Tilt GLUINC CHARACTERISTICS CIF 15 SPECIES CIF WOOD WITH CCM- Information

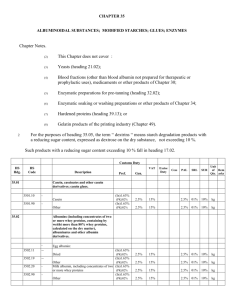

advertisement

OREGON FOREST PRonucTs LAtIORATOKI LIBRARY Tilt GLUINC CHARACTERISTICS CIF 15 SPECIES CIF WOOD WITH CCMSLUING, UEFA-14SM GLUES Information Reviewed and Reaffirmed January 1955 No. 1342 UNITED STATES DEPARTMENT OF AGRICULTURE FOREST SERVICE FOREST PRODUCTS LABORATORY Madison 5, Wisconsin In Cooperation with the University of Wisconsin OREGO:1 FORT:ST PPODUCTS LABORATORY LIBRARY THE GLUING CHARACTERISTICS OF 15 SPECIES OF WOOD WITH COLD-SETTING, UREA-RESIN GLUES1 By H. W. EIMER, Engineer The study here reported was made to compare the gluing characteristics of various species of wood when glued with cold-setting, urea-resin glues, since it is known from previous studies . that there are considerable differences in gluing properties among species when gluing with other woodworking glues. The species under test in this preliminary study are those which appear to be .of primary importance in war production work. Others may be tested as the need arises. It was the aim to conduct the tests in such a way that the results could be compared with those obtained previously on the same species when glued with casein glues,3.In addition, tests were made to see if there is any difference in the gluing properties of the heartwood and sapwood of several of the species when glued with urea-resin glues. Procedure Species and. Selection In this study, the following species were selected on the basis of their importance at the present time: ash, white basswood birch, yellow Douglas-fir fir, noble hickory, pecan mahogany maple, sugar oak, red oak, white pine, Southern yellow spruce, Sitka sweetgum walnut, black yellow-poplar 1 . -This report is one of a series of progress reports prepared by the Forest Products Laboratory to further the Nation's war effort. Results here reported are preliminary and may be revised as additional data become available. The work was completed in April 1942. U. S. Department of Agriculture Bulletin 1500, entitled 1 The Gluing of Wood," by T, R, Truax. Report No, 1342 -1- Both heartwood and sapwood of the seven following species were selected and glued separately to determine if there was any difference in their gluing properties: birch, yellow hickory, pecan maple, sugar oak, recl oak, white sweetgum yellow-poplar Nominal 1-inch lumber was used for all species. The material was so selected that the average specific gravity of each species was approximately equal to the average for the species as listed in U. S. Department of Agriculture Technical Bulletin 479.-q The stock was then cut into pieces about 1 by 3 by 14 inches in size. The pieces were placed in a room where the relative humidity was 65 percent and the temperature 80 0 F., and allowed to remain there until they had reached approximate equilibrium in moisture content. The stock was then between 11 and 12 percent in moisture ,content. The blocks of each species were weighed, arranged in order of their weights, and the adjacent blocks were then paired so that blocks of nearly the same specific gravity could be glued together. As there were four glues used in this study, the pairs of blocks were divided into four groups having similar ranges of specific gravity by selecting every fourth set for each glue. Just prior to gluing, the blocks were cut to a size of 7/8 by 2-1/2 by 12 inches and the faces planed smooth. Glues and Gluing Conditions Four commercial cold-setting, urea-resin glues in common use at the