xplosion Protected Panelboards D2Z Series IF 1416 Installation & Maintenance Information

advertisement

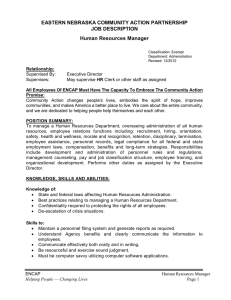

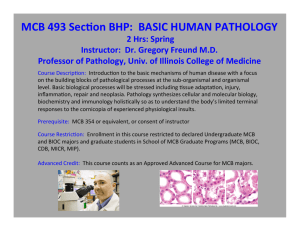

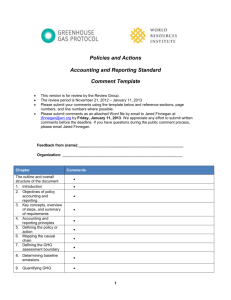

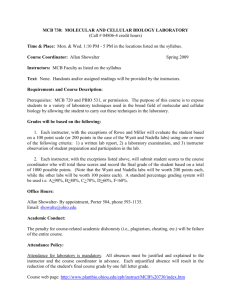

Explosion Protected Panelboards D2Z Series IF 1416 Installation & Maintenance Information SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE APPLICATION The D2Z Series panelboards provide a centrally controlled switching system and short circuit protection for feeder or branch circuits to control lighting , heating, appliance, heat tracing, motor and similar circuits. EPD (equipment protection devices) options offer personnel and equipment protection respectively. D2Z Series panelboards are designed for use in Class I, Zone 1, Div. 2, Groups A, B, C, D; (classified) areas as defined by the National Electrical Code® (NEC) and Canadian Electrical Code (CEC) as well as in damp, wet locations – indoors and outdoors. Panelboards should be installed, inspected, maintained, and operated by qualified and competent personnel. Read entire instructions before starting installation of this product. Contact your Crouse-Hinds Sales Representative, Crouse-Hinds Customer Service or your Crouse-Hinds Distributor if you have any questions. INSTALLATION 1. WARNING To avoid fire or shock hazard, the electrical power must be OFF before and during installation and maintenance. Select a mounting location that will provide suitable strength and rigidity for supporting the panelboard and all contained wiring. Figure 1 shows the mounting dimensions. Approximate shipping weight of a panelboard fully loaded with breakers is 200 lbs. DIMENSIONS – In Inches & millimeters X = Mounting Dimensions 8.25 (211mm) 10.5 (271mm) x 9.75 (247mm) 4.5 (116mm) 10.5 (271mm) .5(11mm) 5.5 (136mm) 10.5 (271mm) 6 (155mm) 8.75 (211mm) 4.5 (116mm) (11mm) .5 Safety Switch 31.5 (798mm) 10 x 9.75 (247mm) 10.75 (275mm) x 10.5 (273mm) 10.5 (271mm) x 31.25 (793mm) Note: Used only for fuses on 80, 125A, disconnect switches and 80A switch. (254mm) 4.5 (116mm) 32 (817mm) 10.5 (271mm) x 9.75 (247mm) x 9.75 (247mm) 20.5 (520mm) 21.5 (544mm) Note: Used for main breaker Note: Used only for 125 or 180 A disconnect switches without fuses. Note: Used for – 40 A switch with fuses and 1 window, or – 40 A switch and 2 windows, or – 3 windows of branch breakers. Figure 1. IF 1416 • 4/00 Copyright © 2000, Cooper Industries, Inc. Page 1 2. With panelboard securely fastened to the mounting surface (figures 2-4), attach conduit system. Tapped conduit openings are provided for main circuit and branch circuits. WARNING To avoid dangerous overheating and fire, do not use aluminum wiring. Use copper wiring only. Use 60°C or 75°C conductors. CAUTION To prevent external fire or explosion, DO NOT connect to a supply circuit capable of delivering more than 10,000 RMS symmetrical amperes. DO NOT install equipment which will