Pea Freezing Operations &ad dad Ejjeceegeeed Part 2. Packaging and Freezing

advertisement

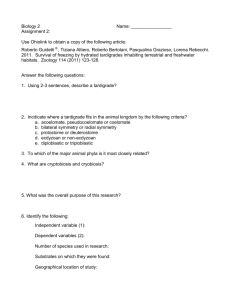

&ad dad Ejjeceegeeed • deeet • • • Pea Freezing Operations Part 2. Packaging and Freezing G. B. Davis H. M. Hutchings N3—R441 ' 1 APR 25 1960 \Oft, Miscellaneous Paper 87 March 1960 Agricultural Experiment Station, Oregon State College, Corvallis in cooperation with Agricultural Marketing Service, United States Department of Agriculture This report is the second•in a series dealing with costs and efficiencies in pea-freezing plant operations. The first dealt with vining and has been published by the Oregon Agricultural Experiment Station as Miscellaneous Paper 66, January 1959. These studies are being made under a regional research project concerned with the marketing of frozen fruits and vegetables. The Experiment Stations of Oregon, Washington, California, Hawaii, and the Agricultural Marketing Service, U. S. Department of Agriculture are cooperating in this program. Authors: G. B. Davis is Agricultural Economist H. M. Hutchings is Junior Agricultural Economist INTRODUCTION The Pacific Northwest produces and processes over 60 percent of the nation's frozen peas. This region is able to supply the market with such a large proportion of its needs because it has been able to compete effectively with other regions on the basis of cost and quality of product. Increasing labor, transportation, and supply costs in the Northwest relative to other producing areas, however, make it necessary for both producing and processing segments of this industry to be aware of ways to improve efficiency and reduce costs. This must be done if the Northwest is to continue as a major supplier of frozen peas. This report has been prepared in hope that information presented will guide freezing plant managers in making decisions to reduce costs and maintain or improve their competitive position. Results presented are based on economic-engineering-type cost studies made in a sample of eight pea-freezing plants located in the Pacific Northwest. Costs cited are not actual averages of current plant operation costs, but are based upon labor and equipment standards of performance obtained from time and production studies, equipment manufacturers' specifications and plant record data. These costs are somewhat lower than average costs of the plants in the sample, but are attainable by the more efficient producers and processors in the industry. Pea freezing plant operations often are divided into several stages or processes for purposes of cost determination. The following is a list of these phases of the total operation as used in this study: (1) wining, (2) receiving, (3) preparation, (4) packaging and freezing, (5) storage, and (6) shipment of product. - 2 - This particular report is concerned only with costs and efficiencies of number (4) above--freezing and packaging. Costs are shown for different rates of output under the following conditions: (1) Packing into different size containers. (2) Different lengths of processing season. (3) Repacking and direct packing. (4) Different methods used in processing. Costs are included for a continuous capacity operation of that portion of the freezing plant extending from the grading table through packaging, freezing, casing, and placing the product in cold storage. Included in these operations are the costs of all labor, equipment, buildings, and package materials. Costs of electricity, depreciation, interest, insurance, taxes, and maintenance and repairs are taken into account. Not included are costs of the raw product, management, sales, and office. RESULTS Container Sizes and Costs Size of package has a marked effect on plant operating costs (Figure 1). If it is assumed that the entire plant output goes into one package size, packaging and freezing costs for the 2 1/2-pound package are about 65 percent of the costs of the 10-ounce, the 50-pound bulk box 33 percent, and the 1600-pound bulk box 24 percent. This further assumes that all products are loose frozen in a belt tunnel. The larger rates of output, regardless of package size, tended to have lower costs per hundredweight of peas. This lower cost is most pronounced when output is increased from 5,000 to 10,000 pounds per hour. At lower rates, both equipment and labor have excess capacity. Increases in output over the 5,000-pound level increases the efficiency with which both are used. Beyond the 10,000-pound-per-hour rate, costs decline at a much slower rate. This is because a single packaging and freezing line of 10,000-pound capacity is relatively efficient, and increasing output beyond that point is accomplished by duplicating complete lines. Also fixed costs--building, equipment, and supervisory labor--represent only a small proportion of packaging and freezing costs for the small-size containers. Variable costs-container materials, equipment operating costs and most labor costs--remain constant per unit of output, regardless of rate of output. Decreases in costs beyond the 10,000-pound per hour level are attributed to better utilization