A study of adapting soft wheat evaluation procedures to barley

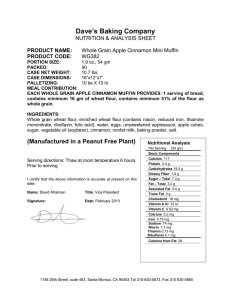

advertisement