Document 13476709

advertisement

Heat transfer from vertical, bare and longitudinally finned tubes to a fluidized bed of large particles

by Terry Allen Todd

A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science in

Chemical Engineering

Montana State University

© Copyright by Terry Allen Todd (1982)

Abstract:

Heat transfer coefficients were measured from vertical, bare and longitudinally finned tubes to air

fluidized beds of wheat and millet particles. Experimental parameters were fin height, particle

diameter, and fluidizing air mass velocity.

Results obtained using the bare tube indicate that with a given size of particles, the heat transfer

coefficient increases with increasing air flow rate. Heat transfer coefficients also increased with

decreasing particle size with the bare tube.

Results obtained using the finned tubes show increases in heat transfer coefficients with increasing air

flow rate. Heat transfer coefficients generally decreased then increased with increasing fin height. For

both particle sizes, the highest values of heat transfer coefficients were obtained using the bare tube and

the next highest values were from using a 3/4 inch fin height. The lowest values of heat transfer

coefficients were obtained with a 3/8 inch fin height. The effect of particle size on heat transfer

coefficients varied with fin height but was relatively small compared to the effect of air mass velocity

and fin height.

Correlations were developed using dimensionless quantities in power series equations to obtain an

equation to fit the wheat and millet data. i

HEAT TRANSFER FROM VERTICAL, BARE AND LONGITUDINALLY

FINNED TUBES TO A FLUIDIZED BED OF LARGE PARTICLES

by

Terry Allen Todd

A thesis submitted in partial fulfillment

of the requirements for the degree

of

Master of Science

in

Chemical Engineering

MONTANA STATE UNIVERSITY

Bozeman, Montana

December 1982

V.MN LIB.

ii

75^5

Cop. <9

APPROVAL

of a thesis submitted by

Terry Allen Todd

This thesis has been read by each member of the thesis committee and has been found

to be satisfactory regarding content, English usage, format, citations, bibliographic style,

and consistency, and is ready for submission to the College of Graduate Studies.

30

. /78

Date

Chairperson, Graduate Committee

Approved for the Major Department

3 6 ) / € (r >

Date

i X

/'

(Head, Major Department

Approved for the College of Graduate Studies

I

Date

% Zy

Graduate Dean

^

iii

STATEMENT OF PERMISSION TO USE

In presenting this thesis in partial fulfillment of the requirements for a master’s degree

at Montana State University, I agree that the Library shall make it available to borrowers

under rules of the Library. Brief quotations from this thesis are allowable without special

permission, provided that accurate acknowledgment of source is made.

Permission for extensive quotation from or reproduction of this thesis may be granted

by my major professor, or in his/her absence, by the Director of Libraries when, in the

opinion of either, the proposed use of the material is for scholarly purposes. Any copying

or use of the material in this thesis for financial gain, shall not. be allowed without my

written permission.

ACKNOWLEDGMENT

The author wishes to thank the staff and graduate students of the Department of

Chemical Engineering at Montana State University for the help given in this research.

Special thanks go to Dr. Robert Nickelson, who advised this research, and Lyman

Fellows, who helped with much of the mechanical construction.

Finally, the author would like to thank his parents and friends for their encourage­

ment and support.

vi

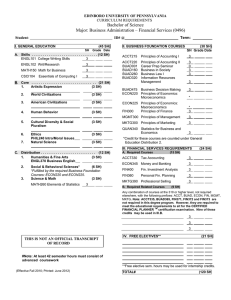

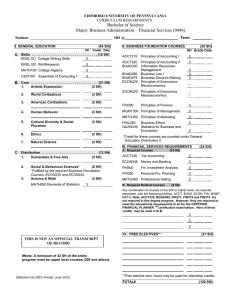

TABLE OF CONTENTS

Page

APPROVAL.....................

ii

STATEMENT OF PERMISSION TO USE.........................

iii

VITA.....................................................................................

iv

ACKNOWLEDGMENT.......................................................................................................

v

TABLE OF CONTENTS.................................................................................s .................

vi

LIST OF TABLES...............................................................................................................

viii

LIST OF FIGURES...............

ix

ABSTRACT..........................

xi

INTRODUCTION...............................................................................................................

I

Advantages.................................................................................................................

Disadvantages.............................................................................................................

2

3

PREVIOUS RELATED RESEARCH..............................

5

THEORETICAL BACKGROUND.....................................................................................

8

Mechanism of Fluidized Bed Heat Transfer.....................

8

EXPERIMENTAL EQUIPMENT.......................................................................................

14

Fluidizing Column........... ......................................................................................... .

Fluidizing System .......................................................................................................

Electrical System......................................................

Tube Assembly.........................................................-................................................

14

16

17

17

EXPERIMENTAL PROCEDURE................................. '.............................. ...................

22

Minimum Fluidization V elocity.......................... : .......... ....................... ...............

Procedure for a Typical, R u n .....................................................................................

22

22

via

TABLE OF CONTENTS-Continued

Page

DEVELOPMENT OF THEORETICAL MODEL FOR

FINNED TUBES........................................................................

Finned T u b e s....................................................

Development and Results of Correlations...............................................................

Comparison of Correlations.......................................................................................

Reproducibility of D a ta ........... ................................................................................

24

33

33

43

44

SUMMARY OF RESULTS..........................................................

47

NOMENCLATURE..........................................................................

48

LITERATURE C ITED ......................................................................................................

51

APPENDICES..................................................................................... : ..............................

55

Appendix A. Calculations.........................................................................................

Appendix B. Results of Runs...................................................................................

56

59

viii

LIST OF TABLES

Tables

Page

I. Previous Related Research at Montana State University...................................

II.

7

Finned Tube Dimensions.........................................................................................

19

III. Bare Tube Correlations.............................................................................................

45

Appendix Table

IV. Empirical Correlations Tested..................................................

84

ix

LIST OF FIGURES

Figures

Page

1. Film model for heat transfer.................................................................................

9

2. Packet model for heat tra n sfe r............................................................................

10

3. Particle model for heat transfer............................................................................

12

4. Schematic view of experimental sy ste m .............................................................

15

5. Cartridge heater elem ent................................. ......................................................

18

6. Detailed view of the column assembly.................................................................

21

7. Proposed model of a longitudinal fin....................................................................

25

8. Iimodel versus h, Tubes #2, #3, #4, and # 5 .................................; .....................

28

9. h versus air mass velocity, Tube #1, bare.............................................................

31

IP.

Bare tube data comparison of millet d a ta ..........................................................

32

11. hmodel versus air mass velocity, Tube #2, 1/4 inch fin h eig h t...........................

34

12. hmodel versus air mass velocity, Tube #3, 3/8 inch fin h e ig h t...........................

35

13. Iimodel versus air mass velocity, Tube #4, I /2 inch fin h eig h t...........................

36

14. hmodel versus air mass velocity. Tube #5, 3/4 inch fin height . ........................

37

15. hmodel versus air mass velocity, wheat, alltu b e s .................................................

38

16. Iimodel versus air mass velocity, millet, all tu b e s .................................................

39

17. Correlated Nusselt number versus experimental Nusselt number,

wheat, all tubes................................... .............................................................. .. .

41

18. Correlated Nusselt number versus experimental Nusselt number,

millet, all tu b es..............................................

42

19. hmodel versus air mass velocity, millet, Tube # 3 .....................................

46

X

Figures

Page

Appendix Figures

20. Heat transfer program ...........................................................................................

60

2 1.

Results from Run # I , Wheat, Bare Tube...........................................................

61

22. Results from Run #2, Wheat, Bare Tube......... : ..................................................

62

23. Results from Run #3, Wheat, Bare Tube............. '. .............................................

63

24. Results from Run #4, Millet, Bare T u b e ...........................................................

64

25. Results from Run #5, Millet, Bare T u b e ...........................................................

65

26. Results from Run #6, Millet, Bare T u b e.......................................

66

27. Results from Run #7, Millet, 1/4 inch Fin Height...........................................

,,6 7

28. Results from Run #8, Wheat, 1/4 inch Fin H e ig h t.........................................

68

29. Results from Run #9, Millet, 3/8 inch Fin Height............................................

69

30. Results from Run #10, Millet, 3/8 inch Fin Height............................................

70

3 1.

Results from Run #11, Millet, 3/8 inch Fin Height...........................................

71

32. Results from Run #12, Wheat, 3/8 inch Fin H e ig h t.........................................

72

33. Results from Run #13, Wheat, 3/8 inch Fin H e ig h t.........................................

73

34. Results from Run #14, Wheat, 3/8 inch Fin H eig h t.........................................

74

35. Results from Run #15, Wheat, 1/2 inch Fin H eig h t.........................................

75

36. Results from Run #16, Millet, 1/2 inch Fin H eight........................

76

37. Results from Run #17, Millet, 3/4 inch Fin Height......................■....................

77

38. Results from Run #18, Millet, 3/4 inch Fin Height...........................................

78

39. Results from Run #19, Millet, 3/4 inch Fin H eight:.........................................

79

40. Results from Run #20, Wheat, 3/4 inch Fin H e ig h t.........................................

80

41.

