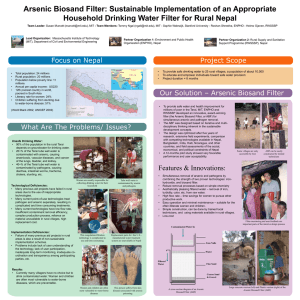

Clean Water for Nepal, Inc

advertisement