EFFECT OF INORGANIC SALTS UPON TUE SWELLING AND TUE SIHRINICING OF WOOD

advertisement

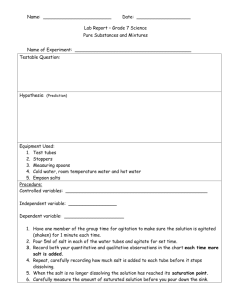

\s) FOREST PRODUCTS LIBRARY FOREST RESEARCH LABORATOR (r) OREGON STATE UNIVERSITY EFFECT OF INORGANIC SALTS UPON TUE SWELLING AND TUE SIHRINICING OF WOOD Information Reviewed and Reaffirmed March 1936 No. 1156 Minim Ain imp p minim mill, lip UNITED STATES DEPARTMENT OF AGRICULTURE FOREST PRODUCTS LABORATORY MADISON 5, WISCONSIN FOREST SERVICE In Cooperation with the University of Wisconsin CO c EFFECT OF INORGANIC SALTS UPON THE SWELLING AND THE SHRINKING OF WOOD By A. J. STAMM, Chemist Forest Products Laboratory,? Forest Service U. S. Department of Agriculture Wood, like all other fibrous materials, possesses the property of shrinking and swelling upon the loss or grain of moisture. The swelling, according to the classification of Katz,3 is of the maximum swelling type. On drying green wood no shrinkage occurs until the moisture content is reduced below the fiber-saturation point (the moisture content below which the activity of the water becomes less than one). The shrinkage as manifested by the percentage change in external dimensions increases with an increase in the density of the wood. It is greatest in the tangential direction (tangent to the annual ring), varying from 6.o to 12.0 percent. In the radial direction (from the center of the tree to the periphery) it varies from 3.0 to 7.0 percent and in the longitudinal direction (parallel to the fibers) it is only a small fraction of a percent. The practically negligible longitudinal swelling and shrinking is accounted for on the basis of the swelling taking place only between the threadlike micelles which, in general, are oriented parallel to the length of the fibers. The greater shrinkage in the tangential direction than in the radial is accounted for on the basis of ray cells which have their longitudinal component in the radial direction of the wood, restraining the dimension changes in that direction. X-ray studies have shown that the swelling of a cellulosic fiber by water does not affect its crystal lattice. 3- The water must go between the constituent units of the structure rather than within these units (intermicellar swelling as contrasted to intramicellar swelling). Concentrated solutions of certain salts such as lithium thiocyanate, as well as of alkalies, however, change the crystal lattice,t showing that their action is intramicellar. –Presented before the Colloid Division, American Chemical Society, Chicago, Ill., Sept. 11-15, 1933. Published in their Journal May 1934. 2Maintained at Madison, Wis., in cooperation with the University of Wisconsin. Katz. Trans. Faraday Soc. 29, 279 (1933). -Katz and Derksen. Rec. Tray . Chim. 50, 149, 737, 746 (1931). Rept. No. 1156 -1- Agriculture-Madison Unfortunately, it is extremely difficult to determine the total swelling of fibrous materials from the dimension changes. With wood, where the external dimension changes are easy to follow, it is extremely difficult to even approximate the internal changes that take place in the lumen of the fibers. In a homogeneous material free from stresses and strains the lumen would change in size on swelling and shrinking of the material, the same as the external dimensions of a piece of the material which would just fill the lumen. This, however, is not the case for wood or any other fibrous material. Because of these difficulties, swelling and shrinking measurements have, in general, been made in terms of weight change. This procedure may, however, be very misleading as swelling can only be proportional to the weight change over the adsorption range. Absorption by the grosser capillary structure cannot cause swelling. Data for the absorption of salt solutions by wood, such as that of Schwalbe and Fischer are, therefore, hardly a measure of the swelling and further give no information as to whether the salts remain in solution in the water which becomes sorbed, or if they are merely dissolved in the free capillary water. There also seems to be a lack of information on the effect that these salts have upon the subsequent shrinkage of the fibrous materials. Swelling Measurements To avoid the foregoing difficulties as far as possible, measurements in the studies reported here were made on a combined weight change and external dimension change basis on small wood sections of Sitka spruce and white pine, approximately 4 by 4 by 0.2 cm., the short dimension being in the direction of the fiber length. Practically all the fibers were cut across at least once, thus avoiding difficulties in penetration and in removing of air from the sections. For most of the measurements the sections were first oven dried to determine the weight of