time the study was made were employed in gluing all the foregoing woods. The glues were made by four different manufacturers and were selected as representative of the better brands of the cold-setting, urea-resin glues then available. The glues were mixed as directed by the manufacturers and spread with a small mechanical spreader equipped with a rubber roll which was adjusted to deliver a spread of between 20 and 25 grams per square foot. Assembly periods (interval between spreading and pressing) of 5 and 15 minutes were used to approximate a range commonly used in commercial operations. The gluing pressure was 150 pounds per square inch. This pressure was allowed to remain on the blocks for a period of about 16 hours. The temperature in the gluing room and of the material in the press was maintained between 75° and 800 F. Four joints providing 20 test specimens were glued at each assembly time for each glue, which resulted in 32 joints per species, or 64 joints when the sapwood and heartwood of the species were glued separately. ---"Strength and Related Properties of Woods Grown in the United States," by L. J. Markwardt and T. 2, C. Wilson. Report No. 1342 -2- After removal from the press, the glued blocks were placed in a room at 80° F. and 65 percent relative humidity where they were allowed to condition for 1 week before being cut into test specimens. Testing 4 Five shear-test specimens of conventional design were cut from each block. These specimens were broken in shear in a universal testing machine with a head movement of approximately 0.015 inch per minute, the load at failure recorded, and, the percentage of wood failure estimated. Results and Discussions The results of the tests on joints of the various species, averaged for the four cold-setting, urea-resin glues, are shown in table 1. For .comparison, the results obtained in previous tests with casein glue are also shown. The species all glued well and, considering the percentages of wood failure obtained, the joints made with the cold-setting, urea-resin glues appeared, generally superior in quality to those gued with casein. The average wood failures of the joints glued with the resin glues ranged from 83 to 100 percent, while those glued with casein ranged from 30 to 99 percent. The better results obtained with the resin glues were most evident on the species of higher specific gravities, suFh as sugar maple, red and white oaks, white ash, and walnut. From thisiippears that there is less difference in the gluing characteristics of the different species when urearesin glues are used than when the gluing is being done with casein glues. The average results, based, on the four glues, for the different species are shown graphically in figure 1. The species are arranged in increasing order of their average specific gravities. Conforming with results of previous experiments with other glues, ?-- the shear strength tends to increase with an increase in specific gravity. From the detailed data also it appears that within a species the denser specimens tend to produce the higher test values. The joint strength in hickory was abnormally low considering the specific gravity of the wood and the amount of wood failure developed.. The results obtained with each of the four resin glues on the 15 different species are shown in table 2. There is very little difference in the results obtained by using the various glues, but Glue B did show somewhat less wood failure and, shear strength values, especially in the denser species. This glue had a tendency