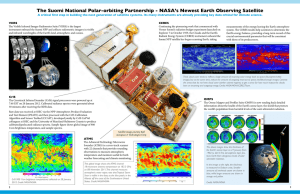

The Cross-track Infrared Sounder: Sensor Design & Projected Performance

advertisement

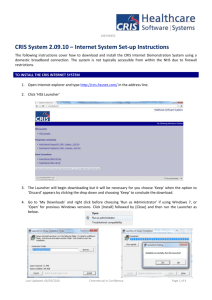

The Cross-track Infrared Sounder: Sensor Design & Projected Performance Ronald Glumb & Joseph Predina ITT Industries, ITT Aerospace/Communications, 1919 West Cook Road, P.O. Box 3700, Fort Wayne, IN 46801, USA CrIS ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS CrIS System Overview The Cross-track Infrared Sounder (CrIS) • CrIS NPOESS Mission – Retrieve temperature, moisture and pressure profiles of the earth atmosphere – Component of the CrIMSS (Cross-track Infrared/Microwave Sounding Suite) – NPP launch 2005, NPOESS launch 2007 • CrIS Space Segment – 833 km orbit, 98.7 degree inclination, 101 minute period – Measures upwelling IR radiance in 1305 spectral channels (3.9 um to 15.4 um) – 918 Interferograms measured each cross-track scan (8 second period) • 30 Earth scene Fields of Regard (FOR) • 4 calibrations (2 Deep Space + 2 Internal Calibration Target) – 1.25 Orbit Raw Data Record • 35,062 FORs, 315,562 FOVs, 946,687 Interferograms • CrIS Ground Segment – Sensor Data Record (SDR) algorithms • Transform CrIS interferograms into fully calibrated and geolocated spectra – Environmental Data Record (EDR) algorithms • Transform SDRs spectra into temperature, pressure and moisture profiles CrIS ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS Section 1 - 2 CrIS System Overview CrIS NPP Mission Scheduled for Early 2006 Launch ModuleLevel DDRs PDR Phase 2 Phase 1 ATP DDR EDU3 Adds 1394 and GIID Upgrades; Available to NPP 6-12 Months Before First Flight Unit DDDR Detailed Design GIID Mods EDU2 Build EDU2 Test Demos and Breadboards CDR EDU3 Build and Test Plan Contract (12/04) 2/05 Flight Unit #1 (NPP) Build and Test EDU1 at PDR Validated CrIS Design Concept 1999 CrIS 2000 Flight Unit #2 (Delivery in 2/06) EDU2 Greatly Reduces Risk: Flight-Like Hardware Built and Tested Before CDR 2001 ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS 2002 Section 1 - 3 2003 Flight Unit #3 (Delivery in 8/07) 2004 2005 CrIS System Overview Overall Relationship of CrIS RDRs, SDRs and EDRs • 833 km orbit • 98.7° Inclination • CrIS • ATMS RDR = Raw Data Record ( Uncalibrated ) SDR = Sensor Data Record (Calibrated) EDR = Environmental Data Record Central or Regional Ground Stations 2,200 km Swath Decode Spacecraft Data RDRs to Users Raw Uncalibrated Data Sensor Calibration Algorithms SDRs to Users Calibrated and Geolocated Radiance Data EDR Algorithms EDRs to Users • Temperature Profiles • Moisture Profiles • Pressure Profiles 20 minutes CrIS ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS Section 1 - 4 CrIS System Overview Characteristics of CrIS Scan Footprints CrIS Field of Regard (FOR) Definition • 1 FOR = 9 FOVs • 1 FOV = 3 IR bands Single CrIS Scan Line (full sweep, 30 FORs) 3.33 degree steps Nadir 48.33 degree 0.963 degree (14.0 km) Anti-sun 3 6 S/C Velocity 9 1.100 degree Edge (16.0 km) 2 5 8 1100 km 1 1.024 degree (14.9 km) 4 7 0.897 degree (13.0 km) Three Successive CrIS Scan Lines (nadir to edge sweep) CrIS ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS Section 1 - 5 CrIS System Sensor Design Overview Reqmnt ID Requirement SDRP907 Spectral Bands SDRP944 Unapodized Spectral Resolution 1/(2*max OPD) SDRP3546 Spectral Uncertainty SDRP6841 ILS Shape Uncertainty SDRP3481 Radiometric Uncertainty SDRP1033 System NEdN SDRP3696 SDRP3696 LWIR Scan Extent SDRP882 SDRP3731 Mapping Uncertainty LOS Jitter MWIR 650 – 1095 cm 0.625 cm -1 SWIR 1210 – 1750 cm -1 1.25 cm -1 2155 – 2550 cm -1 2.5 cm -1 -1 10 ppm (flight unit 1) 5 ppm (subsequent flight units) 10 ppm (flight unit 1) 5 ppm (subsequent flight units) 10 ppm (flight unit 1) 5 ppm (subsequent flight units) 0.5% FWHM 0.5% FWHM 0.5% FWHM 0.45% 0.58% 0.77% See Chart See Chart See Chart Same as LWIR Same as LWIR 0.3 0.2 0.3 N/A 0.3 0.2 0.3 N/A FOV Size (km) 70% width (in/x track) 50% width (in/x track) 10% width (in/x track) 1% width (in/x track) FOV Shape Match (km) 70% width 50% width 10% width 1% width SDRP3628 SDRP3630 CrIS CrIS Science Mission Cardinal Requirements 11.8/12.7 13.2/14.2 14.9/16.0 16.8/18.0 0.3 0.2 0.3 N/A 30 x-track FORs: +/- 48.333 ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS o 1.5 km 50 rad/axis Section 1 - 6 30 x-track FORs: +/- 48.333 1.5 km 50 rad/axis o 30 x-track FORs: +/- 48.333 1.5 km 50 rad/axis o CrIS System Overview Predicted Sensor Noise Performance NEdN (mW/m2 sr cm-1) 1.0 0.1 0.01 0.001 600 800 1000 1200 1400 1600 1800 2000 2200 2400 2600 2000 2200 2400 2600 