A study of California kneading compactors ability to optimise angular... and interlock of large stone asphalt mixes in Montana

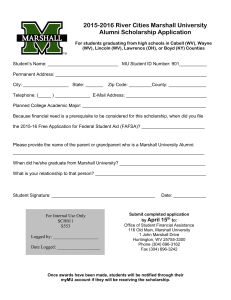

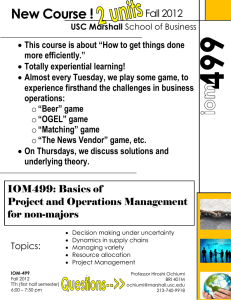

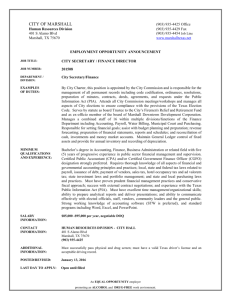

advertisement