MODULE DESCRIPTOR MECHGM01 – Applied Thermodynamics and Turbomachinery

advertisement

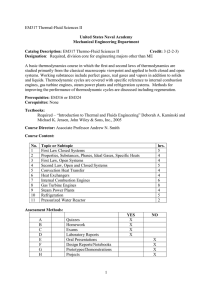

MODULE DESCRIPTOR MECHGM01 – Applied Thermodynamics and Turbomachinery Code: Alt. Codes(s) Title: Level: UCL Credits/ECTS: Start: End: Taught by: MECHGM01 MECHGR01, MECHM005 Applied Thermodynamics and Turbomachinery M 15/6 September March Prof M Zangeneh (65%) Module Coordinator Prof N Ladommatos (35%) Prerequisites Completion of second year Thermodynamics (MECH2004) Course Aims Develop a good understanding of the various gas turbine, steam turbine and combined cycles for electricity generation. Understand basic fundamentals of turbomachinery with particular emphasize on axial turbomachinery. Understand the basic fundamentals of fuel cells. Develop a good understanding of the thermodynamic, design and operating principles of diesel engines including four- and two-stroke naturally aspirated and turbocharged units. Gain an appreciation of diesel engine environmental pollutants and their mitigation. At the end of the course students will be able to: • Understand the main sources of CO2 emission from different sources and especially power generation and the effect of different trends in power generation on emissions. • Understand the effect of intercooling, recuperator and reheat on gas turbine efficiency and specific work. • Understand impact of gas turbine pressure ratio and maximum temperature on optimum efficiency for different gas turbine cycles. • Carry out preliminary analysis of intercooled/recuperated gas turbine. • Effect of free power turbine and its applications in marine field. • Understand the main features of steam cycles and main parameters affecting cycle efficiency. • Understand the effect of reheating and direct contact and non-contact feed heaters in steam cycles. • Carry out basic cycle analysis for combined cycle plants in terms of efficiency, work ratio, ratio of mass flow rate in steam to gas turbine cycle, pinch point temperature. • Understand impact of dual and triple pressure levels on combined cycle efficiency. • Understand velocity triangles in axial compressor and turbines and main geometrical and flow related parameters and main non-dimensional groups for characterising turbomachinery. • Understand the characteristic of turbomachinery and off-design flow effects such as surge. • Carry out matching computations between compressor and turbine for generator sets and free power turbines. • Understand the basic designs of combustion chambers and cooling arrangements and emission problems from gas turbines. • Understand basic fundamentals of fuel cells, Gibbs function and ideal efficiency, main sources of loss in PEM and SOFC fuel cells. • Use basic empirical functions for fuel cells to predict the actual voltage for PEM and SOFC. • Use basic thermodynamic cycles to identify the main variables affecting spark and compression ignition engine efficiency. • Understand and describe the gas exchange and combustion processes in diesel engines. • Describe basic models to represent various gas dynamic and thermodynamic processes in diesel engines • Analyse the performance of two stroke diesel engines, including large displacement slow speed engines used for marine propulsion and stationary power generation • Analyse and evaluate the performance of naturally aspirated and turbocharged diesel engines, including the compressor and turbine power requirements and the enhancement in engine power output and efficiency • Gain an appreciation of a wider range of topics on fuels and combustion in reciprocating engines via coursework and student presentations Page | 1 Method of Instruction Lecture presentations, tutorial classes and 2 pieces of course assignment. Parts of the lecture notes (Slides and tutorials) are made available in Moodle before the lecture. Assessment The course has the following assessment components: • Written Examination (2 hours, 65%) • A critical review/ appraisal of a chosen topic related to application of fuel cell(e.g.automotive, submarine, 100 person ferry or combined gas turbine and SOFC.). Submission is on “turnitin”. • Critical written review of a chosen topic on fuels and combustion. Students encouraged to use IMechE and IMarEST libraries for sources. Submission through Moodle. Individual Power Point presentation of the review by each student to their class. To pass this