Gavilan College AMT 100 Rigid Fluid Lines and Fittings Project

advertisement

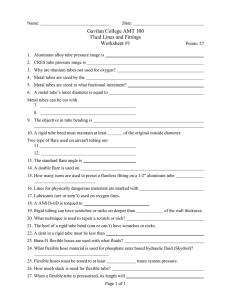

Name: Date: Gavilan College AMT 100 Rigid Fluid Lines and Fittings Project Objective: Learn the basic skills of rigid hydraulic tube cutting, bending, and flaring. Reference: AC 43.13-1B Par 9-30 Provided Material: 1. Aluminum tubing 2. 2 – AN818 Nuts 3. 2 – AN819 Sleeves Instructions: 1. Cut a 6” piece of aluminum tubing 2. Create an “S” with the tube by making two 90° bends in the tube, in opposite directions. 3. Install AN nuts and sleeves. 4. Flare one end of the tube using a single flare method. 5. Flare the remaining end of the tube using a double flare. The tube and fittings must meet the standards outlined in AC43.13-1B. Answer the following questions: 1. What is the flare angle used? 2. Why is a double flare used? 3. When is a double flare used? 4. How is a crack on a flare repaired? 5. What is the acceptable criterion for flats on the bend? 6. How are scratches and nicks, on the straight sections of the tube, repaired? 7. How are scratches and nicks, on the heel of the bends, repaired? 8. What is the acceptable criterion for scratches and nicks? 9. What is the acceptable criterion for dents? 10. What is the minimum bend radius for the tube used? 11. What are the torque requirements for the fittings used? Instructor signoff: Page 1 of 1