Solid sorbents for the recovery of nitrogen oxides (NO and... by Christopher John Evoniuk

advertisement

Solid sorbents for the recovery of nitrogen oxides (NO and NO2) for MHD exhaust gases

by Christopher John Evoniuk

A thesis submitted in partial fulfillment of the requirements for the degree of MASTER OF SCIENCE

in Chemical Engineering

Montana State University

© Copyright by Christopher John Evoniuk (1976)

Abstract:

Nitrogen oxides (NO and NO2) are air pollutants produced in high, temperature combustion processes.

Th generating power by the Magnetohydro dynamic (MED) process high temperatures are used and

subsequently nitrogen oxides are produced. Two methods which:' are technically feasible for the

control of the nitrogen oxides (NO ) are: combustion modification to reduce the amount of NO

produced and recovery of the NO for the manufacture of nitric acid or nitrate fertilizer. This research

was performed to study solid sorbents for the recovery of nitrogen oxides.

Results of this work indicate that the carbonates of lithium, sodium or potassium and the first row

transition metal oxides are not effective absorbents. However, mixtures of sodium or potassium

carbonate with manganese dioxide or ferric oxide are very effective absorbents of NO and NO2. Ten

grams of a 1:1 mole mixture of alkali carbonate and metal oxide in a temperature range from

380-450°C reduced the NO concentration from 9000 ppm to less than 100 ppm from a feed of

500Xml/min consisting of 15% CO2, 18% O2, 66% N2 and .9% NOx in a contact time of less than 4

seconds. Other equally effective sorbents were potassium manganate and decomposed mixtures of

sodium nitrate and ferric oxide.

Sorbents could be regenerated and then reused by heating in a temperature range of 600-700°C. During

the regeneration process, NOx could be recovered at concentration levels from 20 to 50% and the

major component of the NOx was NO2. STATEMENT OE PERMISSXOli TO COPY

In presenting t h i s thesis in, partial, fulfillment of the require­

ments for an advanced degree at Montana State University, I agree that

the Library shall make it freely available for inspection,

I further

agree that permission for extensive copying of this thesis for schol­

arly purposes m a y he granted b y m y major professor, or, in his absence

b y the Director of Libraries.

It is understood that any copying or

publication of this thesis for financial gain .shall not be allowed

without m y written permission.

Signature'

Dat e

:

Vf 7^1

SOLID S ORBEMTS FOR THE RECOVERY OF

' MITROGEM OXIDES (MO AMD NO )

FROM MHD EXHAUST GASES ^

by

CHRISTOPHER JOHN EVOMIUH

A thesis submitfed in partial fulfillment

of the requirements for the degree

of

MASTER OF SCIENCE

in

Chemical Engineering

Approved:

Chairperson, Graduate Committee

Head, Major Depantmerrt''"]

Graduate 9Dean

MONTANA STATE UNIVERSITY

Bozeman, Montana

Decemher, 1976

tit

ACKUOELEDGEMENTS

TIie author wishes to thank!.the faculty and staff of the Depart­

ment of CIiemical Engineering for tIieir assistance, especially Dr. F.P.

McCandless for his Iielp and suggestions.

Special thanks is extended'

to the aut h o r 1s wife, Marian, for her help in typing and editing the

thesis and for Iier patience.

Financial support for this study was provided b y the Energy

Research and Development Administration for Montana State University

M H D Program Contract Mo. E (.49-18)-l8ll. Task HIV, administered

through the Montana Energy and MHD Research and Development Institute

Inc.

TABLE OF CONTENTS

Page

T O T A .......

ACKNOWLEDGEMENTS

Ii

..................

LIST OF TABLES ........___ ............... ................ .

IiI

v

'

LIST OF FIGURES ............

vi

ABSTRACT

IX

INTRODUCTION

I

OBJECTIVES .... ................ ■--- ........---- ■............ .

6

APPARATUS AND P R O C E D U R E .......

7

RESULTS

.......

13

APPLICATION .............................

67

CONCLUSION ......................

70

RECOMMENDATION .............

72

LIST OF R E F E R E N C E S ... ...........'.......... ....................

73

V

LIST OF TABLES

Table

I.

Page

Equilibrium Constants and Rate Constants

.................l4

II.

Equilibrium Values

of NO and NO0 ..........

15

■III.

Equilibrium Values

of N^O^ ...........

l6

IV.

Equilibrium Values

of N g O ^ ..... .

l6

V.

VI.

NO^ Absorption b y the Metal Oxides

..... .

20

NOx Absorption b y Mixtures of Na^CO^ and

Metal Oxides ............................

VII.

24

Effect of Flow on Temperature Gradients

in the Reactor and NOx Absorption ...... ......... .

VIII.

33

NOx Absorption b y KMnO^ and Mixtures of N a N O ^ 5 Na^CO^,

KgCO^j KNO^ with Fe 5O^ and MhO^ ..:.......... ...... .

IX.

35

Equilibrium Constants for Reactions

Involving NO and COg .....................................

X.

Melting and Boiling Points of Alkali

Carbonates and Oxides

XI.

XII.

XIII.

49

....................................

Thermal Stability Characteristics of Alkali Oxides

Possible Reactions of the Sorbents

53

.... 54

.......... ..........

58

Melting and Decomposition Temperatuhes of

Alkali Nitrates, Nitrites and Hydroxides ............... 60

XIV.

XV

Cost of 7.28 x 10^ Moles of Sorbent Mixture

Cost of Chemicals

67

69

LIST OF .FIGURES

Figure

1.

FI ott Diagram of Apparatus

2.

Reactor Cross Section ...

3.

NO

4.

NO

5.

NO

X

X

X

6 . NO

7.

NO

X

X

8 . NO

9.

NO

10.

NO

ll.

NO

X

x.

X

12 . NO

NO

l4.

NO

15.

NO

16.

NO

17.

NO

CO

NO

H

13.

19.

NO

20. NO

X

X

X

X

X

X

X

X

X

X

Absorption Curve for Li 2CO 3

Absorption Curve for Na2CO3

Absorption Curve for KgCO 3

Absorption Curve for TiO 2 .

Absorption Curve for Co2 Os

Absorption Curve for MnO 2 .

Absorption Curve for Pe2 Os

Absorption Curve for PbO 2 .

Absorption Curve for Al2O3

Absorption Curve for Na2CO

+ TiO 2

Absorption Curve for .Na2CO3 +

Absorption Curve for Na2CO3 + Cr2 O

Absorption Curve for Na 2CO 3 + MnO 2

Absorption Curve for Na 2CO 3 + Fe2O

Absorption Curve for Na 2CO 3 + Co2O

Absorption Curve for Na2CO3 + NiO

Absorption Curve for Na 2CO 3 + CuO

Absorption Curve for Na2CO3 + Cu2O

Vii

Figure

Rage

21.

Absorption Curve for NagCO^ + Al^O^ ..................

29

22.

MOx Absorption Curve for Decomposed MaWO^ + Fe^O^ .......

31

23.

MO^ Absorption Curve for Ma^ Fe^ O ^ .... .............

31

2i.

Effect of Temperature on MOx Absorption b y

i

25.

Decomposed MaMO^ + Fe^Og ......... ........ ................

Effect of COg on MOx Absorption b y Decomposed

MaMO

.26.

32

+ Fe 2O 3 ......... .............. ....... . ..... ........

34

Effect of MO to Og Ratio on MOx Absorption b y

Decomposed M a M O 3 + FegQ 3 ......... ........................ . 34

27.

MOx Absorption Curve for MagCO 3 + FegO 3 (Bed)

...........

37

28.

MOx Absorption Curve for MaMO 3 + FpgO 3 (Bed) .............

37

29.

MOx Absorption Curve for KgCO 3 + FegO^ (Bed) ............

38

30.

MOx Absorption Curve for Decomposed KMO 3 + FegO^ (Bed) .. 38

31.

MO

(Bed) ............

39

32.

MOx Absorption Curve for KgCO^'+ MnOg (Bed) .............

39

33.

MOx Absorption Curve for KMhO^ + SiOg (Bed) .............

4i

3^.

MOx Absorption Curve for Decomposed MaMO 3 + MnOg (Bed) .. 4i

35.

MOx Absorption Curve for MagCO 3 + SiOg (Bed)

............

43

36.

MOx Absorption Curve for .KgCO3 + SiOg (.Bed) .............

43

37«

MOx Absorption Curve for MnOg + SiOg (.Bed) ............... • 44

38.

MOx Concentration During Regeneration of KgCO 3 + MnOg ... 45

39.

Regeneration of KgCO 3 + MnOg ..............................

x„

Absorption Curve for Ma CO

2

3

+ MnO

^

45

viii

Figure

Page

40.

Loading Curve for KgCO^ + F e g O ^ .......... •................

4-7

41.

Loading Curve for KgCO^ + MnOg ........... ................

4%

■42.

Effect of Metal Oxides on Decomposition of Carbonates ... 56

43.

Amount of

.... .....

63

44.

Amount of Og Released From KgCO^ + FegO^ ........ ........

63

45.

