SD4 33 U5-2- .1q“, THE VISCOSITY-TEMPERATURE-TOTAL SOLIDS

advertisement

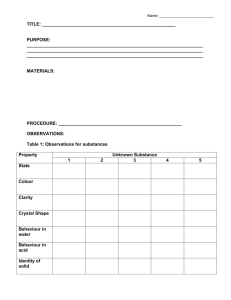

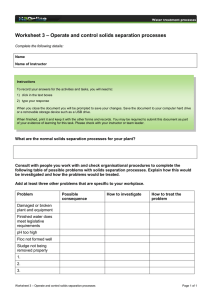

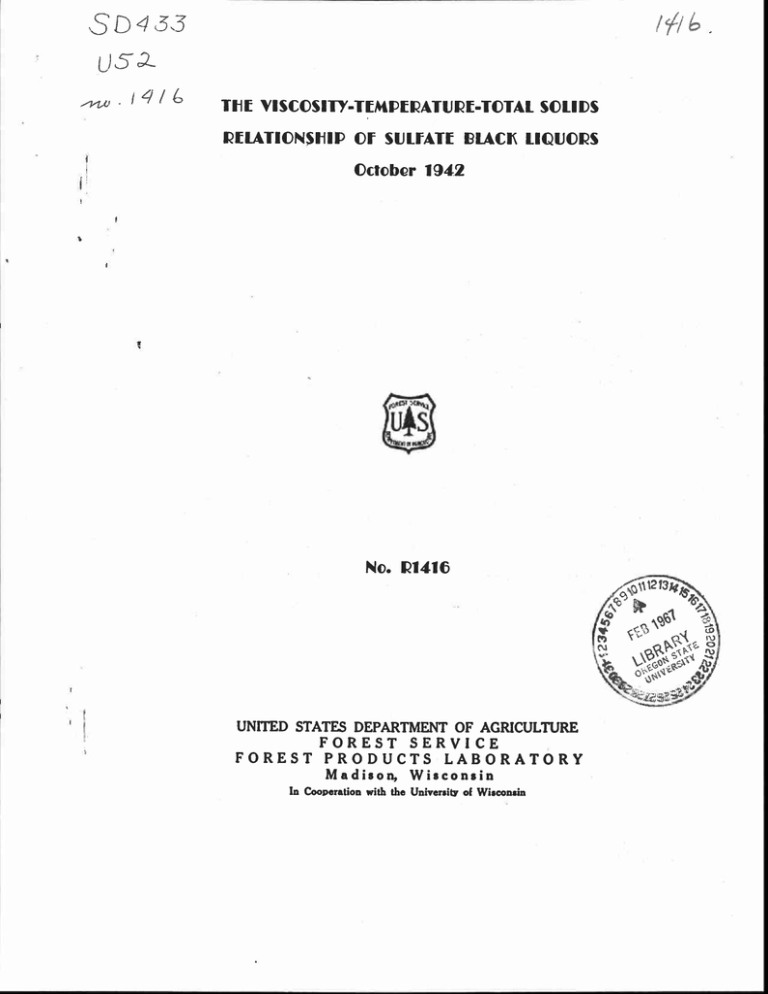

SD4 33 U5-2.1q“, THE VISCOSITY-TEMPERATURE-TOTAL SOLIDS RELATIONSHIP OF SULFATE BLACK LIQUORS October 1942 No. 81416 UNITED STATES DEPARTMENT OF AGRICULTURE FOREST SERVICE FOREST PRODUCTS LABORATORY Madison, Wisconsin In Cooperation with the University of Wisconsin TEE VISCOSITY-TEMPERATURE-TOTAL SOLIDS RELATIONSHIP OF SULFATE' BLACK LIQUORS By SIDNEY L. SCHWARTZ, Assistant Engineer SYNOPSIS Sulfate black liquors increase in viscosity with increased concentration. Above a totall solids concentration of 40 percent, the viscosities of the liquors rise rapidly with increases in concentration, but are markedly decreased by increases in temperature. At concentrations of less than 40 percent the viscosities are, relatively sneaking, not much greater than that of water, and the effect of temperature is relatively slight. INTRODUCTION In the evaporation step incident to recovery of chemicals from sulfate black liquors, the liquors are usually concentrated in multiple-effect vacuum evaporators to total-solids contents ranging from 55 to 6o percent. In this evaporating process the flow of the liquor and the transfer of heat to the liquor are two problems confronting both the equipment designer and the operator. Since the viscosity of a liquid is an important factor (5) in both of these considerations, the investigation reported here was undertaken with the objective of measuring the viscosity changes which occur with changes in temperature and concentration of several sulfate spent or black liquors. MATERIALS AND PROCEDURE Three black liquor samples, designated as liquors A, B, and 0, were studied. S ample A was a commercial sulfate black liquor secured from a "Wisconsin mill. Sample B was a laboratory seMicommercial loblolly pine sulfate black liquor, and sample C was a laboratory semicemmercial jack pine sulfate -black liquor. As these black liquors resulted from various cooking conditions, they can best be characterized by the„ data in table 1. Mimeo, No. R1416 -1- Several samples of each were evaporated on a steam bath. Total solids of these samples were determined and several batches of each liquor of various total solids content were prepared from the concentrated liquor. In cases where the concentrated samples were used prior to making more dilute solutions, the total solids co:Aent of the samples so obtained was determined. In no case was the concentration of a liquor carried beyond 60 percent of total solids., The total solids were determined by means of a modification of the Method described by 0-iffin (2): A sample of black liquor (20 to 50 cc. depending on the approximate -..)Lcentrain of the liquor) was weighed, diluted to 500 cc. with water in a -vo,Llaatri: rusk; . and mixed thoroughly. A 50-cc. aliquot was run into a weich'd IOC 'mil: porcelain evaporating dish, evaporated, and then dried for 16 hoars (Over night) at 105 u C. The purpose of vary4.ng the size of the samples weighed out was to secure