ 11 Figure 6 - Lamp Filament Orientation.......................................................... 12 Parts List...............................................................................….....……....... 13-15 Ordering Information..................................................................................... 16 Lamp Type..................................................................................................... 16 1.0 GENERAL DESCRIPTION – FCB (L-864) BEACONS 1.1 The Cooper Crouse-Hinds FCB series red beacon is used for nighttime obstruction marking of tall, man-made structures such as TV, radio communications, and transmission line towers that may present hazards to air navigation. When installed together with Cooper Crouse-Hinds OLF / PCF series Flasher units or with OLC series Obstruction Lighting Controllers (sold separately), the beacons can be made to Flash On and Off as per FAA Type L-864 Medium Intensity Red Beacon requirements. Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 3 IF 1557 Rev 1 New 02/08 2.0 INSTALLATION INSTRUCTIONS – Model # 41257G Warning Denergize circuit before re-lamping or working on fixture The light fixture is shipped from factory completely assembled and ready for installation. Lamps are shipped separately to avoid breakage. 1. Select a mounting location that will provide suitable strength and rigidity for supporting the light fixture. Unit Weight: 80 lbs. 2. The flight fixture base has 4 pre-drilled holes to assist with securing the unit to its desired location (mounting hardware not provided). 3. To install lamps, loosen the wing nut (see Figure 1) and rotate the eyebolt down. 4. Carefully fold the top half of the beacon over to the open position and install lamps in top and bottom lamp holder (two lamps required per each beacon). NOTE: For optimum performance, the lamp filaments should be 180º opposed. The upper and lower filaments should never face the same direction. The lamp filaments should never face closer than 90º from each other. (see Figure 6) 5. Close the light fixture, reposition eyebolt, and tighten wing nut securely. 6. P/N 41257G is supplied from factory with 5 feet of 14/4 500W cord pre-wired to a terminal block inside light fixture base. Connect the factory supplied cord to incoming wiring system in accordance with the National Electrical Code® plus any other applicable codes. This model can be wired for use with either 120V or 230 volt lamps (lamps sold separately). See Figure 5 for wiring diagrams. Lamp Type Watts “A” “B” “C” 700 700 620 Volts 120 230 120 Base Type Lamp Catalog # Mog.Pref./PS40 Mog.Pref./PS40 Mog.Pref./PS40 10047-2543 10047-2445 620PS40/1P Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 4 IF 1557 Rev 1 New 02/08 3.0 INSTALLATION INSTRUCTIONS – Model # 41257G-H Warning Denergize circuit before re-lamping or working on fixture The light fixture is shipped from factory completely assembled and ready for installation. Lamps are shipped separately to avoid breakage. P/N 41257G-H are suitable for use in Class 1, Division 2, Groups, A,B,C,D hazardous locations as defined by the National Electrical Code®. 1. Select a mounting location that will provide suitable strength and rigidity for supporting the light fixture. Unit Weight: 80 lbs. 2. The flight fixture base has 4 pre-drilled holes to assist with securing the unit to its desired location (mounting hardware not provided). 3. To install lamps, loosen the wing nut (see Figure 2) and rotate the eyebolt down. 4. Carefully fold the top half of the beacon over to the open position and install lamps in top and bottom lamp holder (two lamps required per each beacon). NOTE: For optimum performance, the lamp filaments should be 180º opposed. The upper and lower filaments should never face the same direction. The lamp filaments should never face closer than 90º from each other. (see Figure 6) 5. Close the light fixture, reposition eyebolt, and tighten wing nut securely. 