Hydrodenitrogenation of indole and quinoline with a nickelous chloride -... catalyst system

advertisement

Hydrodenitrogenation of indole and quinoline with a nickelous chloride - gaseous hydrochloric acid

catalyst system

by Thomas Joseph Buller

A thesis submitted to the Graduate Faculty in partial fulfillment of the requirements for the degree of

MASTER OF SCIENCE in Chemical Engineering

Montana State University

© Copyright by Thomas Joseph Buller (1973)

Abstract:

A supported NiCl2- gaseous HC1 catalyst was used in the hydro-denitrogenation reactions of indole, a

nonbasic compound, and quinoline, a basic compound. The reactions were carried out at a reactor

temperature of 400&deg,C; a reactor pressure of 850 psig; space velocities of 4.0, 1.6, 1.0, and 0.7275

LHSV; a hydrogen rate of 500 SCF/bbl of liquid feed; a chloride to nitrogen content of eight to one;

and using p-xylene as the carrier oil.

Nitrogen compositions were determined by a Kjeldahl analysis and a Mohr test was used to determine

chloride contents. The amine forms of basic and nonbasic nitrogen compounds from indole and

quinoline runs were isolated. These compounds were then identified using gas chromatography and

mass spectrometry.

In this research, nitrogen was found easier to remove from the product oil of quinoline than indole at

4.0 LHSV. However, little difference, was' observed for lower -space velocities.

Different reaction mechanisms were proposed for the denitrogenation of indole and quinoline. It

appeared that hydrochloride intermediates are present in the reaction sequences and that nitrogen leaves

the reaction zone as ammonium chloride. Also, possible limiting steps in the reaction sequences were

proposed. In presenting this thesis in partial fulfillment of the require­

ments for an advanced degree at Montana State University, I agree

that the library shall make it freely available for inspection. I

further agree that permission for extensive copying of this thesis for

scholarly purposes may be granted by my major professor, or, in his

absence, by the Director of Libraries.'

It is understood that any

copying or publication of this thesis for financial gain shall not be

allowed without my written permission.

'i

HYDRODEHTROGEMTIOIf OF IIfDOLE AHD QUIWOLIIfE

WITH A WICKELOUS CHLORIDE - GASEOUS HYDROCHLORIC

ACID CATALYST SYSTEM

"by

Thomas Joseph Buller

A thesis submitted to the Graduate Faculty in partial

fulfillment of the requirements for the degree

of

MASTER OF SCIEWCE

in

Chemical Engineering

\

Apprrared:

Head, Major Department

Chairman, Examing Committee

Graduate“Dean

MOWTAWA STATE UHIVERSITY

Bozeman, Montana

December, 1973

iii

ACKNOWLEDGEMENTS

I would like ter,thank the entire Chemical Engineering staff,

particularly my advisor Dr. F.P. Mc Candless > for their help and

support in this project. 'I would like to thank Mr. J. Tillery andMr. A. Huso for maintaining and repairing the equipment.

Also, I would like to thank the Chemistry departments at hoth

Montana State University and the University of Montana for allowing me

to use their mass spectrometers.

Finally, I would like to thank the Department of Chemical

Engineering and the Petroleum Research Fund for financial support

in this research.

iv

TABLE OF CONTENTS

page

List of T a b l e s ....................

vi

List of F i g u r e s ............................................... vii

A b s t r a c t ...................

I.

II.

III.

ix

Introduction ............................................

I

A.

B a c k g r o u n d ..........................................

I

B.

T h e o r y ......................

3

Research Objectives . . .

.............................

Experimental Apparatus, Procedure, and Analyses.

A.

B.

Materials

8

...

9

• • '...............* ...................

9

1.

Charge S t o c k ............

9

2.

Catalyst and F i l l e r .........................

10

Equipment . . . . . . . . . . . . . . . . . . . .

10

o

C.

D.

IV.

Operating Procedures . . . . . . .

...............

13

1.

Process Conditions ...........................

13

2.

Reactor Charging ........................

14

3.

Reactor Operation

I^

............................

Analytical Methods ............................ .

.

15

Results and D i s c u s s i o n ................................

17

A.

Nitrogen and Chlorine Analyses.....................

17

B.

Identification of C o m p o u n d s ........ .

23

I.

...........

I n t r o d u c t i o n .................... . . . .

23

V

page

2.

Basic Compounds from Quinoline Buna . . . . . . .

23

3.

IfonBasic Compounds from Quinoline Runs

29

ty.

Basic Compounds from IndoleR u n s ................ 33

5-

Ifonbasic Compounds fromIndole R u n s .............. '36

. . . .

6 . Summary ........................................... 38

C.

V.

Reaction M e c h a n i s m s .................................. 39

Summary and Conclusions

VI.

VII.

VIII.

................................... 48

Recommendations for Future W o r k .....................

A p p e n d i x ................................................. 50

Literature Cited

............... ..

. . . ........... 74

49

vi

LIST OF TABLES

page

l6

TABLE I :

Chromatographic Columns.....................

TABLE 2 :

Nitrogen and Chloride Analyses of White Crystal.

. .

17

TABLE 3

:Mass Spectrum

for Trace U of Figure 9

TABLE U

:Mass Spectrum

for Trace 7 and p-Propylaniline . . . . .

TABLE 5

:Mass Spectrum

for Trace U of Figure 1 0 ...........

. 31

TABLE 6

:Mass Spectrum

for Trace 7 of Figure 1 0 ...........

. 33

TABLE 7 : Mass Spectra Data on Traces 3,

............26

28

.and 6 .............33

of Figure' 12

TABLE 8

:Mass Spectrums of

TABLE 9

:Mass Spectrum

Trace 5 and o-Ethylaniline

....

35■

for Trace 7 of Figure 1 2 ............35

TABLE 10 : Mass Spectra Data on Traces S 9 ^ 9 and . 5 .......... 36

of Figure 13

TABLE 11:

Approximate Compositions of Identified Nitrogen.

Compounds

. .

38

vii

LIST OF FIGURES

page

FIGURE I

: Common Heterocyclic Hitrogen C o m p o u n d s ...........

FIGURE 2

: The Electrons in the P Orbitals and

i t

2

............. 7

Clouds of Pyrrole and Pyridine

FIGURE 3 :

Schematic Diagram of Reactor S y s t e m ........ . . . .

11

FIGURE It : Detailed Diagram of the R e a c t o r .................. 11

FIGURE 5

: Effect of Space Time on Hitrogen ..................... 20

Removal from Oil

FIGURE 6

: Curvilinear Regression Line for Quinoline Runs

FIGURE 7

Curvilinear Regression Line for Indole Runs

. . . 21

....

FIGURE 8

: Chromatogram of Mixture of Basic Compounds .........

FIGURE 9

: Chromatogram of Basic Compounds from 1,6 LHSV

22

2b

'• • - 25

- Quinoline Runs

FIGURE 10 :

Chromatogram of Honbasic Compounds from Ir.O . • • . 3 0

LHSV Quinoline Runs

.

FIGURE 11 :

p-Xylene, p-Xylene Dimer, and Ions................. 32

Figure 12

Chromatogram of Basic Compounds from 1.6 LHSV •, * - 34

Indole Runs

FIGURE 13 :

Chromatogram of Honbasic Compounds from 1.6 LHSV

Indole Runs

• 37

viii

page

FIGURE

:

Possible Reaction Mechanism for Quinoline . . . .

hi

Hydrodenitrogenation

FIGURE 15 :

Possible Reaction Mechanism for Indole

Hydrodenitrogenation

........

43

ix

ABSTRACT

A supported NiClg - gaseous HCl catalyst was used in the hydrodenitrogenation reactions of indole, a nonbasic compound, and quinoline,

a basic compound.

The reactions were carried out at a reactor tempera­

ture of 400°C; a reactor pressure of 850 psig; space velocities of 4.0,

1.6, 1.0, and 0.7275 LHSV; a hydrogen rate of 500 SCF/bbl of liquid feed;

a chloride to nitrogen content of eight to one; and using p-xylene as the

carrier oil.

Nitrogen compositions were determined by a Kjeldahl analysis and

a Mohr test was used to determine chloride contents.

The amine forms of

basic and nonbasic nitrogen compounds from indole and quinoline runs were

isolated.

These compounds were then identified using gas chromatography

and mass spectrometry.

In this r e s e a r c h n i t r o g e n was found easier to remove from the product

oil of quinoline than indole at 4.0 LHSV. However, little difference,

was' observed for lower -space velocities.

Different reaction mechanisms were proposed for- the denitrogenation

of indole and quinoline. It appeared that hydrochloride intermediates

are present In the reaction sequences and that nitrogen leaves the

reaction zone as ammonium chloride. Also, possible limiting steps in the

reaction sequences were proposed.