Wavenumber(cm-1) N EdT @ 250K 10 1 0 .1 0 .0 1 600 800 1000 1200 1400 1600 1800 W a v e n u m b e r (c m -1 ) CrIS ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS Section 1 - 7 CrIS System Overview CrIS Produces Superior Performance Compared to HIRS While Retaining Comparable Size & Power Consumption LWIR Spectra Measured By HIRS (12 Channels) CrIS ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS LWIR Spectra Measured By CrIS (713 Channels) Section 1 - 8 40 Performance Above Threshold (%) 12 cm 10 cm 30 8 cm Volume Constraint 20 10 5 cm 0 0.98 1 1.02 1.04 1.06 Relative Life Cycle Cost An 8 cm CrIS Aperture Was Selected as a Cost-Effective Way to Improve EDR Performance CrIS ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS Section 1 - 9 Performance Above Threshold (%) CrIS Was Optimized for a Very Specific Atmospheric Sounding Mission CrIS System Overview 30 20 Cost Constraint Power Constraint 4-Stage, PV Active, PV 10 3-Stage, PC 0 0.9 1 1.1 Relative Life Cycle Cost Photo-Voltaic (PV) LWIR Detectors and a 4-Stage Passive Cooler Result in Optimum Cost Versus Performance 1.2 CrIS System Overview Key Technical Features of CrIS Sensor CrIS Sensor Features • Large 8 cm Clear Aperture • Three Spectral Bands • 3x3 FOVs at 14 km Diameter • Photovoltaic Detectors in All 3 Bands • 4-Stage Passive Detector Cooler • Plane-Mirror Interferometer With DA • Internal Spectral Calibration • Deep-Cavity Internal Calibration Target • Modular Construction Physical Requirements CrIS Volume Mass 80 x 47 x 56 cm < 98 kg Power < 95 W Data Rate < 1.5 Mbps ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS Section 1 - 10 CrIS System Overview Compact Optical Design Allowed the Largest Possible Aperture Given Volume Constraints Large 8 cm Aperture Yields Better NEdN 1.5% FOV Co-registration Achieved Between Bands Telescope Optics Scan Mirror Back End Optics & Detectors Cooled for Better Noise Performance Detector Assemblies CrIS ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS Section 1 - 11 Interferometer Optics CrIS System Overview Rigid Interferometer Structure with Balanced Mechanism Minimizes Susceptibility to Spacecraft Vibration Balanced Moving Mechanism Dynamically Aligned Optics Yields Stable ILS Over Mission Life Eliminates ILS Tuning by Ground Algorithms Input High Tolerance to Vibration Keeps Noise Artifacts from Being Generated CrIS ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS Fast Reaction Servo Controlled Optical Alignment Mirror Section 1 - 12 CrIS System Overview Post Interferometer Optical Processing Separates Optical Energy into 3 Bands and 9 Fields of View Athermalized Aft Optics Assembly (Cooled to 220K) Bolt-Together Detector Optics Arrays Boeing Advanced Photovoltaic Detectors CrIS ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS 3-Element On-Axis Telescope Section 1 - 13 Electrical CrIS System Signal Flow Overview Interferograms, Engineering Data & Science Telemetry Comprise CrIS RDRs SPACE SEGMENT - CrIS Sensor Detector DS ADC I (x ) Interferogram Interferometer (photons) 255 Tap FIR I (x ) L(s ) ES: Earth Scene DS: Deep Space ICT: Internal Calibration Target Filtering & Decimation Reduces data rate ~ I ( x ) complex Engineering Data (three different types) Must be done first real ICT Observed scene Impulse Noise Clipping Bit trim format data laser frequency info: NNe, NL ICT emissivity tables & model data Polarization correction tbl (if needed) ILS parameters for 54 channels CrIS mounting angles LOS angles for each FOV Signal ID/QC Data IGM start time (UTC) FOR index (0-31) Band ID (LW,MW,SW) FOV ID (1-9) Sweep direction ZPD min, max & position Quality control flags Impulse noise count Bit Trimming Downlinked to Earth RDR Packet Encoding Interferograms Calibration Data Once per 8 seconds Laser diode temperature/current ICT, BS, Scan mirror temperatures All optic temperature telemetry SSM pointing errors Science TLM Data Only Processing of Science Data Shown CrIS ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS Section 1 - 14 CrIS System Overview CrIMSS Projected Performance 1 30 100 100 25 Altitude (km) 10 Altitude (mbar) Altitude (mbar) “Threshold” Performance 500 20 15 10 5 1000 1000 0 0.5 1 1.5 Retrieved Temperature Error (K, rms) CrIS ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS 0 0 5 10 15 20 Retrieved Moisture Error (%, rms) Section 1 - 15 25 0.0 0.5 1.0 Retrieved Pressure Accuracy (%) CrIS System Overview Expected Improvement Over HIRS CrIS CrIS HIRS HIRS RMS Measurement Uncertainty, Global-Average Basis CrIS ITT INDUSTRIES - AER - ABB BOMEM - BALL - DRS Section 1 - 16