rpr 523210 FOREST PRODUCTS LABORATOR Y

advertisement

523210

U. S. Department of Agriculture, Forest Servic e

FOREST PRODUCTS LABORATOR Y

In cooperation with the University of Wisconsi n

MADISON, WISCONSIN

SORPTION OF WATER VAPOR B Y

PAPER-MAKING MATERIAL S

1 - Effect of Beating

By C . O . SEBORG

Junior Chemist

an d

ALFRED J. STAMM

Chemis t

Published i n

INDUSTRIAL AND ENGINEERING CHEMISTR Y

November, 1931

rprf

V-

_

L

▪

I

r

I{

I

.

a

III)il

J I

11

II

eh

-

1

111

%J

T

. 1

ti l I ~

JI

1 1II1

1 I~~I

II

41 '1'

SORPTION OF Ws.T .Lt VAPOR BYL PAP. R-Mi KING MaTr IAL

T-

u`r ; ,

I

1

1 . Effect of Beatingl

4I

f

.m

:

-

n

1

- -.

By

r . ` 1I I1 _ `

C . O . Seborg ,

Junior Chemis t

q~

ti

-11 .

and

A .

J . Stamm,

Chemist

1

71'

1

-

Synopsis

•

I

11

n1

I,c

►

1Y

I

.'r[ ' _ 1 1

Measurements were made of the moisture content-relative ° -i r

humidity and moisture content-electrical conductivity relationships o f

pulps and stuffs .

An apparatus was designed for measuring the relative humidit y

relationship of materials at atmospheric pressure, using a method i n

which air, humidified by passing through various saturated salt solution s

to give the desired relative humidities, was circulated about th e

adsorbent material suspended from a sensitive quartz-helix balance . The

extensions of this balance were measured with a cathetometer . The

hydration (hygroscopicity) of the pulp, which the regularity of the curve s

showed to be physical rather than chemical, was not affected by beating .

Electrical conductivity-moisture content relations likewis e

showed no differences between beaten and unbeaten pulp .

1

.'resented before the Division of Cellulose Chemistry at the 82n d

Meeting of the American Chemical Society, Buffalo, N . Y ., August 3 1

r,

to September 4, 1931 .

J

-r' . .

'

M4

I

rl

R967

-1-

I I

1

_ 1

itI•

. ya

m

1

• r

■

J

The so-called hydration of the paper industry is not a true

hydration . It is probably a phenomenon of fiber-fiber bonding rathe r

than of fiber-water bonding .

Introductio n

410

The objectives in this series of studies are to determine the

hygroscopicity of pulps, stuffs, and the various components of wood unde r

normal atmospheric conditions ; to determine the relations of the sorptio n

hydration (hygroscopicity) to the so-called hydration of the pape r

industry, that is, the change in properties of fibers produced by beatin g

which in the past has been assumed to result from a change in thei r

ability to retain water ; to determine the extent to which this sorptio n

hydration affects the fiber-bonding properties ; and to critically study

the desorption-adsorption hysteresis .

The various materials to be studied are sulfite, Icraft, soda ,

and semi-chemical pulps ; bleached pulps ; beaten pulps ; isolated woo d

components, such as lignin, Cross and Bevan cellulose, and alpha cellulos e

from both pulp and Cross and Bevan cellulose ; and furnishing materials ,

such as coatings, sizings, and fillers .

This paper deals only with the effect of beating on th e

sorptive hydration of a sulfite pulp . The word "sorption" is the same as

used by McBain (8) to include both adsorption and absorption phenomena .

Previous Sorption Studie s

A number of investigators have published papers on subject s

pertaining to the hysteresis of the adsorption and desorption of wate r

vapor by various materials, which ranged from silica gel to textiles an d

paper (1, 2, 6, 1, 11, 12, 3 , 15, 16, U, 1S, 19.) a

All of these investigators, with the exception of Patrick (11 )

and his ho-workers, have obtained definite hysteresis effects . Th e

hysteresis effect in non-elastic gels, such as silica gel, has bee n

attributed by Zsigmondy (19) to a difference under adsorption and de sorption conditions in the curvatures of the menisci of the liquid fillin g