Absorption of Og b y KgCO^ + MnOg and KgCO 0 + FegO^ ......

66

Or

. Released From K d

0CO Z

0> + M nO d

0

td

ix

ABSTRACT

Nitrogen oxides- (NO and NO^ I are air pollutants produced in high,

temperature combustion p r o cesses. T h generating power b y the Magneto­

hydro dynamic (MED) process high, temperatures are used and subsequently

nitrogen oxides are produced.

TVo methods which:' are technically feas­

ible for the control of the nitrogen oxides (NO ) are:

combustion

modification to reduce the amount of NO produced and recovery of the

NO

for the manufacture of nitric acid or nitrate fertilizer.

This

research was performed to study solid sorbents for the recovery of

nitrogen oxides.

Results of this w o r k indicate that the carbonates of lithium,

sodium or potassium and the first row transition metal oxides are not

effective absorbents.

H o w e v e r , mixtures of sodium or potassium car­

bonate with manganese dioxide or ferric oxide are very effective ab­

sorbents of NO and NO^.

Ten grams of a 1:1 mole mixture of alkali

carbonate and metal oxide in a temperature range from SBO-U^O0C red­

uced the NO concentration from 9000 ppm to less than 100 ppm from a

feed of 500Xml/min consisting of 15% C O g , 18% O g , 66% N^ and .9% NO^

in a contact time of less than 4 seconds.

Other equally effective "

sorbents were potassium manganate and decomposed mixtures of sodium

nitrate and ferric oxide.

Sorbents could be regenerated and then reused by heating in a

temperature range of '600-T00°C.

During the regeneration process, NO^

could be recovered at concentration levels from 20 to 50% and the

major component of the NO^. was N O g .

INTRODUCTION

Removal and control of nitric oxide from exhaust gases is a prim­

ary concern for all combustion processes. - Nitric oxide (NO) is not

.

considered as an irritant in itself and is not considered to have ad­

verse health effects at concentrations found in the ambient atmosphere

Its greatest toxic potential is due to its oxidation to nitrogen di­

oxide (NOg).

Nitrogen dioxide exerts a toxic effect on the lungs

and concentrations of greater than 100 ppm are lethal to most animal

s p e c i e s , including man. ■ Long term exposure to low concentrations does

not cause acute inflammatory responses but does have an accumulative

sustained effect.

Results of community exposure to NO^ levels of .062

to .109 ppm for long periods of time (6 months) gave an increased

respiratory illness rate of 18% (Pollution Control Technology, 1973).

On a global basis the total amount of nitrogen dioxide generated

I

by n a t u r e .exceeds that made by man-made technological sources.

Nat­

ural scavenging processes in nonurban areas keep background levels on

the order of 2 -■ 4 ppb.

In urban areas the levels are frequently

higher because pollutants are added faster than scavenging processes

can control them.

Fuel combustion is a major source of nitrogen dioxide in air

pollution.

Combustion of coal, oil and gasoline accounts for the ma j ­

ority of man-made emissions.

The estimated global breakdown of nitro­

gen dioxide emissions in the year

1965 is as-follows (Seinfield, 1975)

2

Source

Emissions in Trillion grams of

Coal combustion

2h.h x 10

Petroleum processes and combustion

20.2

"

Natural gas combustion

1.9

«

Miscellaneous

1.5

" •

(fires, etc.)

EPA emission standards for KOg from coal fired steam generators

a r e -0.TO Id. per million Btu of heat input or "approximately 600 ppm

(Walters and G o o d w i n , 197^)•

an efficiency of

would be

For a 1000 Megawatt MHD generator having

50% it is estimated that the exhaust gas flow rate

1.25 million standard cubic feet per minute and could contain

from less than 600 ppm NO to greater than 30,000 ppm NO

(3%) depen- .

ding on the combustion process used (Hals and Lewis, 1973).

To comply with EPA standards the MHD process would have to limit

NOx (NO and NO^) emissions.

Of the methods which appear promising,

the most practical would be either combustion modification or absorp­

tion of the NOx produced.

Previous Work

Combustion modification would reduce the amount of NO formed by

lowering of the combustion temperature (Pepper, Eustic and K r uger,

1972).

However, a preliminary economic" analysis indicated that if the

nitric oxide is collected and converted to nitric acid or a nitrate

fertilizer, the income from marketing the product would be much greater

3

than that from the sale of electricity produced, b y the MHD generator

(Wright and Yo u d e r i o n , 1976; Hals and Jackson,

1969).

Since profit­

ability is the prime concern of any industrial process,collection of

the nitric oxide would be preferred over combustion modification.

A method which is technically feasible for the recovery of the

nitric oxide is absorption

by liquids or solids.

Liquid absorption

appears promising for it can be used to absorb both HO and SO^. Usually

alkaline solutions or sulfuric acid are used in conjunction with equi­

molar concentrations of HO and HO^ (Hals and Jackson,

1969).

Absorp­

tion of HO^ by liquid systems is' improved by having equimolar concen­

trations of the two oxides rather than just HO^ (Koval and Roberts,

i 960).

The increased absorption is due to the formation of HgO^

from the HO and HO^, whi c h is then absorbed to form nitrous acid.

Hitrogen dioxide would have to be recycled to the incoming gas stream

to achieve the equimolar concentration.

Among the alkaline scrubbing systems which have been tested,

lime-water or magnesium hydroxide solutions have been reported as

showing the most promise (Bartok, et al, 1971).

The magnesium hydrox­

ide is said to be better due to advantages in regeneration of the nit­

ric oxide from the nitrite formed.

From the standpoint of forming a nitrate fertilizer, liquid ab­

sorbents form nitrites which would have to be oxidized to nitrates.

Also the regeneration of liquid sorbents produces HO and little HOg

k

which, means that an added investment would he needed to oxidize the

W

to N O .

-Among solid sorbents, metal oxides, especially manganese and fer­

ric oxides, have been reported to show technical potential (Leung and

G i d a s p o w , 1974).

Patent literature indicates that sodium and calcium

carbonate or calcium oxide can be used to. absorb

M o r e l l o , and Peters,

1969).

but not NO (H a r r e s ,

Nitric oxide is removed at normal temper­

atures and pressures by inorganic salts of hydroxy acids

(FeSO^, KMnO^,

KClO^) by inorganic oxides (Na^O^, PbO^) or by inorganic halides (KI,

CuCl2 ) (Lewis, 1975).

A ferric oxide-sodium oxide sorbent developed by R» A. Ogg and

J. D. Ray (U.S. Patent 2,684,283) absorbs NO at 400°C forming sodium

nitrate and little sodium nitrite.

The sorbent was prepared by heat­

ing 2 moles of sodium nitrate (NaNO^)-and I mole of ferric oxide

(Fe 2O ^ ) in a temperature range of JOO to 900°C until the sodium nit­

rate was largely decomposed and no nitrogen oxides were being given

off.

When a gaseous mixture consisting of 0.7% NO, oxygen and nit­

rogen was contacted wi t h the sorbent the NO was absorbed and sodium

nitrate was formed.

Nitrogen oxides could then be recovered in a con­

centrated form on heating the sorbent to a temperature of over 700°C.

A sorbent of this type would be particularly useful since a nitrate

fertilizer could be directly formed or a concentrated stream of

nitrogen oxides could be produced for the manufacture of nitric acid.

5

The importance of HO and.NO^ concentrations in the formation of nitric

acid is best shown hy the following example:

I atm and 25°C containing 5$ H

of which

For a gas mixture at

Q0% is oxidized to NOg the

equilibrium- strength of nitric acid with this gas mixture is

weight

(C h i lton„

55% by

1968), while if the gas contains 50% HO^ of which

80% is oxidized to HOg then the equilibrium strength of nitric acid is

rJ0% b y weight.

The increased concentration is useful if the nitric

acid is to be concentrated.

Also by increasing the pressure of the

concentrated NO^ stream the equilibrium strength of nitric acid

would be well over

70%.

OBJECTIVES

The purpose of this research

was to develop a solid for the re­

moval of NO and NO^ (NO^I from the M HD exhaust gases and either convert

them to a nitrate or on regeneration produce a more concentrated

stream of NO^ or NO.

Other objectives were to determine the factors

w h i c h affect the absorption and regeneration processes.

APPARATUS AED PROCEDURE

Figure I is a schematic of the apparatus used.

Individual gas '

■

streams were passed through rotameters and into a mixing chamber to

r

form a test gas of similar composition to that expected for the MHD

exha u s t .

From the mixing chamber the gas could be passed directly to

the HO^ analyzer to determine the NO^ composition.or it could be

passed to the reactor and then to the NO^ analyzer.

Septum ports were

located on b o t h sides of the reactor to permit taking of gas samples

for analysis of CCR,, E^ and CR,.

Figure 2 is a schematic of the reactor.

a stainless steel pipe

The reactor consisted of

10.5 inches long with an outside diameter of

7/8 inch and an inside diameter of 5/8 inch.

couple well made from l A

A stainless steel thermo­

inch O.D. and 5/32 I.D. tubing was situated

in the center of the reactor.

