Preliminary Design Review E M F

advertisement

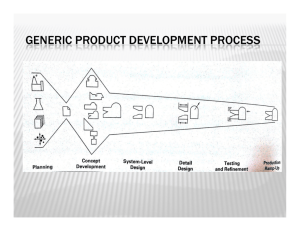

Preliminary Design Review May 7, 2002 Space System Product Development Class Department of Aeronautics & Astronautics, MIT Electro Magnetic Formation Flight Of Rotating Clustered Entities Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Introduction Geeta Gupta Subsystems Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 2 EMFFORCE Mission Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Demonstrate the feasibility of electromagnetic control for formation flying satellites. Subsystems Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 3 Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Definition of Formation Flight A cluster of cooperating satellites flying in a desired formation. Subsystems Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 4 Applications of Formation Flight Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Subsystems Operations Implementation Conclusion Large sensor apertures z Servicing z Can replace failed formation elements individually Upgrade and Maintenance z Can work on individual components without removing whole mission Change formation geometry z 5/24/2002 Increased resolution Evolving mission sensing requirements CDIO3 Class Project 5 Advantages of Formation Flight Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Large baselines to improve angular resolution Smaller vehicles z Redundancy z Subsystems Operations Implementation Conclusion 5/24/2002 Ease of packaging, launch and deployment Mission does not fail if one satellite fails Reconfigurable z z Replace individual space craft Can integrate new technology during mission CDIO3 Class Project 6 Challenges of Formation Flight Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Command and Control z Propellant Drawbacks z Subsystems Operations z Implementation Conclusion z 5/24/2002 Control multiple vehicles’ absolute positions/motion vs.. relative positions/motion Fuel limits lifetime Exhaust particulates contaminate imaging instruments Exhaust creates haze which limits imaging CDIO3 Class Project 7 Introduction Definition of Electromagnetic Control •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Subsystems Operations Implementation Conclusion Implement electromagnetic dipoles to create forces and torques between the vehicles Dipoles can be controlled by varying the amount of current through the electromagnet coil. z z 5/24/2002 Can provide steady forces and torques for maneuverability Can provide disturbance rejection for more precise control CDIO3 Class Project 8 Advantages of EMFF Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Subsystems Operations Implementation Conclusion 5/24/2002 No thrusters Fewer consumables Æ Longer life z Zero pollution Æ No contact contamination Æ No radiative contamination z Controls relative position/motion vs.. absolute position/motion CDIO3 Class Project 9 Challenges of EMFF Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Control Problem z z z z Operations z Ferromagnetic material is heavy Electromagnetic force is weak z z 5/24/2002 Each vehicles’ motion affects all other vehicles Electromagnet Drawbacks Subsystems Implementation Conclusion Unstable – not unique to EMFF Coupled control Force in the far-field drops of as the 4th power of separation distance Electromagnetic interference with other electronic subsystems CDIO3 Class Project 10 Customer Requirements Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Subsystems Operations Implementation Conclusion Multiple Vehicles Representative Formation Flying Vehicles Control to replace thrusters Control three degrees of freedom (DOF), traceable to six DOF Robust controller z z 5/24/2002 Disturbance rejection Reposition vehicles CDIO3 Class Project 11 Constraints Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Subsystems Operations Implementation Conclusion 5/24/2002 Schedule Budget Limited human resources to CDIO class and staff Testing facility No use of umbilical resources; power, air supply, communications Recorded test data Safety of people, facility, and system CDIO3 Class Project 12 Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview System Functional Requirements Musts: z z Shoulds: z Operations 5/24/2002 