the oven-dry wood (although this does slightly affect the subsequent swelling, it was shown to have no effect upon the nature of the results). They were then soaked in water with the application of alternate suction and pressure to remove the air. This procedure took practically a day to replace all the air with water. The sections were then rapidly wiped on the surface with a towel, weighed, and the dimensions determined. The completeness of the removal of air was tested by a comparison of the weight of the water taken up with the theoretical amount that could be taken up, calculated from the total void volume. The fractional void volume is given by the equation V = 1 - d do (1) in which d is the overall density of the wood and d o the density of wood Schwalbe and Fischer. Kolloid Z. 57, 338 (1931). Rept. No. 1156 -2- 6 At the bottom of columns substance determined in water. — 5 and 6 of Table 2 such a comparison is given. The agreement is satisfactory, considering the difficulty in removing surface water without removing capillary water when wiping the sections. The water-soaked sections were then placed in saturated salt solutions with an excess of salt present and allowed to remain for at least two weeks. Swelling beyond the water-swollen dimensions was found to be complete for most of the salts in a few days, but calcium and magnesium chlorides required about a week to come to equilibrium. The swelling of Sitka spruce, which is expressed throughout this section of the paper as the percentage swelling beyond the water-swollen condition in terms of external dimension changes, is given in Table 1 (columns 10, 11, and 12) for a series of chloride and potassium salts together with some of the physical properties of the salt solutions. In no case was there a measurable longitudinal swelling. The radial swelling was much smaller than the tangential swelling and where the tangential swelling was small the radial swelling was negligible. The order of decreasing tangential and volumetric swelling for the different salts is practically the same as the order of decreasing solubility of the salts in terms of mol equivalents per kilogram of solvent (see Table 1, column 3). The only reversal of order occurs with magnesium and manganese chlorides. In this case the solubilities differ but slightly and as magnesium salts stand higher in the lyotropic series for swelling and dispersion of colloids in general, such a reversal might be expected. The relative positions of these two salts with respect to other physical properties given tends to further confirm this reversal effect. Potassium bichromate is the only salt considerably out of position. This salt seems to be reduced by the wood as shown by the greenish color. The amount taken up by the wood is also abnormal, as shown in Table 2, column 7. The order of decreasing swelling is also the same as the order of increasing relative vapor pressure over the salt solutions (see Table 1, column 5) in all cases but the abnormal potassium bichromate. If the salts entered only the gross capillary structure of the wood and not that within which swelling takes place, the sections should all shrink rather than swell and those which gave the greatest swelling should have shrunk the most for this would be equivalent to having small desiccators throughout the wood for controlling the moisture content of the cell walls, according to the relative vapor pressure. The fact that wood is swollen the most in salt solutions which show the lowest relative vapor pressure is strong evidence that the salt solutions must enter the swelling structure. It is interesting to note that the order of decreasing swelling is also the order of decreasing surface tension of the saturated salt solutions (see Table 1, column 6) with the one reversal of position of potassium oidide and chromate. The fractional volume of the salt solution occupied by salt in solution (see Table 1, column 4) -Stamm. J. Phys. Chem. 33, 398 (1929). Rept. No. 1156 -3- 100 + g ds V sol = - 100.1 (2) 100 + g ds where g is the solubility of the salt in grams per 100 grams of water and dB is the density of the salt solution, follows the swelling order with but two changes of position. The effect of the hydrogen-ion concentration upon the swelling was determined. The measurements were made with a glass electrode. Hydrochloric acid and potassium hydroxide were used for varying the pH in a salt-free unbuffered system. The swelling-pH relationship is shown in Figure 1. There is no swelling on the acid side, but an appreciable swelling on the alkaline side at higher pH values. The pH values of the saturated salt solutions (see Table 1, column 7) were also determined. These show no apparent relationships with swelling. Only