to lump in the container upon Described in U. S. Department of Agriculture Bulletin 1500 and in Army, Navy, and Federal glue specifications. Report No, 1342 -3- standing, with the result that it was difficult to mix properly. Following the start of the tests, this glue, as then formulated, was removed from the market. The data in table 3 indicate that there is no consistent difference in the results obtained with the 5- and 15-minute assembly times on the different species and the averages for all the 15 species are identical. Within these limits good joints can be obtained with urea-resin glues. Heartwood and Sapwood In table 4 the results of gluing the heartwood and sapwood are shown for seven species. Allowing for the differences in specific gravity between the specimens of heartwood and sapwood used, only hickory showed a consistent difference in strength and wood failure between heartwood and sapwood. In the case of sweetgum, the lower percentage of wood failure obtained with the heartwood, as compared with the sapwood, is consistent with the higher shear strength and specific gravity of the heartwood. Normally, of course, there is no consistent difference in specific gravity between sapwood and heartwood. Summary The results of tests on the gluing of 15 species of wood with four cold-setting, urea-resin glues indicate: In general, all the species tested can be glued with urea-resin glues to produce joints as strong in shear as the wood itself. Hickory appears to be somewhat more difficult to glue than , the other species. Generally, the shear strength of the joints increased 'as the specific gravity of the woods used in making the joint increased. The average wood failures were usually higher on joints glued with the urea-resin glues than were obtained previously on the same species glued with casein glues. The wood failures of the resin-glued joints were fairly uniform for all the species tested. This is in contrast, with a general decline in wood failures with an increase in specific gravity of the wood of casein glued joints. There was very little difference in the results obtained among the four urea-resin glues used in this study, although one of the glues showed slightly lower strengths and wood failures on the denser species. Joints of essentially equal quality were obtained for assembly periods of 5 and 15 minutes. No significant difference in gluing properties was found between heartwood and sapwood in the seven species compared, with the possible exception of hickory for which the heartwood appeared to be somewhat more difficult to glue than the sapwood. Report No, 1342 -4- Table 1.--Comparison of the results of gluing 15 species with cold-setting, urea-resin and casein glues Urea-resin glues1 Casein glues-4 4 4: Species3 : Speci-;Average--;Average: Specific-:average .3 :Average: Specific-roans : shear : wood : gravity : shear : wood : gravity : aver-:strength:failure: of wood :strength:failure: of wood : aged : :Number: Lb. per:Percent: sq. in. Ash, white.. Baswood.. 160 2.,265 : S 160 1,441 : 5 Birch, yellow-.; 320 : 2,840 . Douglas-fir.,„.: 160 : 1,686 : 7ir, noble....