of supervisors, mechanics, engineers and some savings in building costs. Had costs been included for relatively fixed departments, such as management, sales, and office, decline in costs would have been substantially greater with increases in rates of output as well as in length of operating season. The cost of container material was the most important single cost item, varying from 78 percent of total costs for the 10-ounce operation to about 35 percent for the 60-pound bag (Table 1). Only in packaging into bulk containers--50-, 60-, and 1600-pound sizes--did costs of labor exceed 10 percent of total packaging and freezing costs. Labor costs were less than equipment costs for all container sizes. Mechanized casing of 10-ounce packages and use of nonsewed 60-pound bags made substantial reductions in labor costs over hand casing and sewed bags. Use of these methods for a 20,000 pound per hour rate of output and a season of 1,000 hours reduced the crew by 14 persons in the 10-ounce and 2 in the 60-pound bag operation. (Appendix - 5 - Tables 5 and 6 show crew organization and material costs for different containers.) Table 1. Comparative Costs of Packaging and Freezing Peas in Different Size Containers, 1958 /1 Cost item Labor Equipment Belt tunnel Packaging, casing and materials handling Container materials Building TOTAL 10 ounce Size container 50-pound 60-pound 1600-pound 2 1/2 box bag/2 pound box (costs per hundredweight peas) $ .26 $ .23 $ .17 $ .11 $ .14 .34 .34 .34 .34 .34 .20/3 .13 .06 .06 .05 2.83 1.64 .62 .29 .33/4 .02 .02 .02 .02 .02 $3.65 $2.36 $1.21 $ .82 $ .88 11 Assumes output of 20,000 pounds per hour, belt tunnel freezing, and 1000-hour season. /2 Nonsewed bags. /3 Automatic casing. lit Assumes re-use of container materials - see Appendix Table 6. Packaging and freezing costs cited above are intended to illustrate the cost relationship between different size containers if only one size were used. Actually, few plants package and freeze in only one size container. Container sizes used and proportion of pack going into each will depend on available facilities and sales policies of the individual plant. In plants using different combinations of container sizes for their pack, the higher the proportion going into the larger sized containers, the lower the costs (Figure 2). These estimates are based upon an 6 Figure 2. Freezing and Packaging Costs with Different Container Proportions, 1958 $14 k(100 %10 oz. oz. 25% 2 lb. V 25% 50 lb. So% 10 1150% 10 oz. 5Q% 50 lb. 1\100% 50 lb. 0 -1\0( 11—i700030,000 10,0 Rate of output per hour (pounds of peas) A Costs based upon these assumptions: a. 1000•hour operating season b. Belt-tunnel freezing c. Automatic casing for 10-ounce A - 7 - efficient 1,000-hour operation utilizing belt tunnel freezing for all peas and automatic casing for the 10-ounce pack. Each of the four cost lines shown in the chart are based upon low cost combinations of labor and equipment with the freezing equipment operating at a constant rate o f output. Efficient packaging and casing operations were selected for the outputs shown and have a minimum of excess capacity. The chart is not intended to portray a single plant with sufficient flexibility to produce the volume of each combination of container shown at the indicated cost for that combination. For example, a plant with an output of 10,000 pounds per hour of 10-ounce and a like amount of 50-pound bulk would not be equipped to pack 20,000 pounds per hour in either the 10-ounce or 50-pound alone. A plant with such flexibility especially as it relates to the smaller containers, would have substantially higher costs. Length of Processing Season and Costs Season's length for processing is usually fixed by climatic conditions within an area and product characteristics. However, there is a certain amount of flexibility in hours per season of plant operation when the number of hours of operation per day can be varied. Where the hours of plant operation can be increased, it is possible to reduce processing costs. The longer the processing season the lower the costs at all rates of output and for all container sizes (Figure 3). Lengthening the season from 250 to 500 hours has a substantial cost reducing effect. Each additional increase in season's length beyond 500 hours results in smaller cost reductions. For example, by extending the season from 250 to 500 hours for a 10-ounce belt-tunnel operation of 10,000 pounds per hour, costs, per unit can be reduced by about 17 percent. If the season is lengthened to 750, 1,000, and 1,250 hours, costs are reduced by only 6, 3, and 2 percent respectively. Operations having the greater percentage of fixed costs are most effected by season's length. As the season is extended, fixed costs are spread over a greater season's output. The ratio of fixed to total costs declines. This results in diminishing rates of reduction in the total cost per unit of product. Since the possibility of extending the season for any given commodity is rather limited, some cost advantage may be gained by lengthening the operating season through the processing