From: AIPS 2000 Proceedings. Copyright © 2000, AAAI (www.aaai.org). All rights reserved.

Mixed,-Initiative

Resource Manage inent:

Marcel

A. Becker

+u,~t

Stephen

"[’h,’ lhA.,,~tic.-. Iusritul.,’

Carnegie M~,ll, m l’uiv,,rsity

5000 Forbes Av,.nu+, Pit t,d>urgh.

rob81 sf.sh,.s omu.edu

(412) 268-,’1811

Abstract

!n Ill[,. palwr, we drscrib,. Ihe Barr’<l..lll:,,’a£of,

:’..,.cheduling Leo[ drvt:lopt-d for day-to-day allocation m’d m",Jatagemrtlt of airlift and tmhker

l’t’,’.,.OllrC,’.’..,

ilt the [’SAI" .’kit" Mobility

{’<)lrllll~.~lld

(AMt’j. The syat, en.i utilizes ml illcrenmnt+~l arid

configura[~i,z con~trailit-l,a.-,cd ~carch frameworkto

pi’O~,iduar.;ttlgc of &UtOl|l,tt.t:d ;.u|d ~t:mi-,J.lit,)tltated

-whrduhng c;l,pabilities,

including generating an

initial solution It) the fleet assignmenl problrm,

selL.clive re-optimize!ion el resource allocations

uo i:lcorporare new higher priority missions while

nlininlizing sohlt.ion C]lallge,

mergingo[" previously

planned mission.-, t.o reduce non-productive flying t,ime, attd generation and synchronization of

tanker missions to satisfy air refueling requiremerits. In situations where all mission requirements calulot b(! incL. the system can generate

mlcl compareel.It ernalive constraint relaxation eel ions. The currrnt version of Barrel Allocator will

t

go illto operational use el. ¯AMC

as a module of

(-~[{Please 2.0 of AM. s Consolidated Air Mobility

Planning System (CAMPS) in early 2000.

Introduction

l’3li,’ient

allocation of aircraft and crews to transportation missions is an important priority el. the USAFAir

MobiLity (’omnmnd (AMC), where airlift

drmand must

increasingly be met. with less capacity attd at lower cost.

The A MC resource management problem presents

several interesting challenges:

¯ problem scale - Over a typical short-term (e.g., 2,

week) scheduling horizon, several thousand air ulissions are flown world-wide, utilizing

several hundred

air<’raft and active-duty air crews. In titles of crisis.

these numbers can increase substantially,

and additionally inwflve both reserve units and comntercial

aircraft.

¯ probletu c’.omplexity - Resources must be allocated to

missions in a way that minimizes non-productive flying time. attends to mission priorities,

attd maximizes

*Authors listed in Mphabetic order

(:opyright (~) 2000, American Association for Artifici,d

tcUigence (www.aaai.org). All rights reserved.

32

AIPS-2000

The AMCBarrel Allocator

F. Smith"

PA 15213

the nunlb,:r or" support,.d missions,whih. at i.lt,, sam,.

time rnsuring that decisions are fra.-+ibh’ with r,"Sl,,’<’t

to aircraft availability at,d operating ,’l,;.u’aetcri..,ti,’s.

crew ,t,ity clay limits, required mission :,x,cul ion windows.airport capacity and lauclitl..m.t.ittte r,’sl ri,’l ions.

and other mission ,:ot~str:.tit~ts. In ,’ase.-: wht.rv all ,’oustraints cannot be satisfied, sol[re may br select iv+.ly

rclax<..d +mdtradeofEs thus[ be LlJ.ad,: bctwv,.nt ah,,rua! iv<, opt ions.

¯ solution continuity- Like most pra,’l i,’al <lot[rains. rt.sourc,, allovation is sil.ual ed in a cent iutt,m..,ly ,.x,’,’uting r.llvironxnent.I’:a.<’h tim,. a rt’,’,~:,lUL’C¢’;L..-Sigliill,’ull iS

+

chaltged,

llQW orders Ill[IS[

bC’ r,’-cOIllnllllliC;Ll+’<l

IO th<

affected wings and r++-assimilat,,d into lo<’ally plalm,+d

m’tivitics,l-I,-nc,,, il ix ]llll)r+t’t;lllt

tt:, Itl;Itl:’lg,’

:|ll, I ztninin,izo solution ,.’]tange as now ,,issions ,r,. in,’,,rporated into the scheduh+ over time.

¯ interacting planning and scheduling prol31,:nts- I:ll’t.ctire allocation of resour<:es requires a tight interl+lay

of planning and schedt,ling capabilities.

By ,h.fm.th,

missionsart. i)lanncd a.s round trip el)[.rations and

eacli assignedaircraft returt,s to its homebast, upc,n

comp/etio||. [lowever, lift capacity can ,.~fteu I., incroas<,d by contbinlitlg two or moreLnission.s :tttcl "’r,.’cycling" l.ho satlle aircraft front one ntissi,.m I,, uh,,

nrxt. Aht’rnatively. a l)lanno, l airlift missi,.,u nlmy r,,quireairrefueling,

hl thiscase.tatuker

capa,’it.y

mtust

b,+~sourced, and a slipporting

t, al’lker

missioJt must I)i,

generated

and sym’l’m:mized

in tim+,.

Duo t.o the time pressure of decision-m+~king

and tit,.

lack of autotnat~’d scheduling tools, Ihr AMC."’Bartel Masters" responsible for tnakittg allocal.ion decision~

typically make allocation decisions in a litttilrd,

myopic

fashion and routinely miss oplmrt unities to opt imize r,:source usage.

In this paprr we descril~+, 13arr,,l All,~,’at,Jr.

a t,~ol

for generating and evaluating such optimizat ion ol>portunities.

Dev<,loped through applicalion o[" thr ()zon,

scheduling framework (Smith ct ,l. 1990; Ik’<’k,.r 1998).

Barrel Allocator utilizes incremmlt el, con.,,l.raiul-l.mso,

I

s<’heduling techniques to allow integration of n,,w tnissions and response to changing requirements arid availability,

while minirnizing disruption to most previous

From: AIPS 2000 Proceedings. Copyright © 2000, AAAI (www.aaai.org). All rights

ally reserved.

specify which wing they

assignments. In situations where all constraints cannot be satisfied, the Barrel Allocator’s search model

promotes selective constraint relaxation to find an acceptable solution..Mission scheduling and resource allocation capabilities can be invoked in automated or

semi-automated modes; in the latter case, the system

generates and compares different options that might be

taken by the user.

Experimental results with Barrel Allocator, obtained using historical data extractcd from the current

ADANS

airlift planning system indicate the potential

for substantial improvement in resource usage, through

better optimization of air wing assignments, selective

combinationof missions to efficiently "r~,cycle" aircraft,

and more effective integration of tanker and airlift missions. Following positive review by AMCpersonnel, a

version of Barrel Allocator has been delivered to the

Tanker Airlift

CommandCenter (TACC) at AMCfor

extended user review and testing. Current plans call for

Barrel Allocator to go into operational use withill the

"I\a.CC early next year as part of release 2.0 of AMC,’s

Consolidated Air Mobility Planning System (CAMPS).

The remainder of this paper is organized as follows.

Wefirst briefly summarizethe Barrel Master allocation

problem and current practice at AMC.’this is followed

by an overview of the functional capabilities provided

by the Barrel Allocator tool. In the next two sections,

we discuss the underlying representations and search

procedures that provide the system’s technical basis.

Wethen provide some details on the status of the hnplementation and technology transition effort. Finally,

we discuss some planned extensio~ls.

The AMCBarrel Master Allocation

Problem

The AMC"Barrel Master" (or Barrel for short) is

charge of resource allocation and resourcc management

for the USAFAir Mobility Command. The different

planning offices at AMCsubmit resource allocation rr~

quests to the Barrel in the form of missions or lnission requests. Thcse missions represent, for example.

requests to move cargo and/or personnel, or requcsts

to reserve resources for a numberof training activities

and exercises. Althoughdifferent types of missions create different types of resource requirements., all planned

missions specify a particular type of aircraft to be used,

an itinerary, a priority, a preferred air force unit or wing

to fly the mission, and a time period, represented as a

set of dates, in which the mission should be executed.