the capillary spaces . These differences in curvature are supposedly du e

to differences in the wetting of the capillary walls, which are les s

readily wetted after drying . ix somewhat different explanation, by Urquhar t

and Williams (17), is more applicable to elastic gels, such as cellulose ,

in which the swelling follows adsorption from the start . Thes e

investigators attribute the effect to the free secondary-valence bonds o f

the hydroxyl groups of the cellulose molecules . In the original water-soake ,

R967

-2-

1

0

condition, the free hydroxyl groups are practically all satisfied b y

water . When the cellulose is dried, these hydroxyl groups are freed and ,

as a result of the shrinking, pairs are drawn together so that the , ,

individual groups mutually sat i y each other . Upon adsorption, part of

the hydroxyl groups that hav e

ually satisfied each other are not free d

for water adsorption, thus g i

decre

ption . ~r

. . . .

^ +...i .• .

_ick (11 .

t the hys t

effect obtained by all o

due to th e

.e

of

gases

eni

o .

"

them

have worke d

1'

evacuated systems . Pat r

ments

s a

F ter•

n h h t e greatest precaut .ri~:• .

air from their silica gel . .

'q6T

y sh e

e

hysteresis effects but the curves

6* _ r.1 _ ssure a content -- are parabolic rather th .

~n shae-, .

Elder ( )

I

have studied the adsorption o_

.

epare,o

feren t

{ i L,g, .methods that gave dif ex t .

y

the

Ell

obtained a parabolic curve ; with mo rn

id curves ; and wi t

the most porous gels, parabolic curv

erse curvature .

zt thus appears quite probable tha n

of adsorption, as obtained by Patrick, may h .

only

gels that show parabolic sorption curves . E

~. f

stating that the hysteresis effect in non-ela n1

b

the fact that the last traces of non-condensabl .- gases have no. _

removed, this does not necessarily imply that the hysteresis s

by ' ~

elastic 'gels, such as cellulose, is also due to the presence o ~ ~

■~

condensable gases . Furthermore, since cellulose cannot be rig s

degassed without decomposition, the hysteresis effect may just

accepted as a property of the system as to be attributed to experimenta l

error .

41, .

Ther seems to be little object, therefore, in working in an

1

xcept when diffusion of the vapors is depended upon fo r

tblvment of equilibrium .

iw

ii thug, sees

only justifiable but also advantageous t o

r e four

,+

it e .- - -ntal work an atmospheric-pressure system i n

'which Alit

ied by passing through different saturated salt solution s

to give the desired relative humidities (3), is circulated about th e

adsorbent material suspended from a sensitive quartz helix balance (8) the

intension of which is measured with a cathetometer . With such a syste m

tbm

-nts are normally= garde under conditions corresponding to thos e

data will be used . The method has a further advantage i n

h equilibrium point is obtained under constant vapor-pressur e

ns . In all of the researches cited, in which a vacuum system wa s

recent work of Pidgeon and Maas (12) is excepted .}, a definit e

volume of water vapor was admitted, and, as adsorption progressed, the

vapor pressure diminisle:d . Under such a system the most readil y

accessible part of the i atelHHal may initially adsorb more water vapo r

than the final equilibrt : amount, thus permitting a subsequen t

combination of both adsorption and desorption to take place at the sam e

time . Such a condition might readily affect the normal hysteresis .

For the same reason a number of simultaneous determinations cannot b e

made in a single apparatus under changing vapor pressures, whereas the y

can be made when the humidity and temperature are held constant .

Th~a gimp' 'recent measurements of Pidgeon and Maas (12) hav e

bean made at . ei munstant vapor pressure in an evacuated system, by holding

the temperate of the vapor-supply bulb- (which is left open to the re's't

of the system after evacuation) below that of the rest of the sorptio n

apparatus by -Pm amount--that gives the desired relative humidity in th e

sorption system . Under these conditions the accuracy with which th e

relative humidity is maintained depends directly upon the accuracy wit h

which the two temperatures are held . At high relative humidities, 9 5

per cent for example, a deviation of 0 .2° C . from the required temperatur e

difference between the vapor-supply bulb and the sorption system at 25' G .

causes a deviaViAla in relative humidity of 1 .2 per cent . When saturate d

salt solutions a,rm used to- maintain the relative humidity, , the effect o f

temperature deviation is much less ., For example, a saturated potassium

sulfate solution that give's approximately the relative humidity jus t

mentioned (95 per cent) would require a temperature deviation of 30° C . t o

cause the same deviation (1 .2 per cant) in relative humidity (5) .