Results from Run #21, Wheat, 3/4 inch Fin H eig h t.........................................

81

42. Results from Run #22, Wheat, 3/4 inch Fin H e ig h t.........................................

82

43. Correlation program ............................................

83

xi

ABSTRACT

Heat transfer coefficients were measured from vertical, bare and longitudinally finned

tubes to air fluidized beds of wheat and millet particles. Experimental parameters were fin

height, particle diameter, and fluidizing air mass velocity.

Results obtained using the bare tube indicate that with a given size of particles, the

heat transfer coefficient increases with increasing air flow rate. Heat transfer coefficients

also increased with decreasing particle size with the bare tube.

Results obtained using th e ,finned tubes show increases in heat transfer coefficients

with increasing air flow rate. Heat transfer coefficients generally decreased then increased

with increasing fin height. For both particle sizes, the highest values of heat transfer coeffi­

cients were obtained using the bare tube and the next highest values were from using a

3/4 inch fin height. The lowest values of heat transfer coefficients were obtained with a

3/8 inch fin height. The effect of particle size on heat transfer coefficients varied with fin

height but was relatively small compared to the effect of air mass velocity and fin height.

Correlations were developed using dimensionless quantities in power series equations

to obtain an equation to fit the wheat and millet data.

I

INTRODUCTION

A fluidized bed is the result of forcing a fluid to flow upward through a column con­

taining solid particles at a velocity sufficiently high to lift and mix the particles in a fluid­

like motion. The quality of fluidization is dependent upon the physical characteristics of

the system and the velocity of the fluid flowing through the system.

Several regimes of fluidization exist and can be characterized by the fluid velocity. At

low fluid velocities the fluid simply passes through the void spaces between stationary par­

ticles. This is a fixed bed.

As the velocity of the flow increases, the drag exerted on the particles increases. With

the fluid flowing upward through the bed, the drag force tends to cause the particles to

rearrange themselves within the bed to offer less resistance to the fluid flow. This rearrange­

ment causes the bed of particles to expand homogenously and is called an expanded bed.

With further increase in the fluid velocity, expansion of the bed continues until the

drag force exerted on the particles is enough to support the weight of the particles. In this

state, the fluid-particle system begins to behave like a fluid. This state is called minimum

fluidization and the velocity corresponding to this state is called the minimum fluidization

velocity. The pressure force across the bed is about equal to the weight of the fluid and

particles in the bed [I]. Only mild mixing of the particles occurs and no bubbles are formed

at minimum fluidization.

Increasing the fluidizing velocity above minimum fluidization causes bubbles to form

from the excess fluid. The bubbles expand and coalesce as they rise upward through the

bed, carrying particles with them. When a bubble reaches the top surface of the bed it

bursts and releases the particles on the top surface. Agitation becomes more violent and

2

the movement of solids becomes more vigorous. This regime of fluidization is called aggre­

gative or bubbling fluidization.

Bubble size increases as fluid velocity increases until the bubble diameter approaches

the diameter of the column. This is the onset of slugging. The top surface of the bed rises

and collapses with regular frequency as slugs form and burst. Slugging is strongly affected

by vessel geometry and gas distributor design. Slugging is usually undesirable since it

increases the problems of entrainment and lowers the performance potential of the bed for

both physical and chemical operations [2].

Another regime which occurs with large particles (greater than Imm in diameter), as

used in this investigation, is spouting. The spouted bed is a combination of a jetlike upwardmoving, dilute fluidized phase surrounded by a slow, downflow-moving bed through which

gas percolates upwards. The spouted bed is limited in applications because of poor contact­

ing of gas and solid.

The fluid bed has both desirable and undesirable characteristics. A number of advan­

tages and disadvantages are [ 1,2,3,4]:

Advantages

1. Ease of handling fluidized solids.

2. Rapid mixing of solids leads to nearly isothermal conditions throughout the bed.

3. Well suited to large-scale operations.

4. High heat and mass transfer rates between gas and solids.

5. High rates of heat transfer between the fluidized solid and immersed surfaces.

6. Earlier implementation of continuous recycling of solids.

3

Disadvantages

1. The process demands the expenditure of power for fluidization.

2. Particle attrition and elutriation require that particles be replaced and lead, to gas

clean-up and solids recovery problems.

3. Counter-current contacting of solids and gases is, in general, not possible because

of the high degree of mixing that occurs. This provides a less favorable driving force.

4. Operating rates are limited by the minimum fluidization velocity and the terminal

velocity of the particles.

5. The absence of thermal gradients may be undesirable for certain applications.

6. Confident scale-up is difficult when reaction conditions are critical.

Despite some of its drawbacks, there are many industrial applications of fluidized

beds. The use of fluidized beds by the petroleum industry in the catalytic cracking and

reforming of oil [2] has led to much of the early development of fluidized bed technology.

Recent studies show promise in the use of fluidized beds of limestone or dolomite to

reduce sulfur dioxide emissions from coal combustion [5,6,7] . Other industrial appli­

cations of fluidized beds include [2,8]: coal processing, coking, gasification, and combus­

tion; reduction of iron ore; ore roasting, calcining, and drying; calcining of nuclear wastes;

thermal coking of residual oils; and several chemical synthesis reactions.

Heat transfer is a very important factor in the design of a fluidized bed system. There

are several methods in which heat may be transferred to dr from the fluidized bed, includ­

ing: heat transfer surfaces immersed in the bed; heat transfer surfaces around the periphery

of the bed; injecting hot gases into the bed; and exothermic reactions occurring in the bed.

The objectives of this research were to experimentally study heat transfer from verti­

cal, bare and longitudinally finned tubes immersed in an air fluidized bed. Millet and wheat

were used as the bed material. Heat transfer coefficients were determined experimentally

4

and correlations were developed to predict Nussell numbers from experimental parameters

used in this investigation. Experimental variables included fin height, particle diameter, and

fluidizing air mass velocity.

5

PREVIOUS RELATED RESEARCH

There have been numerous authors that have reported information on heat transfer

from immersed surfaces in fluidized beds. The bulk of published experimental work has

been for fluidized beds of small or intermediate particle size (less than Imm in diameter).

Published work has consisted of heat transfer from horizontal or vertical immersed cylin­

drical tubes [9-24] and from horizontal or vertical immersed extended surface tubes [17,

18,25-31].

In fluidized beds of large particles the major fraction of the total heat transfer is by a

gas convection mechanism [9-13]. Adams and Welty [9] and George etal. [11] developed

a gas convection model of heat transfer to a horizontal cylinder immersed in a large parti­

cle, gas fluidized bed. They were able to predict instantaneous local heat transfer coeffi­

cients around the circumference of the cylinder. The assumptions of the model are expected

to be valid for spherical particles when the gas convection mode of heat transfer dominates.

Recently Catipovic, Fitzgerald, George, and Welty [24] conducted experiments to validate

the Adams-Welty model. Results support the main assumptions of the model and show

that the range of applicability is wider than originally expected.

Botterill and Denloye [13] modeled heat transfer by gas convection to vertical tubes

in packed and fluidized beds. The quiescent bed coefficient was taken as a measure of the

interphase gas convective component of the heat transfer coefficient. The results of their

model compare closely to those of Baskakov and Suprun [12].

Chen and Withers [17] studied heat transfer from bare and helical finned vertical

tubes in a fluidized bed. Experimental variables included fin height, fin spacing, particle

size, and gas mass velocity. Gains of up to 190% for heat transfer coefficients were observed

6

with some of the finned tubes compared to the bare tubes. Data from Chen and Withers

fall between correlations of Wender and Cooper [15 ] and Genetti, Schmall, and Grimmett

[18].

Genetti, Schmall, and Grimmett [18] have also investigated the relationship of tube

orientation to heat transfer coefficients with bare and finned tubes in fluidized beds. Mini­

mum heat transfer coefficients were observed at orientation angles of 45 and 60 degrees

from horizontal for bare and serrated fin tubes respectively.

Numerous investigations into heat transfer from immersed surfaces in air fluidized

beds have been conducted at Montana State University under the direction of W. E. Genetti

and R. L. Nickelson. Table I is a summary of recent investigations made at M.S.U.

Table I. Previous Related Research at Montana State University.