comparable re g idral sarples. A liquor con:,aiming slightly less than 20 percent of total :.ol:Os will yield a residual sample that approximates 1 gram : when a 50-cc. weighed saml,e is taken. V There is a tendency towards :polymerizationand carbonization of-the organic material black liquor which - occurs cn eva-po2atnfT, especially at high .temppramrec., In ihe Dreoelice of alkali(6) . In reog y,it i_Jn of this fact a ana usea as a sample of liquor L was concentrated by vascout control. The relative viscosities of the black liquors"were-deterthined by means of This was accomplished b5 measuring the time of efflux an Engler vis ,..:Ometer of 200 ec. of each liquor through the orifice of the instrument. The time of efflux for 200 cc—of water at 20° C. th•cugh a standard orifice on the Engler is,51 seconds (3). The relative vis-:o:,ity cf any liquid at ,any temperature to that of water at 20° C. may bd comp:Lted by dividing its time of efflux in secona': by 51. This is called the "Engler number" or "Engler ratio," and all the viscosity data secured were so computed. The absolute viscosity may be approximated from the following formula (3) -i 71 for an apparatus of normal dimensions: (0.001435T _ 3.22/T) where 1 = coefficient of viscosity in C.G.S. units. T = time of effluxof'200 . specific gravity a:t'the temperature in ,que-stion. For this reason the specific gravities of the various liquors , at the various temperatures encountered in this study were determined. A. sUitable temperature control apparatus for determining specific gravities at various temperatures was provided by inserting a porcelain disc in the viscometer pan upon which to rest the small, 5- to 10-cc. pycnometers. Water in contact with Mimeo. Do. R1416 -2-- the pycnometer in the viscometer pan was allowed to come to a equilibrium with the temperature of the bath and kept there for 10 minutes. The pycnometers, clean, dried, and desiccated, were weighed. The specific gravity was determined relative to water at 20° C. The range of total :solids .coVered was from temperature range was from 20" to 960 0.: a3.5 percent to 59.7- percent. The RESULTS AND DISCUSSION The vi s cosity-temperature-specific gravity data for liquors.A, B, and at various degrees of concentrations, are recorded in tables ,"2; 3, and 4, and plotted graphically in figure I. The data show that the viscosity of black liquors at 20° C. increased with higher concentrations. The increase in viscosity was especially rapid for total-solids concentrations above 40 . percent. The viscosities of the liquors above 40-peroent total solids were markedly affected by increased temperature. ko concentrations-below 40-percent total solids the viscosities were, relatively ?p eaking, not much greater than that of water, and the effect on viscosity , due to increase in temperature was comparatively slight.