I- INTRODUCTION

A.

BACKGROUND

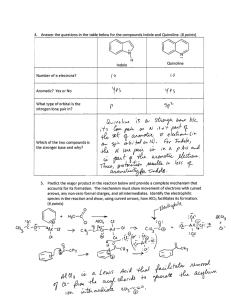

Indole and quinoline are heterocyclic nitrogen compounds which have

been found in fossil fuel stocks.

Indole, a nonbasic compound, has been

isolated in petroleum crude oil'(28) and in coal tar (3 ).

Quinoline, a

basic compound, has been identified in crude oil (2k, 28), coal tar (3),

and in hydrocracked shale oil (4, 7)•

The structure and other signifi­

cant data on both these compounds as well as on other important nitrogen

bases and nonbases are presented in Figure I.

Nitrogen compounds are' not desirable in fossil fuel stocks.

There

is now: much evidence to suggest that the nitrogen in fuels is as important

as the nitrogen in air in the formation of nitrogen oxides during combus­

tion (.10, 3l).

Nitrogen oxides in the presence of sunlight undergo a

photochemical reaction with hydrocarbons to form smog.

Also, in the

petroleum industry, nitrogen is a poison for many catalysts.

Its effect

is most notably seen in catalytic reforming where nitrogen decreases the

isomerization efficiency of dual-functional catalysts (2, 12, 15).

Today, with the United States experiencing a domestic shortage of

production crude oil, different sources of energy must be found.

One

potential source is the Green River shale oil formation of Colorado, Utah

and Wyoming.

It contains an estimated one trillion barrels of oil.

However, it also contains 2.k percent nitrogen (?)•

Before this oil can

be utilized, the nitrogen content must be reduced considerably.

Hydrodenitrogenation has been found to be the best way of removing

nitrogen from petroleum stocks (12).

In this destructive hydrogenation

basic

c o :-:i’

o u ;:d :

Aniline

79. :o

m.p.

116 C

Quinoline

m.v. 93.13

m. p.

b.p. l8L C

129.16

Indoline

119.17

m.p. -16 C

237 c

NOMBASIC COMPOUNDS

Pyrrole

. 67.09

-2h C

b.p. 131 C

Indole

m.v. 117.15

m.p. 52 C

b.p. 253 C

FIGURE I: Common Heterocyclic Nitrogen Compounds

Carbazole

. 167.21

m.p.

- 3 -

process the most widely used catalysts are cobalt molybdate, nickel

molybdate, and nickel tungsten sulfide.

These catalysts systems

generally denitrogenate nonbasic compounds easier than basic ones (12).

Also, most nitrogen from these treatments ends up as ammonia.

These

systems are also better suited for desulfurization than denitrogenation.

This department, in hope of finding a better denitrogenation

catalyst system, has been, doing work on a niekelous chloride-gaseous

hydrochloric acid catalyst system since 1966 (11,19,20).

This work has

primarily been aimed at determining, the operating variables for maximum

denitrogenation.

However, work has also been done to determine the

relative ease of denitrogenating a number of heterocyclic nitrogen

compounds.

1)

This system has shown some unusual characteristics:

Basic compounds are generally easier to denitrogenate

than nonbasic compounds.

2)

There is a higher denitrogenation than desulfurization

activity.

3)

Hydrochloride intermediates are suspected in the reaction

sequence.

H)

Nitrogen appears to leave the reaction zone as ammonium

chloride.

The work detailed in this report has been done to find a mechanism to

account for these characteristics.

B.

THEORY

In understanding the mechanism proposed in this report, "basicity"

- 4 -

Pyrrole P Electrons

Pyrrole

it

Clouds

Pyridine

it

Clouds

unshared

electrons

Pyridine P Electrons

FIGURE 2: The Electrons in the P Orhitals and u Clouds

of Pyrrole and Pyridine

- 5 is a very important concept.

Generally, heterocyclic compounds are

arbitrarily classified as "basic" or "nonbasic" by their ability to

react with a perchloric acid-acetic acid solution.

Basic compounds

can react with this solution and nonbasic compounds can not.

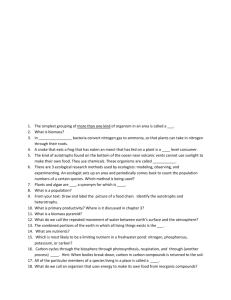

The reason for this difference can be found by studying the

electronic configurations of the pyrrole and pyridine carbon and

nitrogen atoms.

As can be seen from Figure I, pyrrole and pyridine

are very similar in molecular structure to indole and quinoline

respectively.

In pyrrole, a nonbasic compound, the electronic configurations

the carbon and nitrogen atoms are as follows:

Is

CARBON

(y)

2s

g)_o_g, o

sp

Is

NITROGEN

2p

2

hybridization

2s

2p

-O O 0,0

sp

2

hybridization

- 6 Each carbon and nitrogen atom is bonded to three other atoms by a

bonds using the trigonal-planar, sp

2

hybridization orbitals.

This

leaves one electron in a p orbital for each of the four carbon atoms

and two electrons in a p orbital for the nitrogen atom.

these six p orbitals gives rise to a

of the molecule.

cloud above and below the plane

it

The electrons in the

sharred by all five atoms (3).

Overlap of

it

clouds are delocalized and

This gives a stabilizing effect to

the ring known as an "aromatic sextet."

It should be noted that in

pyrrole there are no unsharred electrons in the outer valence state.

In pyridine, a basic compound, the electronic configuration of

the carbon and nitrogen atoms is as follows:

CARBON

0 O OQO

sp

NITROGEN

hybridization

O ,O O 0,0

sp hybridization

As can be seen only the electronic configuration of the nitrogen atom

has changed.

In pyridine nitrogen in bonded to only two other atoms and

- 7 only one electron in a p orbital is needed to complete the aromatic

sextet.

Therefore, there are two unshared

orbital which can be shared with acids (3).

orbitals and the

tt

electrons in the sp

2

The electrons in the p

clouds of pyrrole and pyridine are shown in

Figure 2.

Since the basic or nonbasic classification is an arbitrary one

and since some heterocyclic nitrogen nonbases can react with strong

acids, a more universal definition of basicity will be used.

report, the Lewis theory of basicity will be used.

Lewis stated that

a base was anything which has an unshared pair of electrons.

and quinoline fit this classification.

For this

Pyridine

Lewis also stated that an

acid was anything which could attach itself to such a pair of electrons.

For instance:

+

HCl

Pyridine

Base

Pyridine

Acid

Hydrochloride

Pyrrole and indole while not forming salts with even strong acids cannot

be considered acids so the classification of "nonbase" will be used for

these compounds.

II.

RESEARCH OBJECTIVES

The primary objective of this research was to identify intermediate

compounds in the hydrodenitrogenation of indole and quinoline which then

could be used to speculate as to possible reaction mechanisms.

Other

objectives were to prove the existence of. ammonium -chloride and hydro­

chloride intermediates.

III.

EXPERIMENTAL APPARATUS, PROCEDURE AND ANALYSIS

MATERIALS

I.

Charge Stock

The two nitrogen compounds used in this work were indole and

quinoline.

They were chosen because they are both found in coal

tar and crude oil and because they are both available in large

quantities, in pure form, and at reasonable prices. The nonbasic

compound indole was obtained in reagent grade from the Aldrich

Chemical Company.

The basic compound quinoline was supplied by

the J. T. Baker Chemical Company in reagent grade.

The carrier oil initially chosen was "Peneteck" a commercial

mineral oil produced by the Pennsylvania Refining Corporation.

However, this oil proved to be unuseable since it interfered with

some nitrogen peaks on the chromatograph.

Therefore, p-xylene, a

compound with a retention time less' than the nitrogen compounds was

selected.

This compound was obtained 99% pure from the Chevron

Chemical Company.

The charge stock also included methylene chloride and hydrogen.

Some of the hydrogen reacted with the methylene chloride to form

gaseous hydrochloric acid under the reactor conditions.

Hydrogen

was supplied in 2000 psig cylinders by H . R. Oxygen Supply of

Billings,

Montana.

The methylene chloride was obtained in

reagent grade from the J. T. Baker Chemical Company.

H

O

pump

flask

scrubbers

FIGURE 3: Schematic Diagram of Reactor System

11

pressure gauge

rupture disk

aluminum block

catalyst support

thermowell

catalyst pellets

I controller

insulation

metal can

heating coils

Variac

glass-wool plug

section for NE,Cl accumulation

support rod

FIGURE I4: Detailed Diagram of the Reactor

- 12

2. . Catalyst and Filler

The catalyst used in this work was prepared hy Fedoruk (ll).

