SCREEN ANALYSIS AS AN AID I N PULP EVALUATION

advertisement

AIRICUL1URE

ROOM

SCREEN ANALYSIS AS AN AID I N

PULP EVALUATIO N

Revised November 193 9

M

SCHOOL OF FORESTR Y

OREGON STATE COLLEG E

CORVALLIS, OREGO N

UNITED STATES DEPARTMENT OF AGRICULTUR E

FOREST SERVIC E

FOREST PRODUCTS LABORATOR Y

Madison, Wisconsi n

In Cooperation with the University of Wisconsin

SCREEN AlgLYSI .S AS AN .AID IN PULP EVALUATIO N

A, resume of work at the :Forest Product s - Laborator y

By

E . R . SCHAFER ,

Enginee r

This article supercedes a publication of the same title, (1) ; :-.and ..

brings together the results of several'indepe'identinvestigations, some o f

which have not been previously reported . The ' Laboratory first became iinterested in the fractionation .offiber masses into length classes as, a

means of pulp , evaluation in a study of insulating board from sawmil l

waste . The fractionation was effected with an experimental flat-plat e

diaphragm screen provided with a series of interchangeable slotted plate s

of the type ordinarily used in pulp mill screening operations . Th e

apparatus was later modified for application to evaluating groundwoo d

ahd chemical pulps by substituting . wire screens for slotted plates .

Further study brought improved ef`iciency• through the development o f

maltiple"plate screeriin which the stock flowed through four compartment s

each fitted`with a:screen of different site openings . Experiments will be described of the screen analysis of insulatin

gboardpuls,groundw puls,andchemialpuswithbo esingla d

multiple diaphragm plate sereea-as well as a limited amount of work with . :.

the Bauer-McNett Classifier .

SCREEN ANALYSIS . OF INSULATING BOARD STOCK S

Single Plate Scree n

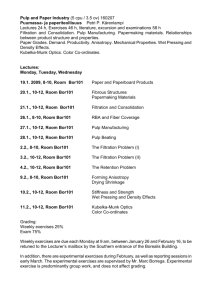

The plates used in the single-plate diaphragm screen (see fig . 1 )

were 10 inches wide .by l2 inches long .and contained 6o slots, eack 4 inches long . The widths of the slots in the series of plates . were 0 .020 ,

0 .015, 0 .012, and o .OC g inch, respectively . The material was firs t

screened on the screen having the smallest slots . The fraction of th e

material passing through the screen was caught in a drain box with a

"0

Acknowledgement is made to the Appleton Machine Company, Appleton, Wis . ,

for cooperation in working out detail s , of, desig n, ,of ; this screen an d

for building models in the various stages of development . . The machin e

is commercially known as the Appleton Selective Screen ,

R gg4 .

Fourdrinier wire bottom .. Thescreen ,plate was then replaced by the nex t

larger in the series and the screening rep'a tads _ ..':T e

ter ,lduring eac h

screening was vigoroi .sly .,agitated on the screen with water sprays . On e

hundred grams of the original

'b er' ' required about- lO r minirtes screening o n

each plate to effect a practical separation . Continued screening cause d

the various sized fractions to blend into each other . The various fractions obtained in this way were then dried and weighed .

fi

The screen analysis and other 'propertie's-of three well-known commercial insulating boards and one of an 'experimental Douglas fir board ar e

given in table 1 . These boards are composed of various materials that hav e

been processed in different ways . It is, therefore, not surprising t o

find no general relationship between the strength properties and th e

screen analysis . Nevertheless, a change in the fibrous composition o f

any one of them would undoubtedly influence not only the strengt h

properties but its density, formation, insulating value, and appearance .

Having developed a, product of, satisfactory quality, the screen analysis ,

therefore, presents, a means of Oontrol'in manufacture . Plate 1 shows th e

fiber aggregates obtained from insulating boards .

The Bauer =McNett -Classifie r

The .Bauer-McNett Classifier is a ` four compartment apparatus in whic h

the stock flews . by gravity through a'-mes h ' wire screen from one compartmen t

to the next . The screen plate"is set vertical in the . compartment and a

propeller agitates the stock suspension in a=manner claimed•to orient th e

fibers parallel to the screen surface . Ten grams of material are used i n

each test . The fiber .distribution of seven commercial insulating boar d

stocks as obtained :on this classifier are given in table 2 . .

SCREEN ANALYSIS OF GROL'NDWOOD PULP

Since groundwood pulp will practically all pass through a plat e

with the usual 0 .00 g -inch width slots, the separation of this type o f

pulp must be made with screens having openings smaller than those obtain able in the form of slots . For this purpose a series of screens consisting .of various mesh wires of the Tyler standard screen scale wer e

soldered to perforated brass plates . The screens were 24, 32,-42, and 60

mesh of . the Tyler series which, respectively, have screen openings o f

0 .701, 0.495, 0 .351, and 0.246 mm. in width . The ratio of the width o f

screen opening in one screen to that 'of the next one i n . -this series. i s

approximately equal to the square root of 2 .The procedure for the single-plate screen consisted in using thes e

plates in the apparatus in the order of their size, starting with th e

smallest, The fraction of the material passing through the screen wa s

caught in a catch screen the bottom of which was made up of a piece o f

R gg4

-2-

r•

a)

0

O

P4

•

1

-fI

a)

rCC

tti

a)

o

0

rd

a)

O

b

+)

N

4-1

O

41

•ri

.F.,

4.C

0J

'. l

a)

i

I

0

1

U)

a)

U)

I

0

$-t

i

0I

I

rd

1

I

o

I

1

I

U1

A

+'

••

4A

0

fi

I

•

I

i

I

H

E-1

..