- Moore (4)--reported a similar viscosity-temperaturetotal solids relationship for sulfite waste liquor obtained with a Stormer viscometer. The viscosity-temperature-total solids relationships of the three liquors studied are characterized by the curves in figure 1. Differences in the viscosities of the three liquors are apparent. The viscosity of liquor C above 43 percent of total solids was definitely higher than the corresponding viscosities of the other two, as shown in-table 2. The viscosity of liquor B for all degrees of concentration was comraratively low at 20° C. Anomalous-'results are evident, however, and may be attributed to errors in total solids determinations, irregularities in temperature control, and changes in total solids resulting from the variations in time necessary to bring the temperatures of the various solutions into equilibrium with the temperature-control bath. The latter is an important factor at high concentrations, for a slight change in total solids in a solution containing approximately 60 percent of solids will bring about a marked change in viscosity. It is difficult to attribute the individual viscosity characteristics to individual characteristics of the liquors. Though differences in the free alkali content, the heat value of the residue., and the ratio of ash to total solids, as shown in table 1, existed in the original liquors, the trend of these variations cannot be correlated with viscosity. An attempt was made to duplicate results obtained for several concentrations of liquor A. A sample was concentrated by evaporation on a-steam bath and, upon being tested, showed a total solids content of 57.0 percent. This sample was designated as sample No. 11, from which samples No. 12, 13, and 14, corresponding to 54. g -, 51.0-, and 47.3-percent total solids were prepared. Mimeo. No. 81416 -3- Viscosities were determined and the results, as plotted in figure 1, did not Correspond with previous results. Total solids determinations on all,samples revealed that they did not check with the calculated values. Further tests showed that variations of ± 1.0 percent in total solids could be obtained.. A4 these determinations were run in batches which included all the samples in question, the variations may be definitely attributed to day-to-day variations in the temperature of the drying oven, which was set for 105° C. Temperatures as high as 108° C. were observed. Furthermore, the errors Produced by the variations of temperature in the oven would be greater at the higher concentrations because of the method of sampling. Sample No. 4, liquor A (47.3-percent total solids), which was prepared_ by vacuum distillation at 36° C., was found to have practically the same viscosity as sample No. 10, which was prepared from a concentrated steam-bath Sample. Further rork on vacuum-distilled samples was discontinued because prior work at the Laboratory indicated that the viscosity of sample Yo. 4 was in the range of viscosities of samples obtained by other means of evapfration (table 3). Furthermore, viscosity data made available to the Laboratory by Babcock-Wilcox and Company (table 4), determined by the Sayboltfurol viscometer, are not, though similar in character, comparable to the data obtained. In view of the above considerations, further work on vacuumdistilled samples. does :lot apicedt.Warranted. Moreover, in regard f6 technical Viscometers such as Saybolt, Savbolt-furol, Engler, and others; Bingham (1) had little to recoMtend. They are inaccurate and have many sources of error, , In the case of the tnglet when calibrated with Water at 20 6 di% the kinetic-energy correction amounts to 90 percent of energy expended% The viscosity in. this particular cast has but little part in determining the rate of flow. BIBLIOGRAPHY (1) Bingham, E. C. "Fluidity and Plasticity." 