He impregnated HiClg on a 1/8 hy 1/8 inch Harshaw alumina pellet.

He determined the nickel content of the pellets to he 7.72 percent.

By using only this catalyst, the nickel content of the pellets was

eliminated as a variable in this work.

The Norton Company supplied the filler.

It consisted of inert

alumina pellets and was used to support the catalyst pellets in the'

reactor.

B.

EQUIPMENT

A schematic diagram of the equipment is shown in Figure 3.

The

liquid charge stock was pumped into the top of the reactor by a Lapp

diaphragm pump.

cylinder.

Here the liquid combined with hydrogen from a pressurized

The' hydrogen rate was measured on a calibrated. Brooks high-

pressure gas rotameter after the hydrogen had been deoxygenated in an

Englehard deoxo unit and dehumidified in a molecular seive drying unit.

A detailed diagram of the reactor is shown in Figure

A pressure

gauge which measured the reactor inlet pressure was attached to the top

of the reactor.

Also attached was a 2000 psig rupture disc - in the

event of overpressure this disk would depressurize the charge to the

vent system.

The reactor was' a schedule 80, corrosion resistant. Inconel alloy

pipe 52 inches in length and one inch in diameter.

A six inch diameter

aluminum block enclosed the upper 60 percent of the pipe.

Wrapped

- 13 around the block were three heating coils each with a Variac.

The

middle coil was automatically regulated by a Wheelco Capacitrol onoff controller . Extending down the middle of the reactor as far as

the bottom of the aluminum block was a thermowell.

One iron-constantan

thermocouple measuring a temperature in the middle of the reactor

supplied the input signal to the on-off controller.

Three other

thermocouples connected to a Leeds and Worthrup indicating potentiometer

measured the temperature at the t o p , middle and bottom of the reactor.

The product after leaving the reactor passed through a Grove back­

pressure regulator and into a flask.

The liquid was collected in the

flask and the gas first bubbled through a caustic bath to remove the

acidic vapors and then was vented.

C.

OPERATING PROCEDURE

I.

Process Conditions

In order to identify intermediate products from the reactions,

the system was operated at less than optimum nitrogen removal

conditions.

These reduced conditions were:

a)

The reactor temperature was 400°C.

b)

The reactor pressure was 850 psig.

c)

Hydrogen rate was 5000 SCF/BBL of feed.'

d)

The nitrogen content of the feed was 0.66 percent.

e)

The chloride to.nitrogen ratio was eight to one.

f)

Liquid feed pumping rates were 4.0, 1.6, 1.0, and 0.7275

LHSV for-the quinoline runs and 4.0, L. 6 , and 1.0 LHSV

for the indole runs.

2.

Reactor Charging

The 250 ml of filler and 100ml of catalyst used each run were

dried at 400°C for 2k hours.

These were cooled in a desiccator.

In charging the reactor, half of the filler was poured down the

inverted pipe with the thermowell already in place.

Then the

catalyst, followed by the remaining filler, was added.

After each

layer was in place, the side of the pipe was tapped to insure

complete and uniform settling.

Finally, a glass-wool plug and a

stainless steel coll were positioned to support the catalyst and

■filler as the pipe was turned upright.

Then, with the pipe

enclosed in an aluminum block, the heating coils were turned on

and the reactor was brought up to temperature.

3.

Reactor Operation

With all fittings tightly sealed and the reactor at ^OO0G ,

the back-pressure regulator was pressurized to about 825 psig with

hydrogen.

The reactor itself could then be pressurized to 85O psig

inlet pressure-with the selected hydrogen gas flow.

for gas leaks, the feed pump was started.

After checking

By measuring the

volumetric feed rate of the oil, the adjustable stroke on the

piston pump was set to give the desired space velocity.

During

the run, the temperatures in the reactor were closely watched and

the two manual variacs were adjusted to keep the reactor top

and bottom temperatures as close to 400°C as possible.

To insure

- 15 a completely "lined-out" catalyst, 500 ml of feed were reacted

before any product was sampled.

After 200 ml of product oil

were collected, the reactor was "shut down."

This process

consisted of shutting off the hydrogen rate, the feed pump,

and the heating coils..

Also, the reactor system was depressurized.

When the system had cooled, the reactor was emptied and the

entire system was cleaned.

The catalyst and support were

discarded without being reused.

hot water and acetone.

The reactor tube was washed with

With the indole runs material which had

accumulated in the bottom of the reactor and on the support coil

was also saved for further analysis.

D.

ANALYTICAL METHODS

The nitrogen content of the samples was determined by a standard

Kjeldahl method (l8 ),

Two analyses of each sample were run and an

average of the two analyses was recorded.

Kel-paks obtained from

Matheson Scientific Company which contained a weighed amount of K^SO^

and HgO proved to be time saving.

The chloride content of samples was

determined by the Mohr volumetric method (33).

The nitrogen compounds in the product samples were separated into

basic and nonbasic fractions and then concentrated according to a

method outlined by Hartung and others (l4).

These concentrates were

tentatively identified chromatographically.

The unknown concentrates

were injected into the chromatograph and the peaks observed were compared

for retention time with known compounds.

Also, retention data from

- 16 Poulson (24) proved to be quite useful.

The three columns which

proved to be most successful were given in Table I.

TABLE I:

Chromatographic. Columns

Column No.

,

2

I

3

.

Stationary Phase

Carbowax 20M

Carbowax 20M .

Carbowax 2OM

Support

Chromosorb P

Chromosorb P

Chromosorb P

Special Treatment

KOH

KOH

Length

17 ft.

10 ft,

5 ft.

The KOH treatment was applied as outlined by Smith and Radford (26)

to reduce severe tailing of the nitrogen compounds which was encoun­

tered on untreated columns. The treatment was very successful. The

chromatograph used was a Varian Aerograph 200.

The recorder was a

Sargent Model SR.

The primary tool for identifying the nitrogen compounds was

mass spectrometry.

Two mass spectrometers were used in this research.

One was a Varian Model Ch5 which was located in the Chemistry Depart­

ment of Montana State University,

The other was a Variant Model MAT

111 located in the Chemistry Department of the University of Montana.

Both analyzed samples which had passed through one of the columns

described in Table I.

In this way, the samples were separated into

individual compounds before they were analyzed - unless two or more

compounds had identical retention times.

IV.

A.

RESULTS M D DISCUSSION

Nitrogen and Chloride Analyses'

After every quinoline or indole run, a white crystaline solid was

found deposited on the upper section of the support coil and a large amount

of brown solid was found in the bottom of the reactor.

Previous workers

(ll, 19) felt that the white crystal was probably ammonium chloride.

The

data in Table 2 confirms their hypothesis.

TABLE 2:

NITROGEN AND CHLORIDE M L A Y S E S OF WHITE CRYSTAL

% N

% Cl

1st

26.67

66.76

2nd

27.49 '

66.21

3rd

26.95

67.64

Average

27.04

66.87

Standard

Deviation

0.295

0.510

Actual Value

For Ammonium

Chloride

26.18

66.28

The slight deviations of the experimental values from the actual values are

likely due to small bias in the experimental techniques.

Also, ammonium

chloride sublimes at 3^0°C at atmospheric pressure and so would be expected

to .sublime in the upper section of the cooling portion of the reactor.

Previous workers (ll, 19) felt that the brown solid might be hydro­

chloride salts of the basic nitrogen compounds.

Data taken in this work

supports this hypothesis.- For each of the nine indole runs the nitrogen and

- 18 chloride contents of the solid were found.

The nine nitrogen analyses

showed an average content of 12.67% with a standard deviation of 0.365.

The nine chloride analyses showed an average content of 39.46% with a

standard deviation of 1.379.

Nitrogen and chloride analyses were not run

on the solid from the quinoline runs.

It must he noted here that nitrogen

and chloride analyses were calculated on a different basis.

The chloride

samples were dried at IlO0C for one hour before being weighed, but the

nitrogen samples were not dried.

It will be shown later in this report that aniline was identified in

both the quinoline and indole runs.

Aniline in the presence of hydro­

chloric- acid forms aniline hydrochloride (2l).

nitrogen a n d ,27.35% chloride.

values.

This compound has 10.81%

These values are lower than the experimental

However, if some ammonium chloride were present in the brown solid

and if one takes into account the different basis for the nitrogen and

chloride analyses, the experimental values are possible.

In the 4.0 and 1.6 LHSV quinoline runs and the 4.0 LHSV indole runs,

some of the hydrochloride salt, in the form of a very viscous liquid,

flowed into the product flask.

The salt did not usually enter the product

flask until about 500 mis, of feed had been reacted.