Each Barrel manages particular sets of aircraft and

corresponding crews. These ~ts are defined by aircraft

type and by the geographic locations where the aircraft

are stationed. A set of aircraft, of the same type stationed at a particular air force base constitute a wiT, g.

For example, McGuire Air Force base has a wing of

C141s and a wing of KC135s. Currently, one Barrel is

responsible for all west coast C141s and another Barrcl

is rcsponsible for all east coast C141s. Planners gener-

would prefer to fly a givcn

mission, and when possible, the Barrel will allocate a

plane from this planned wing.

The mission itinerary is the sequcnce of stops or airports the aircraft should visit during the exe,:ution of

the mission. Werefer to the flight between two successive stops as a mission leg or just a leg. Eachleg has an

origin airport, the Point of Embarkation (POE), and

destination airport, the Point of Debarkation (POD).

Each leg is followed (or preceded) by a certain ground

time. During the period the aircraft is on the ground,

a nmnber of activities, or g~wmdevents, can occur: for

example, loading and oflloading of cargo, refueling, crew

rest, crew change. The time period specified ira tile ntission request should be at least as large as the time required by the aircraft, to fly between all intt’rmediatc

stops in the itinerary plus the required ground time at

each airport. The Barrel will try to assign one air,:raft

that is available during this entire period. The earliest

date the mission can start is called the Available to Load

Date (A LD) and the latest date the mission should finish is called the Latest Arrived Date (LAD).The length

of this intcrval should be at least as large as t lw total

duration of the mission.

Aircraft availability is defined for eaclt wingon a daily

basis. Each wing has a total number of aircraft of a

particular type. Considering that sonic planes ar~, undergoing maintcnance and the wing has some need for

training and local missions, the wing will make a subsct of all its planes available to AM(’. missions. Each

day, each wing will provide a certain number of conhuct aircraft that can be allocated by tire Barrel. The

remainingaircraft, designated as fenced aircraft, arc: reserved for local wing use and are beyo,ld thejurisdictio,

of the Barrel.

In her/his daily activities,

the Barrel Master currently managesresource availability using a ~’omT~itmerit matrix. This matrix tracks available aircraft c~,pacity of different wings over time and records those

missions already allocated. As ucw missions are r~

ceived from various planning offices, the Barrel consults

this matrix and tries to allocate r~.sources which satisfy

mission requirements. If all requirements can be satisfied, s/he makes the aircraft assignment and communicates mission commitmcntback to the planner. In those

cases where there are insulficient resources available to

support a particular set of missions, s/he will consider

more disrupt]vc allocation alternatives. For example,

s/he will considcr using resources already allocated to

lower priority missions or will cot,sider using resources

provided by a different wing. Once one or more acceptable options are found, the Barrel communicates these

possibilities back to the relevant planner and a solution

that wouldbest satist~" all sides is negotiated.

Thc AMCBarrel Master problem is similar to tl,e

problem known in the ORlitcrature

as the Fh’¢l Assignment Problem: Given a schedule of flights defining

the departure and arrival times for each fly leg, the Fleet

Assignment Problem is the problem of deciding which

From:

AIPS equipnmnt,

2000 Proceedings.

Copyright

© 2000,

(www.aaai.org).

flight

or fleet,

should

be AAAI

assigned

to each All rights

In reserved.

all cases,

flight segment (Barnhart ,’l el. 1998; L.W. et el. 1996:

R.ushnleier and Knotogiorgis 1997). The AMCBarrel

Master probhun addressed by the Barrel Allocator is

a dynanai,’, string-bas,.d version of this problem. For

commercial airlines, the objective is to maximize revenues minus operating costs. The Barrel Master tries

to maximizell,e total sum of priorities: s/he will try to

assign the maxinmm

re,tuber of high priority missions,

a, td would only consider assigning lower priority missions after all higher priority ones have been assigned.

Tl’aditional OR-basedsolutions to the fleet assignnmmproblemassign fleets to inclividual flight segments.

The Barrel. alternatiw’ly, is concerned with assigning

fleets to a sequence of segmentsor slrings. A slring is a

SeCluenceof conneclecl flight. Sogl,,el,lS

that begins and

ends at possibly d ilferent maintenance stations (B;rrnhart el el. 1998). An AMCmission itinerary is typically planned aa a string that starts and ends at the

seine location (i.e.. a rot,nd trip). Strings that start

awl end at the same station are usually referred as aircroft rotations. If possible, the Barrel would consider,

anti so]not imes even I)refer. using t he same total.ion for

more that, one mission. The di[ficulty in combiuing

missions is in identifying the opportunities for potential ,’ombim~tions amongthousands of missions in the

database.

The hlarrel Ma.ster in charge of refueling resources,

the "l’ankt, r Barrel, in addition to allocating t.ankors to

planned air refueling missions, is also responsible for

linking air vefuelin 9 events with regular airlift missions.

Anair refiwling event is a request for a refiteling mission

that is generated each lime a planned airlift mission requires air refueling. In the data repositories currently

available, there is no explicit linkage betweenair refueling eve,,ts and the missions Ihcy ~Lre supposed to serve.

Thus. the Tanker Barrel currenl,ly has t.o perform this

linkage by manually searching the database for airlift

missions that matches the location and time of air re,fueling events.

The allocation process described in previous paragr;~phs is currently mostly manual. The Barr~q Master uses ~t system lhat provides an electronic commitmeat matrix at,d is linked to current aircraft availabilil.y and mission data. However, resource assignment is

performed one mission at. a time with little automation.

Capabilities fi)r identi~.’ing tnission combinationopportunities are quit~, limited and ~s just meutioned there

is no sysl.em support, for establishing linkages between

tanker and airlift rnissions. The Barrel Allocator system described below aims at automating some of these

tasks and enhancing t he decision-making capabilities of

t.he Barrel master, while still granting fifll control and

visibility over tl,e dc.cision makingprocess.

Functional

Capabilities

The Barrel Allocator provides three core sets of fuactionality to the AMCBarrel Master: n:souwe allocalion, mission combination, and air refueling linkage.

34

AIPS-2000

functionality can be utilized in a more

or less automated fashion, ranging from a fully manual mode where the system does lit.tie

more than decision bookkeeping, to a semi-automatic mode. where

the system generates alternative options and previews

their impa,zt, to a completely automatic mode, where

the system determines selects the best decisions based

oo user-specified preferences. In the paragraphs below.

we first summarizethese core functional capabilities.

In subsequent sections, we then discuss their tm’h,ical

basis.

Resource Allocation

In a typical modeof operation the prol)lem is one of

integrating sets of newly planned missions into an existing current global schedule. In this mode,tl,e ~chcd,I,r will attempt to assign aircraft and schedule new

missions without disrupting the current set of assignments. Any mission that cannot be integrated into the

schedule in this way (which implies that there is not

enough lift capacity to accomplish the mission without changing exisling resource assignments) is flagged

as nnassignable and will require subsequent ,s,.r attention.

The assignment of wings to new missions can be performed in manual or automatic mode. The userselects

some set of unassigned missions, the alternative wings

to be considered fortl,ose missions, and the system will

,:,)inlmte all feasible allocations. In rnanual mode.t, he

application displays all ft, asible solutions and the user

can select the preferred one. In automatic nmde the

system selects the best allocation based on some vser

defined preference. (for example., try to us,. tl,e wingthe

minimizes ow’rall mission time weighted by priority).

The allocation process produces an assignment of (notional) aircraft froLn specific wings to each mission, and

an assigmnentof flight times to each mission leg. If t l,.

locations corresponding t,(,origin and destination of the

mission are different from the location of the wing providing the plane, positioning and d,.-i)ositioning Ilights

will be added to the itinerary.