of additional products. Maximum cost reductions are obtained when the processing of these products utilizes many of the same fixed items such as the freezing system, packaging and casing equipment, building, and so forth. Costs of Direct Packing and Repacking Repacking from bulk containers into smaller cartons--10-ounce and 2 1/2-pound--is a common practice in the industry. This method of packing has been adopted for two reasons. First, individual plants may not have sufficient packaging capacity to initially pack their entire production into small-size containers. Consequently, they pack a portion of their peas in bulk containers and later repack into 10-ounce and 2 1/2-pound. The second reason for repacking deals with sales. Some plants at time of harvest do not have their season's output sold, so rather than pack into unlabeled retail and institutional size containers, the unsold portion is packed in bulk and repacked later on order. Repacking is more costly than packing direct (Figure 4). This is due to the extra handling and to the additional container costs not present - 10in the direct packing operation. Repacked peas are first packed in bulk containers--50-pound boxes in the example--and later are taken out of storage and packaged in the final container. This involves one additional round trip to storage and an additional packing operation, neither of which are necessary when the product is packed directly. When a portion of the season's pack is repacked, per unit costs fall in between "all repacked" and "all packed direct." The greater the Figure 4. Freezing and Packaging Costs for 10-ounce Packages With Different Amounts of Repack from 50-pound Boxes, 1958 /1 / All repacked \J10,000 lbs./hr. direct Balance repacked Rate of output per hour (pounds of peas) Costs based upon these assumptions: a. 1000-hour freezing season b. Belt-tunnel freezing c. Automatic casing for 10-ounce d. Bulk boxes can be used an average of two times, but liners only once. e One 10-ounce packaging line with 10,000 pounds per hour capacity used for all repacking. Length of season varied to accommodate output. portion packed directly at time of harvest, the lower the costs per 100 pounds of product. Variation in Techniques Used in Freezing Plants Pea freezing plants pack a common product, but in doing so use different methods and techniques. Several types of freezing operations and packaging and casing methods are used. Some of these appear to b e considerably more efficient than others. Important differences are dis cussed below. Method of Freeze. Most of the costs cited earlier for the 10-ounce operation have been based on belt tunnel freezing. This, of course, is only one of several types of freezing methods used in the Northwest frozen pea industry. Other methods include plate or contact freezing, tray tunnel, and column freezing. The latter two are not as common in existing plants or in new installations as either the belt tunnel or plate freezing. Consequently, costs of freezing as discussed in this report will be confined to the two more common methods. Freezing and packaging costs were only slightly lower for plate freezing than for belt tunnel operations at all levels of output and for seasons greater than 500 hours in length (Figure 5). The belt tunnel method of freezing had substantially lower labor costs, somewhat lower equipment and building costs, but had higher costs for package materials which more than offset the other advantages (Table 2). - 13 - Table 2. Comparative Costs of Packaging and Freezing Peas in 10-Ounce Containers by Plate and Belt Tunnel Method, 1958 /1 Cost item Method of freeze Belt tunnel Plate (Dollars per hundredweight peas) Labor Package materials Freezing equipment Other equipment and building Total $ .44 2.51 .41 .23 $3.59 $ .26 2.83 .34 .22 $3.65 Costs based upon these assumptions: a. b. c. 1,000 hour operating season Output of 20,000 pounds per hour Automatic casing Cost difference also is reduced if a plant's output consists of both plate and loose frozen 10-ounce products and uses the large wrap designed for the larger package necessary for the loose frozen product. This again can happen because of established sales policy. In this case the larger wrap costs about nine cents more per hundredweight of peas, This would more than offset the cost advantage shown for plate freezing. (See Appendix Table 6 for packaging material costs.) Freezing costs presented here are based on refrigeration equipment firms' estimates of the physical requirements beginning with the engine room through freezing for different rates of output. Current prices for equipment and estimated costs for installation, maintenance and repairs, depreciation, interest on investment and operating expenses were then applied to the physical requirements. Labor requirements were obtained - 14- from time study and accounting record data and then converted to costs by the use of current wage rates. This procedure for determining costs permits development of synthetic operations which are of better than average efficiency but typical of the cost of a new