The constrictions in

the bottom of the reactor and the back-pressure regulator obviously

restricted the flow of the salt.

Since not all of the salt made it into

the product, flask, it was .decided, to,:exclude the salt in the product flask

from the samples for nitrogen analysis.

This was accomplished by simply

decanting the oil product off the very viscous salt.

However, the data

Percent of Nitrogen Removed

100

Operating Conditions

Pressure: 850 psig

Temperature: ^OO C

Hydrogen Rate: 5000 scf/tbl

Cl/N: 8.0

A indole

Q quinoline

80 H -------------------- 1---------------- ---- 1------------------- 10.0

0.5

1.0

1/LHSV

FIGURE 5: Effect of Space Time on Nitrogen Removal From Oil

1.5

- 20 from the nitrogen analyses of the oil product cannot he looked upon as

kinetic data hut more as solubility data.

standpoint, this data is good.

But from a practial engineering

If this process were utilized in a refinery,

one would only need a holding tank to separate the oil from the hydro­

chloride salt.

'

Figure 5 shows the effect of reactant space time on the nitrogen

removal from the oil.

This figure shows that at low space times (high space

velocities).the nitrogen is more completely removed form the quinoline

product than from the indole product.

the higher space times, little

However, the figure shows that at

difference can he detected.

Figure 5 cannot

he compared with the results of previous workers (ll, 19) since the nitrogen

analyses were run on a different sample.

off the top of a settled oil.

Previous workers drew their sample

However, the samples taken in this research

were from a well mixed oil.

The lines through the data in Figure 5 were constructed hy a curvilinear

regression technique.

Straight lines could have been drawn through the data

hut these lines would have gone above 100% removal for the higher space

times.

The curvilinear regression technique consisted of replotting the

'' *

I + P

data with the same abscissa hut with the ordinate changed to In --------- ,

I - P

where P is the fraction nitrogen removed from the oil. The resulting plots

linearized the data as can be seen from Figures 6 and 7*

A linear regression

technique was used to construct the straight lines through the new data

points.

Then the equations for the straight lines were transformed to the

original variables and plotted in Figure 5*

Besides being curved, these

1+p

I-P

5-0

1.0

“

0.0

0.0

1.0

0.5

1/LHSV

FIGURE 6: Curvilinear Regression Line for Quinoline Runs

1.5

6.0

I/LHSV

FIGURE 7: Curvilinear Regression Line for Indole Runs

j

- 23 -

asymtotically approach 100% nitrogen removal.

The regression calculation

and analysis of variance tables for the data in Figures 6 and J is given

in the appendix.

B.

Identification of Compounds

1.

Introduction

Figure 8 is a chromatogram of a known mixture of basic compounds.

It shows that several compounds can have identical retention times.

Therefore, in this research, mass spectra data was essential to

identify compounds with certainty.

This figure also shows that ^-substituted aniline is more strongly

absorbed on Carbowax 2CM than a ring-substituted aniline.

o-Methyl-

aniline has a longer retention time than N-methylaniline.

Likewise,

p-propy!aniline has a longer retention time than N-n-propylaniline.

The reason for this is that- a primary nitrogen is more strongly

absorbed than a secondary nitrogen.

It should be noted that in subsequent identification of basic

nitrogen compounds the amine forms of the compounds are identified.

However, as was shown earlier, the basic nitrogen compounds leave

tlie reactor in their hydrochloride salt forms.

The amines are formed

by treating the salts with a dilute potassium hydroxide solution.

In this paper,, in order to avoid confusion between chromatogram

"peaks" and mass spectrum "peaks" the former will be referred to as

"traces."

2.

Basic Compounds from Quinoline Runs

Figure 9 is a typical chromatogram of the basic compounds from a

Chromatograph Variables:

Temperature: 222 C

Helium Flow: 30ml/min

Column: 17-ft Carbowax 20M

ro

I

F I GURE 8:

I: Syringe cleaning solution

2: Aniline

N-Methylaniline

N-Ethy1-o-toluidine

3: o-Methylaniline

N-n-Propylaniline

I+: o-Ethylaniline

5: p-Propy!aniline

Quinoline

6: 1,2,3, ^-Tetrahydroquinoline

C h r o m a t o g r a m of M i x t u r e of Basic Compounds

Chromatograph Variables:

Temperature: 220 C

Helium Flow: 30ml/min

Column: 17-ft Carbowax 20M

I: Syringe cleaning solution

2: p-Xylene

3: Aniline

U: H-Allylaniline

5: Unknown

6: Unknown

7: o-Propylaniline

8: Quinoline

9: a Methylaniline

10: 1,2,3,4-T etrahydroquinoline

I

M

vn

I

FIGURE 9:

Chromatogram of Basic Compounds from 1.6 LHSV Quinoline Runs

- 26 -

1.6 LHSV quinoline run.

The aniline, quinoline, and 1,2,3,^-tetra-

hydroquinoline traces were identified by comparing the retention times

and mass spectra data of the traces with those of the pure compounds.

Trace 4 is postulated to be N-allylaniline.

A comparison of

Figures 8 and 9 shows that trace H has a retention time similar to

O-methylaniline and N-n-propylaniline.

However, the mass spectrum

for this compound as listed in Table 3 corresponds to neither 0methylaniline or N-n-propylaniline.

TABLE 3:

M/E

MASS SPECTRUM FOR TRACE b of Figure 9

Relative Intensities

Comments

77

32

78

17

79

20

IOif

13

105

24

106

100

107

62

117

27

118

i4

132

45

133

38

146

7

Contamination

147

7

Contamination

Mass spectra■data for o-methylaniline, N-n-prppylaniline, and several

other compounds is listed in the appendix.

the base peak for the compound is 106.

As can be seen from Table 3,

This base peak is typical of

- 27 substituted anilines (5).

The parent peak of 133 with a large 132

peak is very similar to I ,2,3,H-tetrahydroquinoline.

However, the

retention time is wrong for this compound to be 1 ,2 ,3 ,4-tetrahydroquinoline.

Therefore, a compound must be found with a molecular weight of

1.2.3.4- tetrahydroquinoline and a retention time of N-n-propylaniline.

The obvious answer is a N-substituted aniline with an unsaturated

three-carbon side chain.

One possible candidate is N -allylaniline.

This compound could easily be formed by opening the pyridine ring of

1.2.3.4- tetrahydroquinoline.

1,2,3,4-Tetrahydroquinoline

N-Allylaniline

Traces 5 and 6 were not large enough to be analyzed on the mass

spectrometer but these might be o-methylaniline and o-ethylaniline

based on retention times.

The mass spectrum for trace T is listed in

Table U along with data for p-propy!aniline.

- 28 TABLE k:

MASS SPECTRA DATA FOR TRACE 7 AHD p-PROPYLANILIRE

Trace 7

m/e

p-Propylaniline

Relative Intesities

m/e

Comments

Relative Intesities

55

3

55

4

77

27

77

11

79

14

79

9

106

100

106

100

107

12

107

10

118

9

118

5

135

18

135

18

lk6

15

Contamination

I k rJ

12

in trace 7

Table U shows that trace 7 has more than one compound.

However,

it also shows that the major compound in trace 7 is very similar to

p-propylaniline.

A mass spectra comparison with N-n-propylaniline

would be good, but the retention time, would rule it out.

However, the

retention time for p-propylaniline corresponds to trace 8 and not trace

7.

But o-propylaniline could have a retention time like that of trace

7 and would have a similar mass spectrum.

With the propyl group in

the ortho position to the primary nitrogen there could be a shielding

effect to reduce the absorption of the nitrogen.

Thus o-propylaniline

probably has a shorter retention time than p-propylaniline.

Un­

fortunately, no o-propylaniline was available to test the hypothesis.

Trace 9 could not be isolated sufficiently from trace 8 to get a

separate mass spectrum.

However, the mass spectrum of trace 8 has

- 29 contamination peaks at lk2 and 1^3 corresponding to 15% and 22%,

respectively, of the quinoline base peak, 129.

Peaks 11+2 and 11+3

correspond to a methyIquinoline.

When programming the column temperature on the 5-foot Carbowax

column, traces were visible beyond I ,2 ,3 ,4-tetrahydroquinoline which

were too broad on the large column to be seen.

These traces were

invariably composed of more than one compound.

However, large

mass peaks were observed at 156, 157, 170 and 171.

The first two

numbers correspond to a dimethy!quinoline or an ethylquinoline.

The

last two correspond to a trimethylquinoline, a methylethylquinoline,,

or a propylquinoline.