produce external surface temperatures exceeding the ignition temperature of the flammable or combustible materials which may surround this enclosure. DO NOT install arcing components or high temperature producing components such as relays, switches or transformers in the terminal enclosure. Circuit interrupting devices such as circuit breakers which may be installed in the enclosure may fail electrically or mechanically unless they have been investigated and found suitable for operation in the hazardous location involved. 3. 4. After enclosure is positioned and secured in its permanent location, pull wires into panelboard making sure that they are long enough to make the required connections. Make connections of either single or three phase circuits according to wiring diagrams accompanying each panel. 7. Securely tighten all cover bolts supplied with the panelboard. Torque all cover screws to 5 in. lb. 8. It is not necessary nor recommended to remove the panelboard cover during enclosure installation. 9. Mark circuit card directory located on main enclosure cover with appropriate descriptions for proper branch circuit numbers. Place circuit card directory inside clear plastic jacket before placing back in its holder. Mount the holder on a flat surface with the enclosed velcro strips. MAINTENANCE WARNING To avoid electrical shock, fire and or explosions, always disconnect primary power source before opening enclosure for inspection or service. 1. We recommend an Electrical Prevention Maintenance program as described in the National Fire Protection Association Bulletin NFPA No. 70B. It is recommended that it should be at least once a year. 2. Perform visual, electrical, and mechanical checks on all components on a regular basis. • Visually check for undue heating evidenced by discoloration of wires or other components, damaged or worn parts, or leakage evidenced by water or corrosion in the interior. With panelboard securely fastened to the mounting surface, attach conduit system. Only skilled staff should carry out the electrical connection of the units. Tapped conduit openings are provided for main circuit and branch circuits on the terminal rails in the bottom of the enclosures. The supply terminals are located on the left-hand side of the enclosure. All other terminals are for branch circuits. Terminal wiring should be made according to the following table. • Electrically check to make sure that all connections are clean and tight. • Mechanically check that all parts are properly assembled, and operating mechanisms move freely. TABLE 1. TERMINAL WIRING SUPPLY CIRCUITS AMPERAGE mm2 AWG RECOMMENDED TORQUE (IN./LBS.) 40 16 6-18 10.6-12.3 80 35 2-6 21.8-26.1 125 70 8-2/0 35-52 180 95 6-3/0 35-52 BRANCH CIRCUITS AMPERAGE mm2 AWG RECOMMENDED TORQUE (IN./LBS.) 10 4 12-22 3.5-5.3 15 4 12-22 3.5-5.3 20 10 6-14 10.6-12.3 40 16 6-18 10.6-12.3 5. Flange plates: Brass plates are provided with NPT to Metric hub adapters