course, students must: • Obtain an overall pass mark of 50% for all sections combined The examination rubric is: Answer THREE questions, from FIVE offered. All questions carry equal weight. Resources Fuel Cells 1. Fuel cell systems explained, J Larminie & A Dicks, John Wiley, second edition, 2003. ISBN 0-470-84857-X. (comprehensive coverage of all types of fuel cell and manufacture of hydrogen) 2. Fuel cell fundamentals, R O’Hayre, S-W Cha, W Colella & F B Prinz, John Wiley, 2006. ISBN 0-471-74148-0. (readable explanation of basic electrochemistry and how it affects fuel cells) Gas Turbine, Combined Cycle, Turbomachinery 3. Cohen, H., Rogers, G.F.C. and Saravanamuttoo, H.I.H., ‘Gas Turbine Theory’, Longman, 5th Edition, 2001. Chapters 1 and 2 provide a very good introduction to gas turbines. 4. Haywood, R.W., ‘Analysis of Engineering Cycles – Power, Refrigerating and Gas Liquefaction Plant’, Pergamon, 4th Edition, 1991. (VA 166) Older text dealing with the thermodynamics of gas turbine and steam cycles. Relevant material can be found in Chapters 1, 2, 3, 6 and 7. 5. Kehlhofer, R., Bachmann, R, Nielsen, H. And Warner, J., ‘Combined Cycle gas turbine Power nd Plants’, Pennwell, 2 edition.- More practical aspect of combined cycles 6. Horlock, J.H. ‘Combined Power Plants’, Pergamon, 1992. (VA 165) Deals with cycle analysis. 7. Stone, R., ‘Introduction to Internal Combustion Engines’ Palgrave, 1999, especially chapters 2, 3, 5, 7, and 9 8. Heywood, J. B., Internal Combustion Engine Fundamentals, McGraw-Hill, 1988 or later editions. Excellent book, more advanced than the R. Stone book Additional Information None Content (total number of lecture and tutorial hours approx. 44 hours) (I) Revision of Engineering Thermodynamics [3] First Law. Second Law. Steam Tables. Carnot and Rankine Cycles. (II) Fuel Cells[ 3] – Coursework only ( not examined). Basic principles. Applications. Fundamental equations. Review of main types. Proton Exchange Membrane Fuel Cells. Solid Oxide Fuel Cells. Fuel cell losses. (III) Gas turbines, Steam turbines and combined cycles [12] Brief introduction to power generation methods and CO2 emission issues. Gas Turbine:Gas turbine Air standard cycle analysis. Real Cycles. Cycle with heat exchange. Cycle with intercooling. Cycle with heat exchange and intercooling. Cycles with Reheat. Steam Cycles: Methods of increasing the efficiency of standard cycle, Reheating, Feedheating, direct and non-direct contact feed heating, dearators. Combined cycle: Combined cycle efficiency, Heat recovery steam generators, Dual and triple pressure systems. Combustion system design. Fuel systems. Environmental considerations. Practical considerations. Case studies. Page | 2 (IV) Introduction to Turbomachinery (MZ) [6 ] Euler equation. .Basic performance and geometric parameters Axial flow turbomachinery stages, velocity diagrams, efficiencies, degree of reaction. Meanline design of compressors and turbines. Compressor types. Compressor characteristics stall and surge, interstage bleed, variable stator blades and multi-spool designs, blade calculations. Compressor/turbine matching for free power turbine engines Combustion system design. Fuels and fuel system requirements. Environmental considerations - pollutants from gas turbine engine, NOx reduction techniques (V) Internal Combustion Engines: Basic engine cycles. Deviations from ideal cycles and mathematical modelling of engine performance. Thermal loading of components. Two-stroke engines gas exchange processes, definitions, performance. Mechanical supercharging. Exhaust gas turbo charging - component matching for 2 & 4-stroke engines, pulse and constant pressure turbo charging and turbocharger design. Case studies of turbocharged diesel engines and future developments. (VI) Fuels and Combustion: a range of topics are covered through coursework and seminars. These include: current fuels, fuel treatment systems, bio-fuels, pre-mixed and diffusion combustion, ‘knock’ in diesel and gasoline engines, combustion chamber design –diesel engines and gasoline engines, pollutants from diesel and gasoline engines, diesel and gasoline engine fuel system design. Page | 3 1 Learning Outcomes MECHGM01, MECHGR01 General Learning Outcomes Ability to develop, monitor & update a plan, to reflect a changing operating environment N/A Ability to monitor and adjust a personal program of work on an on-going basis, and to