It is interesting to note that Ryffel (25) identified aniline,

o-methylaniline,oo-ethylaniline, o-propylaniline, quinoline and

1, 2j3,l+-tetrahydroquinoline in the product oil of a destructive

hydrogenation of quinoline over a cobalt-molybdate catalyst.

3..

Honbasic Compounds from Quinoline Runs

A chromatogram from a 4.0 LHSV quinoline run is given in. Figure 10.

A 1.6 LHSV run was used in all the other identifications.

However,

with the quinoline runs the nonbasic compounds were such a m i nor'

fraction of the product that the 4.0 LHSV runs had to be used to obtain

a chromatogram with visible traces.

Traces I .and 2 of Figure 10 are p-xylene and an unknown compound.

Trace 3 has not been identified.

A mass spectrum of trace 3 has a

base peak of l4l with other significant peaks at 115, 139, 142, l43

Chromatograph Variables:

Temperature: 221 C

Helium Flow: 50 ml/min

Column: 10-ft Carhowax 20M

I:

2:

3:

U:

5:

p-Xylene

unknown

unknown

Dimer of p-Xylene

a Methylindole

6: a CgH -indole

I

I

U)

I

*

FIGURE 10:

Chromatogram of Nonhasic Compounds from 1+.0 LHSV Quinoline Runs

- B l ­

and 1 U 5 .

Trace 4 is probably the dimer of p-xylene.

Table 5 is a mass

spectrum for this trace.

TABLE 5:

MASS SPECTRUM FOR TRACE h OF FIGURE 10

m/e

Relative Intensities

89

8

91

7

103

11

10 U

■

10

105

100

106

11

118

27

180

11

195

29

210

31

Figure 11 shows the structure and molecular weight of p-xylene,

the p-xylene dimer, and some fragmentary ions.

The mass to charge

ratio of these ions agrees with those of the mass spectrum for trace 4.

No p-xylene dimer was available to compare for retention time or mass

spectrum, but it is strongly suspected that the trace is the dimer.

Trace 5 seems to be a methylindole.

A mass spectrum of the trace

had a base peak of 130 with 131 as another large peak.

Dimethylindole or ethylindole appears to be the main constituent of

trace 6 .

However, as can be seen from Table 6 , a methylindole and a

C^H^-indole are also present.

CH3X o y c H 3

CH3X o y c H 2-CH2X o y c H 3

p-Xylene

p-Xylene Dimer

210

106

CH3~<roy CH2~ CHQ -^o V

CH3-<5>-

M - CH

195

91

CHy-tCcT)- CH 2“ CH 2 *

119

CH3—<^0^>—CH2 *

105

•< 2 ) - CH2 - CH2- CS> •

180

FIGURE 11:

p-Xylene, p-Xylene Dimer, and Ions

- 33 -

TABLE 6:

MASS SPECTRUM OF TRACE 6. OF FIGURE IO

m/e

k.

Relative Intensities

Comments

103

11

115

11

130

39

Methylindole

131

9

Methylindole

143

19

144

100

CgH^-Indole

145

59

CgH^-Indole

157

i4

C^Ht-T-Indole

158

22

C^Ht-T-Indole

Basic Compounds from Indole Runs

A typical chromatogram of the basic compounds from a 1.6 LHSV indole

run is presented in Figure 12.

The identification of these traces was

done in the same manner as with the basic traces from the quinoline

runs.

TABLE 7:

Trace No.

Mass spectra data on traces 3, 4, and 6 is present in Table %.

MASS SPECTRA ON TRACES 3, 4, and 6 OF FIGURE 12

Compound

Parent

Peak

Base

Peak

Other Major

Peaks

93

93

64, 65, 66

77, 79, 89

3

Aniline

4

o-Methylaniline

■107

106

6

o-Propy!aniline

135

■ 106

107, 120, 121, 129

Trace 5 is largely but not exclusively o-ethylaniline.

The mass spectrum

of this trace along with that of pure o-ethylaniline is presented in

Table 8 .

vt

Chromatograph Variables:

Temperature: 221 C

Helium Flow: 30 ml/min

Column: 17-ft Carhowaoc 20M

u>

I

I: Syringe cleaning

solution

2: p-Xylene

3: Aniline

^ : o-Methylaniline

5: o-Ethylaniline

6: o-Propylaniline

a C_H„-aniline and

a C)H^-aniline

height trace 3

2.65 height trace It

FIGURE 12:

Chromatogram of Basic Compounds from 1.6 LHSV Indole Runs

- 35 -

TABLE 8 : MASS SPECTRUMS OF TRACE 5 AND 0--ETHYLAUILINE

Trace 5

m/e

o-Ethylaniline

Relative Intensities

77

21

78

m/e

Relative Intensities>

77

21

6

78

5

79

21

79

14

91

k

91

4

106

100

106

100

107

67

107

9

k

120

4

121

id

121

39

122

1

122

4

120

■

,■

, It is probable that the contamination is o-methylaniline.

Commen-

Contaminat ion of

Trace 5

This

compound has a parent peak. 107 almost as intense as its base peak

106.

Also, the o-methylaniline and o-ethylaniline traces overlap as

can be seen from Figure 12.

/

The mass spectrum for Trace J is presented in Table 9•

MASS S P E C T R U M FOR TRACE r

J OF FIGURE 12

TABLE 9:

m/e

Relative Intensities

13

91

93

Comments

'

12

106

100

107

36

120

' 6l

121

12

134

23

a C^H^-Aniline

135

38

a CgH^-Aniline

149

16

a C^H^-Aniline

- 36 -

This trace seems to be composed of a C^H^-aniline and a C^H^aniline.

Hartung and coworkers (lU) hydrogenated indole using a supported,

sulfactive catalyst under the relatively mild conditions of 300 psig. ,

315°C, and 4.0 LHSV.

The basic products which they isolated were

H-ethyIcyclohexylamine , n-octylamine, g-cyclohexylethylamine, 3-phenylethylamine, o-ethylanilines indoline, quinoline, dimethylquinoline,

1,2,3,4-tetrahydroquinolihe , and indole (from an indole polymer).

5.

Honbasic Compounds from Indole Runs

A typical chromatogram of the nonbasic compounds from a 1.6 LHSV

indole run is given in Figure 13.

The identification of these traces

was done in exactly the same manner as with the nonbasic traces from

the quinoline runs.

The mass spectra data on traces 3, 4, and 5 is

presented in Table 10.

TABLE 10:

Trace Ho.

MASS SPECTRA DATA OH TRACES 3, 4, and 5

Compound

Parent

Peak

Base

Peak

Other Major

Peaks

3

Dimer of p-Xylene

210

105

106, 118, 165, 195

4

a Methylindole

131

130

101, 102, 103

a CgH^-Indole

145

l44

103, 115, 117, 130

5

'

Chromatograph Variables:

Temperature:

221 C

Helium Flow:

50 ml/min

Column:

10-ft Carhowax 20M

FIGURE 13:

I : p-Xylene

2: Unknown

3: Dimer of p-Xylene

4: a Methylindole

5: a C ^ -indole

Chromatogram of Nonhasic Compounds from 1.6 LHSV Indole Runs

- 38 -

With the 5-foot Carbowax column small traces appeared which were

not visible on the longer columns.

These traces had mass spectra

numbers equivalent to carbazole (167) and to methylcarbazole (l80 and

l8l).

Hartung and coworkers (l4) identified the following nonbasic

compounds from their work: • 3-isopropylindole, indole, 1,3-dimethyl2-ethylindole, 3-propylindole, 1-ethylindole, 2-tert-butylindole,

other indole types, and carbazole types.

Si

Summary of Identification of Nitrogen Compounds

A listing of the identified nitrogen products along with their

approximate compositions, which were calculated using peak heights,

is presented in Table 11.

TABLE 11:

APPROXIMATE COMPOSITIONS OF IDENTIFIED NITROGEN COMPOUNDS

QUINOLINE RUNS

Basic Compounds

I .6 LHSV Runs

Compound

Nonbasic Compounds

4.0 LHSV Runs

Composition

Compound

Composition

Aniline

29.1%

a Methylindole

16.1%

N-Allylaniline

29.6

a CgH [.-Indole

83.9

o-propylaniline

11.7

a C^H^-Indole

Trace

Quinoline

Methylquinoline

11.3

6.1

1,2,3,4-Tetrahydro

quinoline

12.2

CgH ,.-Quinoline

Trace

CgH^-Quinoline

Trace

100.0

•

100.0

-

— 39 —

TABLE 11:

APPROXIMATE COMPOSITIONS OF IDENTIFIED NITROGEN COMPOUNDS (Cont).