Approximately 7 inches from the top of

the reactor a stainless steel porous disk was placed.

Beneath the

disk the reactor was packed with stainless steel rings which served to

preheat the gas coming in.

of the disk.

Materials to be tested were placed on top

Glass wool packing at the exit of the reactor prevented

solid particles from blowing o u t .

After each run the reactor was

cleaned with dilute hydrochloric acid, rinsed with distilled water

and dried.

The reactor was heated by an inconel pipe wrapped with 6.5 feet

of ceramic beaded n i chrome wire (.9 ohm/ft) and insulated b y a 6.5 inch

diameter housing packed with zeolite.

Rotatmeters

Air or

N O 2 or NO

Mixing chamber

Sample port

Exhausts

Water cooler

Analyzer

Dilutent

rotatmeters

Filter

Reactor

Temperature

recorder

Figure I.

Flow Diagram of Apparatus

Sample port

9

To analyzer

Inconel pipe

•Glass wool

Thermocouple

well

Heater

coils

Absorbent

Insulation

Porous

stainless steel

disk

Housing

Stainless steel

Stainless steel

rings

Glass wool

Feed gas

Thermocouples

Figure 2

Reactor Cross-section

10

Sorbents

The sodium oxide-ferric oxide sorbent was prepared by heating a

2:1 mole ratio mixture of sodium nitrate and ferric oxide at red heat

in a small rotating kiln over a large burner for approximately one

hour.

Gravimetric analysis indicated a weight loss of approximately

31% w h i c h corresponded to a formula of NagOFe^O^ for the remaining

material.

Bulk density of the substance when loosely packed was. beO

tween

1.33 and 1.44 g/cm .

Transition metal oxides and the alkali carbonates were tested in

the form that they were obtained from reagent grade chemicals.

tures of the oxides and carbonates were made on a

Mix­

1:1 mole basis and

10 g. of the resulting mixture was used for testing.

The chemicals

were dry mixed with a mortar and pestle.

Gas Mixtures

Standards for calibrating the analyzer were made b y diluting .50%

HO (5 0 0 0 ppm) with room air.

The reactant gas mixtures also contained

HO diluted w i t h room air to produce the desired HOx concentration,

generally between .75% (7 5 0 0 ppm) and 1% ( 1 0 ,0 0 0 p p m ) .

Hitric oxide

reacted with oxygen in the air to produce a final gas mixture con­

taining approximately .5% HO and .5% H O ^ .

Carbon dioxide was added to the feed stream and the resulting

concentration of COg was approximately 15%.

Due to plugging of the

11

analyzer B y high, concentrations of moisture, no appreciable amount of

HgO was included in the feed gases other than what was in the room air.

To determine the effect water had on the absorption, the air was

saturated prior to being mixed w i t h HO at 2It0C to get a moisture con­

tent of approximately

2 - 3$.

Analysis of HO and HOg was accomplished using a Thermo-Electron

Model IOA Self-Contained Chemiluminescent HO-HO^. Gas Analyzer, which

has the capability of measuring from 0-10,000 ppm of HO or H O g .

ni­

trogen and oxygen analysis was performed on a Beckman gas chromatograph

using a column packed w i t h molecular sieve- type 13-X.

Carbon dioxide

analysis was performed on a Varian gas chromatograph using a column

packed w ith Porapak Q-S (Waters Associates).

Hitrate Analysis

Hitrate analysis was performed b y using an Orion specific ion

electrode model 93-07.

The solid sorbent was dissolved in water and

the p H of the resulting solution was adjusted to approximately 5.

The resulting solutions were then compared to known mixtures contain­

ing nitrate and nitrite ions.

Presence of the nitrite ions was det­

ermined in the following m a n n e r ;

The amount of HO^ absorbed by the

sorbent was determined from the absorption versus time curves.

Stand­

ard solutions of nitrate and nitrite ions -were made to approximate the

concentration anticipated when the. sorbent w a s .dissolved in water.

12

Comparison of the reading for the sorbent solution and for each stand­

ard solution tras then made to determine if nitrite or nitrate ions

were predominately present.

RESULTS

Due to the reaction of NO with.

to form NO2 , it was necessary

to determine the actual compos'ition of the gas entering the reactor.

Writing the chemical equation for the oxidation of NO to NO 2 as:

'2N0 i O2 = 2N0g

the rate expression for the formation of N O 2 'can he written as:

dpNOgyzdt =

NO P0g

where,

" rate of change in the partial pressure of NOg

dPN0

k = reaction rate constant

PN0 = partial pressure of NO

Pq

= partial pressure of Og

The rate expression can be written in a more useful form L y letting

a = initial partial pressure of NO (atm).

■ L = initial partial pressure of Og (atm)

c = partial pressure of NOg at time t

t = time from start of reaction (sec.)

k = reaction rate constant:

' and.T is in pK' (Chilton,

k = exp( 6^l/T - 0,72p)

(atm ^sec 1 )

1968) .

substituting these variables in the original rate equation gives the

expression:

dc/dt = k(a T c)2 (b - c/ 2 )

Xf b is m u c h larger than c /2 then the last term on the right hand side

Ill

reduces to "b,.

TKe resulting expression can be easily integrated and

solved for c to give;

c = a(l - I / CaKbt t ill

If a = .01, Tb = .21, k g .38 and t = 27 then

c =

Xf a =

.0068 atm C6800 ppm I

.008 and the other variables remain the same then

c =

.00506 atm (5060 ppm]

Approximately 50% of the original NO is' oxidized to UO^ in the time

(2.

7? s e c ) it takes, the feed, stream to reach the reactor.

To determine if the NO^ decomposes significantly as it passes

through the preheat section, the equilibrium constant (K ) and the

P

rate constants for the forward (k^] and reverse (k^] reactions need

to be known.

Table X lists values of k^ calculated from the .expression;

1V M d = kP = P N 0g/P NOp O 2

TABLE I;

°C

38

K

I X

Equilibrium Constants and Rate Constants

200

5

H 6

10

IlOO

I x IOp

I x

2.2 x IO 1

li.3

1.69

2.2 x

ir;3 X 1 0 - 5

•

10

I

(Chilton,

600

800

-I

I x

1968)

10

-3

1.7 x 10 0

P

V

kd

IO-10

,.169

1 .02.

10 . RJ

.Jh5

7.'ii5 x IO 2

As can be seen from the table the decomposition reaction does not

proceed at a significant rate until the temperature exceeds

1|00°C.

15

Since the. decomposition reaction vlll Be Important aBore UOO 0C , it is

important to know* vzhat the' equilibrium .concentrations' of NO and NO^

will he above this- temperature.

Table H

lists- some w a lues for the

concentrations- of NO and NO^ when the initial amount of NO added to a

stream containing

TABLE II:

21$ Og is- known.

Equilibrium "Values- of NO and NOg

Initial NO concentration =

10,000 ppm

®c

Uoo

600

800

N O g (ppm)

677U

17U 0 -

U

NO(pprn).

3226

8260

9996

Initial concentration = 8,000 ppm

N O g (ppm)

5U 20

1390

3

N O (ppm)

2580

6610

7997

Comparison of these values w i t h the values calculated for the feed

composition indicates that the concentration of NO and NOg entering

the reactor will be close to the equilibrium concentration of NO and

NOg at U-OO0C,

Other nitrogen oxide species that could form from the

mixture of NO and NOg are dinitrogen trioxide (NgO^ I and dinitrogen

tetroxide (NgO^).

and Table IV.

Equilibrium values for these are shown in Table III

1

16

TABLE III:

Equilibrium Values for

(Chilton, 1968)

K = P

/PT

P

N 2O 37 NO NO 2

Reaction NO + NO 2 = NgO

0.272

0 .4 7 5

K

0 .1 4 5

Equilibrium Values for N 5O^ (Chilton,

TABLE IV::

Reaction

45

35

25

°C

2N 02 = N 2O 4

kp

°C

P

20

65

12

=

V ZV

1 1

2

80 -

60

Uo

2.7

O

CVJ

K

0

1968)

.'67

Inspection of the equilibrium values indicates that neither of these

species would be .-significant" at temperatures above I OO 0C.

•.Graphs and Order of P r e s e n t a t i o n -•

•

-

•

Some points which are important in reading of the graphs are as

follows:

The feed concentration is in ppm of NO while the exit conc­

entration'' is in ppm of NO^ (NO + NO^).

It should also be noted that

desorption is occurring when the exit concentration (NOx ) exceeds the

original NO concentration in the feed.

Since absorption tests were

performed with changing temperature, the concentration of NO

in the

x

gas stream leaving the reactor and the corresponding temperatures are

17

plotted against time.

The original order of testing sorbents was to examine the sodium

oxide-ferric oxide sorbent in detail since it was reported to be a very

effective solid sorbent.

Then mixtures of alkali carbonates and metal

oxides were tested as was.the individual components of the mixtures to

determine if a more effective sorbent could be found.

For unification

the results are presented in the order that follows.