in the real alkaline salts could any of the swelling effect be attributed to the pH. The order of the solvent power for cellulose of saturated salt solutions at their boiling point (see Table 1, columns 8 and 9) as given by Herzog and Beck,1 is the same, as far as the data go, as the order of swelling of wood in the salt solutions at room temperature. Measurements of the swelling of the wood sections were also made by placing the oven-dry sections directly in the saturated-salt solutions. The same equilibrium swelling is, in general, established as when the sections were .first water swollen, but the process is much slower. The salts tested required at least 9 days to give swelling equilibrium. Magnesium chloride, however, required 58 days to swell to the water-swollen volume. After 100 days the swelling had not yet reached the equilibrium value attained in 7 days by previously swelling in water. This effect might be expected on the following basis: Water alone enters the fine structure readily, causing swelling. After the fine structure is opened the salts can diffuse therein without any great difficulty. If the dry wood is placed directly in the saturated salt solution, the salt solution, which in the case of calcium and magnesium chlorides shows no tendency to wet wood as indicated by the spherical shape assumed by small drops placed on the surface of dry wood, can evidently not enter as such. Presumably the wood tries to take the water from the salt, but such a displacement of the salt-water equilibrium requires that additional energy be expended in the adsorbing process. Only a small amount of swelling could thus take place before salt would have to diffuse into the adsorbed water in order to make possible further swelling. This diffusion into an only partially swollen structure would be very slow. 7 –Herzog and Beck. Z. Physiol. Chem. 111, 287 (1920). Rept. No. 1156 -4- The swelling of wood in the saturated salt solutions is practically reversible for salts which do not hydrolyze. When the salt is removed by repeatedly immersing in fresh water for a couple of weeks, the original water-swollen dimensions are nearly resumed. Measurements were made of the swelling of Sitka spruce in solutions of lithium chloride and potassium thiocyanate of different concentrations. The sections were oven dried, weighed, soaked in water and the air removed, reweighed, dimensions determined, and then placed in a small measured volume of salt solution of known concentration. The containers were sealed and allowed to stand for two weeks to insure swelling equilibrium. The dimensions of the sections were then determined. The equilibrium concentration of the solutions was also determined by evaporation and weighing the residue. The percentage volumetric swelling beyond the water-swollen dimensions is plotted in Figure 2 against the concentration of the salt solution in equilibrium with the wood. No consistent variations between the initial and equilibrium concentrations were obtained, indicating that any selective adsorption is probably small. This is in agreement with earlier measurements of the author which showed that the selective adsorption of ions from dilute solution is very small.— Shrinkage Upon Oven Drying The data given in Table 2 show the absorption of salts by wood and their effect upon the shrinkage when oven dried. The actual weight of absorbed salt solution (column 5) was obtained from the difference between the weight of a salt-solution swollen section and the original weight of the oven-dry section. The theoretical weight (column 6) was obtained from the void volume (calculated with the aid of equation 1) and the density of the saturated-salt solution (column 3). The agreement is as good as could be expected, considering the difficulty in removing only surface solution and not capillary solution when wiping the sections for weighing. The actual weight of absorbed salt (column 7) was obtained from the difference in the weight of the oven-dry wood with and without the salt present. This again is in fair agreement with the theoretical weight of salt (column 8) obtained from the void volume and solubility of the salt in grams per 100 cc. of solution (column 2). Both of these comparisons again indicate that the salts virtually attain the same concentrations in the sorbed water as in the free water. It is true that these data, as well as the analytical measurements just cited, do not constitute so conclusive a proof of this generalization as might be desired due to the fact that the sorbed water occupies only a small fraction of the total void volume (in this case 0.155). Any change in the concentration of the salt in the sorbed water would thus be 6.5 times the measured difference for these data and