Document 13669551

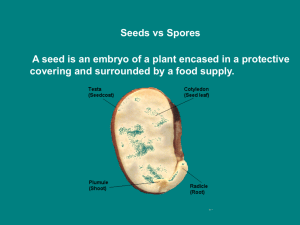

advertisement