Currently, the following constraints are taken into account and enforced in consl.ructing a schedule for all

current missions:

Wing capacity coastraints

- Assignn,enL of ,nissions to wingsdoes not exceed the m,tnber of<’ont ract

aircraft available at each wing.

Mission time requirements

- Missions must be

scheduled within time windows designated by ALD

and LADco,straints.

Enfi)rcemcnt of required ground time - The allocated time ;~:counts h)r aircraft onloa~t, otfload and

minimumtime-on-ground constraints, each specified

as a function of aircraft type. More generally, it is

possible to specify a range of different flight preparation activities and tiv,e constraints.

Flight duration constraints - flight duratio,, cat,

From: AIPS 2000 Proceedings. Copyright © 2000, AAAI (www.aaai.org). All rights reserved.

be specified as an input data or is computed using

great circle route

Aircraft

range constraintswhich are enforced

when determining specific wing assignments (and

hence when creating positioning/de-positioning

flights)

Crew duty day constraintsDepending on designated crew type - basic or augmented - crew rest

is inscrted at appropriate intermediate points of the

mission to enforce crew duty day.

As suggested above, it is not always possible to satisiS" mission time constraints with existing available lift.

capacity. To support resohltion of such situations, the

system gives the user the ability to analyze and compare various constraint relaxation options. Specifically,

for any given set. of uuassignablc missions, t he user can

choose to:

Allow bmnping of lower priority

missions Every mission has a pre-defined priority. If there

is no aircraft available to support a high priority

missiom one ahcrnative is to pre-empt lower priority

missions already in the schedule. Any pre-empted

missions arc then rescheduled in succession and they

may. in turn. pre-empt missions of lower priority

still. At quiescen,:e, any lower priority missions that

cannot be be re-inserted into the schedule within

its constraints are added to the unassiguable list. h

mission locking mechanism is provided to allow thc

user to avoid bumping any specific, lower priority

mission. A fivem, interval,

a period of time in

whi,’h no mission can be bumped, is also enforced.

The freeze interval is required to avoid schedule

turbuh’m’e close to execution.

Over-allocate - Since the number of contract aircraft

is usually smaller than the total number of possessed

aircraft., the user mayalternatively choose Io go over

the published contract level of a given wing. This

happens with a fair anmuntof frequen,’y. It typically

reflects extra knowledgethat. the barrel master may

have about wing assets or agreement on the part. of

the wingto use fen,red aircraft.

Delay the mission- The user may consider the option of delaying the current mission until necessary

resources are available. If delay seems like a potentially viable alternative then this information ,:an be

suggested to the mission planner. Mechanisms for

limiting the amount of delay acceptable and combinations of delay and bumping, and delay and overallocation are also supported.

Use alternative

MDS-Similarly,

it might be possible to accommodatethe mission if an alternative

airframe type can be utilized.

Any of these options can be invoked by the user in

"what-if" mode; a general "undo" capability allows the

retraction of any sequence of scheduling actions that

have been issued by the user, and thus provide a basis

for exploring alternatives. Alternatively, the user can

ask the system to generate all options and compare alternatives. This range of scheduling modes provides a

continuum of scheduling actions that are progressively

more disruptive in the changes that can be made to the

current schedule. There is no formal metrics to compare

alternative relaxation options. Each option will havc its

own disruption metric (e.g., anmunt of resource overallocation, numberof hours late, numberof lower priority

missions bumped). The user is currently responsible for

evaluating and selecting the best alternative based on

his/her ownsubjective criteria.

Mission

Combination

Missions are planned by default aa round trips from a

particular homebase. If the origin and/or destination

of the mission does not coincide with this base, positioning and depositioning flights segments ar~ added to

the mission itinerary. To improve resource utilization

and increase aircraft, availability over time, the Barrel

Allocator provides the capability of exploiting mission

coml)iuations: it will look for opl)ortuuities to link two

missions su,:h that after the end of one mission, the airplane will be "recycled" and redirected to ~upport another mission instead of depositioniug back to its home

base.

The mission combination capability can be used as

an alternative allocation policy to allo,’ate unassignable

missions or as a compression mechanismto increase the

number of airplanes available over a certain period of

time. The user can select or filter the potential n,erge

candidates using three different parameters:

Maximum layover time - the maximum time delay

that can be tolerated between offload (end) of Ol,e

mission and onloaxl (beginning) of second mission

Maxinmln distance-the

maximum distance

that

can be tolerated betweeu location of first missions’s

of Iload and second’s onload

Percentage decrease in overall flying time - the

reduction obtained by combining two misbior, s into

one aircraft, rotation comparedto flying both original

round trips.

Air Refueling

Linkage

’lb support the "additional responsibilities of the Tanker

Barrel, capabilities are also provided for generating aud

assigning tanker missions to airlift, missions that require

air refueling support. A set of refueling events is accepted as input, aaad tanker assignments can be generated either interactively or automatically, lu atttomatic

mode, the scheduler first attempts to link tanker missions that are already included in the schedule (e.g.,

training missions); tanker wing assignments are determined and tanker missions are created for any remaining unsupported airlift missions.

In interactive mode, a map-based display is used to

indicate candidate refueling tracks that are already covered by tanker missions in the temporal iuterval re-

From: AIPS 2000 Proceedings. Copyright © 2000, AAAI (www.aaai.org). All rights reserved.

quired by a given airlift mission. The user call selc.ct

one of these highlighted r~fueling tracks (potent.tally

changing the originally phmnedrefueling location) or

select the planued track (which will result ill t.he creation of a newtanker mission if one is not already ill I.he

schedule). In the ca.se of the selection ol’a pre-existing

lanker mission, the system will also present opportunities to support multiple air refueling events with the

same tanker mission (provided that fuel reqtfirements

mtd tanker fnel capacity ,-onsl raints are sat isfied).

Problem Formulation and

Representation

As indicat.ed at the outset, the Barrel Allocator has

bee. developed through use of the modeling primitives

and class library defined in the Ozonescheduling framework. I)evelopment of an application system in Ozone

involves three basic tasks:

I. Ideal.tidying l.ho outological entities in the domainrelevant 1.o the application donmin.

2. I)efining and &’veloping a domain model, by mapping the problem spe,’ific oat.elegy onto the Ozotw

scheduling ontology,

3. Instantiating and/or ext.ending Ozone probleni solving templates to address tile set of relevant constraints.

In this section we describe the Barrel Allocator’s domain mo&l. In the next, we consider its problem solving procedures.

Ozone domabJmodels are defined in terms of live hasic entities (Smith and Becker 1997): demands, actit:itics, products, resoutr.’es, and ,onstmints. The mission

requests sent. by the planners to the Barrel correspond

to the demands. They are used I;o t.ransla~e the exter,al requirements specified by the user into thn internal constraint model used by the scheduler. The

bmsi,: attributes of the mission request art’: a pair of

dates establishing the earliest date the mission should

start and the latest date it should finish; the type of

aircraft and preferred wing providing it; /lie missioxl

priority (which imposes a partial order on the set of

missions); the itinerary or set of flight segment.s the

mission should fly; and the mission type. The mission

type is the product (i.e., service) of interPst. Satisfaction of a mission request, implies that a certain type of

service has been provided, andthe produ,:t is the atttity

t.hat represenl, s this service within Ozonemodels. Services are provided through the execution of activities.

The flightsegments,or legs, and groundevents

aretheprincipal

types

ofactivities

inthisdomain.

Ear’[~

typeof mission

imposes

special

constraints

on howthe

activitics

shouldbe performed.

Forexample,

refueling

missions

andfuelsupplymissions

require

special

typcs

of resources and temporal synchronization between sets

of activities. Twospecial types of flight segments are

the refueling

leg and the fuelsupplyleg.The refueling

legcorresponds

tot.hem’tivity

ofreceiving

fiwl.