considerably more in the analytical case cited earlier where a still greater excess of liquid had to be present for analysis. Although the differences between the actual and theoretical values given in Table 2 are practically within experimental error, there seems to be a slight tendency for the former to be greater than the latter, thus indicating the possibility of a slight positive adsorption of salt. According to the following data this adsorption must be very small, however. Rept. No. 1156 -5- The shrinkage of these sections from the salt-swollen condition to the ovendry condition (the sections having been dried at room temperature over P205 prior to oven drying at 115° C.) are given in Table 2, column 9. The measurements show a retardation of the shrinkage even after the moisture is virtually all removed. The more soluble salts in general retard the shrinkage to the greatest extent as would be expected if these salts were deposited in the swelling structure. Assuming that the retardation of shrinkage is entirely due to this effect and that the sorbed-water salt concentration is virtually the same as the free-water concentration, it is possible to calculate the expected shrinkage from the fractional solution volume occupied by dry salt (column 4) by means of the equation V dry = gs (3) where gs is the solubility of the salt in grams per 100 cc. of solution and qi is the density of the dry salt. The expected shrinkage is S = (1 V) S o (4) where S o is the shrinkage from the completely swollen condition to the dimensions that would be obtained on drying if no salt were present. These theoretical values are given in column 10. In general, they agree quite well with the actual measured values, especially where the swelling correction is very small. This agreement furnishes the best evidence obtained that the sorbed water attains a salt concentration virtually the same as that in the bulk water. The quantity measured here is a function of the sorbed water and not of the total water as in the other comparisons so that the diffgrences obtained cannot be due to a larger change in a small part of the system. This virtually uniform concentration of the salts in the swollen wood structure and in the bulk water is not in contradiction to Donnan membrane equilibrium. Neale, has estimated the ionization constant of cellulose to be of the order of 2 x 10-14 . This extremely low ionization constant, together with high salt concentrations, would give an unmeasurable concentration difference. Shrinkage measurements were at first made on salt-treated sections that were dried in the oven at 115° C. without first drying at roam temperature over aln connection with some earlier electrical conductivity measurements by the author (J. Phys. Chem. 36, 312, 1932) it was concluded that dilute salt solutions do not enter the cell wall because of the reduced conductivity at the fiber-saturation point. This explanation of the experimental facts is undoubtedly wrong. The results can still be explained, however, on the basis of the salt solution dispersion not being sufficiently continuous to give the full conductivity effect. No change in the calculations or other conclusions drawn in the paper need be made because of this correction. Neale. J. Textile Inst. gc, T373 (1929). Rept. No. 1156 -6- P 2 0 5 . These sections gave smaller shrinkages than those given in ,Table 2 for the same salts. This was especially noticeable for sections treated with salts, the solubility of which increased greatly with an increase-An temperature. Apparently the concentration of the solution in the gross capillary structure increased as water was evaporated and the salt diffused to a greater extent into the swelling structure because of the increased solubility. Shrinkage and Moisture Content at Different Relative Vapor Pressures Salt-treated sections were dried in humidity chambers to obtain the shrinkage and moisture content at different relative vapor pressures. Air was drawn through towers containing saturated salt solutions with an excess of salt present. The towers contained about an inch of mercury on the bottom. The air supply tubes dipped below the mercury surface to prevent the tubes from becoming clogged with salt crystals. The air from the towers was then bubbled through open dishes of the saturated-salt solutions placed in the bottom of vacuum desiccators which served as the humidity chambers. Air was drawn through the system under vacuum of about half an atmosphere at the approximate rate of 10 liters per hour. Under these conditions the theoretical relative vapor pressures in equilibrium with the saturated salt solutions were virtually attained. The temperature of the desiccators was not automatically controlled as the change