I n v e s tig a to r

Tube Type and O r ie n t a t io n

E x p e r im e n ta l P a ra m eters

B a r t e l (26)

19 73

h o r i z o n t a l b u n d le o f carbon

s t e e l s e r r a t e d f in n e d and

b a r e tu b e s

f i n h e i g h t , tu b e s p a c in g ,

p a r t i c l e d ia m e te r , f l u i d i z i n g

gas v e lo c ity

P r ie b e (27)

1975

h o r i z o n t a l b u n d le , o f carb on

s t e e l s e r r a t e d f in n e d t u b e s ,

s t a i n l e s s s t e e l and co p p er

s p in e d tu b e s

K r a to v il

19 76

h o r i z o n t a l b u n d le o f c o p p e r

h e l i c a l f in n e d tu b e s

f i n h e i g h t , f i n s p a c in g ,

p a r t i c l e d ia m e te r , f l u i d i z i n g

gas v e lo c ity

V an d erh o o f (32)

19 78

v e r t i c a l b u n d le o f carb on

s t e e l s e r r a t e d f in n e d tu b e s

f i n h e i g h t , f i n w id th , f i n

s p a c in g , p a r t i c l e d ia m e te r ,

f lu i d i z in g gas v e lo c it y

E v e r ly (29)

19 78

c o i l e d co p p e r s p i r a l tu b e s

g r o o v e d e p th , number o f f l u t e s

f l u t e p i t c h , p a r t i c l e d ia m e te r ,

f lu i d i z in g gas v e lo c it y

Y u ric h

1979

v e r t i c a l b u n d le o f co p p er

h e l i c a l f in n e d t u b e s , co p p er

s p i r a l tu b e s

f i n h e i g h t , f i n s p a c in g , g r o o v e

d e p t h , number o f f l u t e s , f l u t e

p i t c h , p a r t i c l e d ia m e te r ,

f lu i d i z in g gas v e lo c it y

s i n g l e , v e r t i c a l carb on

s t e e l b a r e and l o n g i t u d i n a l l y

f in n e d tu b e s

f i n h e ig h t, p a r t ic le ty p e ,

p a r t i c l e d ia m e te r , f l u i d i z i n g

gas v e lo c ity

(28)

(33)

H ic k e l (34)

1981

, f i n and s p in e h e i g h t , s p in e

m a t e r ia l , s p in e s p er tu r n ,

_ p a r t i c l e d ia m e te r , f l u i d i z i n g

gas v e lo c ity

THEORETICAL BACKGROUND

Mechanism of Fluidized Bed Heat Transfer

Current texts by Kunii and Levenspiel [2], Davidson and Harrison [35], and Botterill

[ I ] describe several major heat transfer models or mechanisms that have been developed to

explain bed-to-surface heat transfer. It is generally understood that heat transfer to an im­

mersed surface in a fluidized bed consists of three superimposed components of: particle

convection, gas convection, and thermal radiation [36]. Particle convection is due to parti­

cle motion in the fluidized bed and against the surface. Gas convection allows for the heat

transfer between the surface and the gas flowing through the particles. Radiation is due to

radiant exchange between the surface and the particles which the surface can “see.” Because

this experimental work was done at low temperatures (less than 600 degrees Celsius), radi­

ant heat transfer will be neglected [37].

An early attempt to explain fluidized bed heat transfer was a film model, Figure I ,

proposed by Levenspiel and Walton [38]. In this model the major resistance.to heat trans­

fer is considered to be in a thin laminar layer of fluidizing gas near the surface. The scour­

ing action of the fluidized particles against the film decreases its thickness, thereby decreas­

ing the resistance to heat flow. A simple expression was derived in terms of modified Nusselt and Reynolds numbers for the effective gas film thickness, assuming the film is broken

whenever a particle touches the heat transfer surface. They then predicted the overall heat

transfer coefficient that would be obtained if heat transfer was limited by the average

thickness of the gas film developing between the points of contact where the film is broken.

Mickley and Fairbanks [22] developed a packet model as shown in Figure 2. Their

model proposed that “packets” of particles contact the heat transfer surface for a short

9

Figure I . Film model for heat transfer.

10

Figure 2. Packet model for heat transfer.

I

11

amount of time. Unsteady state heat conduction from the transfer surface to the packet of

particles begins on contact. This unsteady state conduction of heat into the packet is the

controlling resistance. After the brief contact between the packet and the transfer surface,

the packet leaves the surface, breaks up, and dissipates heat to the bulk of the bed material.

Mickley and Fairbanks found that bed to surface heat transfer coefficients were propor­

tional to the square root of the thermal conductivity of the quiescent bed, as their model

predicted. The assumption that the packet of particles and gas can be treated as a uniform

medium with thermal properties of the bed at minimum fluidization is unrealistic when

close to the transfer surface because of surface effects on local particulate packing.

Botterill and Williams [39] modified the Mickley and Fairbanks model to consider

the separate roles played by emulsion gas and solids, instead of assuming mean properties

for the emulsion. For the short contact times considered, heat cannot travel far into the

emulsion; hence a layer of emulsion slightly greater than one particle diameter thick is all

that needs to be examined. Results show that the solids, with their large heat capacity,

provide an effective heat sink, so heat transfer is located primarily in the region around

the contact points of particles with the surface. Therefore the heat flux can be taken to be

proportional to the number of contact points per unit surface.

Ziegler et al. [40] proposed a similar particle model which was extended by Genetti

and Knudsen [23]. A particle is viewed to move to the surface where it is bathed by a fluid

at the transfer surface temperature. It absorbs heat from the gas by unsteady state conduc­

tion while the gas temperature remains unchanged and particle-surface contact is ignored.

This mechanism is shown in Figure 3.

Botterill and Denloye [13] suggest that for large particle systems the heat transfer at

minimum fluidization conditions, before particle circulation, can be used to estimate the

gas convection component. The quiescent bed transfer coefficient (taken as a measure of

12

P a r t i c l e from th e

b u l k m e d iu m

P a r t i c l e a t the

surface receiv in g

e n e r g y from th e f i l m

H eat tr a n s f e r su rface

H eated p a r t i c l e

r e t u r n i n g to th e

b u l k m e d iu m

Figure 3. Particle model for heat transfer.

13

the convective heat transfer component) has been correlated over an experimental range of

operating pressures up to 10 atm.

14

EXPERIMENTAL EQUIPMENT

Most of the equipment used in this research was already assembled and operable, hav­

ing been used in similar investigations by Vanderhoof, Yurich, and Hickel. Modifications

were made to improve reliability of data and ease of operation. A schematic diagram of the

experimental system is shown in Figure 4.

Fluidizing Column

The fluidization column was constructed of 6.35 mm thick clear plexiglas, with an

inside diameter of 34.3 cm and a height of 1.5 m above the distributor plate. Flanges,

1.9 cm thick, were attached to the top and bottom of the column. One access port, 10.2 cm

in diameter, was located with its center 15.2 cm above the distributor plate. This access

port was not used and was plugged with wood to minimize effects on fluid dynamics.

A 15 cm high galvanized steel funnel, 34.3 cm bottom diameter and 48.3 cm top

diameter, was fitted with a rubber gasket and bolted to the top flange of the column to

serve as a disengagement section. A steel perforated plate was sandwiched between two

plexiglass plates, 6.35 mm thick, with a 48.3 cm hole cut in the center, and attached to the

top of the funnel. This perforated plate allowed for filling of the column and served as the

air exit port. Air leaving the column through the perforated plate was vented outside

through a 20 cm stove pipe. The column was supported by a wooden frame anchored to

the floor.

The distributor plate consisted of two layers of a lightweight cotton cloth sandwiched

between two layers of 100 mesh stainless steel wire cloth which was placed between two

5

(I) Power S u p p ly ;

(2) S w i t c h B o x ;

(3) H i g h L i m i t T e m p e r a t u r e C o n t r o l l e r ;

(4) P o w e r s t a t ;

(5) D i g i t a l T e m p e r a t u r e I n d i c a t o r ;

(6) W a t t m e t e r ;

(7)

Column;

(8) B e d M a n o m e t e r ;

(9) S e c o n d a r y O r i f i c e M a n o m e t e r ;

(1 0 ) S e c o n d a r y

A ir B low er;

(11) S e c o n d a r y A i r V a l v e ;

(1 2 ) S e c o n d a r y O r i f i c e ;

(1 3) M a in

O rifice;

(14) M ain O r i f i c e M an o m e te r;

(1 5) M a i n A i r V a l v e ;

(1 6 ) B y p a s s

V alve;

(17) Main A i r B lo w e r

Figure 4. Schematic view of experimental system.

16

sheets of 0.79 mm thick steel perforated plates. The perforations were 6.35 mm in diameter

and were spaced 1.27 cm apart center-to-center.

A funnel, 34.3 cm in diameter at the top and 5 cm in diameter at the bottom, was

bolted to the bottom flange of the column. The distributor plate was supported by this

funnel which was 30.5 cm high and made of 16 gauge galvanized steel. A 2.5 cm diameter

drain pipe was fastened to the distributor plate and extended through the side of the fun­

nel. A gate valve was attached to the end of the drain pipe.