approved for Zone 1, Division 2 areas. The external ground connection should be torqued to 132 in.lbs. If non metallic flange plates are used, a listed entry method such as Crouse Hinds Meyers STMK hubs must be used. 6. Test wiring for correctness with continuity checks and for unwanted grounds with an insulation resistance tester. CAUTION To maintain the integrity of the enclosure, clean dirt or foreign material from both surfaces of body and cover before closing. IF 1416 • 4/00 3. Large windows permit easy viewing and quick access to breakers without opening the enclosure. The breakers can be actuated, while power is applied to the panel, by opening the window. After actuating the breakers, immediately close and lock the window. The window can be locked with an Allen wrench (5/16" or 8mm). WARNING The access window provides NEMA 4X and IP 66 protection only when the window is closed and locked. When the window is locked, a red locked-position indicator can be seen under the window. The windows and breakers can be locked out. Use a 3-mm lockout for the breakers and an 6-mm lockout for the window. Copyright © 2000, Cooper Industries, Inc. Page 2 4. 5. Replacement parts are available through your Crouse-Hinds distributor. Replace circuit breakers only with Ex-de explosion protected Crouse Hind’s breakers. Main Disconnect Switch 40, 80, 125, 180 A, 4-pole Explosion Protection AEx de IIC T6 Replacing Breakers: A. De-energize D2Z panel. EEx de IIC T6 Class I, Zone 1, Div. 2 Groups A, B, C, D power to the explosion protected Certifications 40-180 A UL, cUL PTB 98 ATEX 1031 U 40 A PTB - No. Ex-93C.1028 U B. Remove cover screws from enclosure cover. 80 A PTB - No. Ex-85B.1055 U C. Remove wires from line and load side of the breaker. 125/180 A D. Remove breaker off the DIN rail by gently extending the release key near both sides of the DIN rail. Rated Operating Voltage Motor Switching Capacity AC 3* E. Reverse the procedure to replace breaker on the DIN rail. Make sure the breaker snaps securely onto the rail. F. Reverse step #3 and reconnect the cables onto the terminals of the new breaker. PTB - No. Ex-86B.1048 U Up to 690 VAC Type 230 V 480 V 40 A 40 A 40 A 80 A 80 A 80 A 125 A 125 A 125 A 180 A 180 A 150 A * See IEC 947-4-1: 1990. WARNING Explosion protected Ex-d (flameproof) components in an Ex-e (increased safety) enclosurew may only be replaced with iden- 6. Closing the enclosure cover: when replacing the cover on enclosures containing switches, care should be taken to align the operator handle with the shaft on the switch. Any foreign debris should be removed from the enclosure. TECHNICAL DATA Main Breaker Branch Circuit Breakers 1-pole, 2-pole, 3-pole, 4-pole; with EPD protection 1-pole + Neutral, 2-pole; 2, 6, 10, 16, 20, 25, 32 and 40 Amps Explosion Protection EEx de IIC T6 AEx de IIC T6 Class I, Zone 1, Div. 2, Groups A, B, C, D Certifications UL, cUL PTB - No. Ex-94.C.1035 U PTB 98 ATEX 1087 U Rated Operating