UOx Absorption.by the Alkali.Carbonates

The concentration of UOx leaving the reactor and temperature

curves for runs made with

10 grams of Li^CO^, Ua^CO^, and K^CO^

are shown in Figure 3, I and 5.

Each carbonate has an initial absorp­

tion m aximum at approximately IOO0C and at 350 - U50°C..

The absorp­

tion at I O O 0C does not occur after the carbonates have been heated.

Absorption capacity increases from lithium to potassium.

carbonate is unique in that it reduces the UO

(UO + UO

Potassium

) concentra-

tion leaving the reactor below the UO^ concentration entering the

reactor at temperatures between 350 and U^O 0C.

It should be remem­

bered that of the original UO that is injected into the feed stream,

approximately half is oxidized to UO^ before reaching the reactor.

Also as UOg is absorbed the possibility exists that the rate of UO

oxidation will increase creating more HOg which can be absorbed.

'- k

18

too ^

£

Sxlt Concentration

500

3

I

kOO

300

Figure 3.

NO

x

Absorption Curve for Li0CO

2

3

Sa2CO3

Feed - $00 al/mio air

(ppm NOx x IO--3)

9000 ppm NO

___

Temperature

Minutes

Figure 4.

NO Absorption Curve for Na0CO0

x

2 3

I

19

[,CO,

Peed - 500 al/ain air

9000 ppm 30

_

_ Temperature

Temperal

_

1,300 ppm

— 300 ppm

Mlnutea

Figure

5.

N O ^

Absorption Curve for

K g C O ^

20

A b s o r p t i o n .of NO^ .by .Metal.Oxides

6 through- 11 are the results of the runs made with metal

Figures

oxides TiO2 , M n O 2 , FegO^, CogO^, PbOg and AlgO^ (activated alumina).

Of these oxides, alumina and lead dioxide showed the greatest potential

for absorbing N O ^ . ■

At room temperature AlgO^ absorbs NOg and possibly some N O . (Fig­

ure .11) while PbOg absorbs primarily NOg (Figure 10).

Both oxides have

an absorption maximum at about 300 - U00°C, but AlgO^ desorbs in the

temperature region from 20°C to 300°C.

Above a temperature of U00°C

AlgO^ and PbOg desorb NO^ and after the desorption AlgOg will absorb

more NO^ at U 00°C than previously

(9200 ppm compared to 800 p p m ) , while

PbOg absorbs less (3500 ppm compared to 6250-ppm).

Manganese oxide absorbs mostly NOg at room temperature but as the

temperature increases from 26°C to 500°C desorption occurs (Figure

8 ),

then as the temperature decreases from 500°C to 300°C some absorption

occurs again.

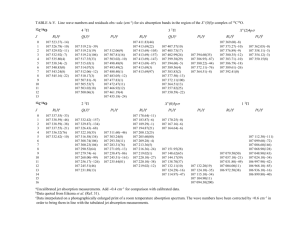

TABLE V.

NO

x

'Table 5 summarizes the performance of the metal oxides.

Absorption by the Metal Oxides

■■ To (ppm)

Oxide

From (ppm)

TiO 2

.9,000

.7,000

MnOg

10,000

7,500

PbOg

7 *000..

750

From(ppm)

To(ppm)

COgOg

9,000

" 6,800

Fe2 Og

10,000

8,900

10,000

800

"Oxide

M

2O 3 '

21

TOO

600 u

8

U00 I

300

6 . NO^ Absorption Curve for TiO^

600

500

Uoo

300

200

100

Figure 7.

NO

Absorption Curve for Co0O

2 3

I

Temperature

Figure

22

-T

•o

700

500

I

I

IiOO

Figure

Tempera!

600 F

I

8 . NOx Absorption Curve for MnO^

Fe2O3

Feed - 500 ml/min air

8,900 PJM

10000 prpm NO

_ Temperatrue

Temperature (°C)

------- ,0x

Minutes

Figure 9.

NOx Absorption Curve for Fe^O^

23

Feed - 500 al/min air

Tempei

7000 rpo SO

Minutes

Figure 10.

NO^ Absorption Curve for PbO^

Activated alumina (AlgO^)

Feed - 500 ml/min air

10000 ppm HO

I

Figure 11

NO^ Absorption Curve for Al^O^

2b

It should be noted that these absorption.tests were performed when .

no COg was present in the feed.

Absorption b y Mixtures of Metal Oxides and Alkali Carbonates

Results of the runs made with mixtures of the first row trans­

ition m etal oxides and sodium carbonate are shown in Figures 12 to

21.

In all cases a maximum absorption occurs in the temperature

range from 350 ' to

h50°C.

No increase in absorption of HO^ occurs

over that for' R a ^ C O ^ .until, oxides of manganese^,.-iron,..c o b a l t , n i c k e l ,

or copper are used.

The oxides of manganese, iron, nickel, and cobalt

when mixed with sodium carbonate reduce the

the reactor to less than 100 ppm.

run made w i t h M n O g ).

concentration leaving

(Rote that CO^ was present in the

Table VI summarizes the performance of mixtures

of RagClg with metal oxides.

TABLE VI.

ROx Absorption by Mixtures of RagCOg and Metal Oxides

Oxide

I t o m (ppm)

To(ppm)

Oxide

FromCppm)

To (ppm)

10,000

3,000

COgOg

9,000

100

. 8,000

1,900

RiO

8,000

30

CtgOg

8,000

3,200

CuO

8,000

800

MnOg

8,000

50

CUgO

8,000

550

FegOg

7,500

25

AlgOg

10,000

600

TiOg

V 2 05

•

25

Ha2CO3 + TlO2

Feed - 500 ml/min air

10000 ppm NO

_

_

_ Tatrperature

7OC

600

HOO

Temiperi

500

30C

3,000 ppm

200

100

0

Figure 12.

NO^ Absorption Curve for Na^CO^ + TiOg

TOO

600

o’

,00

I

I

itoo E

Figure 13 .

NO^ Absorption Curve for Na2CO3 + VgO^

26

Temper!

Exit Concentration (ppm HO

Heed - 500 ml ,'Bin air

3,200 ppn

Minutes

Figure l4.

NO

x

Absorption Curve for Na 0CO 0 + Cr0O

2 3

2 3

Feed - U-OO al/ain air

BCCO ppr RC

Concentration (ppm

Temperature (0C)

x 10*J )

ICC ai /Bin CC

50 ppm

Minutes

Figure 15

NOx Absorption Curve for Na2CO3 + MnO,.

27

'rOO

60C v

500

I

I

too I

30C

2OC

100

Figure l 6 .

NO^ Absorption Curve for Na^CO^ + Fe^O^

600

500

p

§

300

Figure 17.

NO^ Absorption Curve for Na2CO^ + Co2O^

Tempei

8

Uoo

28

Sa2OO3 ♦ SiO

Peed - 500 al/min air

8000 ran SO

_

_

_ Temperature

------

6oo

z

200

200 ppm

Minutes

Figure l 8 .

NO^ Absorption Curve for Na^CO 3 + NiO

Sa0CO, + CuO

500 ni/ain air

8000 ppm NO

600 u

^

Tem pe:

500

800 ppm

Minutes

Figure 19 . NOx Absorption Curve for NagCO3 + CuO

29

700

600 u

Uoo

4»

g

Temperat

50 0

300

200

Figure 20.

NO^ Absorption Curve for Na^CO^ + Cu^O

700

50 0

I

S

g.

Uoo g

Figure 21.

NOx Absorption Curve for Na^CO^ + AlgO^

30

ITO^ Absorption "by Sodium Oxide and Ferric Oxide Mixtures .(Ferrates)

A mixture of sodium nitrate and ferric oxide was heated to decom­

pose the nitrate and form a sodium oxide-ferric oxide m i x t u r e .

Also

a sample of commercial sodium ferrate (WagFe^O^) was obtained and test­

ed.

Even though b o t h substances had the same molecular formula, the

commercial ferrate was red while the ferrate made from nitrate was

yellow.

(Note:

When pure NaWO^ was decomposed, a yellow substance

was produced, presumably sodium peroxide

(Wa^Og)).

The results of runs made with these two ferrates are shown in

Figure 22 and 23.

Both absorb WO^ at low temperature and also absorb

NO and WO^ at approximately 380 - 500°C, reducing the exit concentra­

tion of NO to less than 100 ppm.

test).

(CO^ is" present in the NaNO^ + Fe^O^

It is interesting to note that the temperature where absorp­

tion starts to occur is also the temperature at which the sodium nit­

rate starts to decompose and give off NO (380°C).

The extended temperature range in whi c h absorption occurs may be

due to temperature gradients in the reactor (see Table V I I ).

It can

be assumed that the middle of the reactor is where absorption first ■

occurs and also the point at which the temperature first reaches 380°C.

A test on the effect temperature had on absorption is shown in Figure

2h.

In this test no CO^ was present.

off at approximately 380°C.

Absorption of NO^ starts to drop

31

Feed - UOO ml/min air

7000 ppm NO

100 ml/min C0„

_

_

_ Temperature

------- "°x

100 ppm

Minutes

Figure 22.