..

w

. .

1

r-e I~

I

I

1

I

I

I

I

F4

O

o

I

I

{

0

a)

(••

•

I

f

I

1

I

I

I

O

I P-1

r~

m

I ~.

q I O

..

a)

I

y 1 rd

a) 1 Cd 1

Q)

q

I

ri

I

1)31

0

I

I

1

f

m

I

o

I

1

O

O .

d .

N N

LC\ En

LO

NN

N

. .

. .

O to

00

O O

. .

LO IX1

0

O

p0

l0 ~D

0) CS)

v

v

00

O O

N rI

.. ..

.. .•

MM

.. ..

LC \

..

0

O

H r-1

O

0

0

MM

.. ..

N

N

-

r-1

H

r-•I

. .

r-1

.. ..

r--1

111

LC1

.~'

..

' ..0

..

I •-

.r

CV A 4-,

riO O

•d I r-i

0 r-1

I LCl

▪

..

M

..

0 '•

Ea

t

to _0 +'

IN OU O

I -i O 0 r-1

• .r-I U#

Cj

rn

4-4

0)

..

r--N N

I

I

0

to

0

~I

a)

I

I

r-H

..

Lc)

to

M

~L.0

I

..

i-3

.•

.•

-

.. ..

1

I

0 .'i

L

Pal

a) •rl

U7

d

>~

u) Fa • O

a)

a)

..

MN

to LO

Fr

I

. . ..

• 'a) tc)

42

•r-1 0 O A +'

0

CG

NMM

!,

. .

ri

0

NN

La

I

I

l

U) +~

~~

f

Gd •rl

I r-♦ c)

1 W •r+

1

+'

.1. . .

.. . .

I

a)

R

a)

a) F-t

F4

4

0

s

i U)

♦• . .

I

1

1

I

f

C)

N-

H

0

ty

to

f`

0

I U

C)t

. . ..

f-'ii

a)

U

Fi

a)

Pi

I

r-I

N

.

..

lC)

•

0

r~

r-I

H

Lc)

..

..

..

N-

N

0

to

rI

N

Ql

01

r-

..

1P-

..

L.D

0

r4

I

.0 -P I N

O LCl U O

IIN ri

r-1

1 0 0 • r .1 m

1

f io

1 Q)

I

H

H

0

•O

t O O

No

cd o

a'

0

P,

r-f

p

0

•r~1

O

-1-

o

1

a) a)

P-

f-

M -'

M

•

+)

4•

• -1

m LAO

.

0 us

a)

0

O

O

a)

+3

O

q

a) 0 -P

En

I

f-i

-a)

4-1

4-3

O

•

0

•-1

Pi

Ea

4-4

+) H

q a)

ct

0

cd 4-1

a)

q ra

rd

+

0

5

C~)

0cd

o •-4

R1

U

O

rd

a)

c'.

R

c

0

•H

a)

Retained on 0 .020 inc h

width slots

Passing through 0 .020 inc h

width slots and retaine d

on 0 .015 inch width slot s

Passing through 0 .015 inch

width slots and retained

on 0 .012 inch width slots

Passing through 0 .012 inc h

width slots and retaine d

on 0 .008 inch width slot s

Passing through 0 .008 inc h

width slot s

PLATE 1

Fibers obtained in the fractionation of a pulp used for insulating board. Reduced to 0 .9 natural size .

zM Iz984F

•

q1

. M

• . r-l

4'

O

U

LC\ 0 I t-i

r-1 H r a)

O•

CT to

O

I

r

ri

re

ri

\

H r-i

to LO rO 0 0 LO L0 LO

t0 t0 t0

r-4

r-I

r1

0 Lh r- al 0

to N- N- LO O

r-i

r-1 al LCl r

LO LO LO r-i

rl .-I-

to

r-I

DO

0 0

r-I

r~i

O ~

99

99 99 99

▪

I +'

zn

a)

to

LC1 0 I 0F-i

LO N a

O•

O~

99 99

N- LCI/O

N NN

N- t0

to to to

to to to

r-i i-f r-I

.

H H H r-i ri r-I

99

99

ti

.

r \r l r \

e

r

e

.9 99

99

N\ t0 0 150 0 al

,

Lf ' LCl O re\ H

N N N

N N N

99 99 99

99 99

•

r-1 al 0.