Pressure taps were placed just above the distributor plate and near the top of the

column to measure pressure drop across the fluidized bed ."

Fluidizing System

Air was supplied to the column by two blpwers. The first was a Sutorbilt blower

driven by a 5.59 KW electric motor. The second blower was a size 4L Sutorbilt blower

driven by a 2.24 KW electric motor. The two blowers were connected in parallel to the

bottom of the funnel attached to the bottom of the column. A flexible rubber hose con­

nected the funnel to a T-connection which fed to a 6.35 cm, nominal diameter, schedule

40 pipe that ran from the larger blower, and a 5.1 cm, nominal diameter, schedule 40 pipe

that ran from the smaller blower. Air flow rates were measured by utilizing 3.8 cm orifices

with vena contracta taps in both feed lines and reading pressure differences from water

filled manometers. Gate valves were located in both feed lines, however these were left

open at all times. Air flow rates were controlled by adjusting a gate valve for a 5.1 cm by­

pass line located on the feed line from the larger blower. A similar bypass was located on

the feed line of the smaller blower, but was left closed at all times.

Two sizes of particles were used as the bed material, wheat with a mean diameter of

4.72 mm and millet with a mean diameter of 2.35 mm. The particle densities were nearly

17

identical at 1300 and 1312 Kg/m3 respectively. A stagnant bed height of 46 cm was used

in all runs.

Electrical System

The electrical system consisted of the heater, power supply and thermocouple system.

A Watlow Firerod cartridge heater was used as the heat source in this investigation. As

shown in Figure 5, the cartridge was 25.4 cm long, comprised of a heated section 16.5 cm

long and two insulated ends, one 7.6 cm long and the other 1.3 cm long. The cartridge

heater was 1.59 cm in diameter and fit inside the bare and finned tubes.

The tube surface temperature was monitored by two thermocouples. The thermo­

couples were attached midway between the ends of the fin material, located 180 degrees

apart, in the bare areas between fins. One thermocouple was attached to a Fenwall Model

524 high limit controller which was connected between the powerstat and 110 volt power

supply. The high limit controller would shut off power to the heater if tube temperatures

reached undesirably high temperatures. The other thermocouple attached to the tube sur­

face was connected to an Omega Model 2176A multipoint digital thermometer. Another

thermocouple was used to measure the bed temperature. It was located in a thermowell

30.5 cm above the distributor plate and extended 7.6 cm into the bed. This thermocouple

was also connected to the Omega digital thermometer.

A Powerstat, variable transformer, was used to adjust heater temperature and power

input to the heater was measured by a Simpson Model 390 wattmeter.

.

Tube Assembly

A total of five different vertical tubes, one bare and four longitudinally finned, were

investigated. Tube surface areas and fin heights are given in Table II. The finned tubes were

30.5 cm long and had an outside diameter of 2.54 cm. The iron fin material was removed

In su lated

H eated S e c tio n

1 6 .5 ,

1 . 3 cm

Figure 5. Cartridge heater element.

I n s u l a t e d end

H eater

Leads

Table II. Finned Tube Dimensions.

Tube

No.

Tube

GD.

F ins

per

Tube

Fin

H eight

in

( cm)

F in

Thickness

in

( cm)

-in

(cm)

I

1.0

(2.54)

0.

2

1.0

(2.54)

12

0.25

(0.64)

0 .0 4

(0.10)

3

1.0

(2.54)

12

0 .3 7 5 (0.95)

0.04

4

1.0

(2.54)

12

0.50

(1.27)

5

1.0

(2.54)

12

0 .7 5

(1.91)

F in

Length

in

( cm)

T otal Surface

Area

ft2

(m2 )

0.

0.2618

(0.0243)

6 .5

(16.5)

0.5326

(0.0495)

(0.10)

6 .5

(16.5)

0 .6 6 8 1

(0.0621)

0.04

(0.10)

6 .5

(16.5)

0 . 8 0 35

(0.0746)

0.04

(0.10)

6 .5

(16.5)

1.0743

(0.0998)

0.

0.

20

from 7.6 cm of one end of the tube and 6.35 cm from the other end, leaving 16.5 cm of

the tube finned. The heaters were wrapped with metal tape and coated with copper antisieze compound to maximize contact between the heater and the tube. The heaters were

than inserted into the tubes sp the 7.6 cm insulated end of the heater corresponded to the

7.6 cm bared end of the finned tube. A set screw held the heater in place. The opposite

end of the tube was sealed with Permatex sealant. The tube assembly was then mounted

onto a frame.

The frame was then inserted and bolted inside the column. The heater leads and

thermocouple wires were run through a 20 cm long piece of flexible conduit to a hole in

the column 51 cm above the distributor plate. A detailed view of the column assembly is

shown in Figure 6.

21

H e a te r and

Therm ocouple

Leads

P lex ig lass

Co lu m n

C onduit

Support

Frame

D istrib u to r

P late

Figure 6. Detailed view of the column assembly.

H eated

T ube

22

EXPERIMENTAL PROCEDURE

Minimum Fluidization Velocity

The first step of this investigation was to determine the minimum fluidization veloci­

ties for wheat and millet particles. The minimum velocities were determined by a visual

observation of the bed. The particles were poured into the top of the column until a static

height of 46 cm above the distributor plate was attained. Both blowers were turned on and

the appropriate valves adjusted until the bed was bubbling freely. The heating tube was

turned on and the bed was fluidized for two hours until normal operating temperature was

reached. Air flow was then regulated until the bed was just beginning to expand. The pres­

sure drop across the bed was measured using a water filled manometer. The air flow rate

was regulated several times from both increasing and decreasing flow rates and pressure

drops across both feed-line orifices were measured.

Procedure for a Typical Run

The finned tube to be investigated was chosen and installed in the column as described

earlier. The column was filled to a static height of 46 cm with the appropriate bed material.

The power to the heater was turned on and adjusted to 500 W. The main and secondary

blowers were turned on and flow adjusted so the bed was operating at minimum fluidization

conditions. The column was operated for 90 minutes to reach steady state. The tempera­

tures of the tube surface and bed were then recorded. The pressure drop across the bed,

main feed line, and secondary feed line orifice were then recorded, and an estimate of the

expanded bed height was made. The wattmeter reading was also recorded. The flow rate

was then adjusted to increase flow through the bed and the bed was operated for one hour

23

to reach a new steady state. Readings were recorded and flow rate increased as before. This

procedure was repeated until all of the desired flow rates had been investigated.

The blowers and power to the heaters were then shut off and the particles were

removed through the drain pipe. The bottom of the column was taken apart and the heater

assembly removed. This procedure was repeated until all five tubes and both particle sizes

had been investigated.

24

DEVELOPMENT OF THEORETICAL MODEL FOR FINNED TUBES

All tube temperatures in this investigation were measured from the surface of the

tube. This temperature is the same as the temperature at the base of each fin. Use of this

temperature to calculate heat transfer coefficients, h, would assume that a uniform temper­

ature profile exists across the fin. Since a uniform temperature profile does not exist across

the fin, the temperature distribution in the fin must be taken into account.

Figure 7 shows a fin and the coordinate system used in this model, the height of the

fin is much greater than the width, therefore heat conduction only in the x direction will

be considered. A steady state energy balance was taken around a differential fin element to

find the temperature profile.

Heat flows by conduction through the differential element, entering at the left edge

(x) and leaving at the right edge (x+ x), and by convection from the outer surface of the

fin. During steady state conditions no energy accumulates within the differential element.

-k Y W dTj

+k Y W dTg

d x |x

rate of heat

flow by contion into ele­

ment at x

-2 Y h Ax (T-Tb) = 0

c^x I x+Ax

-

rate of heat flow

by conduction

but of element

at x+Ax

-

rate of heat flow = 0

by convection

from surfaces

between x and x+Ax

where,'

k

= thermal conductivity of the fin material, W/m-k

Y = length of the fin, m

W = thickness of the fin, m

T

= fin temperature, 0C

Ty = bed temperature, °C

25

-►I F i n H e i g h t

Face o f

B ase o f F in

Figure 7. Proposed model of a longitudinal fin.

th e F in

26

h

= heat transfer coefficient, W/Hr-m2-k

Dividing through by Ax, and taking the limit as Ax->0, and simplifying, the following

differential equation for the temperature profile along the fin is obtained.

d2T

2h

(T-Tb) = 0

dx2" ~ kW

Introducing the dimensionless variables,

T-Tb

; X = x/L;

Q

m2

Ts-Tb

2hL2

kW

where,

L = fin height, m

Tg = tube surface temperature, °C

and simplifying yields the following differential equation,

d20

- m20 = 0

dX2

The solution of this equation is of the form,

0 = C1Sinh (mX) + C2 Cosh (mX)

(I)

The two boundary conditions are,

a) 0 = I

b) -

at X = 0

kd0

at X = I

LdX

Applying the boundary conditions to equation (I) yields values of C1 and C2.