6. P/N 41257G-H is with a 1 inch NPT Drilled and tapped entry for connection of rigid conduit or appropriately rated fittings as necessary. Pull wires into the base of the unit and make wire connections to the terminal block located in the base of the light fixture. 7. Connect the factory supplied cord to incoming wiring system in accordance with the National Electrical Code® plus any other applicable codes. This model can be wired for use with either 120V or 230 volt lamps (lamps sold separately). See Figure 5 for wiring diagrams. Lamp Type Watts “A” “B” “C” 700 700 620 Volts 120 230 120 Base Type Lamp Catalog # Mog.Pref./PS40 Mog.Pref./PS40 Mog.Pref./PS40 Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 10047-2543 10047-2445 620PS40/1P 5 IF 1557 Rev 1 New 02/08 4.0 INSTALLATION INSTRUCTIONS – Model # 41257C-TH Warning Denergize circuit before re-lamping or working on fixture The light fixture is shipped from factory completely assembled and ready for installation. Lamps are shipped separately to avoid breakage. 1. P/N 41257C-TH is supplied from factory with brackets at the top and adjustable guide arm at the fixture base for connection with Obstruction Light Lowering Systems (sold separately). Unit Weight: 80 lbs. 2. To install lamps, loosen the wing nut (see Figure 3) and rotate the eyebolt down. 3. Carefully fold the top half of the beacon over to the open position and install lamps in top and bottom lamp holder (two lamps required per each beacon). NOTE: For optimum performance, the lamp filaments should be 180º opposed. The upper and lower filaments should never face the same direction. The lamp filaments should never face closer than 90º from each other. (see Figure 6) 4. Close the light fixture, reposition eyebolt, and tighten wing nut securely. 5. P/N 41257G-H is with a 1 inch NPT Drilled and tapped entry for connection of rigid conduit or appropriately rated fittings as necessary. Pull wires into the base of the unit and make wire connections to the terminal block located in the base of the light fixture. 6. Attach beacon to Lowering System following instructions provided with the Lowering System. Incoming wiring on this model is made through the canopy (top) of the light fixture. Pull wires inside and make wire connections to the terminal block inside the light fixture. This model can be wired for use with either 120V or 230 volt lamps (lamps sold separately). See Figure 5 for wiring diagrams. Lamp Type Watts “A” “B” “C” 700 700 620 Volts 120 230 120 Base Type Lamp Catalog # Mog.Pref./PS40 Mog.Pref./PS40 Mog.Pref./PS40 10047-2543 10047-2445 620PS40/1P Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 6 IF 1557 Rev 1 New 02/08 Figure 1 Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 7 IF 1557 Rev 1 New 02/08 Figure 2 Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 8 IF 1557 Rev 1 New 02/08 FCB-12 FLASHING RED BEACON MODEL 44389C-TH Figure 3 Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 9 IF 1557 Rev 1 New 02/08 Figure 4 Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 10 IF 1557 Rev 1 New 02/08 Figure 5 Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 11 IF 1557 Rev 1 New 02/08 Figure 6 Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 12 IF 1557 Rev 1 New 02/08 PARTS LIST ITEM NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 PART NUMBER 41811-1 41811-2 41811-3 ML2069 41812-4 10048-2 HL5837B HL5833B 0600561 20U32-003 10B07-019D12 41853 13A32-1402 10P26-017C 10G27-016C12 4564-AH FL1945 HL5836B HL5831B HL5835B 41812-2 41856-1 41812-1 41855-1 41855-2 025-F-F 10A07-025D32 601A 10046-2405X/2428-48 10046-2395X/2428-45 41812-3 10047-1222 0600087 10K04-037D 11A12-037D 41854 HL5841B 11C16-012A24 10048-83 HL5829A 10G26-016D32 QTY G 1 QTY -H QTY C 4 A/R 1 3 4 A/R 4 A/R 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 6 2 2 1 6 2 2 1 6 2 2 1 1 3 A/R 3 11 9 1 3 A/R 3 14 12 1 1 2 2 2 1 3 A/R 3 11 9 1 2 DESCRIPTION Base Base Base Lower Tie Rod Lower Lens Gasket RTV 106 Lower