INDOLE RUNS

Basic Compounds

1.6 LHSV Runs

Compound

Nonbasic Compounds

4.0 LHSV Runs

Composition

Compound

Aniline

57.4#

a Methylindole

o-Methlaniline

21.'6

a CgH^-Indole

o-Ethylaniline

' 12.4

o -Propylaniline

8.6

a C^H^-Aniline

Trace

a C^Hg-Aniline

Trace

Composition

45.2#

'

54.8

Carbazole

Trace

Methylcarbazole

Trace

100.0

100.0

The one major surprise of this listing is the absence of indole and

indoline from the indole slate.

This fact combined with the fact that

quinoline and 1 ,2 ,3 ,4-tetrahydroquinoline are present in the quinoline

slate suggests that different mechanisms are involved in the hydrodenitrogenation of quinoline and indole and that basicity must play

an important role in this difference.

C.

Reaction Mechanisms

The nickelous chloride-gaseous hydrochloric acid catalyst behaves as

dual functional catalyst.

It contains sites for a hydrogenation function

and for an acid function.

The hydrogenation function is responsible for

hydrogenation and dehydrogenation reactions.

The acid function is

responsible for cracking, isomerization,, and polymerization reactions (2 ).

With this catalyst system, the following sites for hydrogenation and

acidic activities are possible:

-UoHYDROGENATION

ACIDIC

I)

Ni

HCl

2)

H+ (NiCl3 )-

H+ (NiCl3 )-

3)

H+ (NiClgOH)-

H+ (NiClgOH)

These site combinations all involve nickel and hydrochloric acid.

The

reason for this is that McCandless (19, 20) showed that "a minimum amount

of nickel and a minimum partial pressure of HCl are required for good

denitrogenation activity."

With the first of the above site combinations the hydrogenation

/

functions would take place at a nickel site on the catalyst surface.

The

acidic functions could take place either where hydrochloric acid is

absorbed on the catalyst surface or possibly in the gas phase with gaseous

hydrochloric acid.

In either case, the nitrogen compound would have to

migrate or diffuse from the nickel site to the hydrochloric acid site in

order for the denitrogenation reaction to go to completion.

With the last two active sites an entire denitrogenation reaction

could conceivably take place at one location on the catalyst surface.

The H+ (NiClgOH)

liquid feed.

site is possible since there might be some water in the

Unfortunately, this research did not obtain the type of data

necessary to identify the site combination actually present on the surface

of this catalyst.

Using•the product slates in Table 11 possible reaction mechanisms for

the denitrogenation of quinoline and indole were postulated in Figures

and 15, respectively.

These mechanisms are very similar.

The primary

lU

NiCl

HCl Co)

Salt of Quinoline

Quinoline

I ,2-Dihydroquincline

I ,2,3,^-Tetrahydroquinoline

-continued-

FIGURE l U :

Possible Reaction Mechanism for Quinoline

Hydrodenitrogenation

- 1*2 -

-continued-

-N-CH-C=CH1

Salt of

N-Allylaniline

Salt of o-Propylaniline

Propane

Salt of Aniline

+

Benzene

FIGURE ll+:

NHi Cl

+

Ammonium

Chloride

Possible Reaction Mechanism for Quinoline

Hydrodenitrogenation (cont.)

NiCli

Indole

Indoline

NiCl

Salt of Indoline

Salt of

o-Ethylaniline

-continued

FIGURE 15:

Possible Reaction Mechanism for

Indole Hydrodenitrogenation

-W-

Methane

Salt of

o-Methylaniline

Salt of Aniline

Ethane

Salt of Aniline

EH, Cl

Ammonium

Benzene

FIGURE 15:

Chloride

Possible Reaction Mechanism for Indole

Hydrodenitrogenation (cont.)

EiCl

difference is that indole must first be reduced to a basic compound

before it can react with the active site H+ '(NiCl ) .

being a basic compound can react directly.

However, quinoline

One might speculate that it

is this reduction step which causes indole to be more difficult to

denitrogenate at 4.0 LHSV than quinoline.

However, since indole was not

identified in the 4.0 or 1.6 LHSV product oil from the indole runs, it is

likely that indole was reduced quickly and irreversibly.

Therefore, the

reduction step would not be the limiting step in the reaction sequence.

In Figure I4

the products of reactions 1,3,4 and 5 were identified in

their amine forms.

Also, ammonium chloride., one of the products of reaction

6 , was identified.

I ,2-Dihydroquinoline was not identified but this

compound has been found in the product of a mild reduction of quinoline (25).

It is likely that the salt of I ,2-dihydroquinoline is formed in the reduction

of quinoline but that it is immediately reduced to the salt of I ,2 ,3 ,4-tetrahydroquinoline.

In Figure 15, the products of reactions 3, 4, 5 and the ammonium

chloride from reaction 6 were identified.

indoline was identified.

However,

neither indole nor

.

But this fact could be explained if reactions

1,2, and 3 were fast and irreversible.

Then there would be little indole

or indoline in the reaction product to be identified.

The reactions in Figures I4 and 15 are reasonable.

mechanisms could be possible.

However, other

For instance, it is possible that the

o-methylaniline is an end product and not an i n t o

Jiate in the indole

— 46 —

reaction sequence.

This would mean that reaction 5 would not procede.

Most of the aniline would then come from reaction 4.

A sure way to test

this mechanism would be to react the salt of o-methylaniline at the same

reactor conditions as indole.

Then a comparison of the reaction rates

and product slates would indicate if step 5 is in the reaction sequence.

As such runs and analyses were not made in this research, it is impossible

to positively identify the reaction sequences for the denitrogenation of

indole and quinoline,

The presence of methylated quinolines and indoles in the quinoline

product and high molecular weight anilines, carbazoles, and methylated

indoles in the indole product is the result of destructive alkylation.

Hydrocarbons from cracking reactions react with anilines, indoles and

quinolines.

Methylated indoles and quinolines are harder to denitrogenate

than indole and quinoline (12).

This means that complete denitrogenation

of quinoline and indole would be difficult even at long reactor space time.

Since alkylated anilines were identified in the product oil of indole

and not quinoline runs this would suggest that the denitrogenation of indole

is limited by one of the aniline or methylated aniline reactions.

The

salts of these compounds must have a long residence time in the reactor to

allow alkylation to take place.

Using similar logic, it would appear that quinoline must have a long .

residence time in the reactor to allow quinoline to be .alkylated.

This

would suggest that either the initial reaction of quinoline to form the

-U t salt with the active site or the reduction of this salt to the salt of

I, 2-dihyroquinoline is the limiting reaction.

The former case seems to

he more likely.

If in future work even more reduced conditions were selected and the

product slates for these conditions were obtained for a number of space

velocities then one could speculate with more assurance as ,to possible

limiting reactions.

V.

SUMMABY

and

conclusions

The following conclusions can he drawn from this work on the

hydrodenitrogenation of indole and quinoline:

1.

It is easier to remove nitrogen from the product oil of quinoline

than indole at 4.0 LHSV, hut at lower space velocities little

difference is observed.

2.

Nitrogen leaves the reaction zone as ammonium chloride.

3.

Hydrochloride intermediates appear to he present in the reaction

sequence.

4.

The amine forms of basic and nonbasic nitrogen compounds from

indole and quinoline runs can he isolated.

5.

Different reaction mechanisms with different limiting steps must

he proposed for the denitrogenation of indole and quinoline.

6.

Destructive alkylation reactions seem to occur.

7.

Some of the p-xylene appears to dimerize.

VI.

RECOMMENDATIONS FOR FUTURE WORK

Future work should "be aimed at testing the hypotheses proposed in

this report concerning the type and location of the active sites, the

reaction sequences, and the limiting reactions.

The three programs

outlined "below might be useful.

1.

An intensive analysis of reacted catalyst pellets for nitrogen,

nickel, and chloride content might shed some light on the type

and location of the active sites.

2.

Reaction of proposed intermediate compounds a t .the same reactor

conditions as indole and quinoline and subsequent comparison of

reaction rates and product slates would test hypotheses concerning

reaction sequences.

3.

Analysis of rate data and product slates from the denitrogenation

of quinoline and indole at a number of space velocities and at

less severe "reduced" conditions than those of this research would

test hypotheses concerning limiting reactions in the reaction

sequence.

VIII.