36 AIPS-2000

~nd the fuel supply correspondst.o one (,f providi.g fu,:l.

Suchproblem-spc.cific knowledgeabout the (’oiler r;tinl.s

associated with different mission lylws is encoded into

the product entity and ,s,.d d,ring it,s(:-mii;~ti,,n

:rod

scheduling of nfission ~wtivit.ies.

A flight

segment

a,’tivity requires lbur dill~.r,:ut

types of resources: I,h++ aircraft, the l.wo airports

correspondillg t.o origin and destination of tl,. Ilight,

and tile air crew. Asso,’iat.ed with ea,.’h resour,’,, is

the notion of <’almeil.y: the alH<Jnlfl or quantify ,,f a

<’ertain t.ype of unit, that is availabl,, overI.inw. Airt’raft

availability is definedat. the t~ggregalofleel level. AII<,et

or wing is a pool of aircraft of the same t.yp,. I,:’ated

at a ccrl, ain geographiclocal.ion. Ea,’h ai,’,’,’aft it, a

wingrepresents o,e unit of capacity. ’l’lw tot.al nmi,I),’r

of aircraft I,Mongingt.o a given wing delim.s its tol;al

capacity. Since each plane can only tly on,. luissit,n

at a time, tile tot.al capacity [s the lllaxiliillitt

re,tuber

of mi~qionsflint ,:an 113’ simuhan,.,ou.qy tit any given

time. Thetotal ¢’;~pa¢.’ity ,,f the wingis divi, l,,,.I it,i,,

I.wo subsel.s: I.he contract capacity, relJrc..,enting tl,,’

set of planes available to support AM(’missi,ms, and

lhe fenced capacity, represenliltg the .,,el ,,1" Id;Ul,’s

reserved for local missions and ,’armor I,,., u.,,.d hy llw

Barrel in normalcircumstal,c~,s. Weonly ,’h,~,’k "airport,,

for airplan,’ compat.ibilityr,,stri,’tio..,..q.’Ul)l,,)rt fi,r air

crews is not curret,tly supp,~rted and will b,. in,’h,d,’d

in the next version of Ihe systen~.

Resource capacity is defined ov,.r capacity

intervals.

Ea~-h interval has start, and end tirnes.

and vah,es for total, contr;u’t, fen,’t.d, and et, rn,ntly

availabl,- capacity. Tit,? end time is u.lways larg,’r than

the start time and the nfiniml, msize of an interval is

one time unit. Time is rel)resenle, I conlinu,,usly Io

the granularity of lhe time unit. For ,’xanil)h., Ihe

Barrel Allocator uses minules as t.lw. tim,: gran,la.rity.

Therefore. the minimumdistance Iml.w~,en two tin,.

points is one minute.

The o,tput of the Barrel Allocatc, r is a s,..t of

resourceassignmentsor resourcereservations:

tuples of the form (Mission,Wing, start-time,

end-time),

rl’his rneans thai ntission Mission

is r,’serving one unit of capacity of resource Wing during

the time interval starling at start-time and finishing

at end-time. The duration in nfinutes of this interval

the dist.a,ce betweenstart and t,l,<l tim,.s, is ,.qua[

to the total mission ,lur~ttion. This duration inchld,.s

tile duration of all ti,: flight segments, pl,s required

time tbr all ground e.vents. As we will discuss in /lie

next section, different constraints mayI)e satisli~.d by

this assignment, dependingon the set of parant,A.,,rs selected by the user while act.ivating a particular pml’,l,,m

solving metl,od.

Problem Solving Methods

The planning and schedulin¢,eY procedures used to provide various fimctional ,’apabilit.ies within the Barr,.,l

Allocator are instantiations of ba.si," searct, methodtemplates available in the Ozoneschohtling framework, lit

From: AIPS 2000 Proceedings. Copyright © 2000, AAAI (www.aaai.org). All AssignMissions{Unassigned_Missions.

rights reserved.

config}

While Unassigned_Missions is not empty

Do

/

\

¯

I

.../

Evalce~m

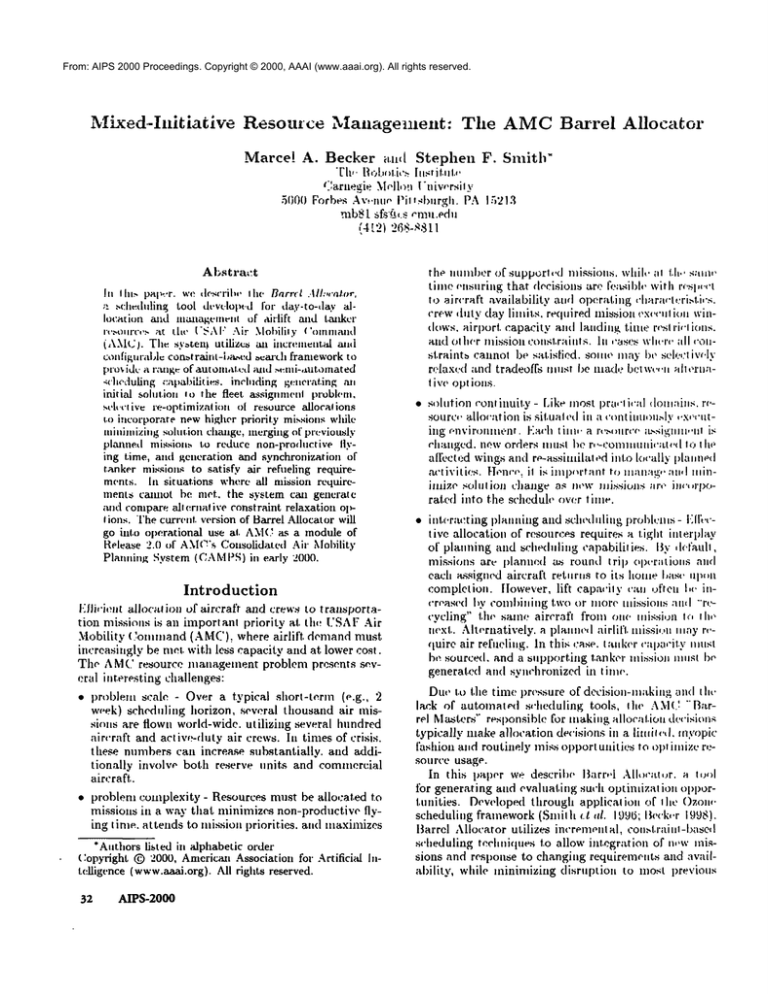

Figure 1: Basic search procedure tbr resource allocation

(assuming that mission being assigned requires C141

aircraft with earliest pickup at ll and latest delivery by

t2).

Ozone. search templates are only partially instant.iated,

producing t)arameterizable problem solving procedures.

These procedures can be dynamically config||red to provide different search behavior as the problemsolving situation dictates. In the subsections below we describe

these core procedures and how they art, composed to

produce user level functionality.

Resource Allocation

The central function supported by the Barrel Allocator

is that of assigning planned missions to w i ngs over ti me.