installation. Costs determined by this means would be below the average of existing installations but attainable by the more efficient. Some of the assumptions used in the equipment cost determinations are shown in Appendix Table 4. Automatic Casing and Hand Casing. Automatic case filling machines are relatively new to the industry and reduce costs substantially provided the operating season is sufficiently long (Figure 6). At operating seasons in excess of 400 hours the automatic caser is more economical than hand casing. The reverse is true for seasons of under 400 hours. This relationship exists for the 10,000 pound per hour operation cited in Figure 6 as well as for other capacities ranging from 5,000 up to 30,000 pounds per hour. Automatic casing costs per 100 pounds of peas are essentially the same for all levels of output so long as they are in 5,000-pound increments. This amount is an efficient operating level for one caser and one wrapper, so increases in output mean an added caser with its attendant crew for each 5,000 pounds per hour increase in rate of output. Increases in the operating season favor the automatic caser because this technique involves a higher proportion of fixed costs than does the hand method. Depreciation, interest and taxes remain relatively constant regardless of the length of season, so increases in the hours of operation tend to reduce costs per 100 pounds of peas. Costs of the hand casing - 16- operation are made up primarily of variable costs that change in direct proportion to the total season's output. APPENDIX Basis of Costs Cost estimates shown in this report are based on labor and equipment standards developed from time and production studies made of actual plant operations. In addition, other cost information has been obtained from plant records, manufacturers' estimates and other sources. Labor standards developed from time and production studies are shown in Appendix Table 1. They represent the output of clean peas per man hour of labor under conditions that are better than average, but below peak performance. Costs are derived from these standards by applying selected wage rates prevailing in the industry during the 1958 packing season. These wage rates are as follows: Job Form, fill, weigh, line, and code cases and 50 lb. boxes, operate automatic caser; quality control; tray filling. Wage rate per hour $1.30 Package forelady 1.45 Load pallets; operate case sealer; package supply and cleanup; load and unload freezers; dump and return trays; form, line, fill, and close 1600-pound bulk boxes; fill and close 60-pound bags; dump 50-pound boxes. 1.50 Operate plate freezer; tunnel operator and defroster 1.60 Wrapper mechanic; mechanic; equipment maintenance; assistant refrigeration engineer. 1.85 Package foreman Refrigeration engineer 1.95 2.15 - 17 Appendix Table 1. Labor Standards of Performance for Freezing, Packaging, and Casing Green Peas, Oregon, 1958. Job Classification Operation for which used Direct Labor Operate Former and Filler Operates and controls former, filler and closer, gets flat packages from carton and places in forming machine Operate Wrapper and Inspect Packages Controls operation of wrapper, removes over-under packages from packaging line, and regulates the flow of packages into the wrapper. Wrapper Mechanic Gets rolls of over-wrap from temporary storage, keeps wrapper supplied with over-wraps, makes adjustments and services wrapper Form Case (Hand) Get, form and dispose of case supply case filler with cases, get supplies Fill Case (Hand) Get and position case for filling, group and slide packages into case, push case away from casing station Form Case and Operate Automatic Caser Get and form case, put on caser, get supplies Fold Flaps and Code Case Fold flaps of case to close, code case with hand stamp and push case toward sealer and compressor Load Pallet and Operate Sealer Get and stack cases onto pallet, get and place empty pallets, and service, adjust and regulate case sealer and compressor Load Pallet Get and stack cases onto pallet, get and place empty pallets. Fill Tray Get and place tray, group and slide packages onto tray, move full tray Lbs. of clean peas per man-hour 10-ounce -Belt Tunnel 10-ounce -Plate 2 1/2-lb - Belt Tunnel 10,125 10,125 10,050 10-ounce -Belt Tunnel 10-ounce - Plate 2 1/2-lb - Belt Tunnel 5,070 5,070 10,050 10-ounce -Belt Tunnel 10-ounce -Plate 2 1/2-lb - Belt Tunnel 10,125 10,125 20,100 10-ounce -Belt Tunnel 10-ounce -Plate 2 1/2-lb - Belt Tunnel 3,600 3,600 6,330 10-ounce -Belt Tunnel 10-ounce -Plate 2 1/2-lb - Belt Tunnel 2,775 2,775 5,130 10-ounce -Belt Tunnel 10-ounce - Plate 5,550 5,550 10-ounce -Belt Tunnel 10-ounce - Plate 2 1/2-lb - Belt Tunnel 6,015 6,015 12,030 10-ounce - Belt Tunnel 10-ounce -Plate 2 1/2-lb - Belt Tunnel 5,120 5,120 7,400 50-lb box - Belt Tunnel 60-lb bag - Belt Tunnel 10-ounce - Plate Cont. next page 13,100 12,000 2,550 18Appendix Table 1, continued Job Classification Operation for which used Direct Labor Cont. Load Freezer Get and place trays in freezer, open and close freezer doors and adjust controls of freezer