_

1

(hCosh(m) + (km/L) Sinh(m))

(hSinh(m) + (km/L) Cosh(m))

C2 = I

Substituting these values of C1 and C2 back into equation (I) yields the following equa­

tion for the dimensionless temperature profile along the fin.

27

6

(hCosh(m) + (km/L) Sinh(m)) Sinh(mX)

(hSinh(m) + (km/L) Cosh(m))

= Cosh(mX)

Applying Fourier’s law, the heat transferred to each fin can be determined.

kYW (T,-Ty) a ,

Qfin

X=O

Taking the derivative of equation (2) with respect to x, substituting it into equation (3),

and evaluating at x=0 gives an expression for the amount of heat entering each fin.

kYW(Ts-Tb )m (mCosh(m) + (km/L) Sinh(m))

^ fin

L

(hSinh(m)

+ (km/L) Cosh(m))

An overall energy balance on the finned tube gives,

Q = NQfin + Qtube

where,

' Qtube = h A ( V T b)

A

= Area of bare tube - Area occupied by the base of fins.

= " DLtUbe " NWY

Substituting the equations for Qfin and Qtube into the energy balance' and rearranging

yields,

q

(Tr Tb )

NkYWm (hmodelCosh(m) + (km/L) Sinh(m))

(hIiiodel^n h (m ) + (km/L) Cosh(m))

+ hIUOdel (» DLtube-NWY)

The terms on the left-hand side of equation (4) are all measured quantities and allow values

of h-model, the average heat transfer coefficient, to be calculated. This model assumes that

the heat transfer coefficient is constant over the entire surface of the tube and fins.

The heat transfer coefficient in equation (4) is based on the model and accounts for

the temperature profile along the fin. A computer program, shown in Figure 20, utilizes a

Wegstein convergence routine to calculate values of h-model. Figure 8 illustrates the

28

Tube #2,

L= 1 / 4 i n c h

Tube #3,

L= 3 / 8 i n c h

T u b e # 4 , L= 1 / 2

Tube #5,

(W /H r-m -K)

Figure 8. hmodel versus h

Tubes #2, #3, #4, and #5.

in c h

L= 3 / 4 i n c h

29

relationship between values of the heat transfer coefficient, h, and the modeled heat trans­

fer coefficient, h-model, for the four different finned tubes.

30

RESULTS AND DISCUSSION

Bare Tube

Results obtained with the bare tube are shown in Figure 9. The experimentally

measured heat transfer coefficients h are plotted against air mass velocity G. Figure 9 shows

the heat transfer coefficients obtained for both wheat and millet particles. The data indi­

cates that with a given size of particles, the heat transfer coefficient increases with increasing air flow rate. The heat transfer coefficient increases rapidly at flow rates slightly above

minimum fluidization and then levels off at higher flowrates. The heat transfer coefficients

also increase with decreasing particle size, but this increase was relatively small for the par­

ticle sizes used in this investigation.

Figure 10 shows a comparison of the bare tube data for millet, with published results

of Baskakov and Suprun [12] and Catipovic et al. [11], and a published correlation of

Genetti et al. [18] as well as the correlation developed as part of this investigation. Similar

results were obtained for wheat also.

The data of Baskakov and Suprun shown is for a vertical bare tube using fireclay par­

ticles with 2-3 mm diameters. Data of Catipoyic et al. is for a horizontal cylinder using

dolomite particles with diameters of 2 mm. The correlation of Genetti et al. was developed

for tubes at angles of 0, 30, 45, 60 and 90 degrees with respect to horizontal and particle

diameters of 0.114, 0.20, and 0.47 mm. Although the particles used to develop this corre­

lation are much smaller than those used in this investigation, a reasonable fit to the millet,

data is obtained.

The bare tube data of this investigation fit between the data of Catipovic et al. and

Baskakov and Suprun.

31

O

O

A

A

A

A

O

a

+

CD'

a

a

A

-f-

+

+

+

O

00"

A

+

+

s S

I

CN

(W /H r-:

E

O

<£)

O

in"

B a re Tube

A M ille t

+ W heat

O

N"

o

roZOO

2'50

JOO

J5 0

TOO

MASS VELOCITY x lO™1 ( K g /H r - m 2 )

Figure 9. h versus air mass velocity

Tube # I , bare.

450

32

150

I

o

Bare Tube Data o f t h i s T h e s i s

—- C o r r e l a t i o n o f t h i s T h e s i s

140

130

Data o f C a t i p o v i c , e t a l .

120

_ HO

W

I

NE

I

£ 100

80

t

0 .9

I _________ I

1 .0

1 .1

1 .2

1 .3

1 .4

1 .5

R e l a t i v e A ir Mass V e l o c i t y

Figure 10. Bare tube data comparison of millet data.

1 .6

1 .7

G/G

1 . 8 I .!

I

33

Finned Tubes

Results obtained with the four different tubes are shown in Figures 11, 12, 13, and

14. Average heat transfer coefficients, h-model, are plotted against air mass velocity G,

for both wheat and millet particles. Data indicate that the effect of particle size on heat

transfer coefficients varies with fin height. Results from using tube #3 show wheat having

a higher average heat transfer coefficient for a given level of fluidization than millet.

Results from using tube #4 show particle size to have nearly no effect on average heat

transfer coefficients. Results from using tubes #2 and #5 show millet having liigher average

heat transfer coefficients than wheat. In general, values of average heat transfer coefficients

for wheat and millet, with a given finned tube and relative fluidization velocity, did not

vary more than 10%.

Figures 15 and 16 show the effect of fin height on average heat transfer coefficients

for a given particle. The data indicate a general trend of heat transfer coefficients decreas­

ing in value with increasing fin height from tube #1 to tubes #2 and #3, and heat transfer

coefficients increasing with fin height from tube #3, to tubes #4 and #5.

The average heat transfer coefficients generally increase with increasing air flow rate

in a similar manner as the bare tube data. In most case, a leveling off of heat transfer coef­

ficient values was observed at higher air flow rates.

Gains in heat transfer duty, hA, were as large as 64 and 67 percent for wheat and mil­

let respectively, when compared to a bare tube of the same over the fin dimension. Heat

transfer duty increased as fin height increased .

Development and Results of Correlations

Correlations of data were developed using selected quantities in power series equa­

tions. A computer program, shown in Figure 43, employed the complex method of Box

34

O

O

Oj

OV

A

a

a

a

a

a

+

a

+

+

+

O

CO'

P

(W /H r-

f

r4

Q)

O

CO'

rO

g

O

UY

T u b e #2

A M ille t

+ W heat

o

'T'

<50

MASS VELOCITY X 10

Figure 11. Iimode] versus air mass velocity

Tube #2, 1/4 inch fin height.

-I

2

(K g /H r- m )

35

o

o

O

CD

+

O

00

+

+

A

+

A

+

X

(M/Hr-

I

rH

O

N

O

CO'

Qj

rO

I

O

in"

T u b e #3

A M ille t

+ W heat

O

roZOO

Z50

JOO

J50

MASS VELOCITY x IQ - 1

Figure 12. Fmodel versus air mass velocity

Tube #3, 3/8 inch fin height.

400

(K g /H r- m 2 )

450

36

O

o

O

CT)

+

+A

+

+ A+

*

A

O

A+

CO'

A

+

O

N .'

(W /H r-

A

+

O

rH UD'

CD

rO

a

O

T u b e #4

A

LO

A M ille t

+ W heat

CD

A

r^ rOO

250

3 '0 0

350

MASS VELOCITY x 10~

Figure 13. hmode, versus air mass velocity

Tube #4, 1/2 inch fin height.

i

400

9

(K g /H r-m )

450

(W /H r-

37

MASS VELOCITY x 1 0 _ 1

Figure 14. hmodej versus air mass velocity

Tube #5, 3/4 inch Fin height.

( K g /H r- m 2 )

38

o

O

A

I

o

CTf

A

\

A 0+

+

0

o+

X

^

»

D

®X

^ X

□ □

0

%

X0

A

O

&

X0

O

CO'

I

A

+

AS>

(W /H r-

K. *

H

D3

X

O

CD'

rS

g

W heat

O

in"

A T ube

X

□

O

+

#1*

#2,

#3,

#4,

#5,

Tube

Tube

Tube

Tube

o

v"

JOO

350

MASS VELOCITY x 10*"

B a re Tube

L= 1 / 4 "

L= 3 / 8 "

L= 1 / 2 "

L= 3 / 4 "

Too

(K g /H r-m )

Figure 15. hmodel versus air mass velocity, wheat, all tubes.