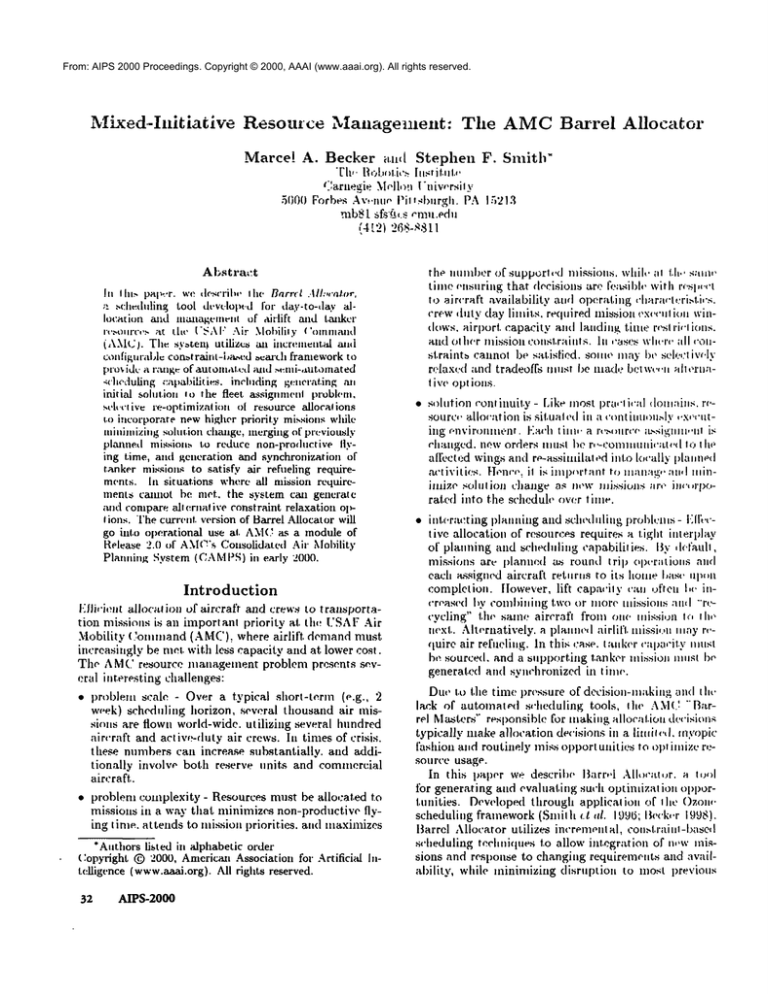

Figure t graphically depicts the general search template

used to make this assignment for a single mission.

The search procedure proceeds in 3 steps:

1. a set of candidate resources (wings) is generated,

2. for each candidate wing, a set of possible allocation

intervals is generatcd, and

3. each <,ing, allocation interval> pair is evaluated and the highest ranked candidate is selected.

As implied by Figure 1, a fidi instant[at[on

of

the AssignMission search procedt, re is obtained by

specifying three components: a search operator for

generating candidate resources (referred to generically as GenRe.sources), a search operator for generating candidate allocation intcrvals (generically called

Gt’)~lnter~ats). and an evaluation metric (Evalcrm#ion

for ranking ahernatives. By parameter[zing the procedure ¢o operate with different sets of operators anti

evaluation criteria, resource assignments can be generated and evaluated under a range of different constraint

relaxation assumptions.

In the most basic case, AssignMission

is configured

to search only for feasible assignments, i.e., <wing,

allocation interval> pairs that are consistent with

the time and resource requirements specified by the

mission and are also compatible with the assignments

Extract a mission Mfrom Unassigned_Missions:

If AssignMission(M, config)

Then Mark M as assigned

Else Mark M as unassigmlble:

EndWhile

End

Figure 2: Overall Mission Scheduling Procedure

oi" previously scheduled missions. This feasible configuration of AssignMission

is obtained by incorl)oralion of the triple < (~enit, questedRrs, GCnPea,.iblL.Ints,

E~’alMinFlyingTime>.

Here, C,t:nReqnestedRes

gclleral.es

candidate wings consistent with aircraft type reqttested

by the nfission. Likewise,(;e nF,.~.~ibt,:tnr, scans a candidate wing’s capacity profile for allocation intervals (I)

with at le~Lst one unit of available capacity (i.e.. an aircraft.), (2) with a duration greater thaal or equal to

time req|,ired to ac,rOml)lish the mission (a function of

mission itinerary, aircraft, speed, wing’s homebas,’ location, crew rest r,,quirements, etc.), and (3) with starl

al,d end times that satisfies the mission’s earliest onload time and latest off-load time constraints. (’anti[dates are differentiated on the basis of total flying tim,,

and tht’ candidate assignment that minimizes this inettic is selected.

By selectively substituting different se~trvh operators

and/or evaluation criteria. AssignMission can ah ernatively be used to fi,d assignnwnts under various relaxed

problem assumptions. For some types of constraints.

relaxation simply implies the consideration of a dift~rent discrete set of options. For example, substitttlio,,

of eenAIternatit, eilts for Ve~tllLqut.stedR: s resull.s in generation of assignments that consider types of air,:rat’~

other than the type requested by the mission planner.

For other classes of constraints, however, relaxation is

more continuous in nature, and in substituting a search

operator that assumes constraints can be relaxed, the

search must also be biased to promote their satisfactiun

to the extent possible.

By varying the operator used to generate ;dlocatio,

intervals anti the evaluation metrit" used to prioritize

candidate solutions, a :mmber of useful AssignMission

configurations are defined:

Delay - Incorporation of t he triple <Genn,~,,~,t,.du,,.

(]CnDelaylnts, ~’l,’tllMinTardincss>

yields an assignment procedure which assumes that mission deadlines can be relaxed if necessary. GcnD..layl,ts uses

the same mechanismused by GenFeasibtel,,ts but considers a larger portion of the candidate wing’s capacity profile, and El,’ul:’~fin’.l"ardiness

ensures that t.he

mission deadline will be relaxed to the nainimunl extent possible

In this configuration advantage can I)e takel, of the

belween Copyright

seardl operalor

;rod(www.aaai.org).

evaluation All rights reserved.

From: relationship

AIPS 2000 Proceedings.

© 2000, AAAI

criterion to effectively constrain the number ofcatldiclare solutions generated. For ex;~mple, hy s(:atming

forward ill time t.ilroligil

U. resource’s capacity profih,.

Ihe Ill’st, interval with available cap;~city foum.l will

I., tho ¢,u, ~ thai lnininLizes delay for that resource.

If this approach is tak~n only one interval need be

g+i,,raled for e+wl] ,’audidat.o resmw(’,.. In ,>l.h,~r C(JILfigural.ions (e.g.. I.lit, pre-,ml,tion case below), wh<.’r+,

there is Ito such donlinan<:+, condition for constraintug soluuion gent..rm ion. tlloro a,l-ho," heurisl.i<’ <.utolr.s

<’till l," used.

()ver-alloeatc: - The

triple

<(Tt ttRf,,lucst ~ ,iRes,

(;enO,,.rlnt+, I’+’l’al.W~,c)c. erl:.,.+:],.> <-]¢fine8 an a.,~sigillllplil

proce, hlre where ca.pacity constraints al’p

relaxable. G¢no,,,.,.+,t.+ scans file cap+wily I)rofile of

a cmldidai.e wing. I,ut, g<.nrral, es allo<.’iuion int.erv~l.-,

that exl<’ltd al)ov,: th<" wittg’s "’<:ontracted" level (i.e..

,lipping inlo ils Io,’ally n,s,.rved or "felwe, t’" pool

uf aircraft cai)acit,y ). Ecal.,lli,,o7 ert’s,l:lt, prOiliOt.e~S

s,.le,’t i, ,n of t.h~’ geueralt,d alloc;d.iun inl.erval ll,;,i

lllinintizt.s the I<’vel of nv,,r-atlo,’ation.

lit this ,’its<:. ituL×inlal inlervals at dill’<’r<’nt

over-idlocat ion ,:an I,e ~’ffi,’i,’ntly

generated

+,;i.r scanof the l’OSt)urce’~,’;qiacit.y profi[<:,

sequeul.ly prllned to tnininiize the teinporal

over-allocai ion.

10:vols ¢,f

via a linaudSLLI)extent of

Priorit.y-based Ilro.-i’.lnptiollA

COllligul’atioll

whicht~SillliC..’-i that semi’nllliib<2r of Im,Vlouslynlad+..

a.~sigilnlent.s (’all b<’ relaxed (or disrupted) is ch’lined

by Ihe triph, <(;cl/Hrqu t,qt;dl-les,

(;¢’;gBa,il,

htts,

El:al.w~.m,,.i,

pt;,,,.,>.Tiffscon[igllral.i(lll inipielllents

a. fern< of I)re-ellil)lion,

basedon liiissioti

priority.

hi sc~uniing a candida.l.t,

wing’s Cal)a,’h,y profil,,.