„: 160 : 1,632 : 5 , Hickory, pecan--: o20 : 2,016 : Mahogany,,..,..; 160 : 1,924 .; Maple, sugar.,: 400 : 3,425 : 5 Oak, red-.,....: 320 : 2,258 : Oak, wh ten ,,,,: 320 : 2,670 : Pine, Southern ; 1,719 : yellow.......: 160 : Spruce, Sitka.,: 160 : 1,306 : 320 : 1,769 : Sweetgum...,...: Walnut, black..: 160 ; 2,393 : i Yellow-poplar.: 320 : : Lb. per:Percent: sq. in.: • 96 : 97 : 96 97 : 42 42 40 : 77 : 0.59 : 2,810 : •40 : 1,700 ; .61 : 2,680 .49 : 1,800 : 6 0.64 ,45 .71 .51 98 : .42 : 83 : 99 : 86 : .71 : 2,800 : .47 : 1,800 : .66 : 3,380 : 63 : 69 : 30 : .66 .45 .66 94 : .63 : 2,370 ; ,63 : 2,050 : 56 : 45 ; .66 .68 94 : 1,452 : 99 : • • • 97 93 91 : 98 : .51 .37 .51 .51 1,950 : 1,300 : : 1,790 : : 2,150 86 97 76 53 : : : : .61 .39 .55 .58 : 100 : .50 : 1,600 : 84 : .45 1 -Results with four different resin glues averaged. , Results are taken from figure 13 in U, S. Department of Agriculture Milletin 1500, "The Gluing of Wood," by T. R. Truax. Joints glued with resin glues conditioned to about 12 percent moisture content; joints glued with casein glues conditioned to about 7 percent moisture content. Specific gravity based on the oven-dry weight and the volume at test. Heartwood and sapwood glued separately. Value recently obtained in studies of the gluing properties of noble fir, but not reported in U. S. Department of Agriculture Bulletin 1500. Report No, 1342 r--1 I o A a ,,--1 0 r- L11. ..P gl cp c) Q.' 0 r--4 0 . . ed al g4 0 0.4 tir, co ,.0 I. 1> 0) -4, to •4 a, tO 0, 0, -1- .--4 1..,N 14 • mg a• •ri .• ,0 cs. .4 co • •• A- 0 ic,•n r-4 ... CV •• •• 4. * •• a, a\ ON N • 0 4, g 0 0 t•-• a) P4 I r-i re\ n1:3 0 Lc, \D re, • W r--0 LC1 153 CV 150 Cr\ \.c. n0 t--- or, 0 N- r--- \O CV01 60 r- 4 ,--4 N a, • N- to 0, 0, r-- a, to r-1 0. re, r--I 0, N-- V .. 4, re, .-1---- oN cr, (TN a, or. ta• •r4 • • do p• .4 ta \.0 N r-4 0 IPn •• •• V0 1k r-f •• •• It CV •• •• r-1 •• •• •• •• cy, gro •• \10 A- LC, \C) I,\ N \O \O -- A' N.- . a, r--1.1 a, r---1% CV04 r1.--f tto •• .---4 60 \D re, N N ak r-4 re, \D .--I K, •• op 0 L!1 l'..-- reN.1 CV -.4 a r-4 0 0 .--1 •• •• 4Hr r- 4 •• •• •• r•n •• •• •• \D 0 LC-1 \O re, 0 Lf1 0 LC\ r4 '0 '60 CY, 160 cy. 0, to Q LC", re\ a, 0, 0' C\J r-4 ON a, to r--1 0 0 r- 4 0, r-- CV44 r-I r-4 ...*.% ‘4) cv CT.• 0 .° * N-1.1 V \U r-4 0 LC\ NU1 o, 0 CV 150 ...L11 r-- f--1 15014 0 I,CV. LC\ tO N-fit r(:)N -4 I'lIk Kl rf\ re, N N r-s ,--1 r-4 N L1\ Lf\ \X) \ .0 re, \D 0 ..... re, \O 150 1---4 ...* I's- N0 L11 • N- 0 1.11• 0\ N.- a, N ,-.4 N ri I-4 CV 1.41 cv ON ft r-i 0 0, r--4 0' r-, r.,,\D r--4 Cr, ...'" ...,* 150 a, \C) r- l'-- ,,,.- 0% C\I ...- 0 Ift • 0 44 .1 IM. a, vs , . LI1 0' • • LC\ 0 0 cr. N .. N 0 0 Lit -P g 15C) \O CV Cf, 1,1 (-4 ‘.0 r, K\ \O '60 c‘i 60 ni m 03 0 0 ON ON '60 0, '60 01 a, N- 0, 0, 0, 0, 0 0' 3.4 0 r--4 ,o1) s-, a) It 4,4 a) 03 I> fil e.-. -.4 X r-4 rs- N 0 (7" to a, r,, "0 LC cv 0 r-f r-- a, cv ti -P a ..1- 0 ,-.1 1-a, 0 a, .--401 rc, a, 4\O a) g h0 t+ a U1 r--4•• \D Lit KN.6 \0 r4 a, VI LI, 1*---ei r-4.. I' •\ r----.. C.4 •,-4 03 03 g .n .1 ft A IR lk .. 3-4 0 0 CV CV r--4 r--4 r--4 N 411 r-♦ r-4 r-4 r-4 CV r-4 C1/41 ,r) cy 0 A 1-• \Di .--1 co to 4.) .. •• .. 0 ...4 •• .. •• •• •• •• •• .. •• •• •• •• .• .. •• .. •• .. .. •• •• - - .• •• •• •• •• •• •• •• •• •• •)• •• 0-4 I 0 \0 r., r\-0 ,---4 0, in LC1 m 0 in cv a, 0 !'s 0) 0 r-I N- 0 0 r-- \C) , r--4 N 0 0 . Q 153 to 44 -p U1 U1 LI1 \.I0 LC1 f'41 r-- ....* Lc, ,...* U1 ...* 03 •r-4 ..e • • L4 o P. m a cd 0 P. -. I -.4 CO bp -P a> a s:I Egpd t• 0' r, ..' 00 rn ..K\ \O a, 0 160 00 I---- 150 0, a al 0 0 Cr\ ON ON a, a, 01 a, 0 cr, 00 cr, ci, a, 0 a, 5 0 .--4 r--1 3. 0 0 •f ft •• 0 1.1-• 0 Ill 0' *60 It. 'mg Ain 150 ilk •• • • '60 N- ,2 03 •rf •r4 ti 0 03 a 0 ,---4 0 a, ON to ED • Z' Ca lt, a 0 r• & 1, -.4 to 40 0 0 bi) rO t. N r--.\-0 -* \-0 \u • '60 0 S-4 03 a a) 01 t> Sa. I-. <4 0) bp 0 0 40 r0 S-4 cd 0 0 1-. 0 .--I (1) 0 4,-4 d I> e.-. -4 .4 4, m NO i.• w '60 .Q, r-f CV 4- in 0 0 -4-, ho I-. 