39

o

o

A

o

X

CD

/

A

A +

x x

+

X

O

O

OO

A

□

O

O

□

6

(W /H r-

CM

E

H

01

K.

O

^

rO

e

O

m'

6

X

□

O

+

o

^ 1OO

2'50

M ille t

T u b e #1,

T u b e #2,

T u b e # 3,

T u b e #4,

T u b e #5

JOO

MASS VELOCITY x 10

B are

L= 1 / 4

L= 3 / 8

L= 1 / 2

L= 3 / 4

4'00

(K g / H r -m )

Figure 16. hmo(lel versus air mass velocity, millet, all tubes.

4'50

40

[44], to find the minimum of the difference squared of the experimental and calculated

Nusselt numbers. Seven quantities were investigated, each being a function of one or more

of the experimental parameters: particle Reynolds number (Re), ratio of the gas flow rate

to the gas flow rate at minimum fluidization (G/Gmf), gas flow rate - gas flow rate at mini­

mum fluidization (G-Gmf), Archimedes number (Ar), (I - void fraction), a fin height ratio

term (I + fin height/,0625), where 0.0625 is the height of the highest fin in feet, and the

mass flow rate at minimum fluidization (Gmf).

Several combinations of the above groups were evaluated using the computer program.

Equations of the form:

N u = a Bb Cc Dd Ee

Nu = a Bb Cc + d Ee Ff

were used to find the constants a, b, c, d, e, and f, where B, C, D, E, and F represent the

variable quantities. The equations were assembled with groups that included functions of

the three experimental parameters: fin height, particle diameter, and mass flow rate. Most

of the groups were selected because of their use in published correlations.

The correlation giving the best fit to the wheat and millet data is:

Nu = 0.558 (G-Gmf)0'2 8 5 O - E r -02 9 + 0.003 (l+ L /.0 6 2 5 ro lls Ar0'542

Results of the correlation are shown in Figures 17 and 18 for wheat and millet,

respectively, where correlated Nusselt numbers are plotted versus experimental Nusselt

numbers.

Figure 17 shows nearly all correlated Nusselt numbers are within 10% of the experi­

mental Nusselt numbers for the wheat data.

Figure 18 shows higher percentage differences between experimental and correlated

Nusselt numbers for the millet data, as compared to the wheat data. An explanation for

the higher percentage differences is because the values of Nusselt numbers are much lower

CORRELATED N U S S E L I

41

^10%

V2

V3

14

EXPERIMENTAL

T5

NUSSEL T

Figure 17. Correlated Nusselt number versus experimental Nusselt number, wheat, all tubes.

CORRELATED N U S S E L t

42

+ 15%

-15%

EXPERIMENTAL

NUSSELT

Figure 18. Correlated Nusselt number versus experimental Nusselt number, millet, all tubes.

43

for the millet data than for the wheat data. It appears that the correlation does not fit the

data as well at conditions near minimum fluidization (low Nusselt numbers). Deviations

between experimental and correlated Nusselt numbers in this region are as high as 42%.

Nearly all correlated values at moderate (4-6) or high (6-9) experimental Nusselt numbers

are within 15% of experimental values.

Comparison of Correlations

The correlation giving the best fit to the wheat and millet data is an attempt to pre­

dict the two superimposed components of particle and gas convection. The terms (G-Gmf)

and (1-e) are functions of mass flow rate and give a relative indication of particle motion

in the bed. The dependence of the Nusselt number on the (1-e) term is very small, how­

ever. The term (l+L/0.0625) is a function of fin height, and the Archimedes number (Ar)

is primarily a function of particle diameter. Together, these two terms account for the gas

convective component of heat transfer. This term is consistent with the correlation of

Baskakov and Suprun to predict the gas convective component of heat transfer:

Nucony = 0.0175 Ar0'46 Pr

With large particles, the gas convective component of heat transfer becomes very

important. The large particles cannot move fast enough to fully utilize their higher heat

storage capacity. This is a similar mechanism to the film model. The total heat transfer is

a large particle fluidized bed, appears to be by a combination of the film mechanism and

the packet mechanism, therefore making modeling difficult.

It should be noted that there is an important dimensionless group which does not

appear in these correlations. The Prandtl number (Pr) appears in several published corre­

lations [ 12,16,41 ]. In this investigation, the Prandtl number remained nearly constant in

44

all runs, varying only slightly from 0.71 to 0.72. Since it was always nearly constant, it was

included in the constant term of the power series equation.

Several published correlations for bare vertical and horizontal tubes are listed in Table

III.

Other correlations evaluated in this investigation, that did not fit the data as well as

the present results, are listed in Table IV along with the minimum sum of the differences

squared of the experimental and calculated Nusselt numbers. These correlations are strictly

empirical and have no theoretical basis.

Reproducibility of Data

,

Results of Catipovic et al. [11] and Baskakov and Suprun [12] are compared to the

bare tube data of this investigation with reasonable agreement in Figure 10. Experiments

run with tubes #1, #3, and #5 were run three times each under the same conditions to

check the consistency of the data. Figure 19 shows the results of three runs made, with

tube #3 and millet, and illustrates a typical spread of the data.

Table III. Bare Tube Correlations.

C o r r e la tio n

A u thor

G e n e t t i , e.t a l .

(18)

Surface

Nu= l l ( l - t ) 0 - 5

. . .

li

0 ,4 4

0 .2 (6 -4 5 )2

( 6 - 4 5 ) ^ + 120

2

Bare tu b e s 0 t o 90

d e g r e e s from

h o rizo n ta l

P a r tic le s

G la s s s p h e r e s

0 .1 1 4 , 0 .2 0 ;

and 0 .4 7 mm

Re0 ’ 2 4 ( P / . 0 0 8 ) l l 2 3 .

Zenz and

Othmer (41)

Nu= 1 4 (G/Gmf) ° - 33Pr0 - 33

(Dt ZDp )'0 -67

Bare h o r i z o n t a l

tu b e

—

V reedenberg

(16)

Nu= 420 P r 0 , 3

Bare h o r i z o n t a l

tube

C oarse p a r t i c l e s

G

D i.

S if

DP 3/ s A 9

0V =

> 205=

o /^ " 6 6

Wender and

Cooper (15)

Nu= O. O33 ( l - € ) (Cs / C g )

Bare v e r t i c a l

tube

G la s s s p h e r e s

0 . 0 4 1 - 0 . 8 9 mm

(DG ^) *23 (Cg T^ZKg) - 43

B askakov and

Suprun (12)

Nu= 0 . 0 175A r- 46P r - 3 3 (UZUm) *3 '

Bare v e r t i c a l

"tube

Corundum 0 . 1 6 - 0 . 5 mm

F i r e c l a y 0 . 8 - 5 mm

B o t t e r i l l and

D e n loye (13)

Nu= 0 . 8 6 SA r-39Kg D-0

Bare v e r t i c a l

tu b e

Copper s h o t 0 . 1 6 - 0 .6 2 mm, sand 0 . 1 6 2 . 3 7 mm

46

O

o

O

of

O

CO"

<5>A ° +

I

O Ao+

A

O +

(W /H r-

O

K."

o

H CO"

QJ

rO

A

O

g

T u b e #3

O

LO'

+ Run #9

A Run #10

O Run #11

O

xT"

^oo

^o-

?do"

MASS VELOCITY X 10

Figure 19. Hmodel versus air mass velocity, millet, Tube #3.

Too

(K g /H r-m

2

4'50

)

47

SUMMARY OF RESULTS

1.

Heat transfer coefficients for all tubes increased with increasing fluidizing air mass

velocity. The rate of increase in heat transfer coefficients was greatest for air mass

velocities slightly above minimum fluidization.

2.

The effect of particle size on heat transfer coefficients varied with fin height, but was

relatively small compared to the effect of air mass velocity and fin height. In all cases,

values of heat transfer coefficients for wheat and millet, with a given tube and relative

fluidization velocity, did not vary more than ten percent.

3.

For both wheat and millet particles, tube #1 (bare) gave the highest heat transfer coef­

ficients and tube #5 (3/4 inch fin height) gave the second highest values.

4.

Tube #3 (3/8 inch fin height) gave the lowest values of heat transfer coefficients for

both wheat and millet.

5.

Nearly all values of correlated Nusselt numbers are within ±10% of experimental

values for wheat. Most values of correlated Nusselt numbers for millet are within

±15% of experimental values.

6.

Gains in heat transfer duty, hA, were as large as 64 and 67 percent for wheat and mil­

let respectively, when compared to a bare tube of the same over the fin dimension.