(/cllBu,,q, lnt.+ considers capacity (:urrently allocal.ed

i.o lower prioril x., inissh)ns ~ available for assignnienl,

al,d geu<.,ral.es all,><’ation intervals Im+ecl on I.his assuinptinl~, li’vaIMinDis:.upti<:n

pronlotes allocation

hll.el’ValS that <lisrupt the fewest nlissiolls and Ihos+

with the lowest I)riorhv. This nlhiimizes the ca.s,:ading eftk, ct (since any mission that is prt~eillptt.d

by

a higher priority nlission is rectlrsively

re-scheduh,d

ushlg the same proc<’duro).

Gh’en the conlhhia.torial nuint)er +if allo,’at.ion iutervals iuld possible sets of bull<peel nlissiotls l.hat can

I)+" generated vi,’t a coulplete capacity prolilo scanniug procedure (O(e.r) where e is the ,:apa,:ity of the,

resource and f is the dur++tion of <’apacil.y profile

fragulents), our ,’urreul imph:nientation utilizes a [hleltr. hell risl ic sa n ipling st riltegy (O(cf)) COlillmtible

with EcalMi,tDi,,,.,,rtio,t.

Briefly. allocation intervals

;tre generated by single forward scan through Ill<’ resource’s cap~’ity prolile over the time interval where

capacity is required. At each tinie point encountered

duriug the scan. I, he set of pre-enlptalJle niissions is

,’oillputed. If uotl-elnpty, I.h,’ currellt alloeat.ion interval is extended by (I) <’OiUlml.ing the subset of preeliif~tal)h, nfissions of lowest priority an,I (2) sel<.cting

38

AIPS-2000

[.’igure :|: l~xplol’atiori of ,’on.-,tt~hil, r,.laxalion ol)l.i,,iis

using configural)lc, lssignllssion

l)ro(’t.thn’<..

I.he niissioit in this subst’t wil.h niaxilnal finish t.inte.

Coniposl/(; Relaxatlolis - (’onlp, m,,ili.s of ih,’ ;tl)ovl’

1)aso

<.’onfiguraliou~

c:-in :llso [.,e ,’,lllll)(.,,~t,tl

1,, ,l,,tin,’

conliguratiolls t)t" hssignXissioawh,,r,, illull il,h’ ,’OlisLrtfints are siinultan,,ously relaxed.

lsstgnX±ssion

(iii all)’ o1" t, he coitligliratinils ,h’s,u’ibedabovc’)canbe apl)lie,.l it) ally .,>t,h,cte, I s,,!.

Inissions vit~ the hssignl4issions llrocochll’< , given in

,, the

Figure ?. Within this CSP-slyh, search llrot-+,dtil’t

curro.nt, iilllllt.’nlenl,il,

lion nsesmissionI)riority aLid lal.,.~+r d,.Ih,ery dale as a heurislic basis for lilissi¢,ii s,,iecl.ion (i.e.. variable¢,’(lering). hipul niissions,’.it’,, sorl(.tl

on this basis +llit] hss±gnllission

is tlmll s<,Clll<,lllially

al)pli,-d to eacil to alloct+te requir,,d rescllii-<-es (ilSillg

wliicll<wer of the ahoy,, c,)nliguraliOus as I)e<.ii ,l+,siguated).

In caseswh<,roa giveui,d,,>.sion hasnufi.asible’, assigli-.,

III<’IIt.S

([.<’., AssignMission(M,

feasible)

is ;qq+lied

and returns no solutiori), all exploration or" pnssihl+, relaxation options can he condu,:l.ed through r,’l)eale, I al>pli,’ation of Assign~ission in di[l’<:r,:ut Collliguralions

(as depicted

ill l-’Jgure 3). Autolnalioti of I[iis i)rocess

i’<,quires a gh)ba] 0valuat[oli criterion siiilal.)le I’~,i" r,’laling opt.ions generaledai-i’oss di|lTi’enl iliv<,caliOli.~ of

hssignMission

(e.g., so<lie liie¢"lSlll’l,

tit" ov,.rall b,:nelit

lind cost). In the current inll)lonleuial.i(~u,

this pr,lcednre i,,, usediu w]i~t.-if nioclo to gel<oral,, all++rlull.[vv

optious, a, iid the iiser l’mr[’oi’iiis the ,,vahl;lliOli ai,l selecl.ion.

Mission Combination

A second ,:ore I’unclr, ioli provided hy the I~;~rrel AIIo,’ator

is mission couibinal.ion, a c~qmbilii, y quite analagous to

Iho mergiugof shnih~rjol)s in a job shol.)lt~ r,,di.tce selup

costs alid [iicrease resource;.wailabil[ty. Tit, hlillloiiieni;d.ion of this calmlfility exl.en,.Is the ha.sic ternlJl;ll.,, pl’¢sented in the previous imragraphs, Collpling tilt. t,xt,t:’tllion of a "planning" compo,,,nt that computes -ill,’,t’l~alive ,’,Jmposite Inissiou iti,eraries wit h a "’sche,:luling"

,-ompolieid, that verifies fe~,-sibility of a giv,’lL ,:ond.,ined

uiis,sion and geuerates a wirlg assigninenl. The sche(lul-

From:

AIPS 2000 Proceedings.

Copyright

© 2000, AAAI

(www.aaai.org).

All rights

binedreserved.

missions.

ing component

is the basic

AssignMission

already

de-

fined.

More generally,

mission eonlbination

can be

seen as a specific configuration of all integrated

planning and scheduling search template,

designated by the following triple of components:

¯ ,

¯1

t

<(,tnpossOomb~GtnFca,,t;ontb,l~J~,alMaxTripRed>

where

(/¢llFca.~t.’o,nb

is all instantiation of hssignMission.

In this case, the operator (;enpossc’o,nb represents tile

planning component. It will generate a set. containing

all possible composite missions involving a certain

mission M. For m~ypair of missions (:’t.ll,M,.,),

there

are two possible combinations: one in which mission

:’tlz flies after the end of mission M1"s last leg; and

one in which mission :’fit flies after mkssion M.,.

Possibl," combinations ,,inslsatisfy the conj,,nction

of constraints established by spatial and temporal

restrictions, plus constraints following from the three

exlernal parall|eters

specified by the user: mininml

pcrcenl.age reduction in total duration of the combined

mission, the n,aximmn layover time, and t.la~ maximum

distance between the end location of the first mission

and the start of the second. The output of this

operator ca_Aabe seen as Ihe set. of all notional combined

missions Mresulliug from ,’oncatenatio,,

of possible

cornbinat ion pal rs (,’tll, M.2).

Once all the possible

combinations

has been

gonerated, tim existem’e of a feasible wing as~igllnlent

wi]]__be delennin~,d via application of

hssignMission(3/,feasible),

where M represents

the mi,ssion generated by combiniugthe itinerary of two

mi.ssions in a possible pair (including an intermediate’

coutmeting flight leg if m:cessary). The allocation interval should be large enough to accommodate the duration of M. Although currently only feasible allocations

are considered, auy of the relaxed hn-~igaHissioa ins!antiations could be u,sed.

Once all feasible combinal ions have been determined.

the. candidate providing the largest overall reduction ill

airplane flying time is selected. Figure 4 summarizes

the procedure.

Ahhough CombineMission

allows only two missions

to be combined at a time, note that the combination

of larger numl~ers of missions can be accomplished by

recursively applying the algorithm to previously corn(.’.ombincMission(M, MaxLay. MaxI)ist, ReqRed)

(hulerate Possible (’.ombinatious:

For each Possible ComlfinationPair (M1..,’vt,.,):

Generate Mission M = :I[I+M1..,+M,.