NO^ Absorption Curve for Decomposed NaNO^ + Fe^O^

* V e2°i.

Feed - 500 ml/min air

10000 ppm NO

_ Temperature

,

u

60 0

°

500

I

Uoo I

300

100

50 ppm

b

Minutes

Figure 23 .

NO^ Absorption Curve for Na^Fe^O^

32

___ Taapermt-.ire

Peed —

2k0ml/mln

7500 M » 10 (.75%)

10% O2

CoocentrstIon of HO. (pj») In Ellt St

Haemlnder Ig

Temperal

-ItOO

Figure

t

2k.

Effect of Temperature on NO Absorption

by Decomposed NaNO^ + F e ^ O ^

33

TABLE V X I .

Effect of Flow on Temperature Gradients in the Reactor and

NOx Absorption

Flow (ml/min)

600

800

1100

1200

T (0C)

457

457

457

457

Tt (0C)

402

400

395

395

Tm( 0 C)

445

445

4oo

. 435

Tb (0C)

330

330

320

310

20

16

18

20

W

NOx (ppm)

T = temperature of outside wall of reactor across from T

w

m

Tj. = temperature I inch below the top of reactor

Tm = temperature I inch above the porous disk (middle of reactor)

Tj3 = temperature

.5 inch below the porous disk

NOx = concentration of exit stream (feed is 5000 ppm NO)

(Temperatures were measured by using thermocouples). *

Also in Table VII the exit concentration of NO

leaving the

%

reactor at the various flow rates are listed.

Even though the flow

rate was doubled the absorption of NOx was not affected.

Figures... 2.5. and 26 show 'the effect CO^ and O^ had on the absorp­

tion of NO and NO

*

oxide.

C.

at 400°C b y the decomposed sodium nitrate-ferric

The presence of carbon dioxide in amounts of 20% or greater

affected the absorption of N0x ; and when the NO to O^ ratio was below

1:2 the absorption of NOx was also severely reduced.

25

Decomposed SaHO^ ♦ Fe^O^

Feed - 325 ml/min air

Exit Concentration Cppe *0^

20

-

15000 ppm BO

15 -

Effect of CO

on NO

Absorption by Decomposed NaNO

+ Fe 0

Concentration (ppn NO^ x

.

1:3

I:'

Ratio of BO:Og

Figure 26.

Effect of NO to Og Ratio on NO^ Absorption by Decomposed

NaNO3 + Fe2O3

35

Performance of Sodium and Potassium Carbonates and Nitrates with

Manganese and Iron .Oxides'.........................

Figures 27 through 32 are the results of tests made with dif­

ferent combinations of manganese and ferric oxides w i t h the carbonate

and nitrates of potassium and sodium.

Table V Z I I ).

and sorbent

(The results are summarized in

In these tests equal volumes of 20-30, mesh. Ottawa sand

(.025 moles) were mixed together and poured into the reac­

tor to form a packed bed.

The volume between the bed and top of reac­

tor was then filled with Ottawa sand to keep the sorbent from separ­

ating out.

TABLE VIII.

NOx Absorption by KMnO^ and Mixtures of NaNO^, Na 2CO^,

KgCO^, ENO^ with FegOg and MnOg

NO

Sorbent

Concentration'Reduced

x

From 9000 ppm To (ppm)

NagCOg + FegOg

200

NaNOg + FegOg

150

KgCOg + Fe2 Og

25

KNOg + Fe2 Og

250

N a 2COg + MnOg

150

KgCOg + MnOg

50

NaNOg + M n O g

2500

KMnOli

25

36

Sodium nitrate-ferric oxide mixtures absorbed slightly more NO

than did the decomposed sodium carbonate-iron oxide.

The first absorp­

tion at 380°C reduced the NO^ concentration to 1900 ppm for the car­

bonate and

ppm for the nitrate, while NO

at the second absorption

x

at 380°C was reduced to 200 ppm and 150 ppm by the carbonate and nit­

rate respectively.

It was found that upon successive regeneration,

the carbonate mixture steadily improves and surpasses the performance

of the nitrate mixture.

Similarly with the potassium carbonate and decomposed nitrate m ix­

tures w i t h ferric oxide (Figures 29 and 30), the carbonate performed

m u c h better than the nitrate, reducing the NO^ concentration to less

than 50 ppm, compared to 400 ppm for the nitrate.

A few factors

worth noting about the potassium carbonate-ferric oxide mixture a r e :

(i) it absorbs more than Na^CO^ + Fe^O^ or decomposed NaNO^ + Fe^O^,

(ii) absorption starts at a lower temperature (300oC) compared to 380°C

for the sodium carbonate,

(iii) a higher temperature is needed for

regeneration (this m a y be caused by the temperature gradient in the

reactor), and (iv) more NO^ is absorbed at lower temperature than for

the previous mixtures.

The effect of using manganese dioxide with sodium and potassium

carbonate is shown in Figures 31 and 32.

Absorption was improved for

the sodium carbonate (the NO^ concentration dropped to less than

100

ppm) and there was a slight improvement for the potassium carbonate

37

TOO

600 t.

E

5 00

5

1.00

£

I

Figure 27.

NO

x

Absorption Curve for Na CO

3

+ Fe 0

(bed)

<- 3

Decomposed IiaHO3 + Fe,

Feed - UOO ml/min air

9000 ppm NO

15.8$ CO2

_

_

_ Temperature

TOO

600

500

UOO

S

I

300

200

100

0

Figure 28.

NO^ Absorption Curve for NaNO3 + Fe^O3 (^ed.)

38

TOO

60 0

o

500

i

Uoo

Temperal

£

300

200

Figure 29.

NO^ Absorption Curve for K^CO^ + Fe^O^ (bed)

Decoaposed KNO^ + Pe^O^(bed)

Peed - UOO ml/min air

9000 ppn NO

15.85 CO2

_

_ Temperature

Temperature (°C)

_

--- 250 ppm

Figure 30

NO^ Absorption Curve for Decomposed KNO^ + Fe^

(bed)

39

700

6oo £

500

I

300

200

ICC

Figure 31.

NO

x

Absorption Curve for Na CO

j

+ MnO

2

(bed)

KpCO 3 + MnOp (bei)

Feed - 100 ml/air. air

9000 ppE

n:

15.2% CCp

_

_ Temperature

Tempe-

_

50 ppm

100 ppm

Minutes

Figure 32.

NO^ Absorption Curve for KpCO3 + MnOp (bed)

(KOx dropped to less than 40 p p m ) .

Again the mixture with

CO^ ab­

sorbs more than the NagCO^ m i x t u r e .

Unlike the potassium carbonate-ferric oxide m i x t u r e , the manganese

mixture formed clumps which could cause problems in a large scale reac­

tor.

The clumpy material when dissolved in water produced a green

colored solution w h i c h is characteristic of potassium manganate

(KgMnO^) (Partington, 1921; Tyree and Knox, 196l).

A test was per-'

formed in which a mixture of KgCO^ and MnOg was decomposed at a high

temperature in an atmosphere of Kg.

When the decomposition was con­

sidered to have proceeded sufficiently the reactor was cooled down and

the material removed.

This material was hard and initially had a blue

color, indicating that potassium hypomanganate had formed (K^MnO^)

(Partington, 1921).

On being exposed to the room atmosphere, the blue

material gradually turned green and became moist.

The green material

is presumably potassium manganate while the moisture m a y be due to the

formation of potassium hydroxide which then absorbs moisture from the

air.

Potassium permangante ('KMnO^) and a decomposed mixture of sodium

nitrate and manganese dioxide were tested to see if they would absorb

N0x .

Results of these two tests are shown in Figures 33 and 34.

performance of the decomposed nitrate mixture was poor.

The

However, the

potassium permanganate absorbed almost all the NOx in the feed.

The

temperature at which the KMnO^ started absorbing is the temperature

KMnOl

4+ Sloshed)

Feed - 1*00 ml/ain air

9000 ppc NO

15.8? CO^

_

_

__ Temperature

7OC

600

500

too

300

20C

IOC

25 ppm

0

Minutes

Figure 33.

NO^ Absorption Curve for KMnO^ + SiO 2 (bed)

700

600 £

t

500

2

I

Uoo I

300

200

100

Figure 3U.

NO^ Absorption Curve for Decomposed NaNO^ + MnO5 (bed)

k2

at which it decomposes

(l90°C) to potassium manganate (K5M n O ^ ) .

The possibility existed that SiCh in the Ottawa sand reacted with

the carbonate or manganese dioxide and increased their sorbent ability.

It'is known "that SiOg will displace CCL from carbonates at high temp­

eratures to produce silicates.

Figures 35 through 37 are the results

of potassium c a r bonate, sodium carbonate and manganese dioxide tested

independently of each other w i t h Ottawa sand.

The Ottawa sand did not

improve absorption.

Regeneration Studies

Figures

38 and 39 are typical regeneration curves for K CCL-MnCL.

Four absorptions- and regenerations were performed w i t h the K^CO^-MhO^

mixture and there was no indication of loss in sorbent performance.