APPENDICES

- 51 -

Linear Regression Calculations for Quinoline

Curvilinear Regression Line (Figure 6)

X = 1/LHSV

1.00

1.375

3 .6864

3.6759

4.1846

. 3.2619

3.5075

3.8275

3.8493

3.0941

3. 6OI 8

3.5638

3.7647

.25

.625

3.2591

n = 12

ZX = 9.75

ZY = 43.2766

X = 0.8125

Y = 3.6064

ZX2 = 10.0313

ZY2 = 157.0639

ZXY = 36.44 i 4

(ZX)2 /n a 7.9219

(ZY)2Zn = 156.0720

(ZX)(ZY)Zn = 35.1622

Zx2 = 2.1094

= .9919

L = Zxy/Zx^ = 0 .606^

Y = Y +

b(X-X) = 3.606k + .6064(X - .8125)

Zxy = 1.2792

- 52 -

Analysis of Variance Table for Quinoline

Curvilinear Regression

\

Source of Variation

Degrees of

Freedom

Sum of

Squares

Mean Square

F_

C

Linear Regression

on Space Times

I

.7757

.7757

36.9k

Deviation from

Linear

2

.0U 82

.02^1

1.15

Pooled Within

Space Times

.8

.1680

.0210

Total

11

.9919

F-test for Slope of Line

Hq

F-test for Fit of Data to Line

: Slope is zero (b = 0)

H q : Fit is good

: Slope is not zero

H^ : Fit is not good

a = .05

a = .05

F

F

c

= 36.9k

Rejection region : We reject

H q if [Fc 3 > 5-32

Conclusion : Reject H q

C

- 1.15

Rejection region : We

reject H q if [Fc ] > k.k6

Conclusion : Accept H0

- 53 -

Linear.Regression Calculations for Indole

Curvilinear Regression

ix =

1+P

-P

.625

2?6555

3.2718

4.2950

2.4)498 ■ 3.0412

4.6469

2.5224

3.7161

5.625

x = 0.625

IY =

Y =

3.2535

29.8522

7)

1.00

.25

X = 1/LHSV

Y = ln(

Line (Figure

n=9

3.3169

IY2 = 103.8046

IXY = 20.5440

(ix)2/n = 3.5156

(IY)2Zh = 99.0171

(IX)(IY)Zn = 18.6576

Ix2 = 0.8438

Iy2 = 4.7875

Ixy = 1.8864

• IX2 = 4.3594

b = Ixy/Ix2 = 2.2356

Y = Y +

b (X-X) = 3.3169 + 2.2356(X-.625)

.

- 54 -

Analysis of Variance Table for Indole

Source of Variation

Curvilinear

Regression

Degrees of

Freedom

Sum of

Squares

Mean Square

F

C

Linear Regression

on Space Times

I

4.2172

4.2172

50.93

Deviation from

Linear

I

0.0736

0.0736

0.89

Pooled Within

Space Times

6

0.-4967

0.0828

Total

8

4.7875

F-test for Slope of Line

Hq

: Slope is zero (b = 0)

H^ : Slope is not zero

■ F-test for Fit of Data to Line

H0 :

HA :

Fit is good ■

Fit is not good

a = .05

a = -05

F q = 50.93

FC =

Rejection region : We

Rejection region : We

reject H q if [Fq ] >'5,99

Conclusion : Reject Hn

U

0.89

reject H q if [F ] > 5-99

Conclusion : Accept

- 55 -

Mass Spectrometry

In a mass spectrometer a beam of electrons bombards a molecule.

The molecule is broken into ions.

The ions have a particular ratio

of mass to electronic charge, or m/e ratio.

Most ions have a charge

of one so that means that the m/e ratio is the mass of the ion.

A

’’molecular ion" or "parent ion" is an ion which has not lost any

mass and has lost only one electron:

+

-

M

+

e

------M

-

+

Se

Molecular

Ipn

A table or plot of all m/e ratios found for a particular

molecule and the respective relative intensities is called a "mass

spectrum".

In a plot of the m/e ratios the peak with the largest

intensity" is called the "base peak".

It is given a value of 100

and all other relative intensities are calculated from it.

the base peak occurs at the molecular ion.

Often

A mass -spectrum for a

molecule can be highly characteristic of that molecule (3)•

This

can be seen by looking at the API mass spectrums (6) and the experi­

mental mass spectrums which follow.

Thus the mass spectrometer is

a very powerful tool for identifying unknown compounds.

- 56 -

EXPERIMENTAL MASS

SPECTRA DATA

Para Xylene

o-Methylaniline

Relative

Intensities

m/e

m/e

23

77

78

79

89

91

92

105

20

12

6

100

8

k

106

7

77

78

79

89

106

107

o-Ethylaniline

Relative

Intensities

21

55

77

78

79

93

io 6

107

135

21

77

78

79

91

7

21

10

100

6l

5 .

lU

4

106

100

107

9

4

39

4 .

120

121

122

N-n-Propylanillne

m/e

Relative

Intensities

m/e

Relative

Intensities

10

20

5

13

4

100

10

18

p-Propylaniline

m/e

55

77

79

106

107

Relative

Intensities

4

11

9

100

10

118

5

135

18

- 57 -

EXPERIMENTAL MASS

SPECTRA DATA

Indoline

1,2,3,^-Tetrahydroquinoline

Relative

■

Relative

m/e________ Intensities___________________ m/e_____________ Intensities

89

17

91

5

90

13

103

4

91

39

104

7

117

28

115

3

118

100

117

11

119

59

118

i4

129

3

130

11

132

100

133

OO

134

5

- 58 -

MASS SPKCTHAL DATA

A m orican Pvtroleum Institute R e s e a r c h Project 4 4

P i t t s b u r g h , Pa.

C a r n e g ie In stitu te of T e c h n o l o g y

C o n t r i b u t e d by t h e St md ird Oil Cynfhmy ( Indi i n a ) , w h i t i n g ,

S n r ia l Na. 123?

A n ilin e ( g i s )

Mass-Chargv

Ratio

(»i 'f)

2

12

U

11*

15

16

21*

25

26

27

28

29

30

31

31.5

32

32.5

33.5

36

37

33

39

1.0

U

12

13

13.5

Ui

Ui.5

IiS

Ii6

16.5

Ii7

M .l

18

Ii9

50

In d ia n a

Typrt

Relative Intensities

fui ivnuiiig %ollsgv» of

volts

70 roll*

.01

of

Peak

Ma.v.Charge

Ratio

(W7C)

Si

52

53

SL

55

.29

.20

.69

1.03

.20

.10

.39

2.06

3.IL

8.OL

.69

.78

.29

.10

.10

.20

d

d

d

60

61

62

63

6L

65

66

67

68

73

7L

75

76

77

78

79

66

67

88

89

90

91

92

.L9

•L9

3.92

7.L5

17.8

6.37

6.18

1.76

.78

.10

.59

1.18

.20

.78

8.82

.19

.10

.10

.69

3.92

d

d

d

m

Tyne

of

Peak

P

I

i

~ 9 ih

95

A n ril

Relative Intensities

fo r ionizing v iiliagrs of

70

ro/fs

Mass ChargRatio

Type

( H l7C)

Peak

rolls

for iom zii.g

70

Viihiigriof

rolls

vo lts

L.Sl

5-30

1.86

L.71

.20

.29

1.67

2.25

I*.61

2.9L

16.3

33.L

L.31

.20

.29

.98

.69

1.15

1.18

1.67

.10

.10

.10

.10

.10

.20

.98

10.6

100.

6.67

.20

Sensitivity for base peak

if

p ip e tte

IH IVifIOHf

93

. ADDITIONAL INFORMATION

RETASTABLE ION TRANSITIONS

L7.1 (93*)->(66*)

'SO. IOStI

Relative Intensities

10?

Spniitjvity for n Hutane

I n d i v i s i o n s p e r m icro n

R e l a t i v e I n t e n s i t i e s f o r C y c lo h e x a n e

427

69

3 1 .1

Relative Intensities for n Butane

81* 100

15

27

29

43

58

S e n s it iv it y in d iv is io n s per p ip e tte

81* 333

r=--rearrangement

m =m etaslable* ion

p --parent peak

i= iso to p e peak

5 .8 4

3 8 .8

4 5 .1

10 0 .

1 0 .6

d= doubly-charged ion

(«1 i t f u s o p e a k )

COMPOUND

M ASS SPLCTKOMKTKH

Name:

M odel:

2 1 -1 0 2

A n il in e

K lcitron l-u r m it

9 3 .1 2

III

Molecular

Weight

( Cltcher ):

SvmI-structural form ula

v o lta g e s:

0 ” "!

Purity

Source:

I

9 .0

mirroomprrr.r

toffs Il (W V)

3692 I 28

2

Tem perature of ionization cham ber:

rolls

1503

----- e C

Basis of pressure measurem,

J . T . Baker C h em ica l Compargr

Hiofr Jn rcrnt

.0 0 1 m l l i q u i d p i p e t t e

LABORATORY:

S ta n d a rd O il Company ( I n d i a n a ) , h l i i t i n g , I n d ia n a

Stt i ll No. W

- 59MASS SPECTRAL DATA

A m e r ic a n Petroleum Institute R e s e a r c h Project 4 4

P ittsb u rg h , Pa.