Representative 5 rotation maneuver z Subsystems Implementation Conclusion Stability with at least three vehicles Control in each relative DOF z One rotation spin-up, 3 rotations steady state, and one rotation spin-down Operate in the far field z Separation distance at least 10x length of electro-magnet CDIO3 Class Project 13 Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Subsystems Operations Implementation Conclusion 5/24/2002 System Operational Requirements Test time 5 minutes Identical interchangeable vehicles Send/record test data Respond to other satellites Respond to user input Demonstrate autonomy Maintain safety CDIO3 Class Project 14 Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Subsystems Operations Implementation Conclusion 5/24/2002 EMFFORCE Testbed Development Approach Conceive and Design EMFFORCE testbed Æ PDR May 7, 2002 Implement testbed Æ CDR Nov., 2002 Operate completed testbed Æ AR March, 2003 z z Operate at MIT Operate at Lockheed Flat Floor Facility in Denver CDIO3 Class Project 15 PDR Purpose Introduction •Mission •Background & Motivation •Requirements Summary •Approach •PDR Purpose •Overview Subsystems To review the preliminary design and identify and resolve high risk elements of the system. Have outside expert review of current progress. Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 16 Space System Product Development Class Actuation Jesus Bolivar William Fournier Lindsey Wolf Melanie Woo Formation Flight Amilio Aviles Andre’ Bosch Oscar Murillo Leah Soffer Electronics Stephanie Slowik Erik Stockham Maggie Sullivan Jennifer Underwood Structure/Power Geeta Gupta Amy Schonsheck Timothy Sutherland 5/24/2002 CDIO3 Class Project Systems Amilio Aviles Jesus Bolivar Geeta Gupta 17 Overview Introduction •Mission •Background & Motivation •Requirements Summary •Approach •Overview Subsystems Operations Implementation Conclusion Sub-System design z z z z Actuation Formation Flight Electronics Structure/Power Operations Implementation z z z z z Resource Tracking Budgets Verification & Validation Schedules Action Items Conclusion 5/24/2002 CDIO3 Class Project 18 Introduction Subsystems •Actuation •Requirements •EM •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Actuation Melanie Woo Reaction Wheel Electromagnet Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 19 Actuation Introduction Subsystems •Actuation •Requirements •EM •Reaction Wheel •Issues •Budgets Estimates •Formation Control •Electronics •Structure/Power EM force induces spin-up of cluster from initial perpendicular orientation RW provides counter torque to balance moments induced by electromagnets Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 20 Introduction Subsystems •Actuation •Requirements •EM •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Actuation Requirements Actuate control of vehicle cluster Magnets must be controllable in necessary DOF No thrusters may be used Electromagnets provide force z Reaction wheel provides torque z Minimize mass and power consumption CDIO3 Class Project 21 Trades – EM Configuration Introduction Subsystems •Actuation •Requirements •EM •Trades •Design •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Possible configurations: z Dipole, Y-pole, L-pole, X-pole Eliminate: z z L-pole: center of mass problem X-pole: mass distribution to 4 dipole legs Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 22 Trades – EM Configuration Introduction Subsystems •Actuation •Requirements •EM •Trades •Design •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Dipole vs.. Y-pole Considerations: z Mass distribution: Force z z z Dipole generates greater force since it energizes larger amount of core mass Y-pole can vary direction of magnetic field without being rotated by reaction wheel Torque z Y-pole generates additional torque to be countered by reaction wheel Implementation Conclusion 5/24/2002 CDIO3 Class Project 23 Trades – EM Core Material •Actuation •Requirements •EM •Trades •Design •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power EM Core Material Induced Field vs. Applied Field Cost Availability Magnetic Properties z z z 2.5 2 B-H curve Bsaturation Permeability Steel vs.. Iron B [Tesla] Introduction Subsystems 1.5 1 0.5 0 0 5000 Operations 15000 20000 25000 30000 