Voltage Up to max. 480 VAC Rated Current Up to 40 A, See Page 10 Rated Switching Capacity 10k AIC Tripping Characteristic “B” or “K” * Tripping Current for EPDs 30 mA (up to 300 mA on request) Enclosure Materials Fiberglass-reinforced polyester Optional Auxiliary/Signal Contacts** Rated Voltage 250 VAC Rated Current 5A * “B” Branch breakers are used for all general applications such as lighting and heat-tracing. Type “K” breakers are used for MOVs and portable power. Contact factory for other applications. ** Aux contacts indicate mechanical or electrical tripping. Signal contacts indicate only electrical tripping and are used primarily on heat-tracing circuits. Branch breakers with signal contacts require next larger breaker enclosure. IF 1416 • 4/00 Copyright © 2000, Cooper Industries, Inc. Page 3 Main Breaker Explosion Protection Class I, Zone 1, Div. 2, Explosion proof Groups C, D Class II, Div. 2, Groups F, G Class III NEMA 3; 7 C, D; 12 Certifications UL, cUL Rated Current 30 to 100A Rated Voltage 120/240 VAC Single, 3-phase Main Fuse, 3-pole Explosion Protection EEx de IIC T4, T6 AEx de IIC T4, T6 Class I, Zone 1, Div. 2 Groups A, B, C, D Certifications UL, cUL Rated Operating Voltage Up to max. 500 VAC Rated Current Current Temperature Class 25A T6 35A T5 50A T4 63A T4 80A T4 100A T4 125A T4 PTB – No. Ex-86.B.1065 U Main Fuse, type NH Recommended manufacturer: Cooper Bussman type NH ØØG fuses for general use or NH ØØM for motor applications. Specify Amperage. (Fuses not provided) Pending UL certification, panels supplied with fuses PTB certified only. Standard Entries Main Supply Branches Brass gland plate with Zone 1 Myers adapter hubs: (STM series) Metric Entries (remove hubs) (1) 2" + (3) 1" (1) M 63 + M 32 (9) 3/4" (9) M 25 Universal Wiring– Zone 1 Myers® adapter hubs for conduit or Terminator™ cable glands IF 1416 • 4/00 Copyright © 2000, Cooper Industries, Inc. Page 4 SPARE BREAKERS Description Pack Qty. Code No. Qty Description Pack Qty. Code No. Qty Exd Encap. MCB 16 A, 1 pole, "K", 10 kA GHG 610 1907 R0023 6 Exd Encap.MCB 4 A, 3 pole"K", 10kA, aux.cont.1no+1nc GHG 610 1914 R0019 3 Exd Encap. MCB 6 A, 1 pole, "C", 10 kA GHG 610 1907 R0127 6 Exd Encap.MCB 6 A, 3 pole"K", 10kA, aux.cont.1no+1nc GHG 610 1914 R0020 3 Exd Encap. MCB 10 A, 1 pole, "C", 10 kA GHG 610 1907 R0129 6 Exd Encap.MCB 10 A, 3 pole"K", 10kA, aux.cont.1no+1nc GHG 610 1914 R0022 3 Exd Encap. MCB 16 A, 1 pole, "C", 10 kA GHG 610 1907 R0131 6 Exd Encap.MCB 16 A, 3 pole"K", 10kA, aux.cont.1no+1nc GHG 610 1914 R0023 3 Exd Encap. MCB 20 A, 1 pole, "C", 10 kA GHG 610 1907 R0132 6 Exd Encap.MCB 20 A, 3 pole"K", 10kA, aux.cont.1no+1nc GHG 610 1914 R0024 3 Exd Encap.MCB 16A,1 pole"K",10kA, aux.cont.1no+1nc GHG 610 1908 R0023 6 Exd Encap.MCB 25 A, 3 pole"K", 10kA, aux.cont.1no+1nc GHG 610 1914 R0025 3 Exd Encap.MCB 6A,1 pole"C",10kA, aux.cont.1no+1nc GHG 610 1908 R0127 6 Exd Encap. MCB 6 A, 3 pole, "B", 6 kA GHG 610 1913 R0201 3 Exd Encap.MCB 