Lens Lower “Z” Ring Cushion Barrier Terminal Block, 3 Position #10-32 X 3/8: Screw Rd Hd Slot SST Lower Hinge Ring Hinge Ring Gasket Speednut- “U” Type(Tap. Scr Thd) #8 X 3/8” Screw-Thd Forming Type B, Rd Hd Retaining Bracket Mounting Ring Upper Lens Upper “Z” Ring Top Lens Top Lens Gasket Canopy Flange Canopy Gasket Canopy Canopy Insulating Washer 1/4” Fiber 1/4 -20 x 1” Lg Rd Hd. Screw Recept. Mogul Pre Focus Wire, Black/Tan or Tan with Black Stripe 16 AWG X 48” Lg. Wire, White (Tan) 16 AWG X 45” Lg. Upper Lens Gasket Tie Wrap Upper Tie Rod 3/8-16 Nut, Hex Hd Finished SST 3/8 Lock Washer Light Helical SST Upper Hinge Ring Hinge Pin 1/8 X 3/4 Cotter Pin Aluminum 1/4 X 1/2 X 40” Sealant Clamp Ring (Color Screen) #8 X 1” Screw-Thd Forming Type B Pan Hd SST Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 13 IF 1557 Rev 1 New 02/08 PARTS LIST ITEM NO. 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 PART NUMBER HL5844 CGB-396 QTY G QTY -H QTY C DESCRIPTION 1 Red Color Screen Connector 20Z47-001 1 #14-4 Cond. Cable 10A07-016D36 10046-2395X/2428-6 10046-2405X/2428-6 FL4276 FL8830 HL5819 41847 41848 10A07-025D20 10030-118 10G60-011D06 41849-1 FL2857 11C16-006A24 11A12-019D 2 1 2 1 1 1 1 1 1 1 IF 1557 10P26-016C 14D01-001 20Y01-001 10A07-016D12 14G04-040 10050-13 10050-14 10050-15 S0099 0601029 0601030 0601031 10047-2411 41813 10A07-025D36 3 3 3 3 2 2 Wire, Black or Tan with Black Stripe 6” `16 AWG 1 3 3 1 1 1 1 1 1 3 2 1 1 1 1 1 1 2 1 #8-32 x 1-1/4” SCR RD HD, Slot, SST Wire, White (Tan) 6” 16 AWG 1 1 1 1 2 1 1 2 1 1 1 1 1 1 1 2 1 1 1 2 Instruction Plate Hinge Pin (Rivet) 1/2-13 Eyebolt 1/2-13 Wing Nut Locking Device 1/4-20 X 5/8” Rd Hd Screw-slot, SST 1/4 Washer, Sealing #4X 3/16 Drive Screw Type “U” STL CD/CLC Nameplate Nameplate 1/16 X 3/4 Cotter Pin Aluminum #10 Lock Washer Med Helical SST Instruction Manual Speednut - “U” Type (Tap. Screw Thd) Vent, Snap-In Screen Type Lug Wire Pressure Type Srt. Connection #8-32 X 3/8” Screw Rd Hd Slot. SST Sleeving, Insulating Sil Rub. Treated Glass, FBR Lower Lens (Red) 3258-DH Upper Lens (Red) 3259-DH Top Lens (Red) 3259-DH Label, CSA Suffix Only Wire Assy Cover, Socket Terminals Cover, Socket & Terminal Block Sleeving Nameplate, U.L. 1/4-20 x 1 1/4” Long Round Hd Screw SST Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 14 IF 1557 Rev 1 New 02/08 PARTS LIST ITEM NO. 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 PART NUMBER 41853-1 41854-1 41855-3 41856-3 10000-474 10031-91 10000-475 10031-92 10037-799 10037-800 41811-4 FL347 / 1009- BH KL5509A / 2498-NH 11C12-018D32 10037-801 FL297B 41855-4 CGB-192 / 6764-D ML2025 / 0600050 ML4625 / 0600053 ML4626 / 0600053 10053-193 41849 QTY G QTY -H QTY C 1 1 1 1 3 1 1 1 Lower Hinge Ring Upper Hinge Ring Canopy Canopy Flange Screw, Hex Head, ½-13 X 6 1/2” Lg. Nut, Thin Self-Locking, Hex, ½ -13 Screw, Hex Head, 3/8-16 X 2 1/8” Lg. Nut, Hex, 3/8-16 Bolt, Carriage, 3/8-16 X 16” Lg. Bolt, Jig Latch, ½-13 X 2 ½” Lg. Base Yoke 2 Support 2 2 1 1 2 Spirol Pin, SST “U” Bolt w/Nuts, ¼-20, Zinc Plated Canopy Flange & Hanger Canopy Connector 2 #12 Single Conductor Cable 1 Wire Lead (White) 1 Wire Lead (Black) 1 1 Sleeving 36” Lg. Nameplate 1 1 1 1 1 3 1 DESCRIPTION Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 15 IF 1557 Rev 1 New 02/08 ORDERING INFORMATION CATALOG NO. 41257G STANDARD VOLTAGE FAA 120 230 120 LAMP TYPE (2 PER FCB) A B C 44389C-TH FAA 120 230 120 A B C 41257G-H FAA/NEC 120 230 120 A B C LAMP TYPE: WATTS VOLTAGE BASE TYPE MOG. LAMP NUMBER 10047-2543 LAMP LIFE (HOURS) 6000 A 700 120 B 700 230 MOG. 10047-2445 6000 C 620 120 MOG. 620PS40/1P 3000 Note: * - Approved Vendor for the HH273-620 Lamp is: H&H Industries, Inc. P.O. Box 735 Elmwood, Illinois 61529 Tele: 800-637-3853 Fax: 309-742-7071 Record Original Lamp P/N here: ________________________________ Cooper Industries Inc. Crouse-Hinds Division PO Box 4999 Syracuse, New York 13221 • U.S.A. Copyright© 2007, Cooper Industries, Inc. 16 IF 1557 Rev 1 New 02/08