For each M in Possible Combinations:

if hssignMission

(M, feasible)

Then add M

Apply EvalM,,~Tripma to Feasible

End

Figure 4: Mission Combination Procedure

Linking Tanker Missions

The linking of tauker missions to airlift missions is similar t.o mission combination. For a mission requiring

air refueling, the algorithm first tries to find an existing tanker mission that is already scheduled Io be in

the vicinity of the requested refileling track in the time

period requested. In the event that ntultiple tanker

missions art, found, the mission that minimizes the perturbation in both missions will be selected. Failing to

find an existing mission, a new I.anker mission will be

created and linked to the requesting mission if there is

available tanker capacity.

The search template for air refueling can Ix, expressed

as <(.~’er$Po.~s Refuel ,(’;~tFeasRefu:.l

..Et’alMin Pert >. Still-

ilar I.o the Mission Combination. the operator

(~en.l, ossRelucl corresponds to I he plamiing component.

It will search for the set of currently planned refiteli,g

missions that could possibly service a ,’ertain mission

M. The linkage of tankers will typically require additional adjustments of start m,d end times of both missions to guarantee the synchronization of tile legs and

resources involved in the air refilcling activity. This is

achieved by establishing temporal constraints betwee,

the activities representing fuel supply and reception.

’File time bounds of both missions involved are l,h~n

updated by propagating these constraints to the entire

mission itinerary.

In contrast to Mission Combination,the "’,-.cheduling"

COml)onent

here. (re’lll.’easRt./~tcl,

iS composed

of twoinstances of hssignMission,

to m;tke airlift aml ta.nk,.r

wing a.ssignments respectively. Ouce the set of possible refueling rnissioos has been identified, and the time

bounds of the missions have been adjusted accordingly.

Genl,’easReluetwill generate the set of time intervai,~ for

which both the airlift, and tanker resource are available

simultaneously during the entire duratkm of the refileling. If there are consistent wing assignutents for I)oth

missions, the pair will be markedas feasible.

After all feasible pairs havc. beenidentified, tilt. evaluation function is used to select the pair thai, n,inimiz~-s

perturbation in the missk)ns’ itine.raries. If no feasible

pair is found, and there is enough tanker capacity. ;,

newreflleling mission servi,g the airlift mission is created. 1 Figure 5 summarizes the air refueling linkage

proccdure.

Utilizing

the Core Components

The three

core procedures

discussed

above.

AssignMission~

CombineMission

and LinkTankers.

are composed in various ways to provide user-level

functionality. I"ach can be inw)ked individually on

I With regard to current intended use, the creation of a

newmission is equivalent to reporting failm’e. The creation

of a dunuuymissiou is the mechanismthat can be used to

notify the plmmerthat there is a mission that carmot be

refueled giving the existing set of missions.

I.i,kTank,,rs(M)

I.hereserved.

AMC

(’.orpor~d.e

From:

AIPS 2000 Proceedings. Copyright © 2000, AAAI (www.aaai.org). All rights

Generate Possible I~.eI’ueling Links:

Find possible pairs (M.R)

Adjust ~rlltt l)roi~agate, lime boundsfor pair (M.R)

For ,:ach Possible Refueling pair (M.R):

If AssignMission(M,

leasible)

and AssignMiss

ion (R, feasible)

Thenadd p~ir(M. R) to Feasible.

If l"ea.,~il)le is not empt.y

Theutapply1.5"FttlMi,li.,ert

tO l"~’asiblt,

Else generate new refl,,ling mission

End

Figur,, 5: Air Roflwling Linkage

giv,,n soh,,:tcd mission: this is thetint,st

granularily

modeof inLeraction with the system. Mort, typically.

howew’r,user a,’tion is tt~ken relative to sea,’ selected

set. of input missions. The AssignMissions

l.,rore~lur- (Figure ??) provides a bxsis for simuhalleo,sly

tdlo,’at.ing resources Io $olne sel of tnission.q under

;L given set of constraint relaxation assumptions.

Ana.lagous ,’OltLposite procedures are simihwly defined

and provided for CombineMission, to allow overall

,’,)ll,pt’es,.,iol, ,.,f i’(.SOllrCO

usageow,rSOlll(: interval,

for LinkTankers,t o allow sinlultaneous I, reat Jnent of a

set of unsatisfied air r~.fiwling requests.

At. i~resenl., taw configuration of ftm,’tional eapabilit.i,,s

for mission allocation, eonlbinalion and linkage for refueling is under user-control.

Typically,

Ass ignMissions is used in f’¢msible assignment modeto

conslr,t,’t a base allocation, interh’aving the us,: of an

AssignTankersromposite as needed t.o reconcile refitcling re, luirement.s. CombineMission

(or its contposite

(.’o]lnlerpart CombineMissions)

are th,,n applied in ,’on.i,,lt,:tion wi!]l va, rious relaxt,d forms of AssignMission

toit,:ral iv+,ly inLprov,,,’eSOllrrt~ us,+g,, and ac,’olmn,>d~u.e

addiLional, lower priority tnissions. Oil-’ a.rea of curry,hi

workis l.h,’ design of il.,,rative inlprov<,nlentscar<’h pro,’edtm.-.s for automatingt.his pro<’ess.

Implementation

and Status

The scheduling <,ngine of the Barrel Allocator is imple,l,,nl.od

in Allegro CommonLisp 5.01. Tile ilser

interface is in Java 1.2. The curl(at version rtlns on

WindowsNT plal.fornls.

The yore mission sch<’duling

procedure is quite efficient a 2 week i,tervml of ntissions extrax:ted from the current. Corporate datt~ base

(approxitn;ttely 1001) missions, 5000flights) is scheduled

from scratch in less than 20 seconds on a Pent, lure II

400MI Iz. Increment al planning and scheduling all.ions

are exe,:ute¢l in real-lime.

With support, from Logicon Corporation, the principal developer of AMC’sConsolidated Air Mobility

I’lanning System (CAMPS),the NTversion of the Liarrel Allocator has been integrated to communicatetransparently with other CAMPScomponetlts and to support AMC’soverall business process. Connections to

40 AIPS-2000

I);tta Bast’ and to oth,:r (’AM

tools areaccomplisl-’d thrtmg, h a COM

int~rfa.,’c.. The

hlarr,,l Allo<’a.l.or

,’,)lllll, OllellliS illll)l,"nt~’nl,’d:t., a (’OM

s<.’rvt+l’ that ran I)e <:~dl,.d froma.lty clio,t in (’A.MPS.

It a.lso Illakes Its, + of sew~ralCOM

s~.rv,.l’S :~vaila.l,h. in

CA).II’S.

Tl,e AllocatorI,,a, ls i’o~our,:t, availal,ilitv an, I ittissio,

descriptiondat ;~ fromtile AM(’ ( "orporat,. I’):41 a has,,

ing one such (!OMsorv,-r st.rver pr(,vided by (’.AMPS.

Thisserv,.r makesIhe querie.~ to l.he dat;dmsoat,.[ t ran.sh~tes missiol~ and r<,sour(’,, it~formationil,l.o a t,)rnlal.

the Allocator can list,. Theuser sp,,,’ilios :t tim~’ int,,rval. and a certain s,.I of air ba.,~,.s an, I air,’rafl lyp,,s

of intr’l’OSL. Thesyslemwill t.h,’n, l.hl’t,u~h th,’ (’().XI

serv,,r, query1.he dat.abase for n,,ntinal r~.s,,Ire,, availabilityl,,vels (i.,:., tmntb,.rsofcoltt.r;Lel.,t’~.ll,’,.,I :llld I,’~sst.ssedaircraft.) and;dl ,,fissions I’,’qilirillg I lit’ it.",,’ ,’~1’

I.hose reSollr(’es duringt l,. Sl,.,’iliod titlto i,t,.’l’V;,I.

"1"ostq~porl,colttinuousdaily Ol)er;d.iOllS.1.h,. ~nissi,,ns

retrievedfromflit, tl:~tal.m..4eare ulark,.dI~al’l.il i,,t,.tl ilfl.~.,

threel)ossiblest at,e,-,:

¯ .\’~ w missiom~:missionst,ewly rt’,.ated or im,,lifivd by

the plannerandl)eltcling a.i)pr,,val I,y th,, I~arl’,.I.