10A,1 pole"C",10kA, aux.cont.1no+1nc GHG 610 1908 R0129 6 Exd Encap. MCB 10 A, 3 pole, "B", 6 kA GHG 610 1913 R0202 3 Exd Encap.MCB 16A,1 pole"C",10kA, aux.cont.1no+1nc GHG 610 1908 R0131 6 Exd Encap. MCB 16 A, 3 pole, "B", 6 kA GHG 610 1913 R0204 3 Exd Encap.MCB 20A,1 pole"C",10kA, aux.cont.1no+1nc GHG 610 1908 R0132 6 Exd Encap. MCB 20 A, 3 pole, "B", 6 kA GHG 610 1913 R0205 3 Exd Encap. MCB 6 A, 1 pole, "B", 6 kA GHG 610 1907 R0201 6 Exd Encap. MCB 25 A, 3 pole, "B", 6 kA GHG 610 1913 R0206 3 Exd Encap. MCB 10 A, 1 pole, "B", 6 kA GHG 610 1907 R0202 6 Exd Encap.MCB 6 A, 3 pole"B", 6kA, aux.cont.1no+1nc GHG 610 1914 R0201 3 Exd Encap. MCB 16 A, 1 pole, "B", 6 kA GHG 610 1907 R0204 6 Exd Encap.MCB 10 A, 3 pole"B", 6kA, aux.cont.1no+1nc GHG 610 1914 R0202 3 Exd Encap. MCB 20 A, 1 pole, "B", 6 kA GHG 610 1907 R0205 6 Exd Encap.MCB 16 A, 3 pole"B", 6kA, aux.cont.1no+1nc GHG 610 1914 R0204 3 Exd Encap.MCB 6A,1 pole"B",6 kA, aux.cont.1no+1nc GHG 610 1908 R0201 6 Exd Encap.MCB 20 A, 3 pole"B", 6kA, aux.cont.1no+1nc GHG 610 1914 R0205 3 Exd Encap.MCB 10A,1 pole"B",6 kA, aux.cont.1no+1nc GHG 610 1908 R0202 6 Exd Encap.MCB 25 A, 3 pole"B", 6kA, aux.cont.1no+1nc GHG 610 1914 R0206 3 Exd Encap.MCB 16A,1 pole"B",6 kA, aux.cont.1no+1nc GHG 610 1908 R0204 6 Exd Encap. MCB 6 A, 4 pole, "C", 10 kA GHG 610 1916 R0127 2 Exd Encap.MCB 20A,1 pole"B",6 kA, aux.cont.1no+1nc GHG 610 1908 R0205 6 Exd Encap. MCB 10 A, 4 pole, "C", 10 kA GHG 610 1916 R0129 2 Exd Encap. MCB 2A, 2 pole, "K", 10 kA GHG 610 1909 R0017 4 Exd Encap. MCB 16 A, 4 pole, "C", 10 kA GHG 610 1916 R0131 2 Exd Encap. MCB 10A, 2 pole, "K", 10 kA GHG 610 1909 R0022 4 Exd Encap. MCB 20 A, 4 pole, "C", 10 kA GHG 610 1916 R0132 2 Exd Encap. MCB 16A, 2 pole, "K", 10 kA GHG 610 1909 R0023 4 Exd Encap. MCB 25 A, 4 pole, "C", 10 kA GHG 610 1916 R0133 2 Exd Encap. MCB 6A, 2 pole, "C", 10 kA GHG 610 1909 R0127 4 Exd Encap. MCB 32 A, 4 pole, "C", 10 kA GHG 610 1916 R0134 2 Exd Encap. MCB 10A, 2 pole, "C", 10 kA GHG 610 1909 R0129 4 Exd Encap. MCB 40 A, 4 pole, "C", 10 kA GHG 610 1916 R0135 2 Exd Encap. MCB 16A, 2 pole, "C", 10 kA GHG 610 1909 R0131 4 Exd Encap.MCB 6 A, 4 pole"C", 10kA, aux.cont.1no+1nc GHG 610 1917 R0127 2 Exd Encap. MCB 20A, 2 pole, "C", 10 kA GHG 610 1909 R0132 4 Exd Encap.MCB 10 A, 4 pole"C", 10kA, aux.cont.1no+1nc GHG 610 1917 R0129 2 Exd Encap. MCB 25A, 2 pole, "C", 10 kA GHG 610 1909 R0133 4 Exd Encap.MCB 16 A, 4 pole"C", 10kA, aux.cont.1no+1nc GHG 610 1917 R0131 2 Exd Encap.MCB 2A, 2 pole"K", 10kA, aux.cont.1no+1nc GHG 610 1910 R0017 4 Exd Encap.MCB 20 A, 4 pole"C", 10kA, aux.cont.1no+1nc GHG 610 1917 R0132 2 Exd Encap.MCB 10A, 2 pole"K", 10kA, aux.cont.1no+1nc GHG 610 1910 R0022 4 Exd Encap.MCB 25 A, 4 pole"C", 10kA, aux.cont.1no+1nc GHG 610 1917 R0133 2 Exd Encap.MCB 16A, 2 pole"K", 10kA, aux.cont.1no+1nc GHG 610 1910 R0023 4 Exd Encap.MCB 32 A, 4 pole"C", 10kA, aux.cont.1no+1nc GHG 610 1917 R0134 2 Exd Encap.MCB 6A, 2 pole"C", 10kA, aux.cont.1no+1nc