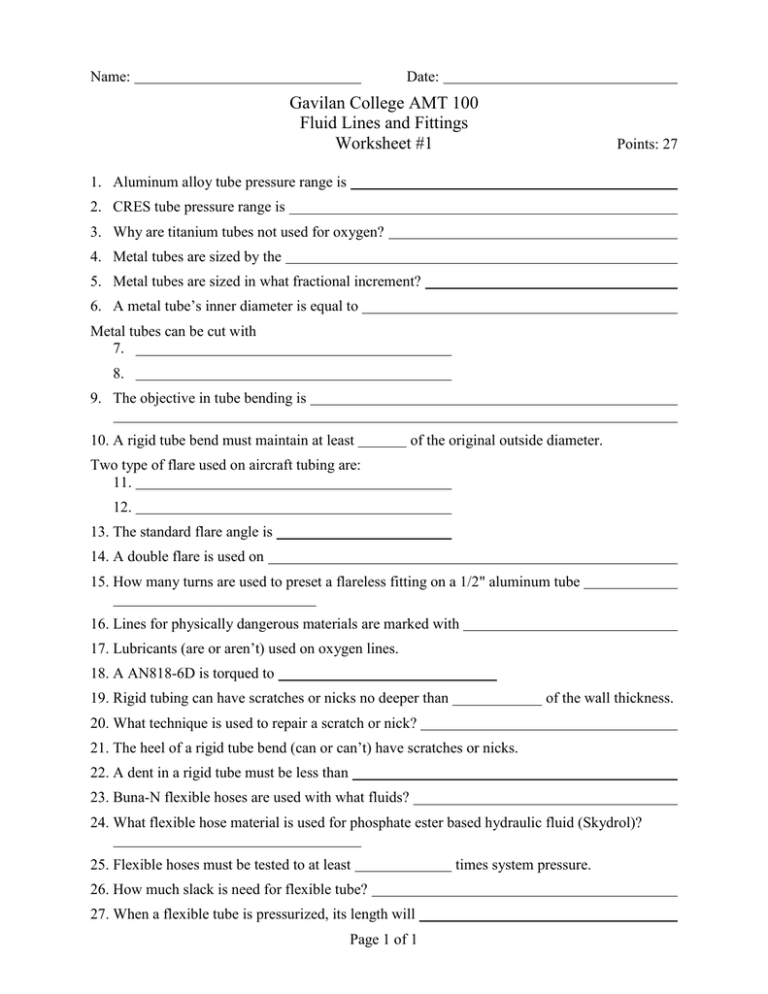

Gavilan College AMT 100 Fluid Lines and Fittings Worksheet #1

advertisement

Name: Date: Gavilan College AMT 100 Fluid Lines and Fittings Worksheet #1 Points: 27 1. Aluminum alloy tube pressure range is 2. CRES tube pressure range is 3. Why are titanium tubes not used for oxygen? 4. Metal tubes are sized by the 5. Metal tubes are sized in what fractional increment? 6. A metal tube’s inner diameter is equal to Metal tubes can be cut with 7. 8. 9. The objective in tube bending is 10. A rigid tube bend must maintain at least of the original outside diameter. Two type of flare used on aircraft tubing are: 11. 12. 13. The standard flare angle is 14. A double flare is used on 15. How many turns are used to preset a flareless fitting on a 1/2" aluminum tube 16. Lines for physically dangerous materials are marked with 17. Lubricants (are or aren’t) used on oxygen lines. 18. A AN818-6D is torqued to 19. Rigid tubing can have scratches or nicks no deeper than of the wall thickness. 20. What technique is used to repair a scratch or nick? 21. The heel of a rigid tube bend (can or can’t) have scratches or nicks. 22. A dent in a rigid tube must be less than 23. Buna-N flexible hoses are used with what fluids? 24. What flexible hose material is used for phosphate ester based hydraulic fluid (Skydrol)? 25. Flexible hoses must be tested to at least 26. How much slack is need for flexible tube? 27. When a flexible tube is pressurized, its length will Page 1 of 1 times system pressure.