Unload Freezer Take trays out of freezer and place on conveyor, open and close freezer doors and adjust controls of freezer Dump Tray Get, dump and dispose tray, operate belt to casing table Adjust Flow of Packages to Automatic Caser Regulate flow of product from tray dumping station into single line lead-in conveyor to automatic caser Return Empty Trays Take full tray racks of empty trays from tray dumping station to tray filling station, return empty tray racks to tray dumping station Form and Line: Box Get and form box, tape bottom closed, line box by use of mandrel, dispose of lined box and get supplies Form and Line Bulk Box Get pallet, frame, shook and liner, assemble box, line, and get supplies Fill and Weigh Box Get empty box and place under filler, operate controls, fill to desired weight and push filled box to closing station Close and Code Box Shake full box to settle peas, close liner, fold flaps of box, tape box closed, code box and push away from station Fill and Close Bag (Unsewed) Get bag, fasten over filler, operate controls to fill bag, remove bag from filler, tuck in valve cover, put bag aside and get supplies Lbs. of clean peas per man-hour 10-ounce - Plate 6,450 10-ounce - Plate 7,050 10-ounce - Plate 6,600 10-ounce - Plate 6,600 10-ounce - Plate 10,125 50-lb box Belt Tunnel 1600-lb bulk boxBelt Tunnel 3,950 5,000 50-lb box - Belt Tunnel 10,000 50-lb box - Belt Tunnel 7,000 60-lb bag - Belt Tunnel 10,140 Cont. next page - 19 Appendix Table 1, continued Operation for which used Direct Labor Cont. Job Classification Lbs. of clean peas per man-hour 60-lb bag - Belt Tunnel Fill and Close Bag (Sewed type) Get bag, place under filler, operate controls to fill bag to desired weight, remove from filling station, shake peas to settle, fold top of bag for sewing, move bag through sewing machine, dispose of bag and get supplies 1600-lb bulk box - Fill and Close Bulk Box Belt Tunnel Adjust box under filler, operate controls to fill, close, tie poly liner and code box Repacking from 50-lb Dump Box boxes to 10-ounce Get and open 50 lb box, dump, fold and stack boxes and liners 5,280 5,000 4,000 Supervisory and Indirect Package Foreman All 30,000 Package Forelady /1 10-ounce - Belt Tunnel 10-ounce - Plate 2 1/2-lb - Belt Tunnel 50-lb box - Belt Tunnel 30,000 30,000 30,000 30,000 Package Supply and Cleanup 10-ounce - Belt Tunnel 10-ounce - Plate 2 1/2-lb - Belt Tunnel 50-lb box - Belt Tunnel 60-lb bag_- Belt Tunnel 1600-lb box - Belt Tunnel Refrigeration Engineer All 30,000 Assistant Refrigeration Engineer All 30,000 Quality Control All 10,000 Equipment Maintenance /3 10-ounce - Belt Tunnel 10-ounce - Plate 2 1/2-lb - Belt Tunnel 30,000 30,000 30,000 Belt Tunnel Operator and Defroster All Belt Tunnel Operations 10,000 Plate Freezer Operator 10-ounce - Plate 30,000 10,000 10,000 20,000 20,000 30,000 20,000 /1 This job is performed by the package forzman for rates of output under 15,000 lbs. per hour for 10-ounce and 21/2-pound and 25,000 pounds for 50-pound box. /2 For rates of output under 15,000 lbs. per hour this job is performed by the refrigeration engineer. /3 For rates of output under 15,000 lbs. per hour for 10-oz. and 22-1b. operations, and 30,000 lbs. per hour for 50-1b. box, 60-1b. bag and 1600-1b. box operations this job is performed by other than packaging and freezing personnel. - 20 - Equipment standards were obtained from production studies made during actual plant operation and from equipment manufacturers' estimates and specifications. These standards have been used to determine the number of pieces of equipment required for different rates of output (Appendix Table 2). Estimated fixed and variable costs for each piece of equipment as shown in Appendix Tables3 and 4 then were applied to obtain total equipment costs. The following is an example of the,calculations made to develop the costs of labor, equipment and container materials for freezing and packaging peas into 50-pound bulk boxes. Operations in this illustration start with freezing and end with the filled 50-pound box placed on a pallet ready to be transported to storage. Building costs and costs of moving the cased product to storage are excluded in the example. It is assumed that the plant output into this size container is at the rate of 20,000 pounds per hour for a 1,000 hour season. Crew requirements are obtained by dividing each of the applicable labor standards of Appendix Table 1 into the rate of output 20,000 pounds per hour. The following is the crew calculated in this manner: No. Workers Job Package foreman Package supply and cleanup Refrigeration engineer Assistant refrigeration engineer Quality control Belt Tunnel operator and defroster Form and line box Fill and weigh box Close and code box Load pallet 1 1 1 2 2 6 2 3 -21 Wage rates shown on page 16, plus an additional 12 percent for employer costs are then applied to the above labor and multiplied by 1,000 hours--the assumed length of the operating season. The total labor cost for the 20,000,000 pound output (20,000 pounds per hour x 1,000 hours) is $34,216. Equipment costs can be derived from