learn independently As with all taught modules on the programme a significant amount of self learning is expected. The courseworks require self study and time management. The ability to exercise initiative and personal responsibility, which may be as a team member or leader N/A The ability to learn new theories, concepts and methods etc and apply these in unfamiliar situations The module is designed to present new subject matter at M level understanding of which is then tested by an exam and a critical review of a specified topic. Specific Learning Outcomes Underpinning Science & Mathematics A comprehensive understanding of the relevant scientific principles of the specialisation Although many students will have studied thermodynamics material (i.e. basic Carnot, Rankine Cycle) at undergraduate level, the module is designed to cover more practical aspects on modern aspects of power generation cycles system design and evaluation, as well as additional topics on fuel cell. Application of thermodynamic cycles and principles to analyse and understand advanced power generation systems A critical awareness of current problems and/or new insights much of which is at, or informed by, the forefront of the specialisation. The module particularly addresses the latest development and application of modern concepts related to combined cycle, gas turbine and turbomachinery for reducing the global warming impact of power generation systems. The recent developments in diesel engine systems are discussed is some detail. The impact of diesel engines toxic emissions on the environment is explained and technologies to mitigate the emission of toxic pollutants are discussed. The importance of thermal efficiency in reducing operating costs and CO2 emission to the atmosphere is emphasised. An understanding of concepts relevant to the discipline, some from outside engineering, and the ability to critically evaluate and apply them effectively. This feature is developed in the coursework element where the students are asked to write a critical review of a specified topic (e.g. Fuel cells for automotive applications; fuels and combustion for diesel engines). Understanding in many relevant and related disciplines is required. Interaction with course supervisor at various stages is essential. Environmental pollution-restricting legislation for gas turbines and diesel engines is discussed at several points during the course. 1 EAB website http://www.engab.org.uk/documentation document Accreditation Of Masters Degrees Other Than MEng last accessed 10 Aril 2012 Page | 4 Engineering Analysis Ability to use fundamental knowledge to investigate new and emerging technologies New concepts/approaches are studied and evaluated in the coursework element of the module. Extensive cycle and performance analysis are included. Ability to apply appropriate models for solving problems in engineering and the ability to assess the limitations of particular cases; Students are taught how to evaluate different design options for optimization based on product/component information, meeting client’s specifications. The ability to collect and analyse research data and use appropriate engineering tools to tackle unfamiliar problems, such as those with uncertain or incomplete data or specifications, by the appropriate innovation, use or adaptation of engineering analytical methods. N/A Design The ability to apply original thought to the development of practical solutions for products, systems, components or processes N/A Economic, Social and Environmental Context Knowledge and understanding of management and business practices, and their limitations, and how these may be applied appropriately, in the context of the particular specialisation N/A The ability to make general evaluations of risks through some understanding of the basis of such risks N/A Engineering Practice A thorough understanding of current practice and its limitations, and some appreciation of likely new developments A significant part of this module addresses the latest development and practice in modern power generation cycles in the context of land, air and sea applications involving power generation Advanced level knowledge and understanding of a wide range of engineering materials and components N/A The ability to apply engineering techniques taking account of a range of commercial and industrial constraints N/A Page | 5