Cooper Lighting, LLC International Sales, USA The Cooper Lighting Family Customer First Center

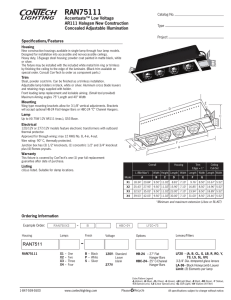

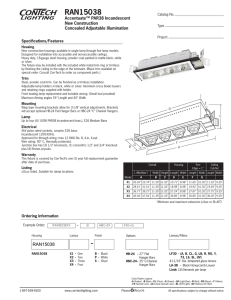

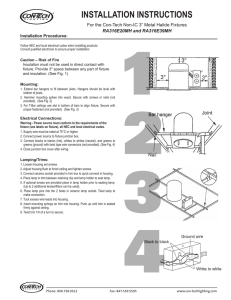

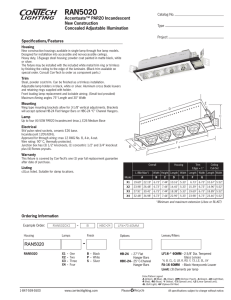

advertisement