Appendix Tables 2, 3, and 4. Appendix Table 2 shows the number of pieces of equipment required for a 20,000 pounds per hour 50-pound box operation. Costs of operating this equipment shown in Appendix Table 3 are then applied to the equipment list. For example, two sets of scales are required for weighing. Their annual cost amounts to $33 each for fixed charges and $10 for variable costs or a total of $43 each. Total equipment costs other than freezing amount to $774. Referring to Appendix Table 4 the estimated annual fixed cost for a 20,000 pound per hour belt freezing installation is $44,477. Variable costs for a 1,000 hour season amount to $23.01 per hour ($6.10 + $.06 + $16.85) or $23,010. Total fixed and variable costs are $67,487. Container costs as shown in Appendix Table 6 are estimated to be 62 cents per hundredweight of peas packed or $.62 x 20,000 hundredweight for a season's cost of $124,000. Total of the above items is as follows: Labor Equipment (other than freezing) Freezing equipment Container Total $ 34,216 774 67,487 124,000 $226,477 or $1.132 per hundredweight - 22 Appendix Table 2. Equipment Requirements for Packaging and Freezing Peas for Different Rates of Output by Container Size and Method of Freeze, 1958. 1/ Item of equipment Hopper Former, filler, closer Coder Metal detector Conveyor 10' live belt Check wt. scales (3 lb.) Wrapper Case forming table Chute for empty case supply 15' Casing table Conveyor 25', live belt Sealer & 12' compressor Sealer & 20' compressor Automatic caser Screw conveyor Cluster breaker Hopper Former, filler, closer Coder Metal detector Conveyor 10' live belt Check wt. scales (3 lb.) Wrapper Tray filling table Conveyor 100' dead roller Tray dumping belt Casing table 4' roller conveyor Case forming table Chute for empty case supply 15' Conveyor 25' belt (live) Sealer & 12' compressor Sealer & 20' compressor Automatic caser Trays-30-10 ounce alum. Tray rack--40 tray cap. Hopper Former, filler, closer Coder Conveyor 10' live belt Number pieces of equipment required for different rates of output (Pounds clean peas per hour) 5,000 10,000 15,000 20,000 25,000 30,000 24 - 10 ounce - belt tunnel operation 2/ 3 3 2 2 1 1 3 3 2 2 1 1 6 5 4 3 2 1 6 5 4 3 2 1 12 10 8 6 2 4 6 5 4 3 2 1 6 5 4 3 2 1 4 3 1 2 1 1 1 1 1 1 1 1 1 1 1 3 1 1 1 2 2 2 5 4 3 5 4 3 2 5 4 3 2 1 1 2 2 1 1 5 4 3 2 2 3 2 1 3 2 2 1 24 - 10 ounce - plate operation 2/ 3 2 1 2 3 2 2 1 5 4 3 2 5 4 3 2 15 12 9 6 5 4 3 2 5 4 3 2 5 4 3 2 6 4 4 2 10 8 6 4 10 10 6 6 6 3 6 3 3 3 3 6 6 18 6 6 6 6 12 12 12 12 10 4 4 2 2 1 1 2 3 2 1 1 6 5 4 3 1 2 3191 2660 2128 1596 1064 532 17 20 14 10 7 4 12 - 21 lb. - belt tunnel operation 3 3 2 2 3 3 2 2 1 1 3 3 2 2 1 1 2 2 1 1 2 1 1 Continued next page 23Appendix Table 2, continued Number pieces of equipment required for different rates of output (Pounds clean peas per hour) Item of equipment 5,000 10,000 15,000 [20,000 125,000 30,000 belt tunnel operation cont. 3 3 2 2 3 3 2 2 3 3 2 2 - Check wt. scales (3 lb.) Wrapper Case forming table Chute for empty case supply 15' Casing table Conveyor 25' live belt Sealer & 12' compressor Sealer & 20' compressor Screw conveyor Cluster breaker Hopper Filler Forming table Chute for empty box supply 15' Lining mandrel Conveyor dead roller 20' Scales Taping machine Screw conveyor Cluster breaker 1 1 1 1 1 1 1 1 1 1 1 1 1 2 1 1 Hopper Filler (Automatic) Filler (hand operated) Scales Belt conveyor (6' live) Sewing machine Screw conveyor Cluster breaker 1 1 1 1 1 1 1 1 Hopper Filler Screw conveyor Cluster breaker 1 1 1 1 1 1 3 3 2 2 1 3 3 2 2 1 3 3 2 2 1 1 1 1 1 1 1 1 3 3 2 2 1 3 3 2 2 1 -lb. box belt tunnel operation 3 2 2 1 3 3 2 2 1 2 2 3 1 1 1 1 2 1 1 60-1b. bag 1 1 1 1 1 1 1 1 0 1 1 1 1 3 2 2 3 2 2 3 2 2 2 3 2 6 4 4 3 2 2 3 2 2 belt tunnel operation 3/ 3 2 2 3 2 2 3 2 2 2 3 2 3 2 2 3 2 2 3 2 2 2 3 2 - belt tunnel operation 3 2 2 3 2 2 3 2 2 3 2 2 1/ Does not include refrigeration equipment--see Appendix Table 4. 2/ Includes equipment for both hand and automatic casing. 3/ Includes equipment for using tuck-in bags as well as bags which require sewing. 3 3 6 3 3 3 3 3 3 3 3 3 3. 3 3 3 .4 14 t0•o 00 L 0 al Fa a) • 0t./ C) C) a CD CD In CD o1 u1 m CACD,AlnitI,o 0 0 CD 0 0 V) .1olcsimm on va In -.I M.O., • PI• 01• 00• vl• sO• c0• co• -.I• c41• el• c0• e4• ,.1.• ...4 -.4 4 01 r4 c0 m -4 m r4 ma o-4 r, ma M n I-1 N.r4 .1 .4 .4 ...4. 0 -. 0, 01 4 cl a). .4 CD C) g g CD CD U1 In 0000 CD CD C) 0 0000 m rs Nr, r, Mml v, M CD re in • r4 • V4 • •mf' • Ch V1 co 0, Co ul. n-4. 0 • a,• • r4• r4 CD ai 04 0M0 •4 U M .4 01 , r4 el M .4 0U 0 0 0 0 ,-.0 in i CO0 in 0 c--)09 m 1i 1/ • • N 0 cs1 w. 0, CA •-n 0 0.4 • i CO • • 1 1 4 N v5 0 c0 CD 1, l•-•Omo-o,-".-1.-10.104,7•00 CD CD CD CD 0 1.• m n,n O., ,r, • • • . • • • . 4 04 al cD r4 ON CA CA co 1-, ei 4 4 rA .-, ,f M0 r,'.4ul cr, va m r1 C4 Al .4 .4 n 4 • M0 0 CD CD C) C) CD 0 CD 04,CD CD CD r4 CD • • • • • • •ul •ul mp• M• vl• vl• ml• 1/1 „1. 04 r, ,4 0 0' nm3 r4 e4 r4 m ml ,4 04 .0 .0 N I I i rf 0 m ta 0 00 n1 al CD C3 0 CD 0 CD 0 CI C) CD 0000 CD CD v, u 0 on I-- r4• Oomm0M •000 CD 004 41 • . • • g v ., 0 0; 1n.1 • • MN • • CY 0• N. MN. r4 W,0 rn 04 0 0 •-1 ..1 c4 .