LO 1` NH HH

9 9

99

99

t

•

N 01 01

LC' -i I

r1

r 1

a)

NCV co

(i

O

r

r

LO N

LC \ LC\ LC \

NNN

9

ti N al

N r \N

NN N

NN N

N N N

99 99 9 9

9

.

e

1

•9

•

CR

I

a) ;

r

Lc\

0. . '.-[

0N

r5l

U

▪ :

▪

)

4

99

• • •

:

•

U)

! U

F!

~N

N

..

•

N-0\

H N

r \ r \r \

e

e

e

..

0

..

•

..

rl O LC\

Lr - -d-

re\ r \ r \

e

..

..

99

..

1- LO LC\

LC \ LCl Lc\

N NN

•6

99

..

N

r \

ref r \ re\

N N N

e

e

. .

. .

M

tO

O

I~-LD t-HH H

. .

99 99 9 9

LC1 N to

Lcllp LC\

H H r-1

.

• •

▪

0 al al

re\ r \ re\

e

9

9

9

•

9

..

.

I

! +)1

0

' OI U

C

H r I ` NFi

•

LC) I

.6

e

I

1

90

•

r- M 0

ti to to

'sr,

•

q

fi

i

U)i

e

99 99

Pi

.S'

r \

O re\

N to

▪

90 99 99

-FD

I O

to al

N

•9

.

.

.

:

•

:

▪

•

:

:

:

••

.

Ol 0 al

N Lc\ re\

re\ M re\

LCI

al

.

Lf 1 N

IYl

N LO .zlN

to 0

Lll_71 111

•

Table 3 .--Fiber size distribution of the various screen fractions o f

groundwood pul p

Fiber length

range

From

mm.

0

0 .073

.147

.220

.294

.36s

.44o

:

: mnn.

:

.

:

:

.515 :

.588

.6o2

.736

.810

.884

.956

1 .030

To

:

:

r

:

: Passing 60

: mesh screen

Fibers

measured

.

:

:

:

.

1 .618 •

0 .073

.147

.220

.294

.368

: 489

: 139

: 78

: 15

.

8

.44o :

4

.515 :

7

.588 .

1

.662 .

1

.736

.810 :

.804 :•

.956 :•

1 .322

1 .398 :

: ■

:

:

:

:

:

:

:

:

1 .691 :

:

1 .691 : 1 .765

1 .765 . 1 .839 :

:

:

:• .•f . . . .

:

1 .618

Fibers

measured

: 65 .70 :

: 18 .70 :

: 10 .50 :

: 1 .92 .

: 1.07 :

:

.54 :

:

. 94 :

:

.15 :

:

.15 :

:

:

1 .470

1 .545 :

:

:

:

1 .839 : 1 .912 :•

1 .912 : 1 .986

1 .986 : 2 .060

2 .060 : 2 .115

2 .115

2 .205

2 .205 : 2 .382

2.382

2 .375

2 .375 : 2 .430

:

Total

Retained

:

between

:

and 60 mesh:32

screens

:

Retained

Retained

between

:

between

and 42 mesh; 24 and 32 mes h

screens

:

screens

?.ers

Fiber s

mei.;_17-. ed

measured

------------------ :Number : Percent : Number : Percent: Numbe :c• J. °cent : Number : Percen t

1.030 :•

: 1 .102 :•

1 .102 . 1 .175 :

1 .175 : 1.250 :

1 .250

1 .322

1 .398

1 .470

1 .545

:

:

: 142

:

:: 2

19

41

: 0.40

: 3 .76

:

.

37

• 7 .33

:10.70

: 9 .70

:1o.50

:14.20

: 5 .52

6 .52

: 4 .36

: 2.58

: 3 .76

: 3 .97

: 1 .38

.

: 2 .18

: .59

: .59

.59

: .20

: .59

:

:

:

:

.

:

:

:

:

:

:

54

49

53

72

28

35

22

13

19

15

7

9

11

3

3

3

1

3

o

1

3

2

1

:

:

8 .12

1 .78

:

:

0

.20

. 59

.

:

:

:

:

.

:

:

:

:

:

:

:

.

.4o

:

.20

:

3

:

8

:

9

8

t,

:

22

22

46

21

34

42

26

:

:

:

:

:

:

:

10

11

:

:

11

11

17

23

12

:

:

:

:

0 .82 :

2019 :

2147 :

2 9

3 .02

3 .52

6 . 0.2-41 :6 .02 :

9 .85 :

5 .75 :

9 .32 :

11 .50 .

7 .13 :

4 .65 :

2 .74 :

3 .02 :

6 .03 :

10 =? ,

8

3 ~;

.

5 $ . J- .-7 :

2

,

5 ,

3 3= : ~

2

.

1 :

.27 :

1 .

.27 :

. . . . . . . . . .

:

:

:

.

. . . . . . ... . . . . . .. . . . . . . .•

10

14

1

2

:

. . . . . . . . . . . . . . :

:

2

:

:

:

:

3

:

:

3

Above 0 .662 :Above 1 .986 irrn . :Above 2 .060 mm.:,Above

3 : 0 .45 ;

1 : 0 .20 :

4 : 1410

---------W

5

: 745 : 100 : 505 : 100

: 365 : 100 : 342

:

1 .1 7

.29

:

.5 9

:

.5 9

.88

:

:

.88

2 .430 mm .