in relative vapor pressure with moderate changes in temperature was small for the salts used. Measurements were made with barium chloride, sodium chloride, manganese chloride, magnesium chloride, and lithium chloride in the humidifiers. The equilibrium relative vapor pressures for each of these salts are given in Table 1, column 5. The dimensions and weights of the conditioning sections were determined at varying intervals to determine the shrinkage and moisture content. The salttreated sections in general required longer to attain equilibrium than the controls. Several weeks' time was required to insure complete equilibrium. Difficulty was encountered in making the moisture determinations on sections that had been treated with saturated salt solutions because of the flaking off of surface-deposited salt while determining the dimensions. It was necessary when the salt concentration was high to use two matched sections, one for shrinkage data and the other, which did not require handling, for moisture content data. The percentage volumetric shrinkage is plotted for a number of different salts and two woods in Figures 3, 4, 6, and 8 against the relative vapor pressures and in Figures 3, 5, and 7 against the moisture content. In all cases the shrinkage begins when the relative vapor pressure under which the section is being dried is slightly less than the equilibrium relative vapor pressure of water over the salt solution at the concentration attained when evaporation has proceeded to the fiber-saturation point. Rept. No. 1156 -7- Figure 3 gives the data obtained by drying sections treated with different concentrations of sodium chloride. The points for sections treated with 36, 25, and 15 grams per 100 grams of water all fall on the same curve. The shrinkage is slightly greater for 5 grams per 100 grams of water and considerably greater for 2 grams per 100 grams of water. When the sections are slowly dried the concentration of the unsaturated solutions increases in the void structure and evidently diffuses into the swelling structure. In the white pine the sorbed water occupies 0.137 of the total void volume so that when the moisture content is reduced to the fiber-saturation point, the concentration is increased 7.3 times. This would cause saturation in all but the most dilute solution, and in the section treated with a solution containing 5 grams per 100 grams of water the concentration would just slightly exceed that required to give saturation. Under these conditions any slight deposition of salt in the grosser structure would prevent complete saturation of the swelling structure and account for the slightly greater shrinkage. According to the relative vapor pressure at which shrinkage begins for this specimen the effective concentration is 30 grams per 100 grams of water instead of 36.5 as calculated for complete diffusion into the swelling structure. The former concentration gives a calculated oven-dry shrinkage of 9.2 percent which is practically identical with the measured value. For the most dilute solution the effective concentration, according to the relative vapor pressure at which shrinkage begins, is 10 grams per 100 grams of water instead of 14.6 as calculated for complete diffusion into the fine structure. The former gives a calculated oven-dry shrinkage , of 10.05 percent. This again agrees nicely with the actual measured value. The maximum antishrink effect can thus be obtained at a concentration slightly in excess of that which will give saturation upon evaporation to the fiber-saturation point. Figures 4, 6, and 8 give the volumetric shrinkage-relative vapor pressure curves for other salts. Figures 4 and 6 give data for sections of Sitka spruce and white pine treated with quarter-saturated salt solutions and Figure 8 gives data for sections of white pine treated with saturated salts which also act as fire retardants. In the quarter-saturated solutions the swelling is negligible, but upon drying to the fiber-saturation point swelling takes place as if the sections had been soaked in saturated solutions, thus giving further evidence that the salts diffuse into the fine swelling structure while drying. The shrinkages are calculated from the saturated salt-swollen volume rather than the initial volume to make the results comparable with those given in Table 2. The shrinkages to the oven-dry condition shown in Figure 4 are nearly identical with those given in Table 2 for sections treated with saturated solutions. The volumetric shrinkage-moisture content data are plotted in Figures 3, 5, and 7. In all cases a linear relationship exists between the shrinkage and the moisture lost from the fiber-saturation point to oven dry. A similar linear relationship exists between the tangential