The concentration of RO

X

obtained on regeneration depends on the flow

rate used,..the amount preabsorbed and the heating rate used in regen­

eration.'

An ROx concentration of greater than 50% was- obtained on

regenerating MhOg-KgCO^ sorbent at a temperature of 600 - JOO0C using

10 ml/min of air.

Furthermore, of the 50%.RO , approximately 49.5%

was ROg and only .5% was. R O .

It is interesting to note the large

amounts of Og that are also given off during decomposition.

This ox­

ygen could be responsible for oxidizing RO to R O g .

Similar regeneration results were obtained with KgCO^-FegO^

mixtures.

After six cycles of regenerating and absorbing, no loss in

8,700 ppo

IIa2CO3 + SiO2 (ted)

Feed - U00 ml/ain air

SWOO ppm IO

700

15.8% CO2

_

_

_ Teeperature

60C

?

Z

500

UOO

5

C

$.

E

300

2,800 ppe

200

100

0

Mlnutea

Figure 35.

NO^ Absorption Curve for Na 2CO 3 + SiO 2 (bed)

I2CC 3 ♦ SlO2 (bed)

Feed - UOO al/aln air

9000 pptn HG

15.8% CO2

_ _

_ Temperature

3,600 ppm

Minutes

Figure 36 . NO^ Absorption Curve for KgCO3 + SiOg (bed)

1+1+

Mo:; ♦ S i O ^ bed)

Feed - UOO m-l/mln air

9000 ppm HO

15.8$ C O 2

_

_

_ Temperature

700

6oo

5,800 ppm

500

UOO

300

200

100

0

Figure 37.

NOx Absorption Curve for MnO 2 + SiO 2 (bed)

5

4$

Regeceration

2 3 ♦ MnO2

I CO

[5.5 gj

Feed — 10 ml/min

--------- Temperature

HO

(H)

t HO.

---------

N0% when NO^% vas equal to 50

Minutes

Figure 38.

NOx Concentration During Regeneration of K 3CO 3 + MnO 3

600 u

Regeneration of absorbent

Minutes

Figure 39 .

Regeneration of K 3CO 3 + MnO 3

k6

sorbent performance was noted.

Other tests on the potassium ferric

oxide mixture indicated that when NO^ is .absorbed at low flow rates

(10 ml/miri) on regeneration, NO is primarily given off, while if ab­

sorption occurred at higher flow rates

given off.

(500 ml/min)? NO^ was primarily

Also after low flow rate absorptions, less oxygen is de­

sorbed than after, h i g h flow rate absorptions.

When desorption was completed a feed of

and NO was passed over

the KgCO^-FegO^ sorbent at temperatures greater than or equal to

TOO0C.

The N

and 0

any NO was present.

content of the exiting stream went up and hardly

This indicates that the NO is reduced b y the sor­

bent to Ng and O g , which corresponds to reports in the literature that

alkali oxides reduce NO to Ng and Og at high temperatures

and M o r e l l o ,

(Harris

1969).

Loading Studies

The time taken for the concentration of NO^ in the exit stream

t o exceed 200 ppm was determined with and without COp in the feed.

r

*

Figures 40 and 4l are typical loading curves.

If COg was present

the loading time was between 30 minutes and 60 minutes.

This corres­

ponds to a conversion of 8.5 to 17% of the .025 moles of sorbent pre­

sent.

When COg was not present the loading time was about equal

to the time needed to theoretically convert all the alkali carbonate

or alkali oxide to an alkali nitrate

(5 - 10 hr).

It was found that

10

Loading Curve

K2CO 3 * Fe 3O 3 (7.5 g)

Feed - LOO ml/min air

Ir Exii

8000 ppm NO

700

15* CO2

— --- - — Temperature

---- H0,

I

0M

Minutes

Figure 40.

Loading Curve for K^CCy + Fe^O^

Loading Curve

K2CO 3 ♦ MnO2 (5.5 g)

Temperature UItO0C

Feed - UOO ml/min air

10,000 ppm NO

15* CO.

Figure Ul.

Loading Cuirve for K^CO^ + MnO,-,

6000

48

if the exit concentration reached 200 ppm when CO^ was present, shut­

ting off the COg would cause the N

concentration to drop below

200 ppm.

COg and H g O .Effects

As was mentioned carbon dioxide affects the absorption of NO and

NO^ but tests showed that no detectable.amounts of COg are absorbed.

The other affect of carbon dioxide is to limit the temperature range

in which absorption occurs.

Addition of carbon dioxide to the feed

will narrow the temperature range from 80 to 20 degrees.

This effect

is less pronounced for the potassium carbonate than for the sodium

carbonate and non-existant for KgMnO^.

'

It is possible by using the free energies of reaction to determine

the equilibrium constants for reaction involving carbon dioxide and

nitric oxide (see Table IX).

The values calculated indicate that the

carbonates do not appreciably decompose by themselves, but by reacting

with NO and O g , decomposition is favored.

When equal amounts (l%) of carbon dioxide and.nitric oxide, along

with 20% oxygen are fed into the reactor, no decrease in sorbent ab­

ility is seen.

It i s n ’t until the concentration of COg is greater than

5% that sorbent performance drops off.

Since the concentrations of

carbon dioxide are far below the values predicted b y equilibrium cons­

tants to cause the reaction to reverse, COg possibly affects an inter-

TABLE' IX:

'"4?/

.Equilibrium’.Constants, .

’for .Beactions’.En-volving .HO .and. COg

Reaction

^

Eree Energy

' Change at 425°C (.Kcal/moleI

Equilibrium

Constant

Ha 2CO 3 = Na2O + COg

52.128

5.09 x IO-17

KgCO3 = K a 2O + COg

68.42

4.3 x IO-22

NagO + 2N0 + 3.5 Og =

Na 2CO 3 +

2NaN0

-143.40

8.58 x IOlllt'

- 91.27

28

3.97 X 10

2N0 + 3.5 Og ? 2NaN03

+ COg

NagFegO, + 2N0 + 3.5 Og =

2NaN0

Na 2CO 3 + Fe 3O 3

47

-150 (estimate)

I x 10

58.24

5.63 x 10

t Fe2O3

Na2F e 2O1^ + COg

-19

50

m e d i a te r e a c t i o n .

F u r th e r m o r e , i f t h e s o r b e n t h a s a b s o r b e d oxygen

p r i o r t o t h e i n t r o d u c t i o n o f a s tr e a m o f NO. an d N ^s t h e n i t r i c

w i l l be a b so rb e d f o r a s h o r t p e rio d o f tim e .

o x id e '

As s o o n a s t h e a b s o r p ­

t i o n o f NO s t o p s t h e i n t r o d u c t i o n o f oxygen t o t h e f e e d w i l l c a u s e

th e a b s o rp tio n t o b e g in a g a in .

, The effect of water on absorption of NO^ was tested b y satur­

ating the air stream at room temperature prior to adding NO to the

stream.

At moisture concentrations of 2-3% no'effect on sorbent per­

formance was detected.

It has been reported that the NO^ absorption

b y the carbonates is facilitated by the presence of.water vapor in the

feed (Lewis, 1975).

DISCUSSION

The potassium and sodium carbonate absorption maximums occurred

at IOO-SOO0C and from SOO-^QO0C.

Generally NOg "was absorbed b y the

carbonates at l o w temperatures (below I O O 0Cj and any NO that was not

converted to NOg passed through the reactor.

The absorption from 100

to 200°C is. possibly due to water being released b y the carbonate.

For

example potassium carbonate had a water content of approximately 8%.

The water is probably due to the decomposition of bicarbonate and the

release of hydrated w a t e r , b oth of which occur in the temperature

range from 100 to S O O 0C.

This would also explain w h y the low temp­

erature absorption m a x i m u m does not occur after the carbonate has

been heated.

It was been reported that the presence of water vapor

improves the absorption ability of carbonates (Harris, Morello and

Peters,

1969).

The high temperature absorption is probably due to a compound

formed during the heating of the carbonate.

Decomposition with lib­

eration of COg and the formation of an oxide is a characteristic prop­

erty of carbonates at h i g h temperatures

(Webb, 1970; pp 304).

The

rate of decomposition depends on the carbonate used and on any imp­

urities present in the material.

The oxide formed depends on its

stability at the temperature in question and the amount of Og present.

It is interesting to note that the reactivity of the carbonates for

absorption of NO^. is in the reverse order of the stability of the

52

carbonates to thermal decomposition.

Tables X and X X list thermal

characteristics of the possible alkali oxides that could be formed.

Thermal studies, on NaO^-NagQ show that the sodium superoxide (NaOg)

decomposes with the rapid evolution of oxygen up to 280°C leaving only

sodium peroxide (Na^0^)

(Webb, 1970; pp 242).

Decomposition of Na^Og

into NagO and oxygen does not take place until the temperature is

above melting (460°C).

In decomposing sodium carbonate in the reac­

tor the compound formed had a yellow color indicating possibly that

Na^Og was formed.

Common oxides of potassium are potassium superoxide (KOg) and

potassium peroxide (KgOg); the superoxide is the most common.