:

1 .4 6

:

10 0

80 mesh wire . Ordinarily no attempt was made to catch the material passin g

through the 60-mesh screen . One hundred grams on the basis of weigh t

of oven-dry pulp was used for the test . After screening, all othe r

fractions were dried and weighed and the portion cassing through th e

60-mesh screen was obtained by subtraction . When it was desired to obtain a auantity of the fine fraction to determine its properties, a piec e

of linen toweling was laid over the wire screen in the catch box . B y

this method more than 75 percent of the fiber passing the 60-mesh scree n

was reclaimed .

The appearance of the different fractions obtained with this serie s

of screens is characteristic and indicates a fairly definite separatio n

of the fibers into groups according to their size (3) .

Table 3 shows the results of fiber measurements made to determin e

the fiber-size distribution in the various fractions . The data represen t

the average of five commercial groundwood pulps . The five pulps wer e

fractionated and the fiber measurements made on each fraction . The fiv e

sets of fiber measurements for a given fraction were then combined . Fro m

350 to 500 measurements were made on each of the fractions retained o n

the 24, 32, 42, and 60-mesh screens, and because of the inaccuracy involved in measuring very short fibers, about 750 measurements were mad e

in the material passing the 60-mesh screen .

The manner in which the fiber lengths tend to group themselve s

about the average, or the freauency distribution, was determined by th e

number of fibers falling within a given range of length instead of th e

__number of fibers of a given single length . This was due to the fac t

that even with the apparently large number of measurements taken, th e

relation of the percentage of fibers of a given length to that of th e

next higher or lower length was very irregular and therefore, a curv e

drawn through such data would not present a true picture of the norma l

distribution of the fiber lengths . A much larger number of measurement s

would have smoothed out these irregularities and permitted the use o f

smaller ranges than reported here . The average fiber length, the standar d

deviation, and the coefficient of variability of each fraction are show n

in table 4 . A high degree of variability is indicated in all fractions ,

that for the material passing the 60-mesh screen being almost twice a s

great as the other fractions .

Table L+ . ;--Average fiber length, standard deviation, and coefficient o f

variability of groundwood screen fraction s

Fraction

•

Passing 60-mesh

Retained between :

42 and 60-mesh

32 and 42-mesh

24 and 32-mesh 4

R884

: Average fiber : Standard

length

: deviation

:

mm .

0 .079 7

:

+0 . 0796

.567 5

.812 0

1 .11-1.

0

. 334

.365

.513

-3 -

: Coefficient o f

variability

- ..

.

Percen t

99 . 9

58 . 9

45 . 0

56 . 1

The abscissas of the pofints on the curves show :n in . figure '3 are:

plotted as the midpoints of the range of length chosen . In spite •o-th e

efforts to insure .a complete 'separation, of the fibers there is a ' considerable overlapping of sizes in every fraction . This does not, however ;

invalidate the usefulness of the method . In commercial work the series'o f

screens needed will depend on the characteristics of the pulp and th e

degree of separation desired . In some cases a sharp separation into fibe r

classes may not be necessary . If•a sharp separation is desired, a-stud y

such as described above, although requiring a large amount of careful work ,

will be needed to determine the number and mesh of the screens required .

Detailed studies of the physical and chemical properties of th e

screen fractions of .groundwood pulp have been presented in other •publica tions (4,) . These investigations have indicated some very definite relationships between , fiber size distribution and pulp properties . .

SCREEN ANALYSIS OF CHEMICAL PUL P

11 '

The screen analysis has been found useful in studies of the effec t

of beating . Then beating a mixture of spruce and birch sulfite pulps fo r

glassine stock, samples were taken from the beater at intervals an d

development of hydration and strength of-the pulp followed by means o f

the'freenessand strength tests . The cutting action of the beater ril l

was followei .b'y-the screen analysis, in this case with the single-plat e

screen . The results of the analysis are shown in figure :4 .

It may be noted that the cutting action of the roll, which was o f

stone Was rapid 4uring the first .120 minutes . Cutting was less rapid, during the . next80 minutes but increased again during the last period of 4 0

minutes : It may be noted further that an increase in the amount o f

material that would p ass the 60-mesh screen was accompanied with a n

approximately equal decreas .e in the amount retained on the 24-mes h

screen . The intermediate fractions remained practically constant i n

amount throughout . This example is cited to illustrate a use the scree n

analysis may serve in determining That is happ ening to pulp in processing .

Another example of the . aid of the screen analysis in the processing of pulp is shown by the data in table 5 . This was a study of th e

production of bond paper from bleached sulfite pulpi Th4 4creening wa s

done on the four-compartment screen .showh in figure 5- . The analysi s

indicates the trend of the processing effect on fiber distribution .