48

NOMENCLATURE

Symbol

Definition

Dimension

a,b,c,

d,e,f

Parameters in correlation program

Dimensionless

A

Area of base section of tube

m2

Ac

Cross sectional area of column

m2

A1

Archimedes number

Dimensionless

B5C5D,

E5F

Variables in correlation program

Dimensionless

C1,C2

Constants

Dimensionless

Heat capacity of gas

KJ/Kg-K

Constant pressure heat capacity

KJ/Kg-K

C0

Orifice constant

Dimensionless

Cs

Heat capacity of solid (particle)

KJ/Kg-K

Cv

Constant volume heat capacity

KJ/Kg-K

D5Dt

Tube diameter

m

Particle diameter

m

g

Acceleration of gravity

m/sec2

Sc

Gravitational constant

Kgrn-mZKgf-S2

G

Air mass flow rate

Kg/Hr-m2

Gmf

Air mass flow rate at minimum fluidization

Kg/Hr-m2

h

Heat transfer coefficient

W/Hr-m2-K

^model

Temperature averaged heat transfer coefficient

W/Hr-m2-K

k

Thermal conductivity of fin

Cg '

cP

0P

’ W/m-K

49

Symbol

Definition

Dimension

Thermal conductivity of gas

W/m-K

Kr

Ratio of Cp/Cy

Dimensionless

L

Height of fin

m

-^tube

Length of tube

m

m

Dimensionless variable

N

Number of fins

Dimensionless

Nu

Nusselt number

Dimensionless

P1

Upstream pressure

Pa

P2

Downstream pressure

Pa

Pr

Prandtl number

Dimensionless

Q

Total heat input

W/Hr

Heat loss from fin

W/Hr

Heat loss from tube base

W/Hr

Re

Reynolds number

Dimensionless

Sc

Cross sectional area of orifice

m

T

Temperature of fin

0C

Bed temperature

°C

Air temperature

°c

Tube surface temperature

°c

U

Gas velocity

m/sec

Um

Gas velocity at maximum h

m/sec

W

Thickness of fin

m

X

Distance along fin

m

X

Dimensionless distance along fin

Dimensionless

Y

Length of fin

kS

■ Dimensionless

r

Q f in

Q fu b e

Tb

Tf

Ts

»

m

50

Definition

Symbol

Dimension

Y0

Expansion factor

Dimensionless

/3

Ratio of orifice diameter to inside pipe diameter

Dimensionless

e

Void fraction of bed

Dimensionless

TT

Pi, 3.1416

Dimensionless

6

Dimensionless temperature

Dimensionless

Viscosity of gas

Kg/m-sec

Density of gas

Kg/m3

Density of solid

Kg/m3

"g

Pg

Ps

LITERATURE CITED

52

LITERATURE CITED

1. Botterill, J. S. M.,

F lu id -B e d H e a t T ra n sfe r,

2. Kunii, D., and Levenspiel, O.,

1st ed. Academic Press, New York, 1975.

F l u i d i z a t i o n E n g in e e r in g ,

1st ed., Wiley, 1969.

3. Othmer, D. F., F l u i d i z a t i o n , Reinhold Publishing Corp., New York, 1956.

4. Leva, M., F l u i d i z a t i o n , McGraw-Hill Book Co., New York, 1959.

5. Montagna, J. C., Swift, W. M., Smith, G. W., Vogel, G. I., and Jonke, A.

S y m p . S e r i e s , v74, n l76, 1978, pp. 203-211.

6. O’Neill, E. P., and Realms, D. L.,

107.

7. Coates, N. H., and Rice, R. L.,

129.

A .I .C h .E . S y m p . S e r ie s ,

A .I .C h .E . S y m p . S e r i e s ,

8. Grace, J. R., and Matsen, J. M., ed.,

1980, pp. 12-21.

9. Adams, R. L., and Welty, J. R.,

F lu id iz a tio n ,

F lu id iz a tio n ,

v73, n l61, 1977, pp. 100-

vl70, n l4 1 , 1974, pp. 124-

1st ed., Plenum Press, New York,

A .I .C h .E . J o u r n a l,

10. Grace, I. R., and Matsen, J. M., ed.,

1980, pp. 225-234.

A ., A . J . C h . E .

v25, n3, 1979, pp. 395-404.

1st ed., Plenum Press, New York,

11. George, A. H., Catipovic, N. M., and Welty, I. R., “An Analytical Study of Heat Trans­

fer to a Horizontal Cylinder in a Large Particle Fluidized Bed,” A.S.M.E. paper No.

79-HT-78,18th Annual Heat Transfer Conference, 1979.

12. Baskakov, A. P., and Suprun, V. M.,

April 1972, p. 53.

I n t e r n a t i o n a l C h e m ic a l E n g in e e r in g ,

13. Botterill, I. S. M., and Denloye, A. O. O.,

pp. 194-202.

14. Canada, G. S., and McLaughlin, M. H.,

pp. 27-37.

15. Wender, L., and Cooper, G. T., A .I .C h .E .

16. Vreedenberg, H. A.,

A .I .C h .E . S y m p . S e r i e s ,

A .I .C h .E . S y m p . S e r i e s ,

J o u r n a l,

v74, nl76, 1978,

v74, nl76, 1978,

v4, n l , 1958, pp. 15-23.

C h e m i c a l E n g in e e r in g S c i e n c e ,

17. Chen, J. C., and Withers, J. G.,

333.

vl2, n2,

vl I, 1960, pp. 274-285.

A .I .C h .E . S y m p . S e r ie s ,

v74, n l7 4 , 1978, pp. 327-

53

18. Genetti, W. E., Schmall, R. A., and Grimmett, E. S.,

n l 16,1971, p. 90.

19. Mickley, H. S., and Trilling, C.

20. Wicke, E., and Petting, F.,

A .I .C h .E . S y m p . S e r i e s ,

A .., I n d u s t r i a l E n g r . C h e m .,

C h e m -In g -T e c h ,

v41, n6, 1949, p. 1135.

v26, n6, 1954, p. 301.

21. Toomey, R. D., and Johnstone, H. F.,

n5, 1953,p . 51.

C h e m ic a l E n g r . P r o g r e s s S y m p . S e r ie s ,

22. Mickley, H. S., and Fairbanks, D. F.,

A .I .C h .E . J o u r n a l,

23. Genetti, W. E., and Knudsen, J.

v67,

v49,

v l, 1955, pp. 374-385.

G .,I n t . C h e m . E n g r. S y m p . S e r ie s ,

v30, 1968, p. 147.

24. Catipovic, N. M., Fitzgerald, T. J., George, A. H., and Welty, J. R., A J . C h . E .

v28,n5, 1982, pp. 714-719.

J o u r n a l,

25. Genetti, W. E., Yurich,. S. P., and Vanderhoof, D. W., “Heat Transfer from Vertical

Finned Tube Bundles in a Fluidized Bed,” A.S.M.E. paper No. 80-HT-l 18, 1980.

26. Bartel, W. J., and Genetti, W.

27. Priebe, S. J., and Genetti, W.

E ., A .I .C h .E . S y m p . S e r i e s ,

E ., A .I .C h .E . S y m p . S e r i e s ,

v85, n l2 8 , 1973, pp. 85-93.

v73, n l61, 1977, pp. 38-43.

28. Kratovil, M. T., M.S. Thesis, Montana State Univ., 1976.

29. Everly, D. W., M.S. Thesis, Montana State Univ., 1978.

30. Bartel, W. J., Genetti, W. E., and Grimmett, E.

1971, p. 85.

S ., A .I .C h .E . S y m p . S e r i e s ,

v67, n ll6 ,

31. Grace, pp. 195-200.

32. Vanderhoof, D. W., M.S. Thesis, Montana State Univ., 1978.

33. Yurich, S. P., M.S. Thesis, Montana State Univ., 1979.

34. Hickel, S. D., M.S. Thesis, Montana State Univ,, 1981.

35. Davidson, J. F., and Harrison, D.,

F lu id iz a tio n ,

Academic Press, New York, 1971.

36. Staub, F. W., “Heat Transfer to Surfaces Immersed in Fluidized Beds,” Presented at

National Science Foundation Fluidization and Particle System-Research Needs and

Priorities, R.P.I., Troy, New York, Oct. 1979.

37. Botterill, J. S. VL., A .I .C h .E .

S y m p . S e r ie s ,

38. Levenspiel, O., and Walton, J. S.,

1954,p .I .

v69, nl28, 1973, p. 26.

C h e m ic a l E n g r . P r o g r e s s S y m p . S e r i e s ,

v50, n9,

54

39. Botterill, J. S. M., and Williams, I.

R . , I n s t . C h e m . E n g r s .,

40. Ziegler, E. N., Koppel, L. B., and Brazelton, W. T.,

v3,n4, 1964, p.324,

v41, 1963, p. 217.

Jn d. E n g . C h e m . F u n d a m e n ta ls ,

41. Zenz, F. A., and Othmer, D. F.,

Publishing Co., New York, 1960.