Apparatus and _. ]xperirental Methods .

Sorptive Metho d

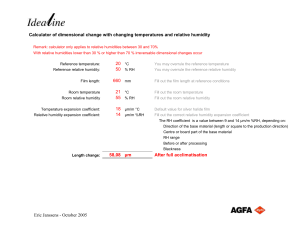

The apparatus used in this part of the . esearch is shown i n

Figure 1 . -Four simultaneous measurements were made in the sorption tube s

f, E, h, and i . These tubes, connected in parallel at the distributin g

head d, were--in series with d, the spray trap c, and the humidif ll-ng '

train., b . The humidified air, after - circulating abo1t the test s4elples

suspended from quartz heljces .;•. was discharged through the glass tubin g

of the hooka-1, k, 1-, and m,- that were -sealed i .to the top of t

sorptio n

tube's . The conditioning tubes were immersed in a thermostatic, water bat h

having glass windows o two opposite faces . The temperature of the ball

was maintained at 250 t 0 .02° C-: and . that of the r- .osm at 23° t 1.0° C a

In making ;measurements at high relative humidities, t .e s],ht drop in .

temperature' of the exhaust air was sufficient t .o cause condensation i n

the upper part of the exit tubes, which were spbsitantially at :room

temperature ; so in -order te .prtaeent this condensation ha .t was applie d

x967

Figure 1 .--Diagram of sorption apparatu s

' -e. ; inle t

b; humidifying chamber s

c; spray trap

At manifol d

stop cocks

f, _g, h, and ; sorption chamber s

Z k, ] and

hooks of glass tubin g

o, p,. and 21 local heating elements

near the ends

p, and g . The

into a beaker

The pressures

to give equal

of the tubes by means of small electric light bulbs, n, o ,

discharge tubes were bent over with the ends barely dippin g

of water to permit observation of the velocity of discharge .

in the tubes were made equal by adjustment of the stopcock s

velocity .

The helices, which were made of quartz fibers, were of suc h

size that a helix with a diameter of about 1 .0 cm . and 30 to 35 turns

ia ; length of 2 to 3 cm . was able to carry a load of 300 to 1000 mg .

to weigh to an accuracy of 0 .1 per cent . Cathetometer measurement s

were made at the fixed ends of the helices as well as at the deflectin g

ands to avoid any possible errors that might otherwise have been cause d

by creeping of the sealed-in rubber stoppers ; all cathetometer reading s

were made to 0 .005 cm .

The humidifying train b consisted of three glass tubes, 35 cm .

in length and 2 .5 cm . internal diameter, connected in series . The tube s

contained short lengths of glass tubing to increase the solid-liqui d

contact surface of the ascending air bubbles . .k.n excess of the salt wa s

placed in the bottom of the tubes before sealing to insure the maintenanc e

of saturation . A pre-humidifying train with large-bore tubes was set up

outside of the thermostat . This arrangement s

e air t o

ap sz4

#4 ti dessai'qs-iiiadpWif

fying

train b,

vent

ppreciable quantities o f

water frua ILl malt s

d have resulted i n

e y.ta%'1U itala and c

system .

_ ailher

idity in equilibriums with each of th e

NkturaOmil'

was determined by a dynamic method as nearl y

comparAle with the c

under which the humidifying tubas wer e

used as possible . Mr w at a constant speed through one of th e

humidifying systems just described and then through an absorption train ,

consisting of a U-tube filled with calcium chloride, followed by anothe r

filled with phosphorus pentoxide suspended on glass wool . The dry ai r

discharged from the phosphorus pentoxide tube was then passed throug h

another humidifying system which was similar to b except that it wa s

filled with distilled water . The saturated air coming from the distilled water humidifier was passed through another absorption train . Both set s

of humidifying tubas and absorption trains were kept in the thermostati c

bath . The ratio of the amount of moisture absorbed in the firs t

absorption train to the amount of moisture in the second, after makin g

volume corrections for the difference in the total air pressure obtaine d

after pssin through each of the sets of humidifying tubes, gave th e

relative 'ginicity of the air in equilibrium with the particular saturate d

salt solution under consideration . In preliminary tests air was passe d

through the system in increasing speeds to determine the speed at whic h

the humidity of the air was no longer in equilibrium with the humidifiers .