When

KOg is heated, reversible decomposition into oxygen and a mixture of

KgOg and KOg takes place at 300 to 400°C (Yost and Russell, 1944).

A

yellow substance was formed when potassium carbonate was heated in

the reactor indicating that the oxide'formed was K O g .

It is possible then, that the active species in absorption at

higher temperatures is not the alkali carbonate but rather the alkali

oxide w h i c h is formed from the carbonate.. This would explain why ab­

sorption increases after the carbonate has been heated to high temp­

eratures.

■TABLE X:

M e lt in g -and --BoTBing-BoLnts-Lof ' A l k a l i . C arB o n ates- a n d O x id e s*

.Formula

Formula

weight

Bip(0 C)

LigCOg

73.89

735

Color

L p ( 0 C)

white

'3590

I

Ha 2CO 3

KgCO3

105.99

854

d 600

white

-138.21

896

d670

white

LigO

29.88

1570

LigOg

1:5.88

dl'6o

NaOg

54.99

d 280

Na2O

61.98

N a 2 Og

77.98

KDg

71.1

K2 O

94.20

d350

d88l

110.20

490

d

.

%

*(jang. 1967; Samsonov, 1973)

d!93

white

920

d 46o

• 402(380)

d657

yellow

d

yellow

white

54

Table

Ll2O

XE

-

--Thermal Stability}:' Characteristics -of Alkali Oxides*

Thermally stable.

Volatility 'increases .and thermal stability

decreases in the series Li— C s .

Li2O^

Decomposes Trith- liberation of oxygen at l 60oC.

Decomposes

completely at 315'-343°C.

Na2O

Volatile above 1300°C.

NagO2

Some loss of active oxygen is observed on heating at 311~400°C

vigorous decomposition begins at 540°C; gives up active oxygen

completely above

6j^°C.

NaOg

Decomposes on heating;

decomposes completely above 540°C.

K 2O

Decomposes at 300-400oC without melting to metallic patassium

and peroxide.

Melts without decomposition.

Thermal stability of peroxides

rises from K to Cs.

KO2

Decomposes completely at 5U3°C.

* (Samsonov, 19731

55

Effect o f '6xid.es on the Decomposition of Carbonates

As was discussed earlier the effect of impurities in the carbon­

ate can m a r kedly affect its decomposition rate.

the results of CO

Shown in Figure 42 are

released from mixtures of carbonate and metal oxide

when decomposed in an air stream.

The presence of the metal oxide in­

creases the rate of decomposition of sodium and potassium carbonate

considerably.

This increase in CO^ liberation m a y be responsible for

the increased sorption ability of the carbonate due to the production

of active alkali oxides.

oxygen or E

It was also found that the presence of

in the feed increases the rate at which COg is released

from the carbonate.

A test was performed using iron powder and sodium

carbonate as the sorbent, although the thermal conductivity of this

mixture would have been higher than that of the other metal oxideNa 0CO 0 mixtures, no increase in NO

absorption occurred above that of

just NagCOg.

The alkali oxide formed from decomposition of a Na^CO^ or NaNO^

is reactive and would combine with Fe^O^ to form a ferrite or ferrate

(NagO-FegO^).

The ferrates are known to be strong oxidizing agents

and it is possible that if a nitrite was formed it would be oxidized

to a nitrate.

The possible reactions that may be occurring are as

f o l lows:

NagOFegO

+ 2N0 + 3/2 Og = 2NaN0^ + FegO 3

N a 2OFe 2O 3 + 2N0g + 1/2 Og =

ENaNO3,+ Fe 3O 3

■

56

Decomposition

Peed - 500 ml/min air

+ Fe,

♦

HnO,

0

Na CO.

l2vv3

Figure

h2

Effect of Metal Oxides on Decomposition of Carbonates

57

It is also possible that NagO2FegQ^ is .formed and undergoes the same

reactions except a half a mole less of oxygen would be needed.

reactions are listed in Table XIX.

Other

In a test using only nitrogen and

NO the ferrate from the nitrate reduced the NO concentration from a

level of

7500 ppm to 3500 ppm, indicating that a reaction will occur

without oxygen present in the feed gas.

The temperature at which absorption occurs and the activity of the

carbonate mixtures compared to those prepared from the.' nitrates might

be explained b y the following paragraph taken from Arvid Eedvall *s

Solid State C h e mistry, "It is in many cases advantageous to ‘start, not

from original oxides but from structurally defect and consequently

particularly active oxides which are formed by thermal decomposition.

An example is the production of ferrites and chromites b y homogenised

heating of the required oxide w i t h iron carbonate or of magnesium

carbonate with chromium oxide, respectively.

In powder mixtures of

ferric oxide and oxides of alkaline-earth metals, the preparations with

structural defects formed ferrites far more rapidly and completely

than the preparations without defects. The differences only disappear

at temperatures above 900°C as the irreversible defects vanish.

Innumerable experiments involving various types of changes -of

structure have provided a basis for a general rule which states that

the temperature (or temperature range) where new phases are formed b y

transformation coincide with a relative maximum of reactivity in a

substance."

Temperatures at w h i c h the nitrates undergo a change are listed in

Table XIII.

Sodium nitrate and potassium nitrate decompose in the

temperature range at w h i c h NO^ is absorbed by the sorbents.

Chemical

analysis also indicates that nitrates are formed when NO^ is absorbed.

An alternate method b y w h i c h the reaction could proceed is

through an oxidation step on the metal oxide.

Before discussing this

Table XIX.

-Possible Reactions of the Sorbents

AHgp8Ckcal/mole)

Reaction

Na 5CO 3 = Na2O + CO2

76.8

K 2C O 3 = K 2O + CO2

9^.05

N a 2CO 3 + 1 / 2 -O2 = N a 2O2 + CO2

55.6

K2CO3 + 1/2 O2 = K2O2 + CO2

62.U5

2NaN03 = NagO + 2N0 + 3/2 Og

166.88

2KN0

192.29

2NaN0

=

KgO + 2N0 + 3/2 Og

= Na2O2 + 2N0 + Og

1^5.68

160.69

2KN03 = K2 O2 + 2N0 + O2

N a 2CO 3 + 2N0 + 3/2 O2 = 2NaN03 + COg

K 2 CO 3 + 2N0 + 3/2 O2 =

2KN0

+ COg

-

90.08

-98.27

59

Table XII; Continued:

Reaction

A Hggg (.kcal/mole)

NO + 1/2 O2 = RO2

-13,51

N a 2O + 2N02 + 1/2 Og = 2NaN0^ .

-139.86

KgO + 2N02 + 1/2 O2 = 2KNO 3

-166.30

2NaN03 + Fe 2O 3 = Na2F e 2O^ + SNOg + 1/2 O2

176.67

N a 2CO 3 + Fe 2O 3 = N a 2Fe 2O 4 ■+ CO2 •

121.75

(32.06)*

N a 2Fe 2O 4 + 2N0 + 3/2 O2 = 2NaN0

+ T e 2O 3

K 2 CO 3 + M n O 2 + 1/2 O2 = K 2M nO 4 + CO2

Na 2MnO 4 + 2N0 + O2 = 2NaN0

+ MnOg

K 2MnO 4 + 2N0 + O2 = 2K N O 3 + MnO2

- 211.78

221.98

-116.78

-133.22

* Matsui., Mototaro and Sakamaki., Tomonosuke, J. S o c , C h e m . Ind. (japan)

30, 29-36 C1927)

6o

0

TABLE- X E H . Melting and Decomposition. Temperatures of. Alkali Nitrates,

■ ■

•'

;•' '"Nitrites and Hydroxides -(Jang, .196.7) "(CRC"H A n d L o o k '4|?th ed)

Eormula

Weight

-DipC0 C I

LiNO 3 .

68.95'

25U

d 600

NaNO0

85. Ol

310

d 300

ENO

1 0 1 .1 0

337

d3U0

LiNO2

52.95

100

d l8 5

NaNO2

69.00

271

d320

KNO2

8 5 .ll

UUo

d350

LiOE

23.95

U62

NaOH

U 0 .0 0

318

KOH

56.11

360

'3

O

Compound

'61

mechanism the oxides used in the oxidation of CO to COg will "be des­

cribed,

The catalytic activity series of metal oxides for the oxid­

ation of CO is from the most active to the least active (Dixon and

, ,

Lo n g f i e l d , i 960):

Co

+2

,Cu

+1

,Ni

+2

,Mn

Cr+ ^, Th+^ , Zr+^ , V+ ^ , Hg+ ^, and Al+ ^.

+Ii

, Cu

+2

, Fe

+ ’R

, Zn

+2

, Ce

+U

,

There is also a qualitative

connection between the activity of the oxide and their semicond­

ucting properties.

The most active oxides are the P type which include

manganese dioxide (Ashmore, 1967 ; pp 239).

In the P type oxides,

electrical conduction occurs b y changes of charge or motion of pos­

itive holes.

N type oxides

(eg. FegO^) which are the next most ef­

fective oxidizers of CO, conduct electricity by free electrons.

At high temperatures carbon monoxide attacks the surfaces of P

and N type oxides to form carbonate ions.

