Azeotropic separation of xylenes from reformed gasoline by Jay Leslie Gleason

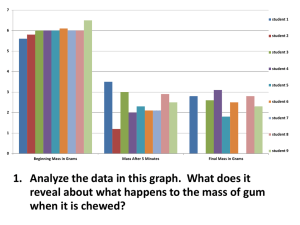

advertisement