GHG 610 1910 R0127 4 Exd Encap.MCB 40 A, 4 pole"C", 10kA, aux.cont.1no+1nc GHG 610 1917 R0135 2 Exd Encap.MCB 10A, 2 pole"C", 10kA, aux.cont.1no+1nc GHG 610 1910 R0129 4 Exd Encap. MCB 6 A, 4 pole, "B", 6 kA GHG 610 1916 R0201 2 Exd Encap.MCB 16A, 2 pole"C", 10kA, aux.cont.1no+1nc GHG 610 1910 R0131 4 Exd Encap. MCB 10 A, 4 pole, "B", 6 kA GHG 610 1916 R0202 2 Exd Encap.MCB 20A, 2 pole"C", 10kA, aux.cont.1no+1nc GHG 610 1910 R0132 4 Exd Encap. MCB 16 A, 4 pole, "B", 6 kA GHG 610 1916 R0204 2 Exd Encap.MCB 25A, 2 pole"C", 10kA, aux.cont.1no+1nc GHG 610 1910 R0133 4 Exd Encap. MCB 20 A, 4 pole, "B", 60 kA GHG 610 1916 R0205 2 Exd Encap. MCB 6 A, 2 pole, "B", 6 kA GHG 610 1909 R0201 6 Exd Encap. MCB 25 A, 4 pole, "B", 6 kA GHG 610 1916 R0206 2 Exd Encap. MCB 10 A, 2 pole, "B", 6 kA GHG 610 1909 R0202 6 Exd Encap. MCB 32 A, 4 pole, "B", 6 kA GHG 610 1916 R0207 2 Exd Encap. MCB 16 A, 2 pole, "B", 6 kA GHG 610 1909 R0204 6 Exd Encap. MCB 40 A, 4 pole, "B", 6 kA GHG 610 1916 R0208 2 Exd Encap. MCB 20 A, 2 pole, "B", 6 kA GHG 610 1909 R0205 6 Exd Encap.MCB 6 A, 4 pole"B", 6kA, aux.cont.1no+1nc GHG 610 1917 R0201 2 Exd Encap. MCB 25 A, 2 pole, "B", 6 kA GHG 610 1909 R0206 7 Exd Encap.MCB 10 A, 4 pole"B", 6kA, aux.cont.1no+1nc GHG 610 1917 R0202 2 Exd Encap.MCB 6A,1 pole"B",6kA, aux.cont.1no+1nc GHG 610 1910 R0201 6 Exd Encap.MCB 16 A, 4 pole"B", 6kA, aux.cont.1no+1nc GHG 610 1917 R0204 2 Exd Encap.MCB 10A,1 pole"B",6kA, aux.cont.1no+1nc GHG 610 1910 R0202 6 Exd Encap.MCB 20 A, 4 pole"B", 6kA, aux.cont.1no+1nc GHG 610 1917 R0205 2 Exd Encap.MCB 16A,1 pole"B",6kA, aux.cont.1no+1nc GHG 610 1910 R0203 6 Exd Encap.MCB 25 A, 4 pole"B", 6kA, aux.cont.1no+1nc GHG 610 1917 R0206 2 Exd Encap.MCB 20A,1 pole"B",6kA, aux.cont.1no+1nc GHG 610 1910 R0205 6 Exd Encap.MCB 32 A, 4 pole"B", 6kA, aux.cont.1no+1nc GHG 610 1917 R0207 2 Exd Encap.MCB 25A,1 pole"B",6kA, aux.cont.1no+1nc GHG 610 1910 R0206 7 Exd Encap.MCB 40 A, 4 pole"B", 6kA, aux.cont.1no+1nc GHG 610 1917 R0208 2 Exd Encap. MCB/RCD 6 A, 1 pole + N, "C", 10 kA, 0,03 A GHG 610 1911 R0006 4 Exd Encap.RCD 25A, 4 pole, 0,03 A. GHG 610 1919 R0002 2 Exd Encap. MCB/RCD 10 A, 1 pole + N, "C", 10 kA, 0,03 A GHG 610 1911 R0008 4 Exd Encap.RCD 40A, 4 pole, 0,03 A. GHG 610 1919 R0003 2 Exd Encap. MCB/RCD 16 A, 1 pole + N, "C", 10 kA, 0,03 A GHG 610 1911 R0009 4 Exd Encap.RCD 63A, 4 pole, 0,03 A. GHG 610 1919 R0004 2 Exd Encap. MCB/RCD 20 A, 1 pole + N, "C", 10 kA, 0,03 A GHG 610 1911 R0010 4 Exd Encap.MCB / RCD 6A, 2 pole "C",10kA, 0,03 A. GHG 610 1920 R0006 2 Exd Encap. MCB/RCD 25 A, 1 pole + N, "C", 10 kA, 0,03 A GHG 610 1911 R0011 4 Exd Encap.MCB / RCD 10A, 2 pole "C",10kA, 0,03 A. GHG 610 1920 R0008 2 Exd Encap.RCD 25A, 2 pole, 0,03 A. GHG 610 1912 R0002 4 Exd Encap.MCB / RCD 16A, 2 pole "C",10kA, 0,03 A. GHG 610 1920 R0009 2 Exd Encap.RCD 40A, 2 pole, 0,03 A. GHG 610 1912 R0003 4 Exd Encap.MCB / RCD 20A, 2 pole "C",10kA, 0,03 A. GHG 610 1920 R0010 2 Exd Encap. MCB 2 A, 3 pole, "K", 10 