shrinkage and moisture content and the radial shrinkage and moisture content, thus showing that the ratio of tangential to radial shrinkage is constant over any moisture content range. Further, the ratio of the tangential to the radial shrinkage Rept. 1156 -8- is the same for salt-treated specimens, for which the swelling beyond the water-soaked dimensions was small, as it is for the controls. In sections treated with swelling salts the ratio is somewhat affected as would be expected, due to the abnormal tangential swelling. The linear relationship obtained on the external-shrinkage basis might be expected to hold on a total shrinkage basis, over the sorption range if the adsorption compression effect is negligible. The fact that it holds for the shrinkage manifested externally indicates that internal shrinkage in the grosser capillary structure must be either proportional to the external change or practically negligible. For the small specimens thus far tested the following relationship seems to hold: S=dxf where S is the fractional shrinkage from the fiber-saturation point to, the oven-dry condition, d is the density of the wood on a dry weight-green volume basis, and f is the fiber-saturation point expressed as a fraction. The relationship requires that the volume of the grosser capillaries does not change with changes in moisture content. This internal swelling is being studied more critically at the present time by a different means. If it is found to be practically negligible according to the foregoing indications, it will account for the linear relationship on the external dimension shrinkage basis. With the preceding relationship it is possible to calculate the moisture content of the salt-solution swollen specimens at the fiber-saturation point. For example, if a section of Sitka spruce could be swollen to the volume obtained in saturated lithium chloride solution in water alone, the fiber-saturation point would be raised from 29 to 33.9 percent. The fractional volume of the solution occupied by dissolved salt is, however, 0.282 (see Table 1, column 4) so that (1 - 0.282) x 33.9 24.4 gives the percentage of water held at the fiber-saturation point. This is in good agreement with the value obtained in Figure 5 by extrapolating to a zero shrinkage. The values calculated for the sections treated in the same manner with potassium iodide and potassium thiocyanate are 23.6 and 15.7 percent, respectively, which are also in good agreement with the values obtained from Figure 5. According to this the salts can in part displace the sorbed water. The balance between the forces of attraction of wood for water, salt for water, and the resistance to swelling of the wood beyond the normal green dimensions results in the wood taking up a greater volume of salt than the volume of sorbed water displaced, thus causing swelling. From this it follows naturally that swelling should be greatest with the most soluble salts. From Figures 4 and 6 it is obvious that no antishrink benefit from the standpoint of constancy of dimensions can be obtained with any of the salts if the prevailing relative humidities are always below the relative vapor pressures in equilibrium with the saturated salt solutions for the rate of change of shrinkage with changes in relative humidity is greater for all of the salttreated sections than for the control. From the standpoint of seasoning, Rept. No. 1156 however, where the extent of degrade in the form of checking and warping of the wood is a direct function of the total shrinkage, the antishrink effect of the salt treatment may be of considerable value. From Figures 4 and 6 it also appears that treatment with a very soluble salt such as lithium chloride would solve the shrinking problem completely for relative humidities below 11 percent are very rarely encountered. Unfortunately, however, sections treated with a saturated solution of lithium chloride are always wet and sticky at humidities just slightly above 11 percent. They tend to take on more moisture from the air, but as the capillary structure is already full of solution, dripping at the surface will occur with the loss of salt. This will continue until a concentration is reached that has a relative vapor pressure the same as the prevailing relative humidity. Treatment with quarter-saturated solutions will give the same antishrink effect, but the sections will not drip, unless the relative humidity is above 78 percent, which is the relative vapor pressure for the concentration. Similarly, a section treated with quarter-saturated magnesium chloride will not drip unless the relative humidity is above 82 percent. Although the sections treated with quarter-saturated salts will not lose salt as readily as those treated