The percentage of fiber retained on the ' 24-mesh screen was redu.ced - proportionately as much by beating as by jordaning although the beatin g

treatment was very mild . . The effect of beating on increase of th e

amount of material passing 115-mesh screen was nearly twice as great a s

the effect of jordaning the beaten pulp . Generally speaking more tha n

two-thirds of the fiber size reduction ofthe "on 24-mesh" material b y

beating appeared as increase in the amount of "through 115-mesh" materia l

whereas only a little mbre than one-third of the size reduction of "24 mesh material ft by jordaning the beaten stock appeared as fine material .

8884

-1 -

N

■■MIlIEN111■ I

n1111N■■11 .11..1119

nnnn

f0

11111■1011 NINE

//E L

.11

r■

i

__

MIR

INN

u

u

u)

IN

nnn

u)

a)

u)

a)

-

et:1

z

-

\J N

iti N Fi

u)

a)

a)

a)

a)

4-3

4-1

-p

a)

a)

a)

-0

0

a) rU

a) u1

,o -0 0

00

acd

0

ifi

k ;-l

OOO

~■

9

g

N-N._1-

-d

N

Pi

o

.H

0 0 0

cd cd cd cd

r-=-f Fri

00 <1

I frIl I A

t)

%I%

.

IMO

E

LE

U

a)

r-1

glom . EEM■ ;

44

4i Fi

O U

U)

,

1

■

IR

sm..

nnn

z

l

_

I

r-~

}

--

■■.alBr 41

>F

~~ I t,

.. , _

INN

X11_-a_E

■ 11

1.111•1=11_n.

N

cH

O

q

•

O

-3

N

I Fvl

1

4-0

0

.H

u)

_D

,d

P

a) z3

N

a)

•H

va H

Fi

a)

a

a)

_

N

o

a)

a)

Fa

U

O

a)

a)

UO

a)

.U

O

0

rc1

.W

O

a)

a)

a)

U

o

U

O

w

~

N

tv l

N

d

d

U

0

~O

cd

f

N

N

N

rrl ~-

s~

m

a)

0

a)

+

-p

P4

f~

N

H

U)

11

cd

a)

EiD

a)

a)

a)

O

al

a)

a)

0

N

cd

Pi

IN=

O

O

N

1.11

0

w

0

uaaxos

txo

pautt;qa .T

4txnoult)

.C

-'

o

I

Ei D

cti

a)

cd a

,O

O

`rS

Cl]

F-i

a)

a) p

U

U)

1

L-

rr-i

a)

P

~

II

(4uao .zacl --

•H

o

Ill■=

!

NAM= •=Il

-.

L

O

a)

1

0

•

U

C

Table 5 .--Screen apalysis .of_unbeaten and processed bleached sulfite pul p

Processing:

treatment

,_ := Retained.

on

42 and : 80 and

80-mesh :115-mesh

24 and

U2=mesh

Pexrcent'

Percent

Unbeaten

'Retained between

: -=

Percent . Percent

:

c

75 .0

6 .)4.

After beating . . . . :

58 .4

10 .1

:

6 .5

3 .2 .

After jordaning . . :.

45 .0

14 .o

:

10.0

4 .0

.5 r

:

4+ .3

: Passin g

:,115-mes h

.

,percent

10 .4 ,

'319

22. 0

, 27 . 0

It . .was also observed in this investigation that the percentage o f

fine material in the furnish was associated with the porosity of the

finished paper . The data in table 6 show that a higher porosity valu e

(more dense sheet) was obtained with furnishes containing the highe r

proportions of fines .

Table 6 .--Influence of amount of fines in the furnish on the porosity

of sulfite bond pape r

: Porosity of shee t

by Gurley

:

:

densomete r

: After jordaning : At head box

:

-------------------------------------------------------------------- Number

Second s

Percent

Percent

Machine

run

:

1257

1272

1261

1267

1259

:

R884

:

Proportion of furnish

passing 115-mesh

:

1y .2

:

33 .2

35 .6

30 .0

9 .3

360

230

143

56

50

STUDIES ON THE SCREENING PROCEDURE '

In the ori-Omal screen analysis test employing' asingle-plat e

diaphragm screen it was necessary to interchange screen plates for eac h

fraction . This appaus was improved upon by building_ four diaphragm

screens into- olie . machine . In the improved machine - each compartment contains a,: $cregn plat e: ;with different size- of . openings than the other three .

The screeni - shown -in figure 5 . I-n operation, from 50 to 100 grams o f

the pulp (depeh$ .ng on the-,fiber size distribution Of the sample), in a

dilute suspension., flows by gravity from one compartment to the nex t

through the series . of screen plates, the openings in the plate ineac h

successive compartment being . smaller than in the one preceding . As wit h

the single ..-plate screen ; mesh wires of the Tyler series have been used ,

but with the .'introduction of-one or two screens of finer•mesh•to th e

series : The fibers under the action of . the vibrating diaphragms and

agitating water sprays in .eaeh compartment, pass through . the- screen s

until they arrive on one, the openings of which are too small to allo w

their-passage . The fibers retained in•each compartment'at the end of th e

screening are washed out, filtered, dried, and-weighed ,

Analyses of several commercial groundwood pulps and one experimenta l

grow:ndwoodpulp were made on both screens in order to compare the result s

ofthe multiple-plate and'the single-plate screens . The results shown-i n

table 7 ' indicate that-the two screens are not comparable except perhap s

in the amount passing the 60-mesh wire .