F l u i d i z a t i o n a n d F lu id - P a r tic le S y s t e m s ,

42. Perry, R. H., and Chilton, C. H.,

Hill Book Co., New York, 1973.

C h e m ic a l E n g i n e e r s ’ H a n d b o o k ,

43. Geankoplis-, C. J.,

Boston, 1978.

T r a n s p o r t P r o c e s s e s a n d U n it O p e r a tio n s ,

44. Beveridge, G. S. G., and Schechter, R. S., O p t i m i z a t i o n :

McGraw-Hill Book Co., New York, 1970.

Reinhold

5th ed., McGraw-

Allyn and Bacon, Inc.,

T h e o r y a n d P r a c tic e ,

55

APPENDICES

56

APPENDIX A

CALCULATIONS

57

CALCULATIONS

Air Mass Velocity

Air flow rates were calculated for each blower using the following equation [42]:

CYS

G = 3600 c- (2g(Pi -P2) P1/(I-P 4 ))°-s

AC

and the sum of the flow rates from each blower taken as the total air flow through the bed.

For a square-edged orifice,

Y0 = I -

(0.41 - 0 .3 5 ( 0

Hr

where,

K1 = CpZCv

The orifice coefficient was nearly constant at 0.61 for the range of flow rates used in

this investigation.

Air Thermal Conductivity

The air thermal conductivity was found by linear interpolation between values listed

in Geankoplis [43]. The linear equation fitting the thermal conductivity data is:

Kg = 7.54 X 10-s Tb + 0.0242

Air Viscosity

The air viscosity was found by fitting the following equation to experimental data

[43]:

Mg = 4.47 X IO'3 Tb + 1.734

58

Heat Transfer Coefficients

Heat transfer coefficients were calculated using the following equation and the Wegstein convergence routine.

Q

(Ts_Tb^

^rnodel

NkYWm (hTnodel Cosh(m) + (km/L) Sinh(m))

L

(hmodel Sinh(m) + (km/L) Cosh(m))

'(TrDLtu b e -NW Y)

Particle Nusselt Number

Nu

hmodel

Particle Reynolds Number

GD.

Prandtl Number

Pr

KS

Archimedes Number

8 DpPgCps Pg)

Ar

59

APPENDIX B

RESULTS OF RUNS

60

150

160

100

DIMENSION D Z l(1 0) ,D Z 2 (1 0 ), D Z 3 U o 1 ,W A T T (1 0) ,TS(IO),TB(IO)

REAL LENGTH,KR

READ ( 1 0 , 1 5 0 ) DZ1,DZ2,DZ3,WATTfTS,TB

FORMAT( 10F«3)

READ(1 0 , 1 6 0 ) FT? READ(10,160) DP? REAB(1 0 , 1 6 0 ) XFINH

READ(1 0 , 1 6 0 ) N? READ(10,160) XGMF? READ(10,160) DENP

FORMAT(4F,8)

2 , 6X,'ARCHIMEDES',/,21X,'MAIN',2X,

3'SEC',3X,'NUMBER',3X,'(KG/HR-',2X,'(W/HR-',6X,

S yz <W / H R - 3 X , 'NUMBER' , I l X , ' PRANBTL', 3X, ' NUMBER' , / , 21X,

u \ Ln ) ? a Xp (Cn) p 12X9

6 ' M 2 ) ', 6 X ? 'M 2 - K ) ', 7 X ,' M 2 - K )' ,2 0 X ,' N U M B E R ',/ /)

200 F0RMAT(20X,F5*2,2X,F5*2,2X,F5*I , 4X,F6»1»3X,F6»2,4X

lfF6«2,5X ,F5,2,3X<F6tl,3X,F4»2,6X ,F9«l,/>

WRITE ( 1 0 8 , 1 0 0 )

KR=I,4? DW=62,185 XGRAV=4, 173E08? THICK=.00333

XX=1770«94? LENGTH=.54166? XKM=35.

DO 20 , 1 = 1 , N

P1=XX+(DZKI)+DZ2(I))*5.182

P2 = X X + ( D Z l ( I) i D Z 3 ( I )) $ 5 , 1 8 2

P3=XXFDZ1(1 ) 8 5 , 1 8 2

B I = , 608? B2=,741

Y1=1-(P1-P3)8(,41-,35#B1*%4)/(P1%KR)

Y 2 = 1- (P 2-P 3)% (, 41- ,3 5*B 28 *4 )/( P2 8K R )

DA1=3.2949E-058P1

DA2=3.2949E-058P2

DA3=3,2949E-05%P3

BX1=1-B1**4? BX2=1-B2**4

55

60

70

XVIS=(2.458(TB(I ) - 3 2 * ) + 1 5 3 8 . I > 8 2 . 688E-05

XRE=GWDP/XVIS

IF(XFINH.EQ.O.O) HTRUE=HEXP?GO TO 70

El=HEXP? EZ=HEXPil,

EE=El? NY=O.

DIM=(28EE%XFINH8&2/(XKM%THICK))*8.5

EC=((-12.SXKMBLENGTH%THICK%DIM%(EE%C0SH(DIM)iXKM%DIM%SIN

lH(DIM)/XFINH)/(XFINH&(EE8SINH(DIM)iXKM%DIM8C0SH(DIM)/X

2FI NH )))iHEXP*FT)/(3,1 4 1 5 9 / 1 2 , -LENGTH$12%THICK)

CALL C0NV(EE,EC,1,NY)

IF(NY-1)55,60,50

EE=E2? NY=2« ? GO TO 50

HTRUE=(EEiEC)/2«

XKG=2.0E-058TB(I)i,0134

m

m

,M i D M ! ^ r R x4 ^ i / x ® ; 2 2 4 o , x v i s / x K 6

WRITE(108,200)DZ2(I)%2,54,DZ3(I)%2,54,XRE,G84.8824,

?HTRUE85. 6 7 8 3 , XNUS, XXGMF84. 8 8 2 4 , XPRAN, XARCH

CONTINUE

Figure 20. Heat transfer program.

DP

MAIN

(CM)

DP

SEC

(CM)

REYNOLDS

G

NUMBER

(KG/HRH2)

QZ(TS-TB)

(W/HRH2-K)

HTRUE

(W/HRM2-K)

NUSSELT

NUMBER

G-GMF

GAS

PRANDTL

NUMBER

ARCHIMEDES

NUMBER

14.22

1 1 .9 4

215.3

3132,4

78.32

78.32

13 ,7 8

447,1

.72

3 5 6 9 1 25 .9

17.27

11.94

224,8

3288,4

89.21

89.21

15.62

603.1

.72

3 5 3 2 2 74 ,6

21.59

11,68

237,3

3471,1

91,19

91.19

1 5, 97

785.8

.72

3 5 3 2 7 7 3 .2

25.15

11.43

245.8

3604.2

90.97

90,97

1 5 .9 0

918.9

.72

3515300.7

29.21

1 1 .4 3

256.0

3764.2

90.64

90.64

15 .8 0

1078.8

.72

3 4 9 7 4 6 6 ,6

34.04

11.18

266,9

3923,6

91,31

91 .3 1

15.92

1 23 8 ,3

,7 2

3498453.7

37.59

1 1. 1 8

275,2

4045,7

91,89

91,89

16 ,0 2

1 36 0 .4

.7 2

3 4 9 7 4 6 6 .6

40,64

1 0 .9 2

280.2

4129.2

92.94

9 2 .9 4

16 .1 6

1 44 3 .9

.7 2

3480750.0

45.47

10.67

289.3

4263.7

92.47

92.47

1 6 .0 8

1578,4

.7 2

3 4 8 0 7 50 .0

Figure 2 1. Results from Run #1,

Wheat, Bare Tube.

DP

MAIN

(CM)

DP

SEC

(CM)

9.14

1 1. 9 4

194.2

2833.5

76.19

76.19

13 .3 7

1 1 .1 8

11.68

200.9

2945.4

79.12

79.12

14.22

1 1 .4 3

212.5

3100.7

90.51

21.08

11.18

234.8

3416.9

28*96

11.18

257.7

39.37

1 1 .1 8

48.77

10.67

REYNOLDS

G

NUMBER

(KG/HRH2)

QZ(TS-TB)

(W/HRM2-K)

HTRUE

(W/HRM2-K)

NUSSELT

NUMBER

G-GMF

GAS

PRANDTL

NUMBER

ARCHIMEDES

NUMBER

148.2

.72

3560 401 .9

1 3 .8 3

260.0

,72

3524230.1

90.51

1 5 .8 9

415.4

.72

35 583 97 .2

91.66

91.66

1 6 .1 3

731.6

.72

35 766 82 .0

3740.9

90.76

90.76

16 .01

10 55 .6