N O T E ' N U F - 2

advertisement

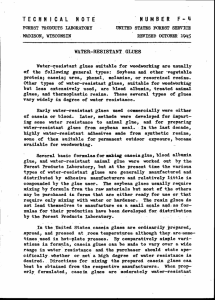

N O T E ' N UM B E R T E C H N I C A L UNITED STATES DEPARTMENT FOREST OF FOREST AGRICULTURE PRODUCTS SERVICE LABORATORY REvlsED MADrsoN 6. wtscoNslN COMMERCIAL F-2 LIQUID December L952 GLTIES Although a number of different typea of woodworking glues are now suPplied in liquid forin, the term "liquid gluerris generally limited to cerare supplied in liquid lain glue" Lf arri*al or sometimes plani originthat In the past, such tiquid gluee"were usually manuform ready to use. More factured from the skins, heads, and swimming bladdere.of fish. recently, other liquidglues have been developed,'based on animal glues Liquid glues are'also derived frorn hides, skins, and bones of cattle. prepared from etarch, natural gurns, casein, and certain thermoplastic synthetic resins. At the Foreet Products Laboratory tests have been made on a number of An earlier serieg of teets indicaied that gluea of animal or fish origin. different glues variedwidely intheir resultant joint strength' Sorre were eo weak as to be entirely unsuitable for woodworking purposes, and other s cotnpared favorably in strengthwith conventional animal glue (tthottr glue More recent tests on samples of liquid animal gluee or rlhide'r glue). although eotne glues gave moie indicated rnore consistentperformance, good reeults than others when bonding wae conducted under a uniformly The better and asser-nbly conditionE. series of different temperature glues were again cornparablewith-rthotrr glue. Insubsequent tests, however, after 6 monthsr storage at 80" F", these same liquid glues Produced joint strengtJr values of only 45 to 65 percent .of their strength No significant physical changes in the glue sarnples when used fresh. These results indicate that were observed during this storage period. samplesof liquidglues ehould be usedas soon aspossible.after receipt. Liquid glues may be tested by gluing tJgether pairs of carefully selected hard maple blocke and testing the joints irt a testing machine to deter(See American Society rnine the force required to shear them apart. for Testing Materials Method D905-49. ) Irr suchtests at the Laboratory, average shearing etrengthfrom the better liquid glues showedvaluesfor 1,600 to 3, 800 pounds per square inch of glue joint, depending on the gluing conditiong used. high adhesive etrengtJr a^ad convenience of use In addition to uniformly are ddEired ia a ligaid glue. as received, certain other characteristics trn its When spread upon wood eurfacee, it should rtsetrt or dry rapidly. tenperaat all ordinary container it should remain fluid and workable of high temtures. It should not be unusually susceptible to thi.action eenei' Liquidglueeless peraturee, high humidity, molds, and bacteria. effecte during gluing than typical rlhotrr gluea wopld tive to temperature of these glues 4ae not yet been adebe $.eeirable, but such versatility quately eatabli+hed. . tests gave evidence that tb.e etrengtJr of a liquid glue, The Laboratory like that of trhotn g1ue, depends largely uPon ite trbodyrr or thicknesE' or Generally the thickest or most etrictly epeaking, upon its viscooity. vidcous gluee showed the greateet adhesive btrength. zx+r26oF lgrlculfure-Iad lson