The effect of the amount of pulp used in the test is shown in th e

The analyses obtained by the two screen s

analysis of'pulp Gi21 (table 7) .

are'more comparable with 50 grams of pulp than when greater amounts ar e

used. In general varying the amount of pulp causes greater variations i n

the -results"from the .,single-=plate screen than from the ■ four dilate ' so '

This isshown in table - . -The variability is greater in the four-pla t

screen for the n on 24-mesh" and passing "60-mesh n but is less for th e

int g rtnpdiate fractions . ' :

,

I

Table 7 .--Comparison of screen analyses made with the single-plate and

the four-plate fractionating screen s

Samplel :

Screen

Retained between

:Passing

Amount :Retained :

:o0-mes h

taken for :

on

:

:analysis :24 mesh :24 and :32 and :42 and :

:32 me sh : 42 me sh: 60 mesh:

Number

Grams

Percent :Percent :Percent :Percen t

:Percent

: 4 .0

: 10 .4

: 60 . 4

; 62 .3

9.1

2 .3

:

:

7,0

6 .9

: 65 . 9

: 62 . 2

.

:

7 .5

5 .3

:

:

5 .8

8 .8

; 66 . 2

: 65 . 4

5 .4

.5

:

:

7 .4

4 .3

:

:

6 .6

8 .2

: 53 . 1

: 58 . 3

:

:

5 .3

.9

:

:

6 .9

5 .0

:

9 .2

11 .1

: 69 . 3

: 64 . 5

:

:

8 .7

3 .7

:

10 .3

6 .0

: 10.2

: 10 .6

: 60 . 5

; 65 .4

:

3 .3

7. g

.

5 .8

4 .3

: 6 .7

: 11 .3

: 4g .2

: 33 . 1

19 .0

24 .5

:

:

4.9

.4

: 11 .7

: 2 .4

l4.o

28 .1

:

4 .o

.5

:

100

100

12 .2

19 .6

:

:

8 .2

.9

: Single plate

Four plate

.

100

100

27 .4

28 .7

:

.

P 901

: Single plate

Four plate

.

100

100

9 .0

18 .5

P 902

: Single plate

Four plate

.

100

100

10.3

24 .3

21

: Single plate

Four plate

.

100

100

36 .0

43 .5

P 888

: Single plate :

Four .plate

100

100

P 895

: Single dilate

Four plate

;:;

100

100

P 896

Single plate

s Four plate

.

P 097

G

:

G

21

: Single plate

Four plate

.

72

75

37 .6

4707

:

3 .8

11 .4

:

.

7 .4

5 .0

: 8 .5

: 14 .4

: 42 . 7

: 21 . 5

G

21

: Single plate

Four plate

.

50

50

38.0

35 .6

: 6 .0

: 10 .9

:

9 .0

4 .o

: 12 .5

: 13 0 5

; 34 . 5

; 34 .0

-Commercial groundwood pulp indicated by "P", experimental by "G" .

R88 4

Figure 5 .--Laboratory size four-plate diaphrag m

fractionating pulp screen .

zM 16105 F

O

Table g .--Comparison of single-plate and four-plate fractionating screen s

in regardtovariability in results caused by varying th e

amountofsampl e

Variability-

Fraction

Single plate screen

Retained on 24 mesh Retained

24 and

32 and

42 and

between :

32 mesh

42 mesh

60 mesh

Passing 60 mesh

:

: Four plate scree n

Percent

Percen t

3 .6

11 . 2

41 .2

2g . g

42 .0

23 . 9

21 .g

2g . 2

15 . 0

15 . g

-Calculated by dividing the average of all differences between value s

by the average of all values and multiplying by 100 . The amount s

of sample were 50, 75, and 100 grams of pulp from grinder run No . 21 .

(See table 7 . )

Table 9 shows a number of duplicate analyses made on the four plate screen picked at random from a large number of tests on groundwoo d

pulp . The results show duplicability to be good for this type of pulp .

It is emphasized, however, that althougn the procedure to be followed i s

not difficult, it is not possible to attain good duplication withou t

attention to manipulative details . Experience has further shown that

analytical precision cannot be, expected from a fractionating screen an d

it is for this - ,reason that an apparatus which may employ a fairly larg e

sample is to be preferred . The sample taken should be sufficiently larg e

for the smallest fraction obtained to be weighed on a balance reading t o

a minimum of one-hundredth of a gram . . A11 tests should be run i n

duplicate .

The degree of dupli,cabil6ety that may be expected on the four compartment screen of the Forest Products Laboratory is a maximum difference of 2 in fractions amounting to 10 percent or more of the pulp ,

a maximum difference of 1 in fractions amounting to between 1 and 9 per cent, inclusive, and a maximum difference of 0 .3 in fractions amountin g

to less than 1 percent, of the whole pulp .