-1 c .. c.4 .. rn ,-1 0.0 VC, M 0 0> un CD CD 44 cD u, 0 ,f CD 0 c) 0 CD ,0 ul CD C) CD C) sONO 0 1-n1 tr)0 .0 4... a, ON 4,10r4c00.-4 6 • • • • . • • co ri 0 In 01 V1 CA V1 ON VZ q) Ul 0 t.... ON (...; ON LA 04 ,4 N. ul Ns W, ,t CO 01 .4 441 ,4 ,4 hl 60 -* ,4 l4 N1 v4 0 e4 0./ en -4 .0u 0. in in v., vn 0 VI 0 1 AA VI .-IVI....4.-rII N im in in in .-1 .4 .4 .4 .4 1-1 V-1 .4 vl .4 v4 .4 ,-I • • ,d 1:1 0 0 0 0 C)c> CD CD CD M ml .4 C)Ul cDWM CD4,tul001 ul 0 r, ,I.CD 43 0 V3 .en U1 .4 N. pl v, N. . 4 3 ..4 N 'I' VD 0 0 u, u, 0 0 C 0 4, C) c4 Al 0 .1 CD CD CD 0 CD CD ,0 CD 04CD 0 141 In CD CM macDM1n1n u, 0cD 0• mCD ul• • •••••• rl r, N r4 04 o-4 c) 0, r, ,4 CO C) v4 VD .4 v4 v, VD N.M. Ns CO C) C) C) C) 0 ,4 V1 VI C) r4 0 000 rl CD cD r4 m ma m •m •rm• r4• r4• r,• • ••m • • On In In M 0 ro ,0 ,0 m 0,1 a, el0 CO c51 04 m 04 VI UI 41 CD C] 0 0 m.4 0 .4 v4 41 .4 v4 .4 .4 V1 0 In v1 CD CD CD01en CDIn Ca 0 ON 00 CAelCICD .1 NI Ul 00 'l CD .4• 44. . .4 01 CA .4 01 (.1. r4a .4 In VD .4 Al .4 .4 M 21 ,u 144 :1 7.1 •1 44 0 Oa C 0 4=4'.. 11 .0000 100 1n 1a X al el 0 0 AC1 0 O O v4 N H XX >I W W X 54 X X /4 X 14 X 14 X 14 XXXXXX /4 XI X X X X X X )4 X X /.. 0ta 00 011 :_- .. 00 00 0. ,..„ 00 e '0Ht.i 0 0 00 a 0 0 0 0 44 4-1 O 44 O. al to (4• 43 ,4 44 41 0 m 11 U 01 , .., 14 ,-1 B 0 0 . v4 44 Al N 0 44 14 0/ l4 • .4 .014 0 ,44 44440 ..4 0 0.4 '4. -XU0 r4?,0.4013 .1 .0 v4 0 04 0 ,..4 X. 7 0 .0 I 0 .4 0 4) <11 0 0 0 'CI 10 0 0 0 X VON., .0 .0 0) U D. 4, •.../ X X X 0 14 U 0 "4 /4 v/›, O al „.04 M. •rlu I.4._.4), O. . O,-v4, 0= . .4 U. U 0 .--1 44 0 8 •+ 44 0 0 )4 U 00 700 (11 O U 14 N > I4 .-1 of .4 0 U 44 44 .4 0, 0 ..4 V 1.1 .4 • 14 O. 44 0 0 N ,., g •-o,) E 4-.., fi 0 w : 80 .0 0U• ,0el U 0) 1 0 m - ,0 0 0 al 0 .0 J3 '0 8 ?• >014 0 to "'0001 000.401 0 14 0 0 .4 41 0 C4 0 T4-4 O.11 0. M140 ,-1.C) 0 - .1 la 0 0 0 14 0 001 . .4 .-1.4 0"0138,1)- 4 U e4• 0 co •• 140 ---.. W .4 elIn1:1 .1 14. 4 A. U 14000 ..--' 14 u u-U13 g W • to 0 @./ 14 0 14''l)4 - - .1503 • a) >.. 0 0 4 i1 or 44 14 H V 0 11 14 0 . 1 .414 0 14 3, ••13- - .- 4.1 000. 00100140 -0014/.-430000 00 el 14 •4 Ps 0. r. I-4 w ..4 .44 •-n 34 .-4 •-n oc,-00 ,1 ,x 14 a) U VI N y r. : : e a, 0 0 43 A: : 031414 0,00 0.0 0 0.U0 0 con 14 0 •-4.+. vo 7 V 0 v4 0000M W MtnUu 00,4 0 =ZX 0 0,4 O0 al 417: •4 .. 0 0 (Arno 4. E. E. En E4 c4 CD 4.3 CD MU V Ca N4 C. No 0 0 10H • to 4.1 4-1 0 alal •r4 0 . .11 0 00 0 M .0 .4 • 0 0. 10 0 •.4 •• . 1-4U At. 44 U1 0. 14 .00 01400 ,4 2, 34 M m •O 0 .1 44 0. 44 .00 0 00 )4 0 44 0. 0 4-4 cl 14 0 00‘44 al 00 al 0 1b-•.1 •4 0 in • 74 0 40 0Oh 44 4, 0 41 •04O...40 14 (3 ,4 1.1 O. 44 CI 0 44 0 1 N0 Fr 44 00 0 00 14 0 N U 0H 0 14 V 0 T/0 44 )4 00/ WO/ 0 a) 0444414 1110.14)4/1)4 n) i 4.04 .214 r0 0 043 • • • U 0 0 Id ./:3 0110 4 u n1 44 14 110 c4 -11 0 .4 (4 4/ U 0 OH O ,-411 14 11 00 3 u 0 0 0. 0 cr go2 go 0 014/44 W zzIMA 25 - r.-1 44 34 CU co ...... 0 W c.) b0 a) ...) - 0 co N co cd erl 0 0 0 0 0 0 .•4 .• PO In LI" in 4 0 0 0 0 co cr.) trl •-1 ,-•i •--4 r-4 0 ...1. Cs4 ON '-4 0 In 0 1-I1 -.1- 00 .1. N. N..1,-1--• 4 ,-1 CNI ON 0 .." "..0 .0.....,CS 4 4 0 os . ... .., 1-4 - • Cn N0 0 r.4 (7%1/40 N. 0 ON v•I C•1 0 N. ,--1 N. I-4 1-4 0 CO VD CO C.4 VD VD 4-1 0 cn C14 10 en .4 .."-n cn I0D <11- (1)-(1).41). <)0)- SIT. 34 tr)- 0)-(1)- .C1)• 0)-0)- U) CO C III cd CO 44 14 0 0 0a) 4 .1-) r-I 4J CO •r-I cr).-cri- to 0 0 0 0 f"... C.4 0 0 .0 ..-i 0 0 in 0 Irl r-- 0 N. C11 ON 4 - - •• - - ∎0 ri 01 n-0 ....t to 10 I-4 Cr$ ...i' en CV tr)..e.n. (r)- tr)--crr .0 04 cr) ON 0 0 0 U10 In CN 0 0-, ,,o cn 00 N. 0 cn 0 ,..0 If) ..-4 0 o0 • • . 1/40 ,..o ..-i ,---n 014 • • • 0 r, 0 %.0 1.42 .0 ...1- .-1 N in C.1 t-4 ...1or tn-Cn• V). -cr)- 46- art 03- 0 Lc) o a) 4J .c.1)-(tf v.), 4-4 )4 4-1 cd E-4 4-) X0 0 .r4 0 01 0. 04 7 4 al 0 a) In 0) U a) -0 d) .,-I t••••I 4.4 O cd a) cro1' c 190 c0au. , 44 0 0. 4-14 0 44 a) a) • 0 C) '0 ..0 0 <11- U CO 0 n-n .1-4 0 $4 0 ....." 3 001 .....) 00 -0 a) 41 0 0) w co W rzl U 4J 01, 60 0 cd 4-4 r4 0. X )4 a) )4 0 04 0 4-I 0 0 N. 0 00 4-4 rt.... co 0ou a) a) • ^ 14 .6‹.,coo c) 0) In 4.) o 0 0. • a) 4 ..... • ›, 0 0 11 PO -- n2 0 44 1..4 cd W -0 ,1 • ••-4 44 .11)- 4-I 1 4-1 ,.0 Q) 0 a) 0 cd 0 (I) ^1110> C) 0.4 01 .1.4 CO W U 0 N 44 C.1 1-4 ,-0 4.1 •.4 • 00 W 01 C0 rf) (1) 0 0 0. 0 " N 1-1 Cd .r4 ,.. 1-1 )4)400444o cc) Ca 44 cd 0 •,-1 A fo. CO. Cd .0 0, W al cd co 0. .0000434> .-1 .4-4 . • ..0 0 CO .1-1 E 4-) P 4-1 0 .0 0 0 U 4J CdA 0 0 o w CO 0 1 CO 0 A ""4 0 C,4 a) n•••••1 )4 0) P . 04 $4 4.4 I O. r4 44 Co 0 54 5 4-1•w o.43 *-1 a) >, cd 4.) 0 c.) o 0 al r--1 N 0 Ca CT' cd 4.4 01-4 cc! co 0 11 4r cd •,-4 )4 al A a) $.4 ca, 1.4 Cf) 4.) 0 0 0 a) -41 -04 0 O •,.4 0b0 11) ,.0 40 „0 n-4 44 34 CO 0) 44 CJ • 41 a) 4-11-1 4-1 44 0 .r4 Z H = rz,1 0 "0 .0 *-1 a) Cr) a) a) as 4) 0 " .-f 144 > Cd 0 $.1 -•,•1 •r-1 CI) 0 $4 La 1-1 Ca t--1 >, 4.1 0 0 •1-1 (11 co cd cr cd 4-3 4.1 . 1 4..) cd 1-1 4J $.4 .r4 44 )4 a) r-i cd 11 -Vi U) t--1 0) P0.1-400000 U La 0) 01) 44 • -4 -,4 0 0 0) CO ,10 .0 • ,-I $4 )4 la0 144 )4 cd .0 14 4J 1.4 Ca 4.1 ,--i •.-4 )4 a) 44 4.4 3 -0 )4 4-) u cd 11 "0 U 0 a) 0 cd 4-4 r-1 cd 4-) 0) d) 0.) 44 14 CU 41:j )4 0-. 