Dehydration of an ethanol-water mixture by sorption using barley as... by James Patrick Law

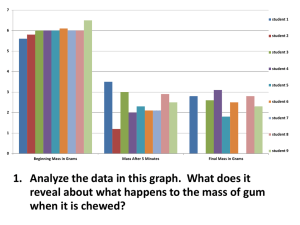

advertisement