The proposed mechanism is

one in which oxygen is absorbed as O'. •and CO reacts with two 0

to

form the carbonate, which decomposes to COg (Ashmore, 1967; Thomas

and Thomas, 1967 ).

A similar scheme can be thought to occur for nit­

ric oxide, since NO and CO are very similar molecules.

The NO^

formed when NO is absorbed would decompose to produce NOg wh i c h would

react w i t h the alkali carbonate or oxide to form a nitrate.

Absorp­

tion of NOg at low temperatures does occur for the carbonates and

studies indicate that NOg is absorbed as NO^ ions on AlgO^ and NiO

surfaces (K h o z i n g e r , 1976) .

Pt is also known that NO will displace

CO from the surface of metal o x ides, indicating that the NO molecule

62

H a s a strong affinity for metal oxide surfaces.

Release of Oxygen from Potassium Carbonate and Manganese Dioxide or .

Ferric Oxide M i x t u r e s .....................

................... ...... •

Tests were performed to determine if oxygen was given off during

decomposition of KgCO^ + MhO^ or K^CO^ + Fe^O^.

As is shown in

Figure 43 and 44, the manganese dioxide mixture releases O^ when de­

composed, while the ferric oxide mixture does not.

The decrease in'

Ng at 200 - 250°C is not due to Ng being absorbed, but from the de­

composition of bicarbonate present to give off HgO and C O g .

Decomposition of manganese dioxide to MhgO^ and Og is responsible

for the large Og p e a k around 450 - 550°C.

Integration of the Og peak

indicates that approximately 1.5$ of the original

ganese dioxide releases O g .

.025 mole of man­

It is possible that MhgO^ is an active

species in the absorption process if it doesn't" revert back to MnOg

below 450°C in the presence of O g .

Decomposition of the carbonate appears to reach a final value for

the MnOg-KgCOg mixture while the FegOg-KgCOg decomposition continues

for a longer period of time as indicated b y the nitrogen composition

of the exit stream.

the original

An approximate analysis indicated that 11$ of

.025 mole of carbonate present in both mixtures releases

COg and the total amount of carbon dioxide released after 70 minutes

is the same for b o t h mixtures.

63

Decomposition of

600 u

Minutes

Figure 43.

Amount of

Released From K 5CO 3 + MnO 5

Decomposition of

•6 0 0

Feed - 10 ml/min I3

Figure 44.

Amount of O5 Released From K5CO3 + Fe5O3

0

A

TIie possible reactions of the manganese mixturein,' an

atmos­

phere are as follows:

1)

K 2CO 3 = K2O + CO2

2)

GMnO2 = M n 3O 3 + 1/2 O2

3)

K 2CO 3 + M n O 2 = K 2MnO 3 + CO2

4)

K 2CO 3 + M n O g = K 2MnO^ + C O

5)

K 2CO 3 + GMnO2 = GK 3M n O 1^ + GCO2 + CO

,

All of the reactions are endothermic and would be favorable at higher

temperatures.

Equilibrium calculations are not app]icable since the

gaseous products are removed by the nitrogen stream but the rates of

the reaction may play an important role. .Exactly to what extent each

reaction takes place is hard to determine.

or K 3MnO^ has been suggested earlier.

The formation of KgMnO^

The presence of

stream indicates that reaction 2 takes place.

in the exit

Analysis of CO was not

possible at the time so definite conclusions can not be drawn on the

extent of any reactions.

Similarly, the reactions that take place between KgCO 3 and Fe 2O 3

c o u l d n ’t be positively identified but some of the likely ones that

could take place in the inert Eg atmosphere are:

1)

K 2CO 3 = KgO + CO2

2)

K 2CO 3 = K2 Q2 + CO

3)

K 2CO 3 + Fe 2O 3 = K 2OFe 2O3 + CO2

4)

K 2CO 3 + Fe 2O 3 = K 2O 2Fe 2O 3 + CO

65

Absorption of CL b y Decomposed Potassium Carbonate, Ferric Oxide and

_______ ' ' '

__________

Manganese Dioxide Mixtures

After decomposing tb_e carbonate metal oxide mixtures in a

Ng

stream, the feed stream was switched over to air and the amount of

absorbed recorded (see Figure U 5).

The initial large absorption of '

Og b y b o t h mixtures is probably caused b y the already existing com­

pound formed when the carbonate decomposed and reacted w i t h the metal

oxide.

Since the manganese mixture initially absorbs more Og and

d o e s n ’t give off C O g , the carbonate in this mixture is largely de­

composed.

Furthermore, once loaded, the manganate does not absorb Og

until.the temperature drops to below 600°C which corresponds to the

reaction MhgO^ + 1/2 Og = 2Mn0g.

The absorption of Og between 600 -

450°C was reversible in that Og

was given off above this temperature

and absorbed when the temperature was lowered.

On the other hand,

the ferric oxide-carbonate mixture continually absorbs oxygen and

gives off carbon dioxide indicating that the carbonate i s n ’t fully

decomposed.

Then when the temperature drops, the carbonate no longer

decomposes and subsequently Og absorption stops.

These tests indicate

that the oxygen is absorbed, therefore MD may be reacting with the ox­

ygen as an intermediate step in the absorption process.

66

Absorption of

Feed — 10 ml/ialn air

•600

0

Minutes

Figure 45.

Absorption of

by K^CO^ + MnO 5 and K^CO^ + Fe 5O^

APPLICATION

■ It was estimated that approximately 1.25 million standard cubic

feet per minute of gas containing 1.5% NO VrillxIiave to be handled for

a 1000 Megawatt MHD generator.

to be 2.37 x 10

k-

gmole/min.

laboratory reactor,

In terms of moles of NO this comes out

Under the test conditions used in the •

.025 mole of sorbent was able to absorb 1.63 x IO-

mole/min of NO for 30 minutes before having to be regenerated.

If the

same conditions are applied to the MEED plant then 3.64 x 10^ moles of

sorbent would be required every 30 minutes.

Assuming a continuous

p r o c e s s , taking a one hour cycle for completion, the total amount of

sorbent that would have to be purchased is 7.28 x 10^ moles or approx­

imately 40 tons.

The initial costs of sorbent mixtures that could be

used for absorption of NO

is shown in Table XIV (individual costs for

chemicals are listed in Table X V ) .

TABLE XIV.

Mixture

In the study performed to deter-

Costs of 7.28 x IO^ Moles of Sorbent Mixtures

Cost .in' Thousands of Dollars.

KgCO^-FegOg

520

NagCOg-FegOg

165

N a 2COg-MnOg

320

KgCOg-MnOg

•

673

mine the economic feasibility of producing nitric acid from a 700 Mega­

watt MHD generator, silica gel was used as the sorbent and oxidizer at

68

cost of over

2 million dollars Offright and Youderion, 1976).

Even

with, this h i g h expenditure for a sorbent the plant showed a projected

rate of return of 31$.

Scaling up the cost of the silica gel for a

1000 Megawatt generator indicates an investment of over 3 million

dollars.

Comparing this cost to the cost of the solid sorbents shows

that the solid systems could save over 2.5 million dollars.

Further­

more, the optimum ratio for the sorbent mixture has not been deter­

mined nor has the maximum flow rate, both of which would further

reduce the cost.

69

' 'TABLE XV. ' 'Costs:'of 'CMrfttcal^ ■ ■

CIiemLcal

NSgCOg

dollar s'/lB

028

dollars/IL mole

2.97

KgCOg

.20

25.00

FegOg

'.QhG

7.36

MnOg

.21

17.00

KMnOj^

CO

82.00

BaNOg

065

KEOg

KCl

CaCOg

CaClg

5.53

.10

10.11

..02

1 .U8

.01

1.00

' .035

3.85

EiO

2.00

Ih9.h2

COgOg

4.27

■708.22

FbOg

.66

157.74

AlgO

.16

16.32

CONCLUSIONS

1.

Ferric oxide or manganese dioxide m i x e d on a one to one mole "basis

with, potassium or sodium carbonate will absorb KCf. in a temp­

erature range from 380 to U50°C.

U s i n g these absorbents, the

concentration can be reduced from

10,000 ppm to less than 200 ppm

from a g a s containing 1 # NO, 15$ C O g , 17.5$ Og and 66.5$ Ng at flow

rates of 500 ml/min.

The effective operating time of .025 moles

of sorbent mixture was' between

2.

.5 and I hour.

Decomposed mixtu r e s of sodium nitrate and ferric oxide (ferrates)

are effective NO^ absorbers when the ratio of Og to NO in the feed

is greater than 3:1.

3.

Nickel o f "cobalt oxides; mixed w i t h sodium carbonate show potential

for absorbing N Q x at high temperatures.

4.

The order of the solid sorbents for absorbing NO is as follows

(in order of increasing ability):

LiCO^, NagCO ^5 K g C O ^ , de­

composed NaNO^ + F e g O ^ , NagCO^.+ FbgO^, KgCO^ + FegO^, NagCOg +

M n O g , KgCO

5.

+ M n O g , KMnO^.