R gg 4

- 7-

METHODS OF USING SCREEN ANALYSIS DATA

A screen analysis as ordinarily made gives from 2 to 5 Values ,

depending on the number of screens used . These may be used for•ctmparison

with a similar analysis on a pulp chosen as a standard . The use o f

several numbers for a test result is somewhat inconvenient and severa l

methods have been devised to make the data more useful . Discussion o f

the relative merits of these methods follow .

•

Screen Analysis Curve s

Screen analyses may be conveniently shown by curves . The plo t

of the percentages of the various fractions against the widths of th e

openings of the screens upon which they were retained is usually s o

irregular that a smooth curve cannot be . drawn. through the points . Ho yvever, if the cumulative percentage 's are. plotted against the screen opening a smooth curve may generally be drawn which rises continuously fro m

the amount retained on the coarsest screen opening to the amount retaine d

on a,hypothptical screen having openings of zero widths, : Since th e

cumulative percentage is defined as the amount of material that would b e

retained on ; a . given screen if it were the only one used in the analyses ,

the amount retained on the screen with openings of zero width is, o f

course, 100 percent . This type of curve is ., therefore, useful i n

estimating the amounts of material that, would . be retained on screen s

not used in the testing series ,

Either Cartesian or semilogarithm coordinates may be used fo r

plotting the widths of the screen openings . Both have certai n

advantages . Owing to a constant ratio between the widths of opening s

in the Tyler screen series the ordinates representing them on th e

uniform or arithmetical scale may become very close together as th e

widths decrease, whereas on a logarithmic scale these ordinates are no t

so compressed and thus offer a more : convenient method of plotting . •

Since the•logarithm of the screen open-lag equal to zero is infinity ,

it is impossible to draw the curve on- stiemilogarithm coordinates betwee n

the smallest screen opening used and screen with zero openings . Thu s

it is impossible to estimate the amounts that might be retained o n

screens smaller than that used in the testing series when the plo t

is made on semilogarithm coordinates . Figure 6 shows several typica l

cumulative curves for groundwood pulp drawn on uniform or Cartesian

coordinates* .

Screen analysis data shown in the form of curVes may o y be •

compared visually . However, certain properties of the curves )

be

expressed numerically and used as a means of comparison . A di®u's+io A

of these factors follows .- .

R884

Table 9 .--De ree of du)licabilit of screen analyses made with the

four-plate fractionating scree n

1

Sampl el

: Passing

: Retained :

Retained between

------------------------_150 mesh

on

42

and

:

g0

and

.

: 24 mesh : 24 an d :

42 mesh : 80 mesh : 150 mesh :

Number

: Percent

: Percent

: Percent

:

Percent

:

Percent

1 .6

1 .4

16 .4

14.5

19 .8

21 .2

58 . 2

59 . 2

6.

g

7 .2

20 .0

19.6

23 .4

23 .6

35 . 8

374 2

2 .1

2 .9

7 .9

10 .0

21 .5

20 .2

217 a

b

4 .0

4.0

19 .0

19.4

11 .6

11 .6

312 a

b

15 .2

14 .2

7 .3

g .4

999 a

b

17 .2

18 .8

4 .8

4 .0

P 1101 a

b

18 .9

17 .2

P 1196 a

b

11 .9

12 .4

G

57 a

b

4 .o

3 .7

G

80 a

b

14.0

12.4

G

148 a

b

G

G

.

:

18 .4

19 .5

50 . 1

47 . 4

50. 0

49 . 2

15 .4

15 .8

15 .4

15 .4

:

49 . 2

48 . 9

13 .4

13 .6

20 .0

20 .8

:

44 . 6

42 . 8

12 .1

12 .7

12 .1

12 .8

16 .6

16 .3

40 . 3

40 . 9

17 .3

15 .9

14 .8

40 . 1

16 .1

15 .0

18 .1

:

12 .9

13 .1

:

Commercial pulp indicated by 'P') experimental by "G" .

Rgg 4

:

38 .4

.

1'

-a-I .

1-

--p -1---t''.

'D

1

E

o

o

i

1

L

0

o

(41190 .10a

O

to

o

peLIT"eq.G .1 4T.12TGn2

o

0

OAT1.13TTLUMD)

0

no

i

=•vr_gla. ,

•

•

Screen Analyses Expressed in Single Number s

A number termed the coarseness modulus has been discussed in previous publications (1,2,1) . This factor is the sum of the cumulative percentages of the screen analysis (omitting the fraction that passes th e

finest screen) divided by 100 . The number is approximately proportional

to the area beneath the screen analysis-cumulative percent curve on semi logarithm coordinates, between the limits of the widths of the opening s

of the coarsest and finest screens used .