C a r n e g i e I n s t i t u t e of T e c h n o l o g y

i s n t r i t'utr-J Iiy th e S t .n .i ir.i Oi I Company ( l n j i . 1n .1l ,

N -E thyl i n i I i n e

T yoc

(»|/«*)

T eak

I n J ia m

A p r il 3 0 . I 9 Vb

S e r ia l No. liM 3

( 9 V .)

Mass-Chargv

Ratio

Ahi t i n g ,

MAss-Charge

Ratio

Ri-lati\f* Intensities

fm ionifIhg VoIiMKfI of

2

.3 $

12

13

Iii

15

16

.2 0

.2 9

.6 7

4 .0 0

• 15

2$

26

27

28

29

30

31

.2 9

3 .0 4

1 1 .0

11. b

5 .2 9

3 .1 1

.1 6

37

3 7 .$

38

39

to

U

12

13

14

4 4 .5

45

4 5 .5

46

4 6 .5

1 .3 5

.0 9

3 .7 7

1 2 .1

2 .2 2

2 .6 0

2 .6 6

1 .0 6

2 . 5°

.0 7

.1 3

.2 0

.0 5

.1 8

d

d

d

d

Tvne

of

Teak

(nii i*)

volts

""70 volt*

55

56

57

5 7 .5

58

5 8 .5

59

5 9 .2

5 9 .5

60

6 0 .5

61

62

63

64

65

66

67

68

MiLSS-Chargi

R atio

Relative Intensities

for iomiinp voUhkm of

70

volts

r o ll!

d

d

d

d

71

.0 7

73

74

75

76

77

78

79

80

81

.1 8

1 .1 1

1 .0 6

1 .0 9

2 3 .3

5 .O8

6 . 3b

.6 6

.0 5

BS

.0 5

70

volt*

VO/ttf

.4 7

.2 b

.Ob

9 3 .4

94

95

103

104

105

106

107

IOd

2 .6 6

.9 8

100.

7 .7 6

.1 3

117

n s

H 9

120

121

122

123

.S i

1 .6 4

•8b

6 .3 b

3 6 .5

3 .1 0

.0 9

P

i

I

.0 5

48

49

50

51

5 1 .5

52

$2 .5

$3

a

5 3 .5

si

d

1 4 .6

.1 1

5 .4 1

87

88

89

.0 7

• 0$

.2 9

d

1 0 .7

.7 3

.7 3

91

92

93

2 .7 9

2 .2 4

1 .7 5

Sensitivity for base peak

in divi#lO*« pcA-mw»w p i p e t t e

541

Sensitivity for n-But.ine

i n d i v is i o n !is p e r m icro n

764

A D DITIO NA L INFORM ATION

R e l a t i v e I n t e n s i t i e s f o r C y c lo h e x a n e

HEiTASTAELE ION TRANSITIONS

$ 9 .2

93 .U

T; r

Peak

(" C f)

.1 6

.1 8

.1 8

.0 4

.1 6

1 .1 1

.3 6

.2 7

• b9

.2 2

.9 7

.4 9

1 .0 6

3 .0 6

2 .3 1

8 .3 2

3 .0 1

.5 1

.0 9

Relative Intensities

for lonizmtr V«HI»*«» vI

69

8b

(1 0 6 ‘ ) -» ( 7 9 * )

*27

(1 2 1 * )-9 (1 0 6 * )

*1$

3 1 .b

R elative Intensities for n-Butane

100

T5

zr

22#

43

S e n s it iv it y in d iv is io n s per p ip e tte

8b

SYMBOLS:

6627

r = rearrangement

m = m eta sta b le ion

(ditfnso pink )

P = p a re n t peak

i= iso to p e peak

5 .8 9

3 8 .8

4 5 .1

100.

. 10.6

58

d=douLly-chargtxl ion

M A SS SPKCTKOM KTKH

COMPOUND

21-102

Nam e.

N-EthZ ! a n i l i n e

Electron current (

Molecular

Height

1 2 1 .1 6

Molecular

Formula

CgH1 1 N

___

Semi structural Formula

Ion accelerating

v o lta g e s:

»102115

Purity

Source:

C U cr -e r

'):

9 .0

•irn'e)

2

Temperature of ioni'/ation ch a m b er:

miVroamperes

volts

(m f )

3692

——

28

volts

1508

*-C

Basis of pressure m easurem ent:

S y n t h e a ia

mo/r pvrernt

. 0 0 1 ml l i q u i d p i p e t t e

Date of m easurement

LABORATORY:

S ta n d a rd O i l C ccpany ( I n d i a n a ) , W h itin g , I n d ia n a

I1/2S/511

S v i i.ii Ni..

-SoMASS SPCCTI!AL DATA

AmeitCAn P e t r o l e u m I n s ti t u te Res oA ich P i o j o c t 4 4

P ittsburgh, Pa.

CArnogio I n s t i t u t o ol T e c h n o l o g y

C o n t r i b u t e d by t i e A t l a n t i c R e f i n in g Coipany, fir i IaUel ph ia, P e n n s y lv a n i a

Mavs-Chargv

Ratio

T vp1

On 1r)

Ve1-Ik

.M.iss-Chargi

Ratio

Relative liiirnsito s

fm iunUMig Vultel:' $ of

3(37

38

39

60

a

O43

4 3 .5

U

4 4 .5

45

4 5 .5

46.

47

48

4 8 .5

49

4 9 .5

50

51

52

53

54

55

5 5 .5

5 5 .7

56

5 6 .5

57

5 7 .5

58

5 8 .5

59

5 9 .7

60

61

62

6 2 .5

63

64

November 30, 1951

S e r i a l No. G3d

C a r ba zo le (gas)

7C volt'

.1 2

.9 2

1 .9 0

5 .6 3

2 .6 4

2 .7 6

.8 6

4 .0 8

.0 3

1 2 .5

.0 3

.3 0

.0 8

.0 9

.0 2

.1 7

.0 3

.2 5

.0 3

2 .5 5

3 .0 4

1 .4 2

.8 8

.3 9

2 .3 6

.1 5

.3 6

1 .0 8

.4 0

1 .9 7

.3 9

.5 5

.0 3

.0 5

.0 9

.2 6

.8 6

2 .3 8

.0 2

4 .5 0

1 .1 7

d

d

d

d

d

d

d

d

d

d

(W f)

(6

67

6 7 .5

68

< 8 .5

69

6 9 .5

70

7 0 .5

71

7 1 .5

72

73

74

75

76

7 6 .5

77

78

79

80

81

8 1 .5

82

6 2 .5

83

6 3 .5

64

8 4 .5

85

86

87

88

69

90

91

92

93

94

9 4 .5

95

Rvlativv Intensities

of

Vcak

d

d

d

d

d

d

d

d

d

d

d

for ionizing Viiltagi-S of

volts

Mass-Chargt

Ratio

T- c

(m c)

Peak

rJQ VOlt S

.2 3

1 .2 5

.0 *

.9 9

.2 1

2 .5 4

4 .9 6

2 .3 4

4 .3 6

1 .2 5

.0 2

.0 5

.4 3

2 .0 3

2 .2 0

1 .2 5

.0 3

1 .1 4

.3 3

.4 0

.2 0

.6 3

.1 2

.6 2

3 .2 0

2 .2 1

1 6 .3

2 .3 2

.1 1

.8 8

1 .3 4

1 .8 8

1 .4 9

1 .8 6

.5 6

1 .8 3

1 .1 5

.3 8

.1 6

.0 5

.4 5

Relative Intensities

for ionizing voltage* of

volts

96

97

98

99

102

103

10 4

105

106

107

108

109

HO

111

112

113

«7q volts

.3 6

.6 9

.9 9

.6 9

.4 8

.1 5

.1 5

.2 7

.1 1

.1 8

.U

.3 4

.4 0

.6 9

.5 0

2 .1 7

1 .6 7

1 .8 6

.8 1

.3 1

.0 7

.1 3

.0 4

.1 5

.1 1

IU

115

11 6

117

118

11 9

12 0

121

122

123

124

125

126

127

128

129

130

131

132

134

135

136

.U

.1 3

.2 5

.3 4

.4 3

.3 8

.U

.06

.0 7

.0 5

.0 5

.1 1

.1 2

S e n sitiv ity for base peak

■* divxiiOKt per m u ron

44

167

AS

S e e s itiv ity for n-Butane

ADDITIONAL INFORMATION

35.9

R ela tiv e Intensities for n-Butane

15

27

29

4.3

58

Vapor T e n p er a tu r e - 560°F