¯ ..Ipi,ror¢d Mis.~itm.¢:

n~i.,,si,,ns t.hat, the. Ilarr,.I all,I Ih,,

phumerha.w’I’e;wh,,d cOns¢.ll~llS:,.l,I [;,r wl,i,’h r,.stmr,’-s hay,. I.,en all,.,.’aled.

¯ RevisedMi.s.~io,s: missi<.,ns t.hat Ihe It:,l’rt.I has alh,r:tl.t~d resourres for tutd,.r rolaxe, l assulnl~li,,l,S ’ but

tile planner ha.s not yet ,:oneUl’l’ed.

Silly ttpprot:td atld re’vistd tuissionsare Ill,’ ini..,si,:,,s

LhcB;trl’el has prt~viouslyalloc;~re,.I. Ih,,y will b,.. ;ultomari,’ally assigned, during load lira,’. Io Ill,. wing

and lille interval SlW,’ifiod in Ihe i’equt.st. "1"1,, r,,._

l.ual resource;wailability level is ol,tain,.,l byt’,.,l,t,’iI,:g

l.he I~ominalavailability by lh,. at~tOll,t ~,f Cal).,’il.v r,’served by already allo,’atcd n~issio,s. Th,. syst,,nl will

flag a conllirl if chang,.sin nominali’t.SOlll’t.’c :,vaihd,ility causea wingto be. unavailal~hrI’~,r alr,.atly a..,sigl,’d

missions. Those problematir missions will 1,, nmrk,’d

as uuassiynable and will rr, quir,, senv: user guided ;wtion to 1)(, reintroducedil,t.o the current schedld(,. Once.

the barrel has finished w(,rking with a s,.= ¢,t" luissi,~ns.

s/he can rotumit the derisions bark t.o !lie database.

Missions that h;we had Lheir flying I.ilues or assigned

rt.sotu’r,,s rhangodbyth,.. lmrl’ol, will I:,c. In;u’k,.d as revised, pentling apl~roval nr further rhang(, I,v !h,. i’,,levent planning ofli,’e. Subseqltently ,’alwt.llt.d missions

missionsthaL the plann,,r has decid,,d will tat, 1,mgr.r b,.

supported- will be rentov,’d froml.ht, srh,,,lul,,. I"fising

I I,’ opportunil, y l o reassossother, pr,.vi,.ms ,"tmSt.l’aint

rela.xal.ion d~cisions.

Themostr,:t.’ent v(’rsioJl of the Ilarrel .’%llo,’at.,~r was

transferred to AM(’.in tnid October1!)!)9 for alpha testing. It is oxpt,cte, I Lo be released as an operat.ional

contponenl of CAMPS 2.0 by March 2001).

Conclusions

From: AIPS 2000 Proceedings.

Copyright © 2000, AAAI (www.aaai.org). All core

rights techniques

reserved. are

In this paper we have described Barrel Allocator, a

mixed’initiative

system for day-to-day managementof

airlift and tazlker resources. The system has been designed to provide a range of mission scheduling and

planning capabilities, including incremental generation

of feasiblc resource assignments for pending missions,

generation of alternative allocation options in casc of

resource contention, identification of opportunities for

marc efficicnt aircraft utilization though mission combination, and generation and synchronization of tanker

missions to meet air refueling requirements. Each of

these capabilities can be utilized with different degrees

of user control ow~r the decision-making process, ranging from user-controlled option generation to fully automated scheduling a~ld planning processes.

The Barrel Allocator implementation derives from

the architectural principles, scheduling ontology and associated class library of the Ozone scheduling framework. which consolidales the results of application

building experiences in a number of similar problem

domains. Although, any new problem domain brings

uniquc requirements and constraints that make it difficult to use pre-existing solutions "out of the box",

this starting point has nonetheless substantially accelerated our efforts to develop and transition the Barrel

Allocator application. The core procedure for mission

allocation, for example, was initially prototyped as a

fairly direct instantiation of a search template previously developed in another transportation scheduling

context, and allowed rapid development of initial mission combination aud linkage capabilities.

Later on.

the architectural and configuration flexibility of the tmderlying frameworkhas allowed us to efficiently refine

this functionality and to quickly respond to requirernent changes re,~ulting from increased user exposure

and evolving AMCbusiness processes and policies.

domains(Becket 1998) have flexibility

C.oncerning the effort involved in this transition, the

greatest challenge has been, and remains, to create a

bridge between the current culture and 1)usiness processes at AM(’., and howsuch processes and culture can

and should evolve as the Barrel Allocator becomesfilly

operational. To gain nser acceptance it has been necessary on one hand to demonstrate the ability to support

current processes. On the other hand, it ha,s been necessary to demonstrate alternative business processes that

better exploit the pol~ential of the Barrel Allocator to

improve decision-making within AMC.

As the Barrel Allocator transitions into operation at

AMC,several extensions to system flmctionality are

currently planned. One near-term extension will ex,tend the system’s resource allocation mechanismto additionally consider air crew capacity and availability

constraints (currently we enforce only constraints on

crew duty day and rest requirements). A second direction of future work is to expand the system’s "reactive" capabilities and support shorter-term response

to exceptional execution events. Muchof the system’s

directly applicable to this rcal-t imc,

execution management process. A third direction of

planned extensions concerns evolution of the inl.era,’tire option generation process. One particular interest

is in developing better techniques for visualizing mid

comparing the impact of change.

Acknowledgements

The current Barrel Allo(:ator system represent.s the ,’umulative efforts of several individuals. Dirk Lem,,,:rmann. Gary Pelton. David Itildum. Mark Shieh. and

Seppo Torma have all made substanlial conttihuli~,ns

to the implementation. Mark Burstein hms been instrumental in the definition of protocols for integral ion with

the AMCCorporate data base. and in steering the overall integration elfort. Brian Gloyer. Lindy Resner and

others at I,ogicon have provided great support in interfacing with various CAMPS

system components, and in

understal,ding user requiretnents. This work has beer,

funded in part by the Depart naent of Defense Advam’ed

R,esearch Projects Agoucyand the US Air Force Ron]~.

Research Laboratory under contracts 1;30602-97-2-0227

and F30602-96-D-0058 and by the CMI" Robotics Institute.

References

C. Barnhart, N.L. Boland, L.W. Clarke, E.L. Johnson.

G.L. Nemhauser.and R.G. Shenoi. Flight string mo,.lels for aircraft Ileeting an,I roul.ing. Traa.sport(tlw,

,qcieuce, 32(3):208-220, August 1998.

M.A.Becket. Ret.’onfigurableA rchih.ct ut~. s J’or Mi,redInitiative Planning and Scheduling. Phi) the.’,is. Graduate School of Industrial Administration and The

Robotics Institute, Carnegie Mellonl;niversity. Pittsburgh, PA..luly 1998.

C!larke L.W., E.L. Hane C.A., Johnson, and (.l.[,.

Nemhauser. Maintenance and crew co,.,s.iderations

in

fleet assignment. Tlvmsportation .g(’iencc, 30:2-19-261),

1996.

R.A. Rushmeier and S.A. Knotogiorgis. Advam’es in

the optimization of airline fleet assignmem. 7i’a,.sportation Science. 31(2):159 1(i9, May19!)7.

S.F. Smith and M.A. Becket. An ontology for constructing scheduling systems. In PuJcetding.~ of the

AAAI Spring Symlu~sium on O,lological Engim criag,

pages 120-129. Pale Alto. CA, April 1997.

S.F. Smith. O. Lassila.

and M.A. Be,:ker. Configurable, rnixed-initiatiw, systems for planning and

scheduling. In A. T’ate. editor, Advanced Planning

Technology. AAAIPress, Menlo Park, 1996.