44 al Pi 1-• 0 0 0 X t. 1> 0) 4, •:4 ; to •• •• •• ,....41 0 •,-1 bD 4-1 -P 03 .ri .1-1 ti0 ic:. 4c-) a, Nr -, 0, K1\C) 'so bp C-i -P GS •r-i •r4 1-. 0 a. 0 0 as 1> P. 1.4 .4 ro aD a 0 el TS &,, el o 0 m 0 r-1 0) 0 • r -i 1> cd 1> .4 cd 4-4 .4 _ 4, 0 bLO 1.4 w 03 0 g 1-• 0 CD X t4 I> 0) 4, <4 4 1., • mg 4P ••-I• 01 ,0 d .4 re\ 0 re\ .. (k) cv r-4 in r., 60 ...- w.• CV r-4 I,- N a, 1,-- in ,---1 w.. r--4 '60 \S\ '50 a,.. 0., Nr4 KN (0 Nr4"., CV U Nr---r CV 0 CV 00a. r-1 '60 CV., r-I 0 K, 'COft r-I U1 \O tr\01 N 0 rc, 0.4 N 0 (0 0 0 4- 9- 0 (0 0 4- 0 00 • La • .s4 U •. CO C-i tO 0 0 ,cs ®a s-. Fal bo t. a) CL) -r-i c0 0 0 0 0 1-• 0,-4 0 & 1> •• 0 4- 0 ...' (0 ... ' ..* 160 ..* 0 0 t0 0 00 •• -thil N-4 t.. •.--1 N-4 a. •• •• • A •• • • • • ,i ..* 1 0, b0 1 0 . . . p -1- i XI 1::)) t° rd0 0 0 0 0 a0 0) ad . 0 -,-, 0 & rn •• • •• • • • c..1 1 0 4 4-, ••-t II 0 4 o Ig •n d -4 t/) to 0 Co 0 , r--4 0 ... .. 4 $04 -,-1 Co m 0 0 0 4-4 .--4 ED 0 ta' . 1.. ,..S4 0 ..-4 03 -I td) 0 cp CZ g P. 0 MI cd 40 0 .0 A •, a .--4 04 A I., . rsi 0 0 • ,r4 • • A (I) 4, it . rs41 03 0 1 0 4- 0 CO 0 .5 4., a g P-4 K \I 0 .61 -P .r4 cil .. a o 0 i.• Ia. co • • ii A. 0 40 4, 0 a co 0 GS r--4 ro . -/- s... al r -4 a• 0 O. -4-,it o 0 r--4 0 ,--4 -4 a d Table 3.--Comparison of the results obtained with 5- and 15-minute assembly times on 15 species with cold-setting, urearesin glues 2 : Average : 5-minute assembly : 15-minute assembly : specific : Species : gravity : Average : Average : Average : Average : shear : wood : of wood : shear : wood : strength: failure : strength: failure usedl ------------------- ------- --- ----- ---------------- ------ : Lb. per : Percent : Lb. per : Percent sq. in. sq. in. Ash, white- 0.59 : 2,294 : 97 : 2,235 : 98 Basswood Birch, yellow......: .40 .61 : 1,434 : : 2,856 : 97 96 : 1,448 : 2,825 : : 97 97 Douglas-fira ... : a Fir, noble ... Hickory, pecan.....: .49 : 1,692 : 97 : 1,680 : 97 .42 .71 : 1,634 : : 2,059 : 98 84 : 1,630 : : 1,994 : 98 83 .47 .66 .63 .63 : 1,933 : : 3,411 : : 2,314 : : 2,646 : 98 84 95 94 : 1,915 : 3,440 : : : 2,204 : : 2,692 : 99 87 93 95 .51 : 1,795 : 97 : 1,743 : 96 .37 .51 : 1,306 : : 1,795 : 94 91 : 1,312 : 1,743 : 92 90 .51 .50 : 2,369 2,151 : 98 99 : 2,416 : : 2,135 : 99 99 • 2,112 : 94 : 2,094 : 94 Mahogany2 . .: Maple, sugar... ---- : Oak, red.. Oak, white - Pine, Southern 2 yellow-...... 2 Spruce, Sweetgum.. 2 Walnut, black : Yellow-poplar.. 06 Average result for : species tested. -- : - 1 Zpecific gravity based on the oven-dry Weight and the volume at approximately 12 percent moisture content. I 2Test values are based on 80 specimens; for the other species the test values are based on 160 specimens, except for sugar maple for which the value are based on 200 specimens. Report Yo. 1342 Table 4.--Results of gluing heartwood and sapwood of seven species of wood with cold-setting, urea-resin glues (Heartwood - 11, Sapwood • Ave rage shear strength Species . : : H S Hickory, pecan H S Maple, sugar ••. . : • 2,783 ' 2,898 2 Averagespecific gravity of wood used Average-1 wood failure . : Lb. per sq. in. Birch, yellow S) Percent : 96 97 : 0.624 .602 1,875 2,157 80 87 .709 •704 H S 3,445 3,404 89 82 .664 .656 Oak, red H 2,219 2,298 94 94 .614 .648 Oak, white H S 2,736 2,602 93 96 Sweetgum H S Yellow-poplar H S : : . : : 1,902 1,635 2,092 2,194 : • 85 , 94 99 99 .672 .592 .536 .478 : : • .507 .503 --Each test value is the average of 160 specimens or more, glued with four different resin glues. 2 Zpecific gravity based on the oven-dry weight and the volume at 12 percent moisture content. Report No. 1342