with saturated salt solutions, they will be wet and sticky above the equilibrium relative humidities. Summary 1. The increased swelling of water-swollen wood in saturated salt solutions was measured. (a) The order of increasing volumetric swelling was practically the same as the order of increasing solubility of the salts, increasing fractional volume of the salt in solution, increasing surface tension of the salt solutions, and decreasing relative vapor pressure over the salt solutions. (b) The pH of the solution had practically a negligible effect upon the swelling, although the wood swelled in alkalies and not in acids. (c) Swelling equilibrium was attained more slowly when dry wood was placed directly in the saturated salt solutions than when previously swollen in water. 2. The shrinkage and moisture content obtained on drying salt-treated sections at different relative humidities were measured. (a) Shrinkage started when the relative humidity under which the sections were dried was less than the relative vapor pressure over the treating solution at the concentration attained when evaporation had proceeded to the fiber-saturation point. Rept. No. 1156 -10- (b) The shrinkage occurring on oven drying of the salt-treated sections was less than that of the controls because of the taking up of salt by the structure within which swelling took place. This shrinkage was also calculated from the fractional solution volume occupied by dry salt by assuming that the salt concentration was the same inside and outside of the swelling structure. Other evidence was also obtained to show that the sorbed water virtually attained the same salt concentration as the free water. (c) The shrinkage of all the sections was directly proportional to the moisture lost. The salt was shown to partly displace the sorbed water from the wood. Those salts which tended to displace the most sorbed water caused the greatest swelling. .3-22 Rept. No. 1156 -11- 0 0 •-4 a) 5, 4d, M •4 0 0 a • o O0 CM O (V Is 0 co "4 I .-I r+ a) 0 4. al c0 se vo. 04. 4. 0 0) 0 1-1 a) R. CS O O H del0* shok el.so sW Or Po sp• Nri .0 0 \ 0 kJ) te\000 0 0 ONCU0Jr400000 • 0 -p 0 H b() 03 •r4 W4 1.-H6060 Cll CU 0-4-0frNISO aclac H HO • • • • • • • • • ONLC1I1\r4 MD CU CU MI WC:1\1,-H hr\r4H r4r4 • • • • • • • • • H 8-48 . 1 C\ I 1:11 H +3 00 0 • • • • • • • $4 s. v. N0100000000 CVCV0000000 • • • • • • • • • • . \DA" VO X0 0.10.4' 0 011\14-Ve\ •-11-1 0 Is-0 • • • • • • • • r-1 14\1"-H ONO al CU CM Pr\ CT\ rr\I-1 HH • • • • • • • • • 8-I 8-1 r-1 E-• .A 4.11 0* • CO CO M 41.1 H P ,o sd E. >,. +3 40 4-1 3-( 0 0 60 0 0 0 +-I 0 +3 0 -•41.r4 cd •r4 Q /4 _0 M M H r4 H otT 03 0 • • • • 14' 0 0 C) TS 01 I> 0000.400 044 H Ft 0 41 r0 -1 0 03 0 0 CO 0 CO CO .14 F-4 oo so O. wo ow es OW mm o• wd ss kJ) \-i• 0 I's:*r-6010 me° H rev)) \O now:, • • . • • • • • 060..1- MM -1- 14-.4- 4- 1-- O O M_1- cu arN 4. 43 • s• oo oo oo sh• qle ms s. .. r-reNt-0000 arNnCV rev411/40 crscr.t.mo o CV • • • • • • • • • 1 - 0160 11-1- ∎13 111.0- ‘.0 O ao A . H al 0 0 rsCV o •n•• 4. al • cd 1+ CU 0 F-I 0.7 O CD 4. 0 r-1 • 00 00 O co cd.) '-.0 F. 0 ro 0 a) 0 0 1.1- 1 co CM 04%* H 60 ON0190 • • • • • • • • • CM 0 I's- Pr \ 0 CU 0 1:11f`- no ma\ aye° 00 r--r-- N8-1 01600'-0 N\000• • • • • • • • • 0 C"CONLL"\-.1- MM 000000 r- r--r- r- r- r- \ CI 0 0 4. 0 .1. 0 I-1 4J, 00 • N .• al O - al • Ctl 0) 4-, al cd H' 0 r-i 0 43 co 7=1 cd 0 4-3 al M • 14 C.) M 1-1 14 0 0 ra• 0 +30 cd co CV C 4. 0 a, O cd m ri• 4-, 0 0) 417.0 O -1-, 0 P. cd cry -c-1 0 0 a 0 SC4 $4 0 0 4-3 0) 0 P 4-I cd •cd 0 4-4 ca E-• P. 4+ cd 0 ca H •• 0 arN qd E-od 0 0 • O M al H Er4 • • 0 ••••1 1. so vs A- 0 Kw° sso 1111-1 8-1 C\1121 WNW r4 8-4 H H CU HO • • • • • • • • • cu r-to Cr.* KN.* H kr/ 11\0NT-rap CM 8-4 CM M N LCNCU H H r4 r4 0 0 0 • • • • • • • • • O 0 a.1 4-, 4.. .4 4. CO H .H H •v-1 ••-I 44 90 a) 0 0 0 CO H H o o 0.0 • •r1 0 1 4. 04-1 H 0 ++ P .0 to cu _M- 0P PO ow .0 s• ae der a 44 •-4 44 •-1J a) co cd Y•• 413 44 ++ a) 0 a) P. 0 •ci O 10 0 8.-1 0 0' a) • H O ISO mm • • • • 00/10 CM N-*0\1014-\ Is-LC\ 0 WA' 11160 8-1 (TAD.* • • • • • • • • • • • • • • • • • • $'4\8-1 000re\rdl 8-1\010.4• MCU tO CU LC\ 8-1 1-1 8-1 a000000 c)0013cd 0 0 0 tzt) ss H o r4 4-4 sir c•--1 to A gH 3•0 b TS a) 0 CU a 0) a) M 4-3-p 0:10000 N (moral al Hx xxx H H1/4.0 \O.* 1--4 14 d H d rl O 00 O ° J O EI H H cd a3 M cd 0 „DO 0 irt 9-1 0‘4. 00 0H rn co H a) or) al 4.) 0 O Pm co 0 co a) Cu a) +3 0 • • co a) 0. P. 0 0.1 LC\O CVO 060 t•r\ • • • • • • • • • 1 - 01e0 •-* ONIINVO to 01 _I- n.,;) sro 00 'co cr. ON a's 01 Cd. cl-t 0 el cd 5-1 0 1*--reu-1rcve0 CU \O • • • • • • • • • LC1010N1-1 0 I-1 CV 14" \ MCC\ P.