H [Amps/m] Implementation Conclusion 5/24/2002 10000 AISI 1010 steel CDIO3 Class Project Remko soft pure iron 24 35000 Modeling Introduction Subsystems •Actuation •Requirements •EM •Trades •Design •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 EM Software: Infolytica MagNet z Input EM configuration and geometry to obtain forces and torques Example: z z z z Y-pole configuration Separation: 2 m Core mass: 19.5 kg Applied current: 10 Amps CDIO3 Class Project 25 Modeling Introduction Subsystems •Actuation •Requirements •EM •Trades •Design •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Energized Coils Results: z Force on A and B equal z z Magnitude: 0.42 N A Torque greater on B than A z z A: 0.052 N-m B: 0.848 N-m B Implementation Conclusion 5/24/2002 CDIO3 Class Project 26 Test Run Video Introduction Subsystems •Actuation •Requirements •EM •Trades •Design •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 27 EM Design Introduction Subsystems •Actuation •Requirements •EM •Trades •Design •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operational Setup Separation: 3m z Spin Rate: 1 RPM z Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 28 EM Design Introduction Subsystems •Actuation •Requirements •EM •Trades •Design •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Magnetic Force for Three Vehicles F mag 3µ oµ Aµ B 3µ oµ Aµ C = + 4 s 4 2 π ( s ) 2π ( ) 2 Set equal to centripetal force Fcent s = Ω ( ) m tot 2 2 Implementation Conclusion 5/24/2002 CDIO3 Class Project 29 EM Design Introduction Subsystems •Actuation •Requirements •EM •Trades •Design •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Substituting in the following relations BVcore Bmcore µ A = µB = µC = = µo µo ρcore And solving for mcore m core Ω ρ core = B m tot πµ o s 5 51 CDIO3 Class Project 30 EM Design Introduction Subsystems •Actuation •Requirements •EM •Trades •Design •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Substituting mtot = mcore+mcoil +mo ρ coil π 4 mcoreα = ( ) H ρ core π C oα 2 m coil 2 3 Where imax Lcore C0 = 2 α= 2rcore πrcoil CDIO3 Class Project m0 = 7 kg 31 EM Design Introduction Subsystems •Actuation •Requirements •EM •Trades •Design •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Substituting z z z B = 2 Tesla α = 10 H = 20000 Solving numerically for mcore yields z mcore = 6.5 kg Solving for core dimensions z z Lcore = .47m rcore = .02m CDIO3 Class Project 32 EM Design Introduction Subsystems •Actuation •Requirements •EM •Trades •Design •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 The applied field is set by the number of amp-turns in the coil Ni = HLcore z z z z Current limited by the wire gauge Number of turns sets coil length and voltage requirements Coil mass proportional to Ni More analysis needs to be done to optimize number of turns CDIO3 Class Project 33 RW Trades Introduction Subsystems •Actuation •Requirements •EM •Reaction Wheel •Trades •Design •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Build vs.. Buy z Will build RW to specifications z z Cheaper Commercial RWs are spacecraft sized Material: Steel vs.. Aluminum vs.. Plastic z Use Aluminum z z Doesn’t interfere with magnetic field Higher density than plastics – RW will not have to be as large CDIO3 Class Project 34 Introduction Subsystems •Actuation •Requirements •EM •Reaction Wheel •Trades •Design •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion System Assumptions for RW Analysis Cluster contains two vehicles Vehicles are modeled as uniform density cylinders Max ΩRW = 2000 rpm ~ 210 rad/s RW is modeled as a ring with a thin plate in the center Ring has square cross section with diameter tring tring 5/24/2002 CDIO3 Class Project rRW 35 System Dynamics Introduction Subsystems •Actuation •Requirements •EM •Reaction Wheel •Trades •Design •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 RWs provides counter torque to balance system: 2 H RW = − H cluster Cluster angular momentum (Hcluster): H = IΩ cluster Cluster moment of inertia (I): 2 s I = 2 I 0 + mtot 2 CDIO3 Class Project 36 RW Dynamics Introduction Subsystems •Actuation •Requirements •EM •Reaction Wheel •Trades •Design •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Moment of inertia of RW (IRW): I RW = mRW rRW 2 1 2 + mRW (rRW − t ring ) 2 RW angular momentum (HRW): 1 2 2 H RW = mRW rRW + mRW (rRW − t ring ) Ω RW 2 RW mass (mRW): mRW = t ring 2πrRW ρ Al 2 CDIO3 Class Project 37 RW Mass vs.. RW Radius Introduction Subsystems •Actuation •Requirements •EM •Reaction Wheel •Trades •Design •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power (kg) mRW = 0.0077 mRW 1 2 − rRW +m 0.5 rRW 2 2 tot = 15kg 2700 π 2rRW 2 Ω = 1rpm = 0.105 rad s Ω RW = 2000 rpm = 210 rad s ρ Al = 2700 kg m s = 2m 3 mtot = 15kg Ω = 0.105rad s ΩRW = 210rad s Operations ρAl = 2700kg m3 Implementation Conclusion s = 2m (m) 5/24/2002 CDIO3 Class Project 38 RW Mass Estimate Introduction Subsystems •Actuation •Requirements •EM •Reaction Wheel •Trades •Design •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power RW has a mass of 0.16 kg given a radius of 0.2 m RW Assembly will not exceed 1 kg - includes motor Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 39 RW Power Analysis Introduction Subsystems •Actuation •Requirements •EM •Reaction Wheel •Trades •Design •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 RW uses power mainly when applying torque – during spin up PRW = τ mag Ω RW Torque induced by dipole (τmag): τ mag = µ A × B Relationship for B-field: µ0 µ B B= 2π x 3 CDIO3 Class Project 40 RW Power Estimate Introduction Subsystems •Actuation •Requirements •EM •Reaction Wheel •Trades •Design •Issues •Budgets •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Magnetic moment (µA): µA = BVcore µ0 Power required by RW (PRW): PRW µ0 µ Aµ B = Ω RW 3 2π x RW power estimate: PRW ≅ 13W CDIO3 Class Project x = 1m L core = 0 . 5 m rcore = 0 . 02 m V core = 6 . 3 × 10 − 4 m 3 Ω RW = 2000 rpm = 210 rad s 41 Actuation Issues Introduction Subsystems •Actuation •Requirements •EM •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 System may not be able to operate in the far field Total mass is large (~15 kg) z Magnet core mass increases rapidly with vehicle mass Magnet temperature must be monitored during operation CDIO3 Class Project 42 Budgets Estimates Introduction Subsystems •Actuation •Requirements •EM •Reaction Wheel •Issues •Budget Estimates •Formation Control •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Part Iron Core Copper Wire RW Assembly Total (vehicle) Cost ($US) 100 Mass (kg) Power (W) 6.5 >120 50 1.5 1000 1 13 1150 9 133 CDIO3 Class Project 43 Control Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Will Fournier Control Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 44 Requirements Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Counteract disturbances Reposition satellites to perform maneuvers One rotation spin-up z Three rotations steady state z One rotation spin-down z Control tolerance to 1/10 separation distance CDIO3 Class Project 45 Design Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Two modes: Steady state Spin-up/De-Spin Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 46 Steady State Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Must model axial dynamics Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 47 Steady State Derivation of Poles for Three Vehicles Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Force Balance 2 mh mv2 Fcent. = = mΩ2 s = 3 s s FEM = Perturbation Analysis m&s& = c0 µavg s 2 4 m(&s&0 + δ&s&) = + c0 µavg (2s) 4 2 − mΩ s 16(s0 + δs)4 s 4 + 2 c0 µavg (2s)4 3µ 0 2π µ A = µ B = µ C = µ avg c0 = 2 17c0 (µ avg+δµavg )2 c0avg mh2 + (s0 + δs)3 c0 µ avg mh2 δµavg mδ&s& − 4 δs = − 4 4s0 s0 CDIO3 Class Project Yields poles at h ± 2 = ±Ω s0 48 State Space Analysis Introduction Subsystems δ s& s 0 0= 2 •Actuation δ &s& Ω •Formation Control •Control s 0 •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 δs 1 s0 + 0 δ s& s 0 0 δµ avg 2Ω 2 µ avg Using the Cost Function: J = ∞ ∫ [x T x& = Ax + Bu ] R xx x + u T R uu u dt 0 And knowing that cost, J, is minimized when 0 = Rxx + PA + AT P − PBRuu−1BT P −1 T u = − Ruu B Px = − Fx Where Rxx describes what states the controller penalizes. Ruu describes the “cost” of actuation. CDIO3 Class Project 49 State Space Analysis Continued Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Choosing: And using: α Rxx = 0 0 0 P11 P= P12 P12 P22 Ruu = ρ Feedback is then: P11 F = R B P = 0 2Ω ρ P12 −1 uu T 1 [ 2 ] CDIO3 Class Project P12 2Ω 2 [P12 = P22 ρ P22 ] 50 State Space Analysis Continued Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Now solve for the closed loop matrix where u = − Fx x& = Ax + Bu = [ A − BF ]x = ACL x Evaluate as α ρ increases from 0Æ ∞ Therefore the closed loop poles for the most efficient controller lie along this curve CDIO3 Class Project 51 Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Steady State Stable Test Setup Stable mode poles at: ± 2 6 µ 0 µ avg πx0 m i CDIO3 Class Project 52 Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power 16.62X Uncontrolled System Step response of plant Negligible damping Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 53 Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power 16.62x Controlled System Phase lead controller Damping ratio: 0.11 ± 0.01 Error caused by distance sensor noise Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 54 Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Steady State Unstable Test Setup Unstable mode poles at: ± 2 6 µ 0 µ avg πx 0 m CDIO3 Class Project 55 Introduction Subsystems Controller for Unstable Test Setup •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Operations Phase Lead Controller Implementation Conclusion p = -20, z = -3, k = 30 Damping = 0.68 5/24/2002 CDIO3 Class Project 56 Spin-up/De-spin Modes Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power More complex Need to model translational forces and torques Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 57 Initial Spin-up Forces Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power S S N N s Operations Implementation Conclusion 5/24/2002 Results in a force and a torque on each magnet CDIO3 Class Project 58 Introduction Subsystems Response to Translational Forces Three regimes of motion •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Two equilibrium points Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 59 Response to Translational Forces Introduction Subsystems F •Actuation trans •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power = 2 3µ 0 µ avg [Sin(α + β )] 4πs Due to the configuration, Ftrans = 0 when α + β = 0, thus when d = ± s 4 Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 60 Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Spin-up Configuration Trade A closer look at the resultant forces on the two dipole configuration S S N N Operations Implementation Conclusion 5/24/2002 s CDIO3 Class Project 61 Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Spin-up Configuration Trade α=0, β=90 µ0µ τB = 8π 2 avg N S 2 µ 0 µ avg τA = [Sin(α − β ) + 3(α + β )] 8π [Sin( β − α ) + 3( β + α )] S B A N s µ0µ [ Sin(α − β ) + 3(α + β )] 2 1 τA π 8 = = = 2 4 2 τ B µ 0 µ avg [Sin( β − α ) + 3( β + α )] 8π 2 avg CDIO3 Class Project 62 Spin-up Configuration Trade Introduction Subsystems Configuration options: •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power • Favors equally sized vehicles • Favors a larger center vehicle Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 63 Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Operations Implementation Conclusion 5/24/2002 Control Location Trade Centralized z All information communicated to a hub which calculates a control solution Independent Control z Vehicles collect and process their own information and derive a control solution for their own vehicle Hybrid control z Certain systems are controlled independently while other systems are controlled by the hub’s control solution CDIO3 Class Project 64 Hysteresis and Saturation Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power Hysteresis z Experimental data for curve Saturation of electromagnets and torque wheels Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 65 Budget Estimates Introduction Subsystems •Actuation •Formation Control •Control •Requirements •Design •Trades •Issues •Budgets Estimates •Metrology •Electronics •Structure/Power No mass No power Cost for maintenance of lab equipment Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 66 Metrology Introduction Subsystems •Actuation •Formation Control •Control •Metrology •Requirements •Trades •Design •Issues •Budget Estimates •Electronics •Structure/Power Oscar Murillo Metrology Operations Implementation Conclusion 5/24/2002 CDIO3 Class Project 67