4-1 0) CI) -4 0 4-1 U 1 cdc4pqrx3Hcc.) cd . •• w B--2 ra "0 • ,-1 4-4 0 r•-I 0 0 0 al. 4a I 0 .•..0 0 4-4 4-1 10 O CO 0 0 to v )4 4.) 0 W 0 C) E 4-1 0 0 0 1 0) 4-1 .: 0 $.4'G • 1 U qi 1 E *0) 4-1 0 (1.4I''' )4 0 4.) t).0 0/ r--1 CO CO 0, r-1 14 ° 1-4 (11 M a) 0W4 444 r-1 )4 00 0 <r).0)-(n- "•••• U 0 ,t •••1 r- 4 CO W •,-1 0 0 *-11 al a) - 4-1 4-) 0 N 4.) 4-1 4.1 0 -"-..1 .1-) 4-1 • 0 co co C4) co a/ CO a) U ,--I 4-1 4-) 4_1 4.) ....pc/ ...., ,, Z r-I 4.4 r-i 40-1 1J •-•• cn 0 .....• 0 •,-.1 0. 04 .r4 04 0) qj CO Q) 5 6 0 4-1 0 ›N = s." E 4J U 4-11-4 I 0 4-1 U 4J PCI 0 0 " CO Cd 0 4-1 U ...1 .....• 4..) w tO 0 4.) 0 (1) (.1 0) 4-) 0 •,•4 4-10 a) 1-4 Ca C1 r--4 CO C/ n-4 CO CO 0 CU • -1 W V) 0 a 01 0 (1.,1J .0 04 " C-) *-1 CO • 0 C-1 r0 u0) 0 0 U 0 T1 Cti CO 0 CO 0 V) 4-1 U)a) 4.4 )01 U (1) U) a) •,-.1 U 0) 4-1 >-% 0 ta $.4 1 , c) X )4 •, $.4 u -.A '13 X 0 •-4 4•11 t ---1 5 co .14 00 01 C0 5 W . .-4 cd OD a) a) a) •--1 0 A ap • a) 0 co 44 (1) 1-i 4-1 IP) • S-4 CO 0 crs o04-1 a) 0 - cv I 0 0 '0 0 co • c0 4 .4 cu .r4 41 04 Ca $4 a) 00 0 "0 0 W 0 0 co td CO 03 .,-1 do ado 44 0) 0) r- I a) (1) 04 W s4 4.) 0 tO 44 a) -1.4 a) 0) 0 •-I 0 34 14 14 4-4 ./.... Or W O4 . 0 U 0 Ca 4-1 0 ,-4 ... . 0 c4 0 PO 0 0 0 co 1 -.4 .,-I CO 0 0o 0 0 cd ,--1 ,--4 6-.9. c4•4 Cr) In 0 N. 00 ‘..0 1-41 r. ... .1. es A -..1. 0n --1• 00 ,..0 Cr) N. ".0 N. M •r-1 4J O 1••1 CO Cn1 0 0 .:11 Ct1 r-4 Cn 17. .C.1)-(1)0.1 04 0 4-1 0 0., cd 'ci 00 q;) I-1 0 r-•• on Ln ,-.4 0 ONcn cn 0 0 0 0 0 0 C.t-1 co al, cn 0 Ln 10h 0.0 c1 "0 00 00 10 1010 0 0 cf 1 4) a) Cn N r-i M N N0 • • • 0^ T0 In 4-1 0 co 0 '-4 '0' 0.4 en • ON , •• - - - 0 0 0 1-4 0 ON 0 ON 0 ‘0 r. c%1 n0 .1c.) 0 0 ^ N cn 01 Cn r..4 CO N 0 C a .0 N v--1 1-4 44 t-4 71 <4}t)-V? t4)-1.4)-41)--11)- <11 t4)• (1). V). <1").Us-<r}<1} V> 0 0 4.1 cd a) 4J pq 4.3 co 14 0 -0 t-4 tr) en h. 0 0,1- -1* r•-• ciN 0 0 00 0 0ON Nr4 O a) 0 I-4 4J I.rt ft. . tr) 09 ch r-1 O %.0 r-1 CO 00 CO 0 0 0 00 CO 0 al 0 O'N o'N . O r 4 " )4 a) O 04 rW 0 a) •cd 0) 0 14 ..... 1.4 4-1 0 0 ,--1 4-1 CO 0 N 0.) • 4 .0 0 4 601 0 4 4 0 $.4 4.) 4J a) 0. 0 110 44 4.) 1-1 4J U) a) n•••4 0 0 0 N 0 CO CO a/ 0. . •..• a) CIN ,• •,-f Lk 11 00.1 N.• 0 a) c0 0 IA a) co )4 cd cd a) ,o C) a) 0W ,4 U 14-4 44 13 0 14 .t-1 U Ca '0 a) 4.3 (1) (1) oa) O Cll 0 0 44 4-4 0) td 1-4 0 4J 4J r 4 al CO $4 Hcd cm3 c..) W 41) r-i a) 0 0 34 44 cd ,C) 4.) ' CI) Z0 H W 4..) 4 J Ct3 JO U co co 1.4 W 4.1 0 .r4 0 al 0 0 1 4-1 0 0 $4 o cnI 0 0 0 A '0 .--. 11 o., cd -0 4 a.011 1111 44 co 4j a) 0 0 00 th 4-1 to c1 ...J. x -1.4 '0 ,'-'1 • " ',I 0 W 03 0 0 ....-,. 4-4 0 E r0 4.) 0 .4-4 0 4-4 ,--I 4.) 0 U ,..4 4-4 ".... (I) U) 44 U) cd -.4 0.1 0 CO CO Ca 4-4 4-40 r-4 "....' 0 < 41 al 0 .,1 1 041 011.41If11".01 - 26Appendix Table 5. Crew Organization for Packaging and Freezing Peas in Different Container Sizes and for Different Rates of Output, 1958 /1 Size container Job 10 ounces Belt Plate frozen frozen 8 2 4 2 2 3 1 1 1 1 1 1 19 1 1 1 1 12 13 Freezing 3 Packaging 8 Casing and pallet loading 1 Storing 1 Equipment maintenance 1 Quality control 1 Cleanup and supply 1 Supervisory 1 6 29 Total 2 3 6 1 1 1 1 1 16 Freezing Packaging Casing and pallet loading Storing Equipment maintenance Quality control Cleanup and supply Supervisory Total 24 6 16 1 3 2 2 2 56 4 6 12 1 3 2 2 2 32 Freezing Packaging Casing and pallet loading Storing Equipment maintenance Quality control Cleanup and supply Supervisory Total 34 9 24 1 4 3 3 2 80 5 9 18 1 4 3 3 2 45 Freezing Packaging Casing and pallet loading Storing Equipment maintenance Quality control Cleanup and supply Supervisory Total 60-pound 50-pound non-sewed 1600-pound 211 bags box pound box (number in crew) 5,000 pounds per hour 2 2 2 1 4 2 1 1 4 1 1 1 11 13 10,000 pounds per 2 2 6 2 1 1 8 13 20,000 pounds per hour 4 4 4 2 11 4 2 2 13 1 1 I 2 2 1 1 1 1 1 2 13 22 29 50,000 pounds per hour 5 5 5 3 16 6 3 3 18 1 1 1 3 3 3 3 1 2 2 1 2 2 17 32 40 10 17 5 12 1 111.0,10i Assumes the following: a. Automatic casing b. Product handled and stored on pallets c. Unless otherwise noted products are belt frozen. 3 2 1 24 -27 - Appendix Table 6. Costs of Packaging Materials for Frozen Peas, 1958 Container Bulk 24 24 60 lb. 60 lb. 1600 12 10 oz. 10 oz. 2 1/2 50 lb. sewed nonsewed lb. loose plate box bag bag freeze freeze pound box (Cost per hundredweight peas) Carton (5 x 4 x 1 1/4") (5 1/4 x 4 x 1 1/2") (9 1/2 x 5 1/2 x 2 1/2") $1.52 $ --- 1.67 OMANI Wrapper (12 x 7 3/8") (13 x 8") (17 x 13 1/2") ON WM .96 -- ler ••• ••• .67 .42 0000 1•11 •n• .50 .36 Box (16 3/8 x 10 3/8 x 14 1/4") (bulk box, frame and liner) -- .49/2 410 .33 /3 Liner (17 1/2 x 10 1/2 x 28") TOTAL COSTS $ $ $ $ .58 Case (15 3/4 x 8 3/8 x 5 1/2") (16 1/2 x 10 3/4 x 4 1/2") (16 1/4 x 9 5/8 x 10 1/4") Bag (16 x 5 x 38") (16 x 5 x 34") L. -- •n•• IMO* 11000 $2.52 $2.84 .13 .1011. 0.00 00* $1.64 $ .62 .26/2 -$ .26 /1 Includes the following allowance for shrinkage: a. Bags and liners - 0.25 percent. b. 10-ounce packages - plate 4 percent and loose 2 percent. c. 2 1/2-pound packages - 2 percent. d. Wrappers 4 percent and cases 1 percent. /2 Includes cost of tape and twine. /3 Years use life - frame and box 4 - liner 1. -.29 $ .29 $ .33