One-third of the maximum permissible speed of 45 liters per hour was use d

in this

if

so as to insure the attainment of equilibrium .

x967

eJ 4

ir

1.

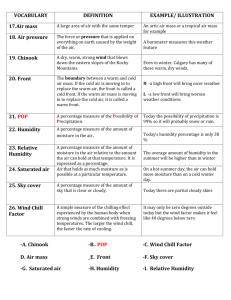

Table 1 .--equilibrium relative humidities of various saturated salt

solutions

Relative humidity

20° C .

. ' 0° C ,

. 100° C . .

25° C .

: Calculated :experimental :0bermiller (10) ;Calculate d

Per cent :

Potassium acid

8748

.

Per cent

.

Per esat

Per cent

953

..........

Sodium chloride, NaCl

•

73 .8

Zinc nitrate ,

Zn(3d0 )2 . 6 H2 O

10 .9

7 4+ .2

'749

53 .4

52 .0

4o . o

42 . o

11 .1

15 .0

75 . 8

11 . 5

In Table 1 are listed the relative humidities obtained at 2 50

0.02° C . in equilibrium with each of the aaturated salt solutions used i n

this research . The experimental values represent the averages of at leas t

six determinations . Variations among individual measurements rarel y

exceed 0 .5 per cent . The results obtained by Obermiller (10), using a

static method, as well as values calculated from vapor pressure an d

solubility data at 0° and 1000 C . obtained from the literature, are give n

for comparison . Unfortunately, data are not available to complete th e

table, In general, the relative humidity decreases slightly with a n

increase in temperature . Obermiller r s value for lithium chloride i s

apparently high, whereas the results of this investigation for potassiu m

acid phosphate and sodium dichromate seem a little high in comparison wit h

the other values . Since good checks were obtained for both of thes e

measurements, the deviations were probably due to differences in th e

purity of the salts .

In these studies the experimental zero humidity was obtaine d

by passing the air through the towers filled with phosphorus pentoxid e

suspended on glass wool .

410

Measurements were made upon an unbleached spruce sulfite pul p

and the same pulp after it had been physically processed for g hours in

a beater . The beaten and unbeaten pulps were thoroughly washed for 2 4

hours with running distilled water and were then made up Into thin tes t

sheets . The wet sheets (containing about 60 per cent water) were cu t

to a size that would weigh approximately 0 .5 gram when ai dry, wer e

rolled into the shape of a cylinder, and prior to the final measurement s

were suspended for about two weeks in an atmosphere of abouc96 per cen t

relative humidity . This was done to remove the large excess of fre e

moisture, thus making it possible to use more sensitive helices as wel l

as to cut down the time required for the actual measurements .

The desorption measurements were started at the moisture conten t

induced by 95 .3 per cent relative humidity and were continued stepwise a t

decreasing relative humidities to zero humidity . The adsorption was the n

followed by using the same sets of humidifying tubes in the reverse order .

Equilibrium was obtained in the desorption measurements at high relativ e

humidities in approximately 2 days and at lower relative humidities in on e

day . In the adsorption measurements equilibrium was obtained somewhat mor e

rapidly, requiring approximately 1 day at high relative humidities an d

considerably less than 1 day at lower relative humidities . In each case a n

additional day was allowed as a factor of safety .

s

Electrical-Conductivity Metho d

The results of the sorptive method were confirmed by electrica l

conductivity-moisture content measurements, using an apparatus previousl y

developed for determining the fiber-saturation point of wood (14) . Thi s

apparatus consisted essentially of a brass screw clamp with circular contac t

faces, 1 .0 sq . cm . in cross section, for making contact with the pulp disk ,

The two contact faces were insulated from each other by 4 cm . of the hardrubber base . The reading apparatus consisted of a portable suspensio n

galvanometer, an ayrton shunt, a key switch, and a single 1 .5-volt dry

cell . The shunt, which allowed 1 .0, 0 .1, 0 .01, or 0 .001 of the curren t

to pass through the galvanometer, was connected in parallel with th e

galvanometer and in series with the dry cell, contact clamp, and key

9 switch .