1st edition, 2a impression, page 324 (1922)% (2) Griffin, R% C. "Technical Methods of Analysis." 2a edition, 2d impression, page 392 (1927). (3) Higgins, W. F. Jour, Soc. Chem. Ind., Vol; 32, page 572 (1913). (4) Moore, H. X% Trans-Am. Inst. of Chem. Eng., Vol: XV, part II, page 240. (5) Walker, tewis, and McAdams. "Principles of Chemical Engineering." 2d edition, pages 73 to 192 (July 1927). (6) "The Manufacture of Pulp and Paper." 3d edition% volume III, part 5; page 99. Mimeo. No. R1416 -4- . co 0 W .,-1 cd ri ,C:5 0 0 ,--t -I-) 4-, -OA r---I 0 0 4-) En. A '8 .. .. .. .. A tri LC1 . o 0 C) CI r-I N . r-1 ie .. 0 1 1 1 r..-% cd-i C..) r-1 .. .. .. s.-4 ,-d . d P-1 0 .. •• '2 g Pa .---I O 4) 0 4., a) 0 .4- " v;) b.) ‘...0 H •• •• .• •• al F.. , a) 0 •H +a • • •• •• II O .P 0 .6 4.1 -I-) fi 0 - i4 d n 0 0 Ei 0" d 0 La cin 1-1 . ,-1 PA -,1 .. . • . • E-4 .. E-I .. 4-' I F-i g 1 0 01 0 0 0 N n i .r.",, F-1 cd 0 za P4 41. 1 ,...?, $.4 O g 0 I k 4-6 C.) 0 p o 0 cr,I 0 r-1 .,-1 ,r2 H .. .. 0nzi k A co 0 0 g 4-) cr) 0 O Pi • FI a) EI 0 0 • ri 0 0 k (1) f, >4 r-— IEI a) fil O Pi 0 6--4•-6-i PA .1-1 0 '..-, Ei El .. .. -1- 2 --. r" 1 ▪cd C.3 0 fa4 co P4 0 tO 0-1 r---- a) N 04 4-I r-i o rd CO 0 0 $4 C0k00 ‘.-...4-- ) 40 -r-1 p.. 0 • . • 0 'd $-1 0A 1:1 . 40 ...0), U) -H l'el rl in H p wi 0 til fa, c..) C rd MI Cf) lb° 0 0 0 N • C.) 0 0 al .4" ri ig .. .. . . . . . . kJ) .. .. a) C) a) $4 0 a) ,-0 • 4-) 0 W d H a) O • CT\ • 4-) C 0 4-, 0 -P 4-) •• • • O tel r.S4 110 Cd 0 I k 0 r-4 O 0 tO ,0 - 0 0 1-1 k 0 .1-1 a) o fEj 0 (11 .• •• •• •• •• •• • re F9 Mimeo. No. 81416 0 • $4 0 El -et 010t •0 CV •H r-I .. 1-1 0 ‘43 .1-1 ..--.. 4-1 0 1-1 4 -' ';' ' g C:1 0 4-) 4-) 4-) 0 d 0 El 0 1 6,0 p, C r..D cti -IP 0:1 up C.) 0 o 0 N • 0 0 a3 al 0 H 1/4..C) Z '.'s •• • • •• •• 4-) rcl r-1 4-1 c1:5 1 41 rd O s=1 ) CI) F4 00 0,1, • • •• • • • . a) • • .• •• • • r.r) 4-) a) .11 A 42 0 o H a) •H +) 0 qu 0 c6.4 0 PI 4.) 0 Fl 0 0 P4 • (1) 41=I 41) 0 0 H Ca 0 .r-1 ri 03 0 0 • r4 0 P• 0 it 0 X) Pi F-6 k 0 cd P4 O CI) A 0) a) •• •• I O El El $.i 0 P.,"\ r--1 in PI cl.4 o -0 in 0 0 en cd k U 0 k -,-1 1.. 0 H0) • +) ..-I 01 r-I AH p, a) r—i 0 4.) w • 0 N r.-; cd r-- •. 9 ,-1 0 -1 -P 4, fi •• cri All" $A)i a) CQ O •• +1.) .. 4.) Gad s-4 a) Q A 2 0 71• kr a) H L., 0 ;-I 0 fa S.• •• L 1 C1.1 • . P 1 9 n i IrD 0- 0 C.-.) rl H -p N -P ri •• LC-1 4-5 a) • • • •n a) 0 • • cd • Tii u)I z cgral 0 ,--I • • • • •n • •• .. •r-I cd • •• ti N1:4) N %...0 •• .. •• •• .• •• •• •• •• .--11 .. .. • k .1=1 1 H 4-5 ',' J ..t.' "' 0 1• k pa FR •• •• •• 4 1 -PIOl Q-)1 g .# P-6 0 N 0 r--I to +d.; -.. 0 9:1 &I ti 4* 0 ra 0 Pi a) 0 14 • rd •H .4- 0 • u) H c\I rl Table 2.