kA GHG 610 1913 R0017 3 Exd Encap.MCB / RCD 25A, 2 pole "C",10kA, 0,03 A. GHG 610 1920 R0011 2 Exd Encap. MCB 4 A, 3 pole, "K", 10 kA GHG 610 1913 R0019 3 Exd Encap. Contactor 24 A, (4 kW) 4 n/o, ESB 24-40, 24 V ac. GHG 610 1921 R3116 4 Exd Encap. MCB 6 A, 3 pole, "K", 10 kA GHG 610 1913 R0020 3 Exd Encap. Contactor 24 A, (4 kW) 4 n/o, ESB 24-40, 230 V ac. GHG 610 1921 R4001 4 Exd Encap. MCB 10 A, 3 pole, "K", 10 kA GHG 610 1913 R0022 3 Exd Encap. Contactor 40 A, (11 kW) 4 n/o, ESB 40-40, 24 V ac. GHG 610 1922 R4001 2 Exd Encap. MCB 16 A, 3 pole, "K", 10 kA GHG 610 1913 R0023 3 Exd Encap. Contactor 40 A, (11 kW) 4 n/o, ESB 40-40, 230 V ac. GHG 610 1922 R4006 2 Exd Encap. MCB 20 A, 3 pole, "K", 10 kA GHG 610 1913 R0024 3 Exd Encap. MCB 25 A, 3 pole, "K", 10 kA GHG 610 1913 R0025 3 Exd Encap.MCB 2 A, 3 pole"K", 10kA, aux.cont.1no+1nc GHG 610 1914 R0017 3 EPD – Equipment Protection Device IF 1416 • 4/00 MCB – Miniature Circuit Breaker Copyright © 2000, Cooper Industries, Inc. Page 5 Mounting Frame for Panel Type "B" Figure 2. 28.75 (730mm) 9.75 (247mm) .25 (5mm) 9.75 (247mm) 1 (24mm) z x 4 mounting holes "Z" 1/2" (12mm) .5 (12mm) x x x z 13 mounting holes "X" 5/16" (7.5mm) 10.25 (260mm) 16.5 (420mm) 15.5 (395mm) x x x 10.25 (260mm) 10.75 (273mm) 31.25 (793mm) 33 (840mm) 31 (790mm) 5.25 (136.5mm) x x 10.25 (260mm) z x x 25.5 (649mm) IF 1416 • 4/00 x x z 12.75 (324.5mm) Copyright © 2000, Cooper Industries, Inc. Page 6 Mounting Frame for Panel Type "C" Figure 3. 39.5 (1000mm) 9.75 (247mm) 9.75 (247mm) .25 (5mm) 1 (24mm) z x 9.75 (247mm) 1 (24mm) 5 (123.5mm) x x x x x z 10.25 (260mm) 16.5 (420mm) 15.5 (395mm) x x x 10.25 (260mm) 10.75 (273mm) 4 mounting holes "Z" 1/2" (12mm) 13 mounting holes "X" 5/16" (7.5mm) 31.25 (793mm) 33 (840mm) 31 (790mm) 5.25 (136.5mm) x x 10.25 (260mm) z x x x x 36.25 (920mm) IF 1416 • 4/00 x x z 18 (460mm) Copyright © 2000, Cooper Industries, Inc. Page 7 Mounting Frame for Panel Type "D" Figure 4. 50 (1270mm) 9.75 9.75 (247mm) 1 (247mm) (24mm) .5 (12mm) 9.75 (247mm) 1 (24mm) .25 (5mm) z x x x x x 9.75 (247mm) 1 (24mm) x x x z 10.25 (260mm) 4 mounting holes "Z" 1/2" (12mm) 16.5 (420mm) 15.5 (395mm) x x 10.25 (260mm) x 13 mounting holes "X" 5/16" (7.5mm) 31.25 10.75 (793mm) (273mm) 33 (840mm) 31 (790mm) 5.25 (136.5mm) x x 10.25 (260mm) z x x x x x 47 (1190mm) x x x z 23.5 (595mm) All statements, technical information and recommendations contained herein are based on information and tests we believe to be reliable. The accuracy or completeness thereof are not guaranteed. In accordance with Crouse-Hinds “Terms and Conditions of Sale”, and since conditions of use are outside our control, the purchaser should determine the suitability of the product for his intended use and assumes all risk and liability whatsoever in connection therewith. Cooper Industries Inc. Crouse-Hinds Division PO Box 4999, Syracuse, New York 13221 • U.S.A. Copyright © 2000, Cooper Industries, Inc. IF 1416 Revision 1 New 4/00