Readings of specific electrical conductance could be made from 10

to 10 3

mho with this simple apparatus .

R967

-7-

The measurements were made upon circular disks approximatel y

3 .0 rpm . thick and 1 .0 sq . cm . in cross section when in water-soaked and

swollen condition . The disks were dried in air for a few minutes, an d

then held in small weighing bottles for about an hour . in order to approximat e

uniform moisture distribution before weighing and making measurement of th e

electrical conductivity and of the dimensions . The disks were then drie d

for a few minutes, after which the procedure was repeated .

.experimental Result s

•

•

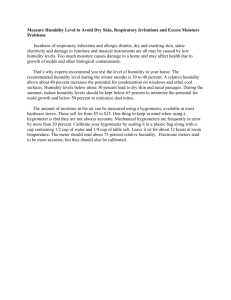

The sorption measurements of four samples of pulp an d

corresponding stuff, conditioned simultaneously, are recorded in Table 2

and plotted in Figure 2 . The results show that beating has a negligibl e

effect upon the moisture content-relative humidity relationship of pulp .

This same result was obtained by Campbell and Pidgeon (2) in an evacuate d

system . The hysteresis loop is not closed at high relative humiditie s

nor does the hysteresis effect disappear at low finite relative humidities .

The fiber-saturation point obtained from extrapolation of the adsorptio n

curve to 100 per cent relative humidity is approximately 29 per cent . Thi s

too is practically the same as the value obtained from the extrapolatio n

of Campbell and Pidgeon t s curve (2) .

The electrical measurements plotted in Figure 3 show tha t

beating has no effect upon the electrical conductivity-moisture conten t

relationship of pulp . Drying and resoaking the pulp also snows no effec t

upon the relationship . This is in harmony with Murphy and Walker's finding s

(3) that there is no difference between the electrical conductivity moisture content relationship of cotton fibers under adsorption and

desorption conditions, thus showing that the electrical conductivity i s

a function of the absolute moisture content and is independent of the mean s

of attaining that moisture content . A linear relationship exists betwee n

the logarithm of the conductivity and the moisture content from the dr y

condition up to fiber saturation . above this moisture content, th e

conductivity changes but slightly . Over the whole range the results fo r

the beaten and the unbeaten pulp are identical within experimental error .

The fiber-saturation point -- the point at which deviation from the linear

relationship starts (28 per cent) -- corresponds quite well with the valu e

obtained by extrapolating the relative humidity-moisture content curve s

to 100 per cent relative humidity .

R967

-8-

Figure 2 .--Moisture content-relative humidit y

relationship of beaten and unbeate n

pulps

20

30

40

50

50

70

Relative Humidity (Per cent )

Figure 2

S()

•

Figure 3 .-- .L ctrica4 conductivity-moisture conten t

relationship of beaten and unbeate n

pulp s

•

S

I'5o

tta.tAi q.onpTTOO

ICY.

TDoz,zq.oata oTIT o2dS

0

'tor

~ri

Ir

I

Table 2 .--2ffectof physical processing on equilibrium moisture conten t

of

-:Relative :

Moisture content (O . D . basis)

:humidity :

Sample :

at

Unbeaten pulp

Stuff (highly beaten pulp )

25o

.

.

'CAM= : Desorption : Adsorption :

Desorption :

Adsorptio n

:Per cent :

1

2

:

:

::

3

4

R967

.

95.3

87 .0

74 .2

53 .4

40 .0

11 .1

0

Per cent :

Per cent :

Per cent

Per cent

32 .7

19,2

13 .2

8,8

5,6

2 .0

0

20 .4

114 .7

10. 14

6 .6

5.9

4 .1

0

143 .0

22 .1

14.9

9.2

6 .3

2 .7

0

21 . 7

14. 6

34 .7

'20 .7

15 .1

9 .5

-6 .-g

2 .7

0

22 .1

114.7

10 .0

6 .7

54 5

2 .4

0

36 .3

21 .9

15 .3

9 .9

6 .6

2 .9

0

23 . 4

15 . 3

11 .9

7 .9

5. 6

2. 3

0

95 .3

87 .0 A

74 . 2

53 . 4 :