--A comparison of the viscosities of liquors A, 3, and C at comparable• degrees of concentration. Liquor samples A C :Temper-:Engler :Temper:Engler :Temper-:Engler : ature : ature : ature 0 0. Total solids ....Percent : :Number : °C. :Number : 20 : Total solids ....Percent : i V : 20 . : .90 : 20 : 90 Total solids ....Percent : : : 20 : 90 1 .9g : 90 : 35,0 . 20 90 20 90 : 10.04. 20 : 1.39: 90 20 90 1.31 : 2.00 : 1.0 g : 20 90 : 40 90 Total solids ....Percent : : : 33. go : 40 : 2.77 • 90 : 16.94 : • .3.92 59.5 Total solids ....Percent : 6o 96 : 7.30 1.41 : 49.6 : 36.40 : 1.90 : 15.14 : 20 : 1.65: 90 - : 25.20 : 1. g 2 : : 53.9 : 15.63 : 4o : 2.32 : 90 : 33.0o : 3.37 5s.5 57.4 6o 2.41 1.0g 43.2 : 5.1 g : 20 : 1.33: 90 54. g53.4 Total Solids ....Percent : : : 20 90 52.2 : 47.70. 1.77 : : 1.51 .9g 35:0 . 50.0 : 25.90 : 20 : 1.67: 90 52.3 : : 45.0 . 51.0 Total solids ....Percent : Mimeo. No. R1416 20 .96 2.12 : 1.10 : : : 47.3 Total solids ....Percent : 1.29 : : 37,5 25.0 25.0 24.9 90 0 0. :Num►ber 6o 95 : 12.39 : : 3.02 : : : : 40.30 : : 4.22 : : : 6o : 95 : --- 59.7 : 29.90 : 6.og Table 3.--Viscosity, temperature, density relationship for sulfate black liquor available a Labortary'prVor to January 1, 1938. • Total solids Temperature •• Percent . : Specific gravity : 00... . .: : 52 70 24 : 1 3 6 : 51 70 90 : : : 31 58 : •: : 6o Engler Seconds Number 1.02 :. : r.96.....3 : : 48 47 .94 1.1110 1.1030 56 1.12 49 1.0935 48 .98 .96 1.0835 47 ,94 1.1670 1.1535 1.1475 1.1375 7o 56 52.5 49 : : : 1.40 1.12 1.05 .98 _s3 58 71 1.2180 1.2055 276 109 5,52 2.18 1.1990 89 1.1900 87 72 1.74 1.46 59 1.2580 1.2520 1.2430 1,120 653 272 71 90 Mimeo. No. R1416 : 'Time of efflux for 200 cc. 51 1.0560 1.0500 1.0400 34 . 70 90" 48 • : : 40 ]. . : : : 22.40 13.10 5.44 Table 4.--Evaluation of data from Babcock and Wilcox Com,mny T s viscosity, temperature charts for sulfate black liquor.' Total solids Temperature Percent °C. 23.8 23.8 23.8 23.8 23.8 43.8 43.8 43.5 43,8 43.8 I : . : Engler Saybolt furol Number Number 37,8 48.9 6o.o 71,1 82.2 9.0 8.o 7.3 7.0 7.0 37.8 48,9 60.0 71.1 g2.2 20.0 16.0 13.0 11.5 10.0 2.5 2.3 2.1 2.1 2.1 .2 4.2 3.5 3.1 2.g 53.8 53.8 53.8 53.8 53.8 : : : : 65.6 71.1 76.7 82.2 93.3 72.0 56.o 43.0 33.0 27.o : 19.0 14.5 11.0 8.5 . 7.o 63.8 63,8 63.8 63.8 . : : : 52.2 87.8 93.3 98.9 350.0 230.0 16o.o 110.0 .. 100.0 60.0 41.o PS.0 98.9 98.9 98.9 98.9 98.9 98.9 6.8 7.0 S.0 9.5 25.0 110.0 14.0 23.5 3.8 3.8 53.5 63.8 1 : : : 2.0 2.1 2.3 2.6 6.g 20.0 Conversion of Saybolt furol values to Engler values made accordirtI . to chart by H. G. Nevitt, Chem. and Met. Eng. June 23, 1920. Mimeo. /To. R1416 4 4 r co MERC/AL 3 30 2 20 /5 (IASCAA 11111111111 111111M11 nom= nummit, /0 Q., isk,.: -.:_ '-/:., . , r'• ''' 61-, ._ . .h. . . . li= MIMI= ME ME MMOMEMEM MEW LI . , IME MOM MMEMMM ,, 11 „; kLez„ 74-. ., P C=. 4° . 35.a X I: . ____ iak......... 0: ... 35 111Pr ''AINI i numwr age iiii MEMEMOgi I I I SAMPLE C EXPERIMENTAL (JACK FINE) SULFATE BLA CK LIQUOR I Ma EMI MEM= • MUM a MEM' MEMIrt, ,mkrima '' /0 0 20 30 40 50 60 70 80 90 /00 TEMPERATURE (DEGREES CENT/GRADE) 25 30 35 40 45 50 55 60 TOTAL SOLIDS (PERCENT) FIG. 1 VISCOS/ TY-TEMPERATURE-TOTAL SOL/DS RELATIONSHIP FOR. THREE KRAFT BLACK LIQUORS Z M 35152 w