Battery active manganese dioxide by chemical synthesis by William G Moore

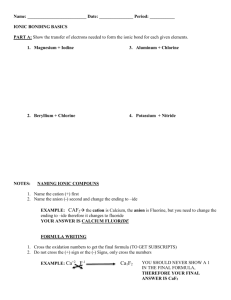

advertisement