40.0

11.1

0

32 .5

2 .0 .5

14.8

9 .4

6 .5

2 .9

0

82 .1

14 .4

10 .0

6 .9

5 .6

2 .7

0

32 .7

21 .7

15 .2

10.2

6 .5

2 .6

0

22 . 2

15. 7

12 . 2

8. 2

6.2

2, 8

0

95 .3

87 .0

74.2

3)4

.0

11 .1

0

32 .7

20 .3

114.5

9 :4

6 .6

2 .7

0

22 .6

14.7

10 .0

7 .3

5.6

2 .3

0

29 .7

19.9

14 .5

9 .5

6 .3

2 .6

0

22 . 3

95 .3

87 .0

714 .2

53 .4

40 .0

11 .1

0

:. .

:

:'

:

t'

.

.

11 . 2

7.4

5. 3

1.8

0

13 . 3

11 . 6

7. 7

5, 5

2 .5

0

Conclusion s

The continuous unbroken form of the moisture content-relativ e

humidity relationship indicates that the hydration of pulp is a physica l

sorptive hydration rather than a chemical hydration in which the bondin g

is in definite molecular proportions .

The desorption-adsorption hysteresis is similar to tha t

obtained by other investigators who used an evacuated system . The

presence of air thus seems to have no effect upon the extent of hysteresis .

The results show that beating has no effect upon the tru e

sorptive hydration of the pulp examined . The total internal adsorptiv e

surface remains unchaed, though the outer surface of the fibers an d

fibrile may be Increased considerably . .It is presumably the increas e

in the, available bonding surfaces .of the f-ibers. : and fibrils for each othe r

that affects the physics,, properties of the resultant sheet of paper (18) .

The so-called byd:rat om of :the paper industry is not a phenomenon of fiber ;o_n

water bonding as the, riche Implies, but appears rather to be a pl e

of fiber-fiber bonding .

•_

The fact that beating has no effect upon the electsica l

conductivity-moisture content relationship indicates that this .••

is a function of the aaount of sorbed water and is not d e.,pen404 upon the

fiber-fiber bonding . Such a relationship is to bw expec. .ed 'AA it i s

realized that the dry fiber is a vary poor conductor (specifier .. onductance :

1o-12 to 10-13 mh.o) .

'11 `

Literature Cite d

(1) Anderson and Kelvi n

1914 . Z. Physik. Chem. 88 : 191 .

(2) Campbell and Pidgeon

1930 . Pulp and Paper Magi Can . 29 :185 .

(3) Hatfiel d

1931 .

J . Abr . Research 42, 301 .

(4) Holmes and Elder

1931 . J . Phys . Chem . 35, 82 .

S

(5) International Critical Table s

1926 . 1, 67 . McGraw-Hill Book Co ., New York City .

(6) Kuyirai, Koboyashi and Toriyama

1923 . Bul . Inst . Phys . Chem . Research 2 :105 ; J . Soc . Chem .

Ind . 42A :8-94 .

(7) McBain and Baker

1926 . J . Am. Chem . Soc . 4g , 696 .

(8) Mason and Richard s

1906 . Proc . Roy . Soc . 78A :412 .

(9) Murphy and Walke r

1928 . J . Phys . Chem, 2, 176 .

(10) Obermille r

1924 .

Ibid ., 109, 145 .

(11) Patrick

1930 . Colloid Symposium Annual 1, 129 ; John Wiley & Sons ,

New York .

(12) Pidgeon and Maa s

1930 . J . Am. Chem . Soc . 52 :1053 .

(13) Sheppar d

1930 . J . Phys . Chem . 34 :l041 .

(14) Stamm

1929 .

Ind . Eng . Chem . Anal . Ed . 1, 94 .

(16) Trouton and Poo l

1906 . Ibid ., 77.x :309 .

(17) Urquhart and William s

.

1924 . Shirley Inst . Memoir's 3 ;197 ; J . Textile Inst . 15T :43 .

1929 . Shirley Inst . Memoirs 8 ; J . Textile Inst . 20T :125 .

(18) Van Bemmelen

1897 .

Z. Anorg . Chem . 13 :3 1