The area under the curve drawn on uniform coordinates may als o

be calculated . This is more complete than the area under the semi logarithm plot because the fraction passing the finest screen may b e

included in the calculation . Although several ways may be used t o

determine this area the following approximation based on the summatio n

of the areas of rectangles is sufficiently accurate and does not involv e

an undue amount of work : Cumulative percentages are read from the curv e

at intervals 0 .05 mm . width of screen opening :

Let :

a represent the amount retained on the coarsest screen used ;

b_ represent the cumulative amount for a screen opening 0 .05 mm . less i n

width than that of the coarsest screen ; n represent the cumulative amoun t

for a screen opening of 0 .05 mm . in width ; and s represent the sum of al l

cumulative percentage readings taken from the curve at 0 .05 mm . interval s

between b and n :

The approximate area under the curve is :

A = (19a + 56b + 50s + 56n +

1875)

100 0

The area under the semilogarithmic curve, as represented by th e

coarseness modulus, may be calculated directly from the screen analysi s

data whereas the curve must first be drawn before calculating the are a

under the uniform coordinate curve . Under normal circumstances th e

values of these areas increase as the proportion of long fibers increas e

and the proportion of the short fibers decrease . Therefore, in suc h

cases they may be used as a measure of average fiber length . The relationship is not rigid, however . It is evident that any change in the

shape of the screen analysis curve always indicates a change . in fiber size distribution, but a change in shape does not always denote a chang e

in the area under the curve or a change in average fiber length of th e

pulp .

1111

A value found to be more closely associated to the average fibe r

length of the pulp has been called the "average-screen opening for th e

pulp"(4) . It is proposed that this rather awkward phrase now be change d

to the "fiber length index," which is a more descriptive term . Thi s

index may be defined as the average of the widths of the openings in a

pair of screens of which one will just permit fibers of the averag e

Rg 8 1+

-9-

length to pass and the other just permit fibers of average length t o

be retained . It is calculated from screen analysis data by assumin g

that the summation of fiber lengths per unit weight of pulp is a constant and that the number of fibers in a unit weight of a given fraction relative ' to the number in'another fraction is in inverse rati o

to the widths of the screen openings . Table 10 illustrates one metho d

of calculation .

Table ' 10 .--1%:ethod of- calculatin• the fiber-leri th index of a pul • fro m

the screen analysi s

Range of screen

i .-esh- : Widths of

. opening

f

:Relative :Relative : Relativ e

:Average : Factor

total

: of

for

:weight of : number

of

lengt h

: widths :relative : pulp

of

of

:mumber of : retained : fibers

fiber s

:openings : fibers

: between :

screen s

B

A

D

mm .

BD .

:

AB D

: Percent .

16- 2 )4 : 0 .991-0 .701 : 0 .846 : :

1 .00

: 12 .3

: 12 .3

: 10 . 4

214- 42 :

.701- .351 :

.526

:

1 .61

:

2 .7

4 .3

2: 3

42- 80 :

.351- .175 :

.263

:

3 .22

: 20 .0

: 64 :4

. 16 : 9

80-150 :

.175- .10 14 :

.139

.

6 .09

.

63 .0

: 384 .•o

53 . 3

.10 1+- .o

Total

.052

:

16 .30

:

2 .0

: 100 .0

:

32 .6

: 1+97 .

1.7

. L8 1+ . Z

150- 0 :

:

Fiber-length index of the pulp . .8 14 .6/497 .6 = 0 .170 mm .

-Tyler standard . The 16-mesh screen represents, in this case, th e

smallest mesh through which all of the pulp w ill pass .

?It will be noted that for a given set of screens the summation o f

ABD will be a constant equal to 100 times the average of width s

of openings of the two coarsest screens .

R88 1 +

-lC-

yam., .

.. - : •v

LITERATURE CITED

(1) Schafer, E .R . and Carpenter, L.A . "Screen Analysis as an Aid i n

Pulp Evaluation ." Paper Trade J .

, No . 19, 57 (May g , 1930) .

(2)

Schafer, E .R. and Carpenter, L .A. "Groundwood Pulp Evaluation b y

Means of Static Bending Screen Analysis and Rate of Flow Tests ."

Tech . Assoc . Papers li,(l) :267 (May 15530) . Paper Trade J . 91 ,

No . 3, 61 (July 17, 1930) .

(3)

Schafer, E .R. and Heinig, Melburn . "Further Studies on Groundwoo d

Pulp Evaluation ." Tech . Assoc . Papers 14, 1, (May 1531) . Paper

Trade J .

, No . 10, 55 (Sept . 3, 1931) .

(4)

Schafer, E .R . and Santaholma, Matti . "Effect of Different Size d

Fibers on the Physical Properties of Groundwood Pulp ." Tech .

, No . 1 9

Assoc, Papers

(1) :442 (June 1934) . Paper Trade J.

4o (Nov . 9, 1933) .

(5)

Schafer, E .R . and Santaholma, Matti . "Chemical Properties of Scree n

Fractions of . Black Gum and Slash Pine Groundwood Pulps ." Tech .

Assoc . Papers 13 (1) :#31 (June 1934) . Paper Trade J. 0j, No . .19

46 (Nov . 9, 1 933)

{