-1,-00 ON CO cd O -1- 0 CU.4- CU re\ 0.1 0.1 CU r-1 CU 14'0 14 0 c (0 H r4r4HHHHQ 0 /4 r4 0 CO C-11,4 IA 000C.100 - HO 0 1-4 CUM 0 M 0.1 CVO 0 44 03 M A aiM th GS ha isel ha *I 13.7 ha hsl NI bd N•40XIMIM=1:403 a 0 CU M 11190 H v-4 H 00000 000 0 0 4a 0 1-1 4-9 a, O m0.4 -14 td El A-I 0 1-1 •cl &I 0 0 11-1 X 0 co 0 bl) 41 O 0 +3 I .400 r40 0 o 0) co b. sd 0 O 4a 0 43 O Xi 40 0 11140 111.4. 0 LC\ \.0.4. • • N•Lf•\ • • • • • LC\ 0\ 01 MON ON 01010 r4 O 0 ••n 14 4) P4 Er\ 0 0 .•e +a al 0 000noornon • • • • • • • • • ko1300101010'06-40 0 3' N NI° co El •-n •-1 1-1 00 00 42 0 al O Vr4o040WN-r-0 • • • • • • • • • O Cr% $4 41) tnaNtommaNmmo pg •p 4) r-1 .0 4a 1-1 1d C1041 Fd H 00.i00 41 0 A-1 0) 03 03 .0 E. 43 reveo Lc1Lr1P-re.-1- o ovco • • • • • • • • • \OW) 0\ 0\ CA 0\ 0 0 H 6--1 r-I 6-4 pew\ • • r-I 6--1 6-4 1-4 .4a 0 co 150 u-Nr•-•revz r-co 010140 0101 • • • • • • • • • Lc\ •-1 r-I gl t•-0\1110.11^V400.1LC‘0.1 0••-4\0\00‘10141010.1 • •••••••• CU KNr-I r-1 r4 0 2 4) .04-, 03 r-I b134-1 4. A-1 0 0 al O 4) CO 0) •4 it 1--1 Lb r-i + ce 0) cd 0 0 re --10100 r4 01014 N-400\400 x4001111001150010 • • • • • • • • • 00.1%.0\00NCAM,..001 ••••••••• LINHH1-10.1 •H Pr\KNHH 1 4. 0 H a) 4. 0 1-4 . 00 00 00 00 00 0 0 00 4-I 0 •0 0 0 0 4) r4 4. AD 4a A4 O 4. C.) ca 14 .0 $46-4 4a O 0 bD 0 Cd 4) A-1 A-4 CO CO 0.0 [-• as g cd 0-4 0 co \0\0 Li1150.4. 12\OCU040 \1:1 \OON•0 CV t0 •\ Cr• \• \ 0• ‘.0• \ 0• Cu• • • • • 1-1 • r4• •.0 • Inn) • • • 6-4• MM MM A- LA* KNKN44Nrr\ Pr‘ MVO • • c‘.1 to• 04. 01/401,-al nDfs• • • • • • • • \.0.4A.4 4. MM MM 0%40 • • Cu al a• 00 00 Oa .0 00 0. 00 .0 0 •0 0 4) 0 .0 -la .4.. 0 .0 ▪ 1)0 0 r-o d .4 m cd •-I .400 co 0 la 0 CO t-1 cd 0 O LC\ C.5 • .4•• H• • \01/40 CV \-0 el • • • • • c."\ rr\ cc\ Pr\ cc .1 00 MO OM 00 00 d. OD ap 410 • • • • 00 mdm 4. Oa OM .0 00 4 11 0 0 >.• •6-4 .0 9-4 0 r-I • cd +3 0 0 ,--10 43 o 0 A-1 4) 0 A-I 030 (\I 0 0 E.. r-1 4-4 0 $44.3 $406-1 0 •0 cd cd 0 co ›-• 010 r-re\ re\ trLO 40 N-40 6-4 rim 01 trie0 trau C\10.10,1 r-I r-1 6-1 0• • • • • • • • • 0 0) cd ED O O IA a) co la -4 4.1,1 CU C5 inrenr•-tno 0 .04 a. P•010 0`t lflrl U1L11 kr:ma al Cu 1,-0 r4r440Wr-.* tUr.4 N 4P-MMI-41-1000 Or4 cu • • • • • • • • • • • • • • • • • • r1 0-4 6-i0-1 r-1 0-1 H Hr-41-41-4Hrir4r4H 4A 0 0 FA 0 4) . 43. Cl OMO1Cs..1-40COW6-1 • • • • • • • • • 0100100.10-10101M 1.1 al • r44.20 44 r-1 .04)o m0 •-1 044 clb 0 0 0 0 co .-c • .. 4) cd 43 r-1 IA r-1 . .0 0. a! g r40 00 O :10 44 +3 744 F-I 0 0 04) .q .0 ••• 441 CO 0 0 • 03 0)47 r-t H 4) 00,0 100 Mr11/40 0 Mr-4 1•10-1 0 al 0 01LnEI1.4•4. nye\ •-I• • FA 0 0• 0• • • • • • O 1 97 r-I 40 q 0• >.F 4.3 cd H q 0 CO 0 +. 0 0 4. Alc• a) 0 0 Cu Q c0 0 0 .0 • .0 t-1 • • cd ri 00 .0 1---Lm0.4-10encucmre. r4 00 00 00 00 WO 0. tO•Lflai OJ 1,-0 00 • • • • • • • • UN* 0\40 0 ONO UNL.Ckal (V 0-1 "-I 0-1 .0 00 O. 00 00 WO 09 CV CU CV CV r4 CV •-I 0-1 r-1 0-1r4r4 C..) 0-1 000000 4,-4Q 0.401:00 cOMO CO N •-1 0 Al 14 = b4 rcl .0 .0 00 00 P. PP 40 PP .0 .0 or-.4 CV 14N res0 14 0 CO $4 m 0146-40cno6-•1 0 01-4081:10Z CV0.10 CV b4 04 b4 04 b4 Erl NI W 04 M -1- 0 0 r4 r4 Or-I 0 • cd 0 F300 0,40 f44•3$4 4409-4 0 4) 0 4) 43 +a Ce00 •-; O 0 O El 0 r40r4 Id N cd 044 44%* NON r-11.4 r4 000 000 2.5 11:co o to E. 2. 0 a, c.o 0 •o „, • < 11, o• coct Po o 1. 5 1. 0 o" CD o CD OQ .5 0 0 0 0 0 1 2 0 3 4 5 6 7 8 pH 9 10 11 12 13 14 Figure 1. --Swelling-pH relationship for white pine. Z M 2 2 40 8 F 2.4 2.2 2.0 `') 0 c 0 co rs 1.8 1.6 0 b0 0 • ,4 1.4 1:1 a.) 1.2 u u 1.0 0 .8 TD" .6 fd .4 .2 0 Concentration of salt (gms. per cc. ) Figure 2. --ffect of concentration of salts upon the swelling of Sitka spruce. Z 22401 F 0 0 N N x an 04 0 m 0 0 P4 6 0 fa. 6 cd Z z • • 0 CO ss) ul n7 M 0 • -1a) PI 0 ;.• 0 04 k 0 04 cr.I • 0 > 0 o 0 r.4 r., 0 cd 4-n • r4 a) r4 tm 00 o 4a' 1) ..-▪ '+4 N ( 00 U) •8 '0 Ti 0r9 a; a) c.) k g 0 0 -1-J U 4-1 •••n••• •ri (I) • r-I id k o -t c.) a) co co a) bA b.0 (i) 0 0 a) ▪4cvs-' 4-4 r cc) 1:1 (I) - g -Im' •••1 w k (1) X k 01 +4 I (1) (I) 0 P-I *1.4 a.) O CI) CO) P14 fil Q.) 4-) cl) • n•• " cd z Z - rd En Q ...-.. cn ?id cn O 0 o g c0c3 M O .14 4.4 ci cd GI 0 k • k 4 Cli k )-4 0 0 0 la t . •-k •,-• s 01 5 F14 -8 4a) "..4 .,_, (in En a) 110 -0 • a) tti 0 t7:4 4a) N3 a) O "'a' o U a) . 0 4..) o u) .1-1 0 , a) .—I I-, ...... I a) c 1 )10 . cis 0 ..-1 ce) ... Ti 0 co0 cl.) •,-1 k k 0 4 4•4 01) En 0 .•,4 r•Z4 Volumetric shrinkage (percent) ..'Z' c.) .0 in 01 ni Volumetric shrinkage (percent) a • No salt 4D LiC1 BaC1 e!) MnC1 0 Ki n NaC1 • 10 2 MgC1 20 KCNS 15 20 25 Moisture content (percent) Figure 5. --Moisture content-shrinkage relationship for Sitka spruce treated with different quartersaturated salt solutions. Z M 22409 F N Ir •41 N Volumetric shrinkage (percent) In1 O No salt • MnC1 O BaC1 e MgC12 2 3 LiC1 Q NaC1 10 15 2 20 Figure 7. --Moisture content-shrinkage relationship for white pine treated with different quarter-saturated salt solutions. Z M 22402 F Volumetric shrinkage (percent)